Variable color fragrance bead for tobacco and preparation method of the fragrance bead

A technology of flavoring and flavoring beads for tobacco, which is applied in applications, tobacco, and e-liquid filter elements, etc., can solve the problems that consumers find it difficult to find consumption experience, and achieve the effect of bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of preparation method of flavor beads for tobacco, concrete steps are as follows:

[0026] (1) Tobacco leaves and anise are taken as raw materials, crushed and sieved at a ratio of 1:1 to obtain the required natural plant powder, and the particle size of the powder is 30 mesh. Fully mix the plant powder with starch, chitosan, and microcrystalline cellulose according to the ratio in Table 1-1 to prepare a solid mixed powder;

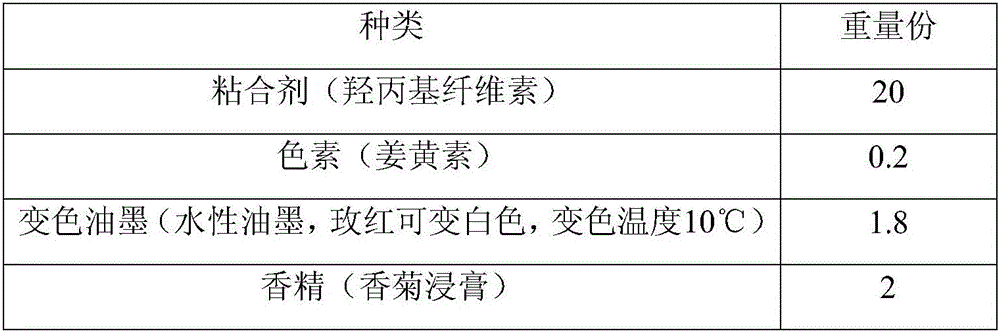

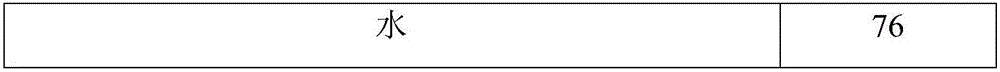

[0027] Table 1-1 Solid mixed powder raw material formula

[0028] type parts by weight Plant powders (tobacco leaves, anise) 10 starch 40 Chitosan 30 microcrystalline cellulose 20

[0029] (2) Get the solid mixed powder prepared in the step (1) and place it in a BZJ type centrifugal coating granulator, then prepare a 5% aqueous solution of hydroxypropyl cellulose and spray it as a binder solution. The mother core is formed by rotating in a centrifuge; wherein the mass ratio of the solid ...

Embodiment 2

[0036] Embodiment 2: a kind of preparation method of flavor beads for tobacco, concrete steps are as follows:

[0037] (1) Take tobacco leaves and lavender as raw materials, pulverize and sieve them in a ratio of 2:1 to obtain the required natural plant powder, and the particle size of the powder is 60 mesh. Fully mix the plant powder with starch, chitosan, and microcrystalline cellulose according to the ratio in Table 1-2 to prepare a solid mixed powder;

[0038] Table 1-2 Solid mixed powder raw material formula

[0039] type parts by weight Plant powder (tobacco leaf, lavender) 20 starch 30 Chitosan 40 microcrystalline cellulose 10

[0040] (2) the solid mixed powder prepared in the step (1) is placed in a BZJ type centrifugal coating granulator, and then the hydroxypropyl methylcellulose aqueous solution of 10% by mass is prepared and sprayed as a binder solution, The powder is rotated in a centrifuge to form a mother nucleus, wherei...

Embodiment 3

[0046] Embodiment 3: a kind of preparation method of flavor beads for tobacco, concrete steps are as follows:

[0047] (1) Take cloves and jasmine as raw materials, grind them according to the ratio of 4:3, and sieve them to obtain the required natural plant powder with a particle size of 80 mesh. Fully mix the plant powder with starch, chitosan, and microcrystalline cellulose according to the ratio in Table 1-3 to prepare a solid mixed powder;

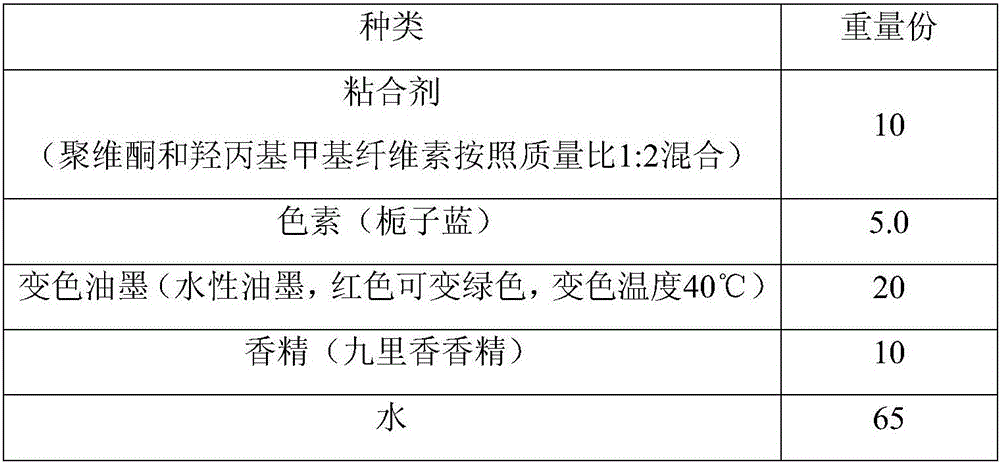

[0048] Table 1-3 Solid mixed powder raw material formula

[0049] type parts by weight Plant powder (clove, jasmine) 30 starch 30 Chitosan 20 microcrystalline cellulose 20

[0050] (2) Place the solid mixed powder prepared in step (1) in a BZJ type centrifugal coating granulator, then mix povidone and hydroxypropyl methylcellulose in a mass ratio of 1:2 to prepare the mixed powder Binder, then dissolve the mixed binder in pure water, and prepare a mixed binder aqueous solution with a binder con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com