Leather water-proof curing agent and preparing method thereof

A curing agent, leather technology, applied in leather impregnation, leather surface treatment, chemical instruments and methods, etc., can solve the problems of brittleness, reduced leather permeability, loss of luster, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

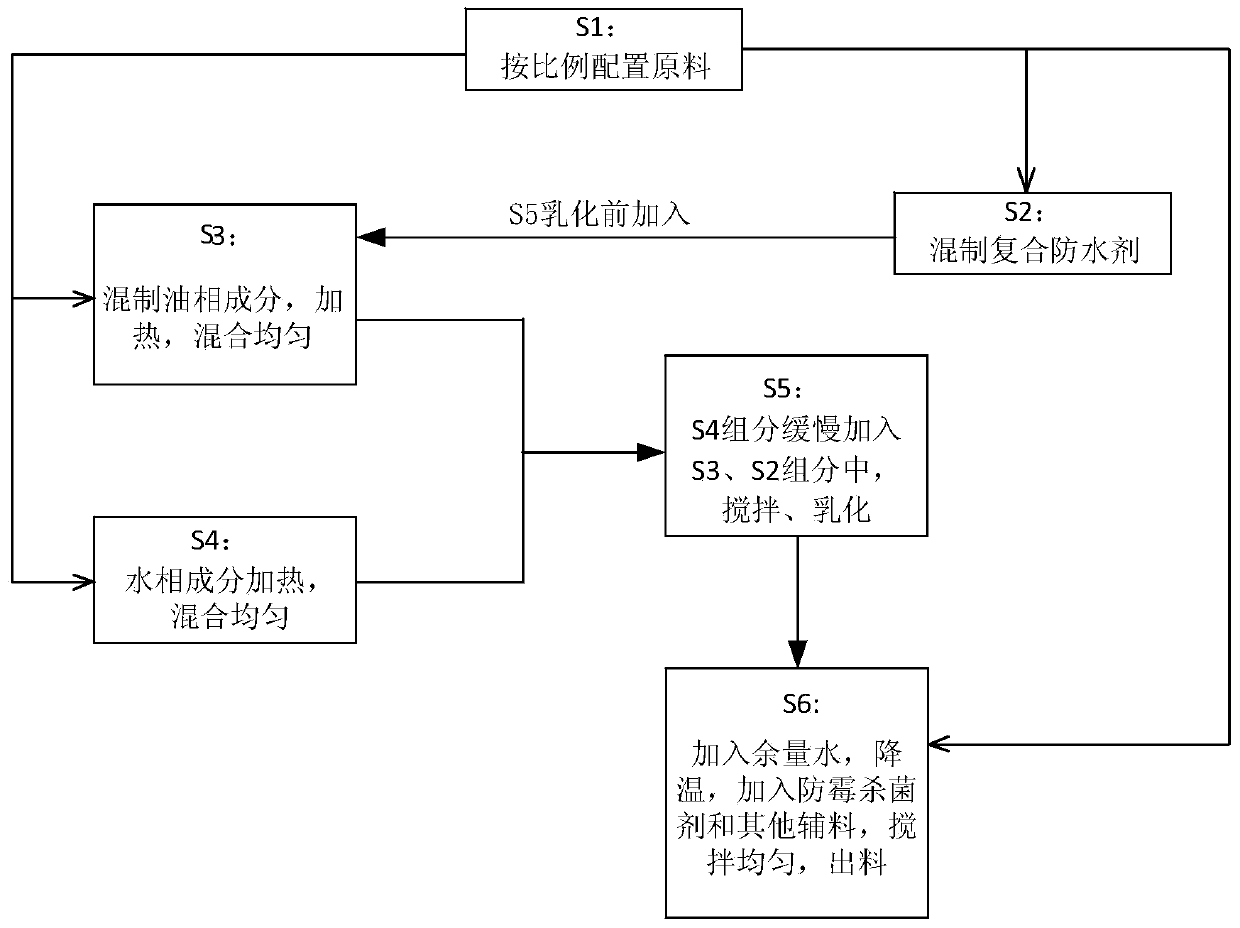

Method used

Image

Examples

Embodiment 1

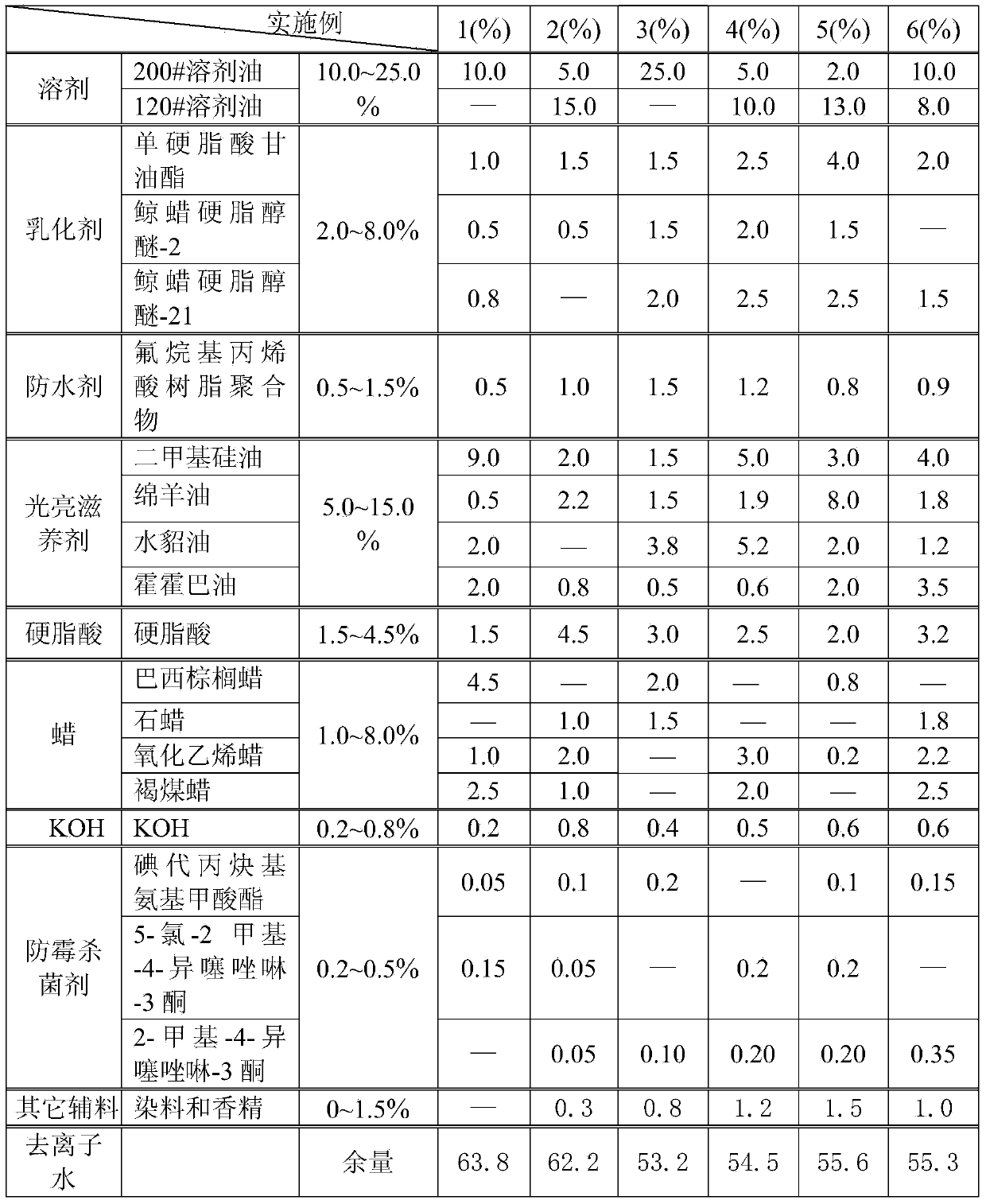

[0168] A new type of leather waterproof curing agent, the weight percentage of each component of the waterproof curing agent is as follows (unit: %):

