Patents

Literature

32 results about "DIETHYL SEBACATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Weather monitoring device and application thereof

ActiveCN102718994AGood dispersionSame plasticizing effectBalloon aircraftsInstrumentsDibutyl sebacateDIETHYL SEBACATE

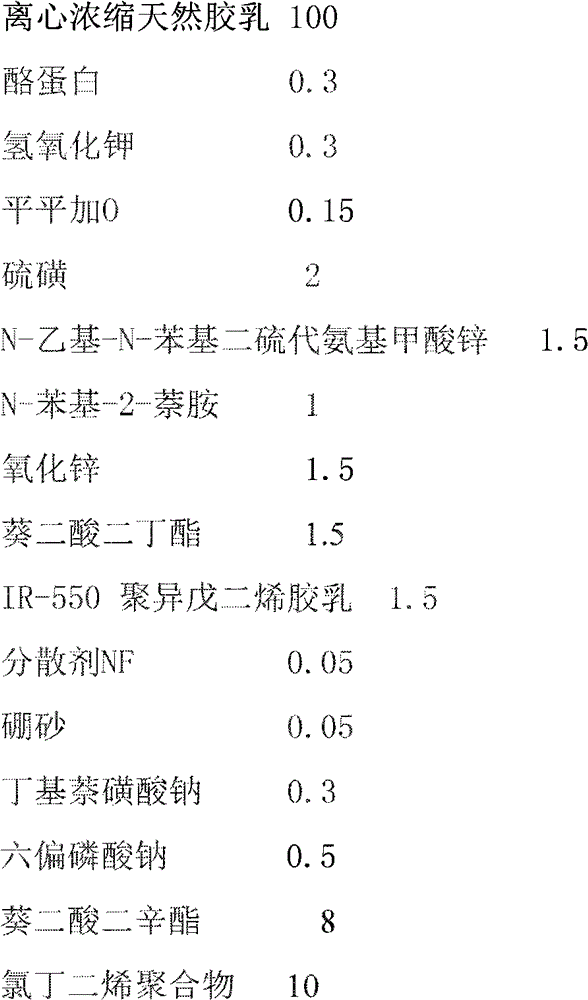

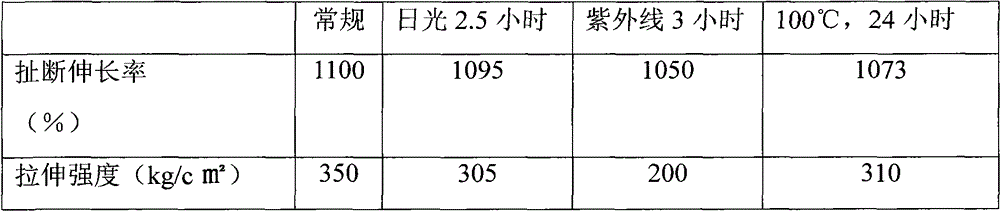

The invention relates to a weather monitoring device, in particular to a new weather balloon, which comprises the following components by weight percent: 100 of centrifugal concentrated natural latex, 0.3 of casein, 0.3 of potassium hydroxide, 0.15 of peregal 0, 2 of sulphur, 1.5 of N-ethyl-N-phenyl dithiocarbamate zinc, 1 of N-phenyl-2-naphthylamine, 1.5 of zinc oxide, 1.5 of dibutyl sebacate, 1.5 of IR-550 polyisoprene latex, 0.05 of dispersing agent NF, 0.05 of borax, 0.3 of sodium butylnaphthalenesulfonate, 0.5 of sodium hexametaphosphate, 8 of dioctyl sebacate and 10 of chloroprene polymer. The new weather balloon provided by the invention has the advantages of high sounding altitude, long sounding time and wide application prospect.

