Environmentally-friendly aqueous spray paint and preparation method thereof

An environmentally friendly, water-based technology, applied in coatings, polyurea/polyurethane coatings, etc., to achieve good aging resistance, high paint film fullness, and VOC reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

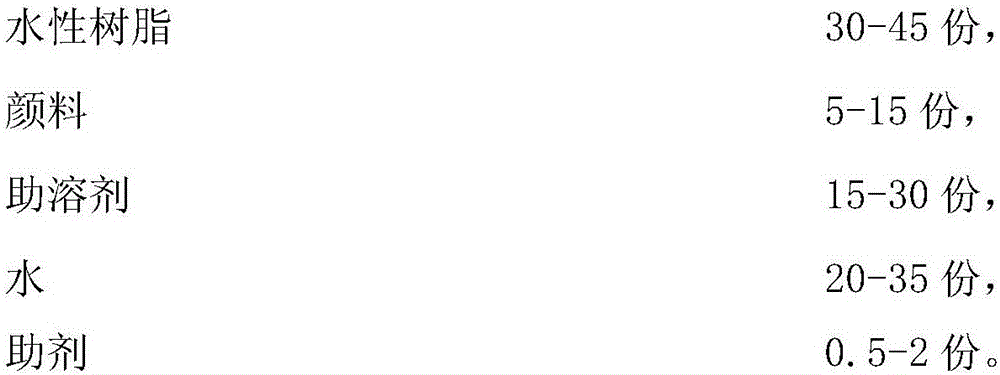

[0026] An environment-friendly water-based self-painting liquid material, comprising the following components in parts by weight:

[0027]

[0028] An environment-friendly water-based self-spray paint, comprising 120g of water-based spray paint liquid and 100g of dimethyl ether.

[0029] Put 25 parts of water-based acrylic resin and 1 part of water-based wetting and dispersing agent EFKA4585 into the dispersion kettle, disperse evenly at 600r / min, then add 15 parts of titanium dioxide pigment, disperse at 1200r / min for 20min at high speed, and grind to The fineness of white pulp is ≤20μm, put in 15 parts of water-based acrylic resin, 20 parts of co-solvent (10 parts of ethanol, 5 parts of isopropanol, 5 parts of dipropylene glycol methyl ether) and 0.3 parts of water-based leveling agent Super9033 at 800r / min , 0.2 parts of water-based antifoaming agent Super0341B and 23.5 parts of deionized water, dispersed for 20 minutes to obtain a water-based spray paint material liquid...

Embodiment 2

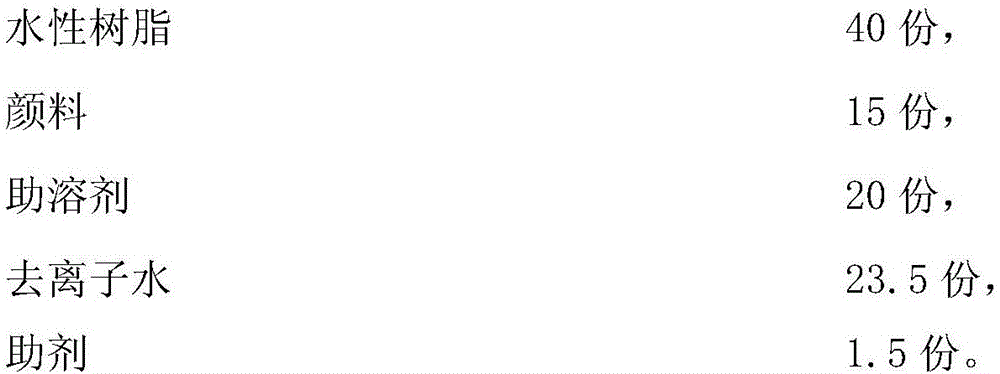

[0032] An environment-friendly water-based self-painting liquid material, comprising the following components in parts by weight:

[0033]

[0034]

[0035] An environment-friendly water-based self-spray paint, including 132g water-based spray paint liquid material and 88g dimethyl ether.

[0036] Put 30 parts of water-based polyurethane resin and 1.2 parts of water-based wetting and dispersing agent TB031 into the dispersion kettle, disperse evenly at 600r / min, then add 8 parts of carbon black pigment, disperse at 1200r / min for 20min at high speed, and grind to The fineness of the black pulp is ≤20μm, put in the remaining 10 parts of water-based polyurethane resin, 16 parts of co-solvent (9 parts of ethanol, 4 parts of propylene glycol, 3 parts of dibasic acid ester mixture (DBE)) and 0.3 parts of water-based polyurethane resin at a speed of 800r / min. Substrate wetting agent WE3220, 0.2 parts of water-based defoamer EFKA2526 and 34.3 parts of deionized water were disper...

Embodiment 3

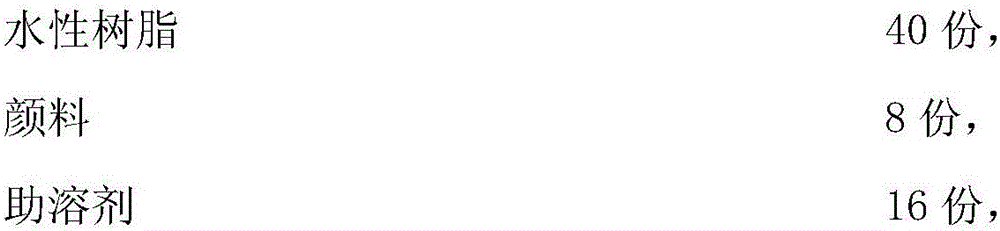

[0039] An environment-friendly water-based self-painting liquid material, comprising the following components in parts by weight:

[0040]

[0041] An environment-friendly water-based self-spray paint, comprising 110g of water-based spray paint liquid and 110g of dimethyl ether.

[0042] Put 30 parts of water-based acrylic resin and 1.5 parts of water-based wetting and dispersing agent EFKA4585 into the dispersing kettle, disperse evenly at 600r / min, then add 10 parts of red powder pigment, disperse at 1200r / min for 20min at a high speed, and grind to The fineness of the color paste is ≤20μm; add the remaining 15 parts of water-based acrylic resin, 18 parts of co-solvent (10 parts of ethanol, 5 parts of butanol, 3 parts of dipropylene glycol methyl ether) and 0.3 parts of water-based leveling agent at a speed of 800r / min WE3500, 0.2 parts of adhesion promoter Super103AT, 25 parts of deionized water, dispersed for 20 minutes, that is, the water-based self-painting liquid mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| flash point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com