Washable graffiti crayon and preparation method thereof

A crayon and washing technology, which is applied to pencil lead, household utensils, applications, etc., can solve the problems of limited functions and usage scenarios, waxy odor, and difficult coloring, etc., to prevent accidental ingestion, biting, and coloring power Strong, easy molding and demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0092] The preparation method of the washable graffiti crayon of the present invention needs to pre-treat the pigment first so that the particle size meets the requirements, and the coloring is more delicate, and a water-based wax liquid is prepared as a base material to ensure the washability of the system, specifically as follows step:

[0093] Step (a) mix and melt white mineral oil with half of the total amount of wax, half of the total amount of stearic acid and half of the total amount of hardened oil at a melting temperature of 80-110°C for 60-120 minutes, then Obtain mixed wax liquid;

[0094] Step (b) adding an environmentally friendly pigment to the mixed wax liquid obtained in the step (a) for uniform stirring, heating while stirring at a heating temperature of 70-90°C, and stirring for 30-60 minutes to obtain a uniform mixture;

[0095] Step (c) grinding the homogeneous mixture obtained in the step (b) with a three-roll mill to process a fine granular semi-solid p...

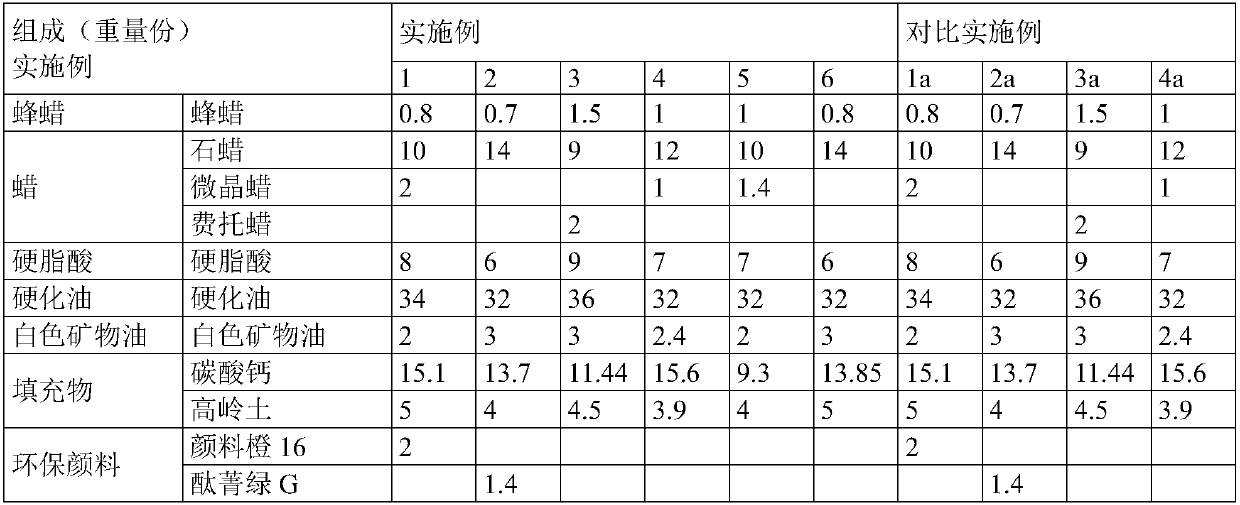

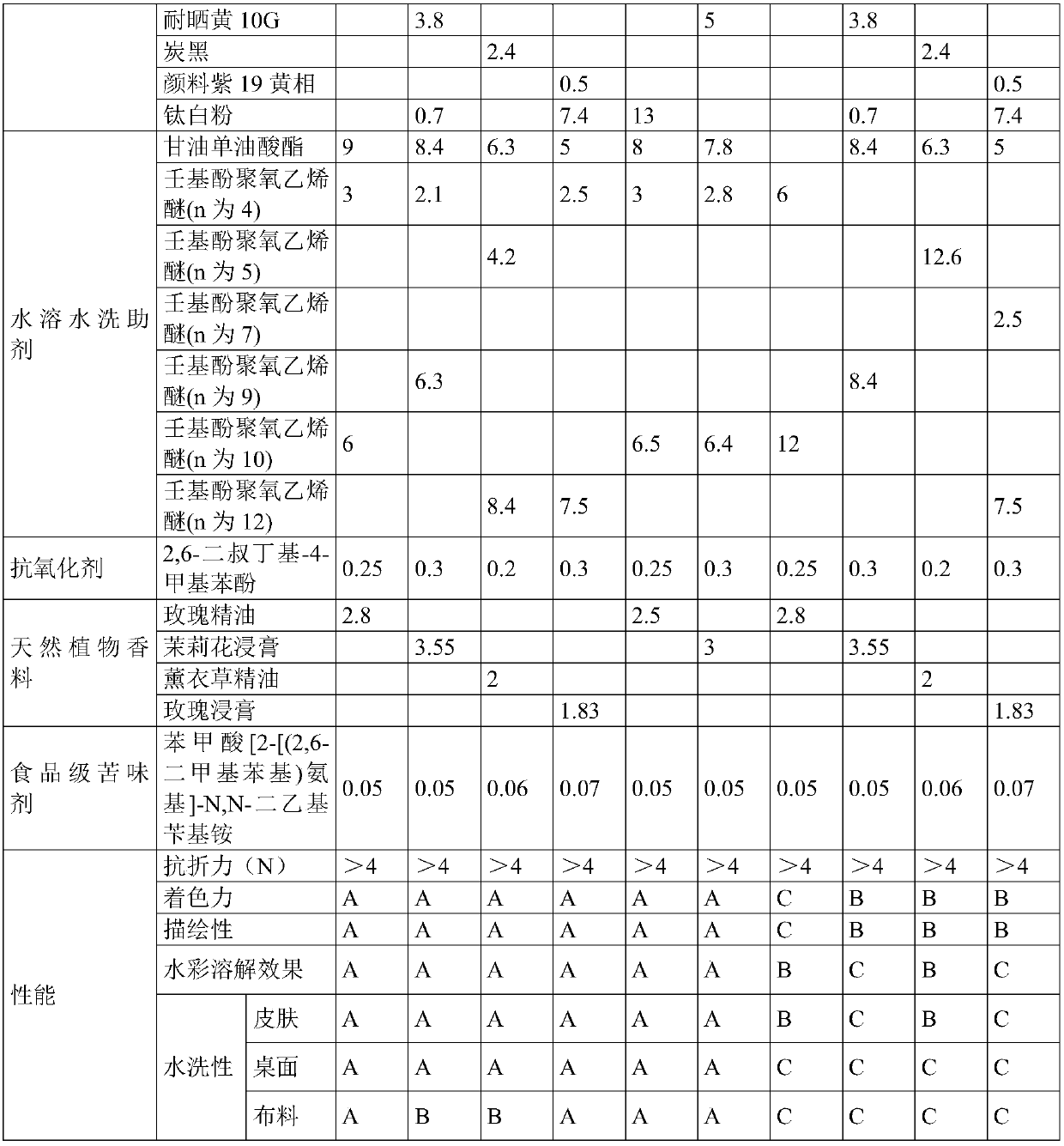

Embodiment 1

[0105] Example 1: Orange Washable Graffiti Crayons

