Preparation method of microencapsulation diolame sodium butyrate

A kind of coating sodium butyrate, microencapsulation technology, applied in the application, animal feed, animal feed and other directions, can solve the problems that affect the customer's recognition of feed quality, strange smell, and high market price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

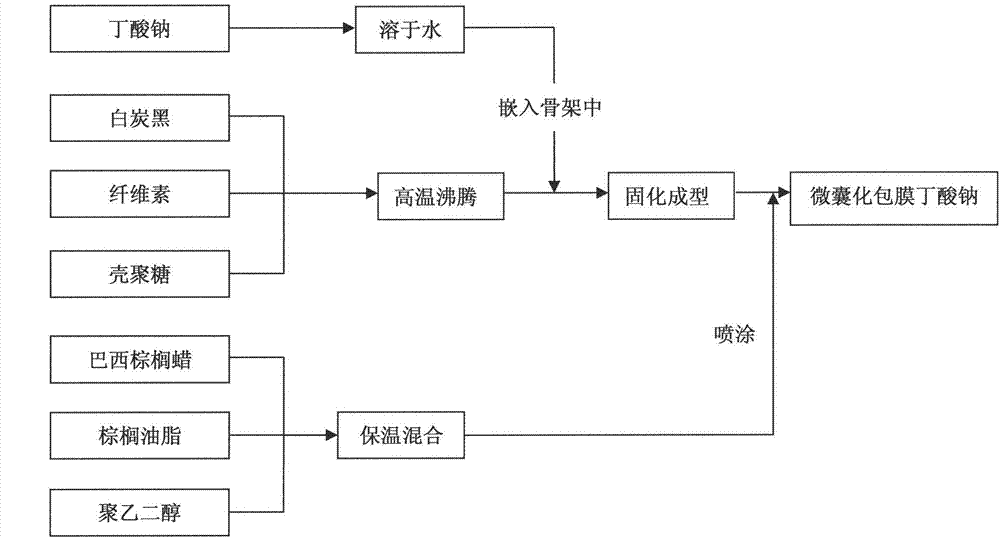

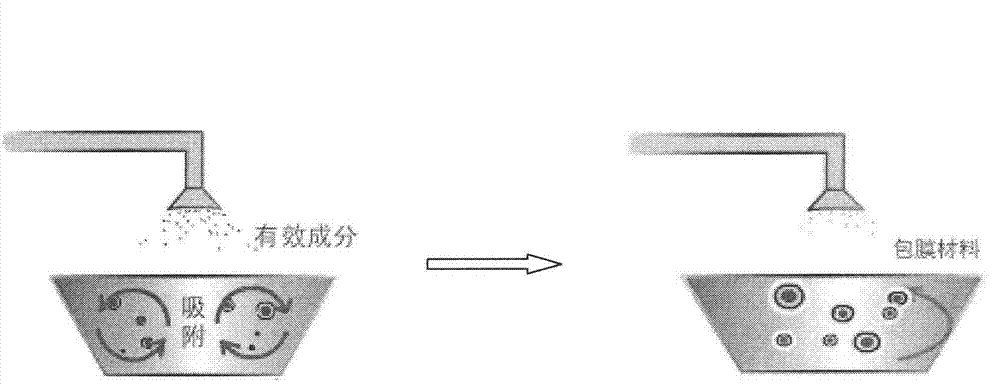

Method used

Image

Examples

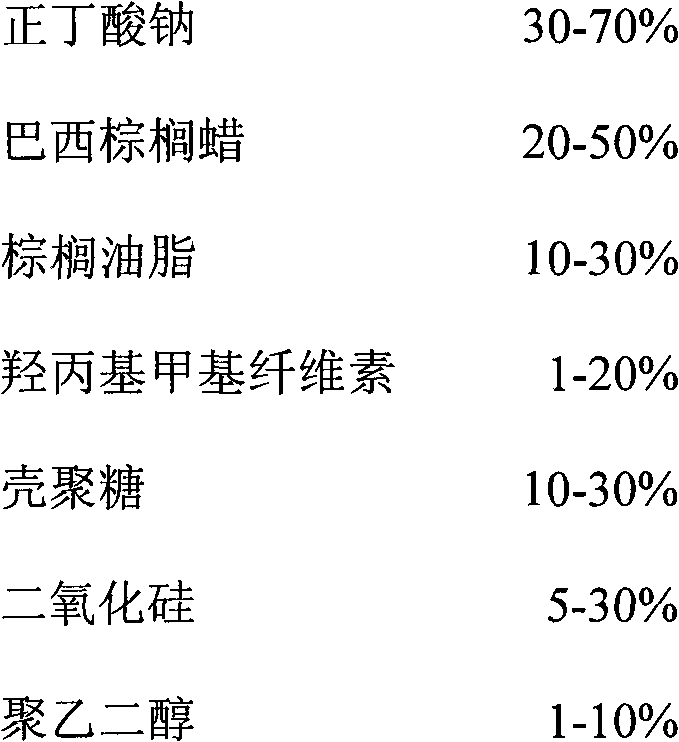

Embodiment 1

[0014] Weigh 300g of sodium butyrate and dissolve it in water, then mix 100g of hydroxypropyl methylcellulose, 150g of chitosan and 100g of silicon dioxide and boil and expand in a fluidized bed at a high temperature of 230°C, then spray the sodium butyrate aqueous solution On the mixture of the above three substances, the sodium butyrate is embedded in the framework material and dried at a high temperature of 120-140℃; after the high temperature drying, it is cured at a low temperature of -5℃ to solidify the sodium butyrate particles, and then 200g carnauba palm Wax, 100g palm oil and 50g polyethylene glycol are dissolved in an organic solvent, and the bottom spray is carried out in a fluidized bed coating machine to evenly spray the coating material on the surface of sodium butyrate particles at a flow rate of 0.1-3L / min. The wind temperature is 50-90℃, the time is 3-4h, and the final product particle size is over 85% and passed through a 20-mesh analytical sieve. Finally, a ...

Embodiment 2

[0016] Weigh 700g of sodium butyrate and dissolve it in water, then mix 20g of hydroxypropyl methylcellulose, 50g of chitosan and 40g of silica and boil and expand in a fluidized bed at a high temperature of 230°C, and then spray the sodium butyrate aqueous solution On the mixture of the above three substances, the sodium butyrate is embedded in the framework material and dried at a high temperature of 120-140℃; after the high temperature drying, it is cured at a low temperature of -5℃ to solidify the sodium butyrate particles, and then 80g carnauba Wax, 50g palm oil and 10g polyethylene glycol are dissolved in an organic solvent, and the bottom spray is carried out in a fluidized bed coating machine. The coating material is evenly sprayed on the surface of sodium butyrate particles at a flow rate of 0.1-3L / min. The wind temperature is 50-90℃, the time is 3-4h, and the final product particle size is over 85% and passed through a 20-mesh analytical sieve. Finally, a sample of mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com