Fluororubber rubber compound and preparation method thereof

A fluororubber and compounding technology, applied in the field of fluororubber compounding, can solve the problems of difficulty in forming, difficulty in high strength and high elongation, poor fluidity of fluorine compounding, and achieves a reduction in the scrap rate and a production process. Enhanced environmental and vulcanizing environment adaptability, bright appearance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The preparation of embodiment 1 fluorine rubber compound rubber

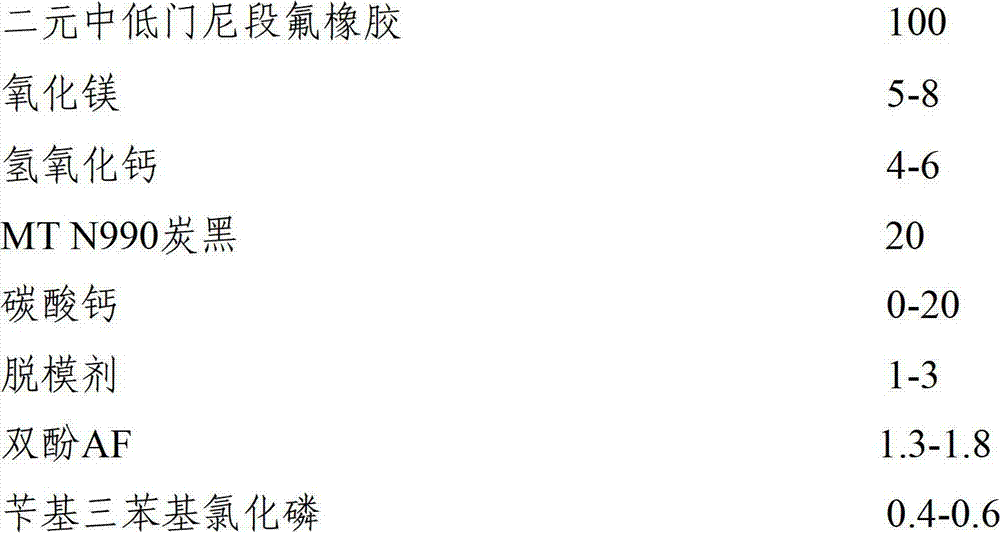

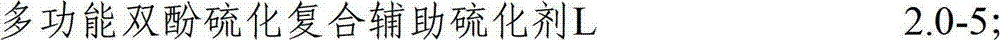

[0022] Table 1 shows the formula and physical properties of the fluororubber compound with high strength and high elongation.

[0023] Table 1 Fluorine rubber compound formula and its physical properties (content in parts by weight)

[0024]

[0025] Oil seals, gaskets, and extrusion in Table 1 mainly refer to the use of fluorine compound rubber. The auxiliary vulcanizing agent L is added to the compound rubber formula to prepare oil seals, gaskets and extruded fluorine compound rubber. The obtained fluorine compound rubber The physical properties are generally higher than that of the blank compound rubber, and the products made of it can eliminate the problems of edge material shortage and demoulding tearing. When used in extruded products, due to the improved fluidity, the extrusion will be smoother. In addition, the extension of T10 time ensures that there will be no scorching during extrusion.

...

Embodiment 2

[0034] Preparation of embodiment 2 fluorine rubber compound

[0035] The formulation and physical properties of the fluororubber compound with high strength and high elongation are shown in Table 2.

[0036] Table 2 Fluorine rubber compound formula and its physical properties (content in parts by weight)

[0037]

[0038]

[0039] The preparation process of the above-mentioned multifunctional bisphenol vulcanization composite auxiliary vulcanizing agent L is the same as that described in Example 1, and the preparation method of the fluororubber compound is the same as that described in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| deformation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com