[0106] The formula is as follows: 0.8 parts by weight of beeswax; 10 parts by weight of paraffin wax; 2 parts by weight of microcrystalline wax; 8 parts by weight of stearic acid; 34 parts by weight of hardened oil; 2 parts by weight of white mineral oil; 15.1 parts by weight of calcium carbonate; 5 parts by weight of kaolin 2 parts by weight of pigment orange 16; 9 parts by weight of glycerol monooleate; 3 parts by weight of nonylphenol polyoxyethylene ether (n is 4); 6 parts by weight of nonylphenol polyoxyethylene ether (n is 10); 2 , 0.25 parts by weight of 6-di-tert-butyl-4-methylphenol; 2.8 parts by weight of rose essential oil; benzoic acid [2-[(2,6-dimethylphenyl)amino]-N,N-diethyl 0.05 parts by weight of benzyl ammonium.

[0107] The preparation method is as follows: 2 parts by weight of white mineral oil, 5 parts by weight of paraffin wax, 1 part by weight of microcrystalline wax, 4 parts by weight of stearic acid...

Embodiment 2

[0114] Example 2: Green Washable Graffiti Crayons

[0115] The formula is as follows: 0.7 parts by weight of beeswax; 14 parts by weight of paraffin; 6 parts by weight of stearic acid; 32 parts by weight of hardened oil; 3 parts by weight of white mineral oil; 13.7 parts by weight of calcium carbonate; 4 parts by weight of kaolin; 1.4 parts by weight of phthalocyanine green G 3.8 parts by weight of Fast Yellow 10G; 0.7 parts by weight of titanium dioxide; 8.4 parts by weight of glycerol monooleate; 2.1 parts by weight of nonylphenol polyoxyethylene ether (n is 4); 9) 6.3 parts by weight; 0.3 parts by weight of 2,6-di-tert-butyl-4-methylphenol; 3.55 parts by weight of jasmine extract; benzoic acid [2-[(2,6-dimethylphenyl)amino ]-N,N-diethylbenzyl ammonium 0.05 parts by weight.

[0116] The preparation method is as follows: 3 parts by weight of white mineral oil are mixed and melted with 7 parts by weight of paraffin wax, 3 parts by weight of stearic acid and 16 parts by weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com