[0169] 200# solvent oil 10.0

[0170] Glyceryl monostearate 1.0

[0171] Cetearyl ether-2 0.5

[0172] Cetearyl ether-21 0.8

[0173] Fluoroalkyl acrylic resin polymer 0.5

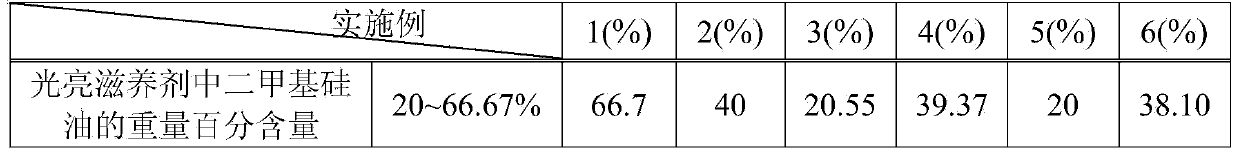

[0174] Simethicone 9.0

[0175] Lanolin 0.5

[0176] Mink Oil 2.0

[0177] Jojoba Oil 2.0

[0178] Stearic acid 1.5

[0179] Carnauba Wax 4.5

[0181] Montan wax 2.5

[0182] KOH 0.2

[0183] Iodopropynyl carbamate 0.05

[0184] 5-Chloro-2methyl-4-isothiazolin-3one 0.15

[0185] Deionized water 63.8

[0186] The preparation method is as follows:

[0187] S1: configuring raw materials according to the above weight percentage;

[0188] S2: The fluoroalkyl acrylic resin polymer and the mixed mineral spirits are mixed in a ratio of 1:2 by weight to prepare a composite waterproofing agent.

[0189] S3: Add glycery...

Embodiment 2

[0194] A new type of leather waterproof curing agent, the weight percentage of each component of the waterproof curing agent is as follows (unit: %):

[0195] 200# solvent oil 5.0

[0196] 120# solvent oil 15.0

[0197] Glyceryl monostearate 1.5

[0198] Cetearyl ether-2 0.5

[0199] Fluoroalkyl Acrylic Polymer 1.0

[0200] Simethicone 2.0

[0201] Lanolin 2.2

[0202] Jojoba oil 0.8

[0203] Stearic acid 4.5

[0204] Paraffin 1.0

[0206] Montan Wax 1.0

[0207] KOH 0.8

[0208] Iodopropynyl carbamate 0.1

[0209] 5-Chloro-2methyl-4-isothiazolin-3-one 0.05

[0210] 2-Methyl-4-isothiazolin-3-one 0.05

[0211] Dyes and fragrances 0.3

[0212] Deionized water 62.2

[0213] Its preparation method is as follows:

[0214] S1: configuring raw materials according to the above weight percentage;

[0215] S2: The composite water repellent is prepared by fluoroalkyl acrylic resin polymer and mixed mineral spirits in a ratio of 1:2 by weig...

Embodiment 3

[0221] A new type of leather waterproof curing agent, the weight percentage of each component of the waterproof curing agent is as follows (unit: %):

[0222] 200# solvent oil 25.0

[0223] Glyceryl monostearate 1.5

[0224] Ceteareth-2 1.5

[0225] Ceteareth-21 2.0

[0226] Fluoroalkyl Acrylic Polymer 1.5

[0227] Simethicone 1.5

[0228] Lanolin 1.5

[0229] Mink Oil 3.8

[0230] Jojoba Oil 0.5

[0231] Stearic acid 3.0

[0232] Carnauba Wax 2.0

[0233] Paraffin 1.5

[0234] KOH 0.4

[0235] Iodopropynyl carbamate 0.2

[0236] 2-Methyl-4-isothiazolin-3-one 0.1

[0237] Dyes and fragrances 0.8

[0238] Deionized water 53.2

[0239] Its preparation method is as follows:

[0240] S1: configuring raw materials according to the above weight percentage;

[0241] S2: The fluoroalkyl acrylic resin polymer and the mixed mineral spirits are mixed in a ratio of 1:2 by weight to prepare a composite waterproofing agent.

[0242] S3: Add glyceryl monostearate and ceteary...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com