Owner:南通市通州区新志浩实业有限公司

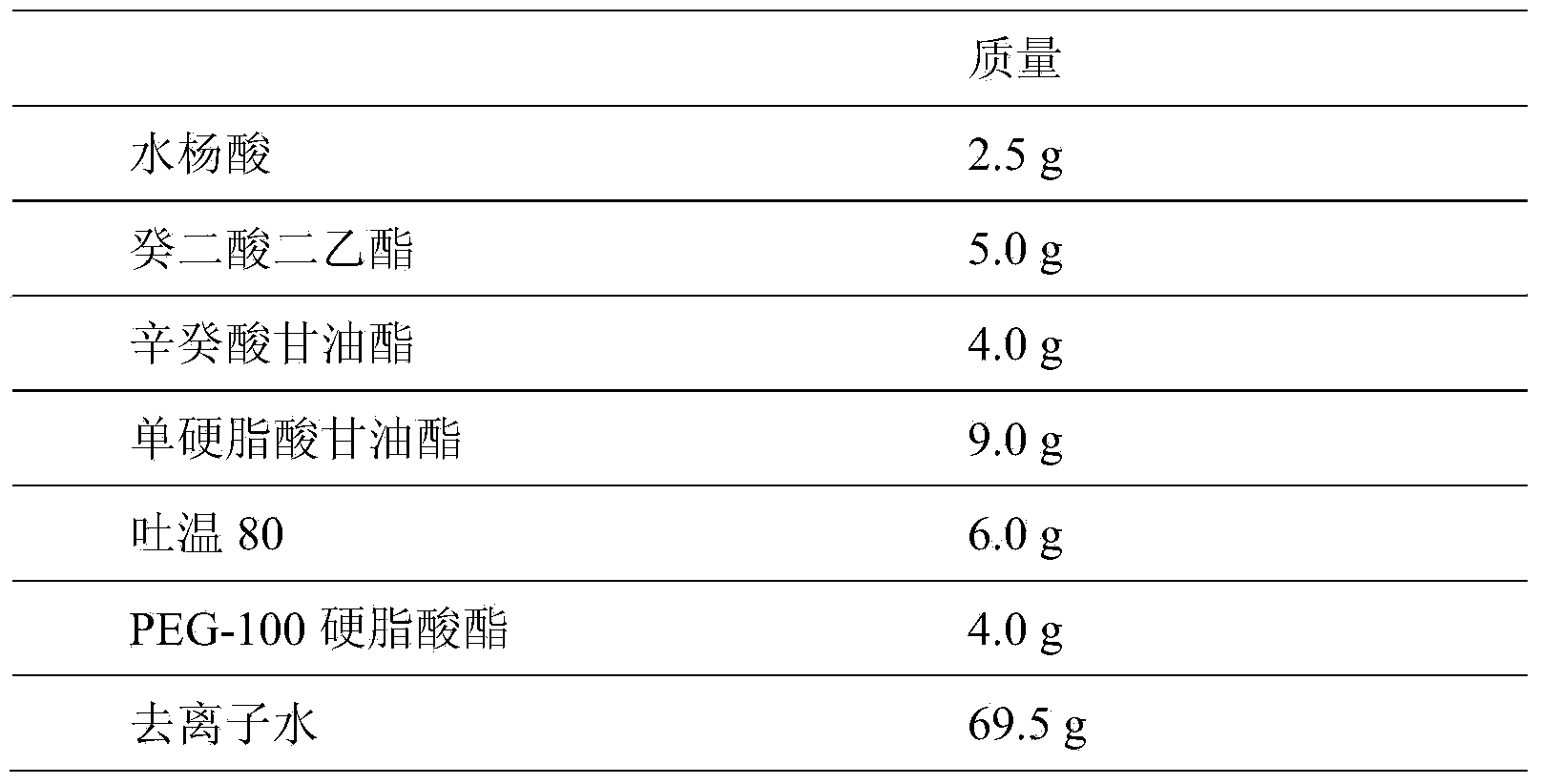

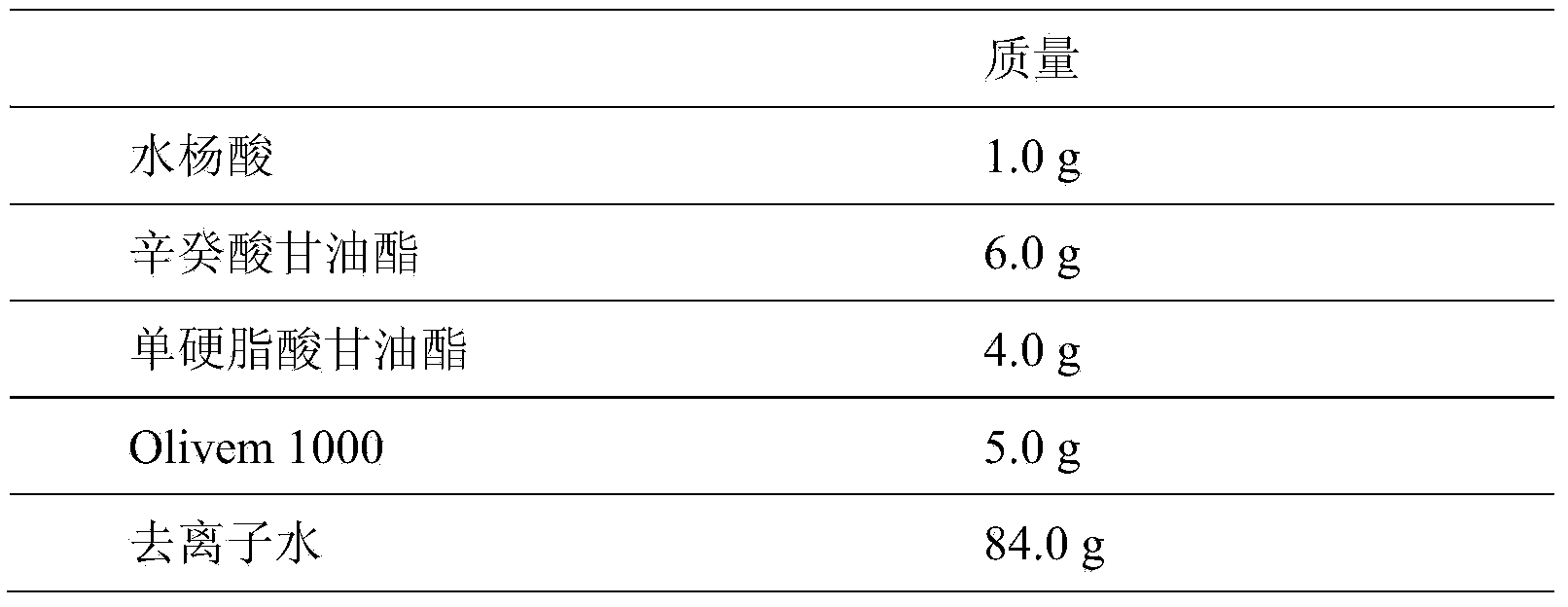

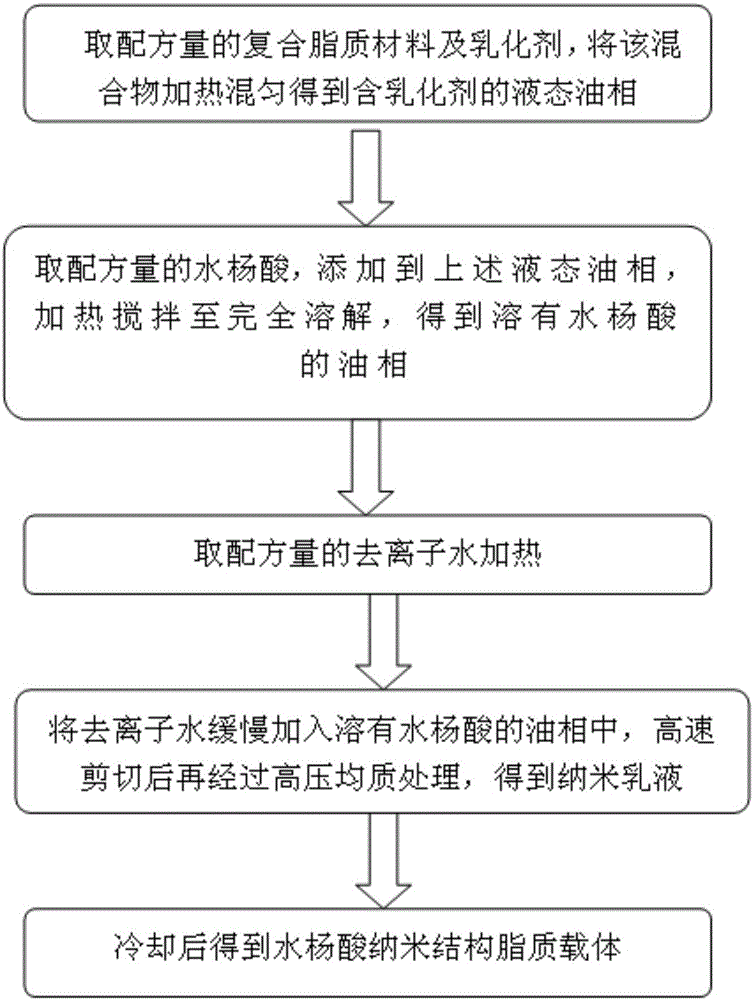

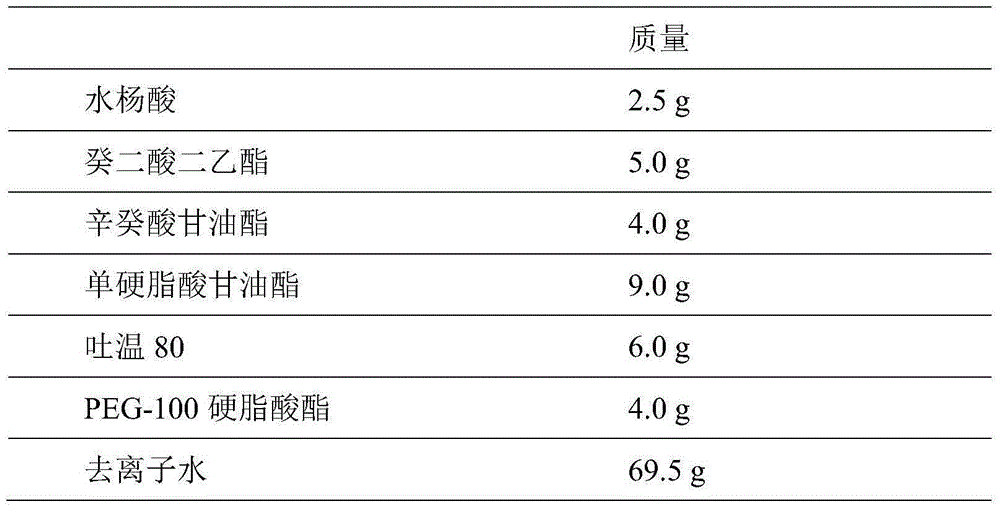

Salicylic acid nanostructured lipid carrier and preparation method and application thereof

InactiveCN103860387AGuaranteed to workPromote hydrationCosmetic preparationsToilet preparationsACETYLATED MONOGLYCERIDEGLYCERYL CAPRYLATE-CAPRATE

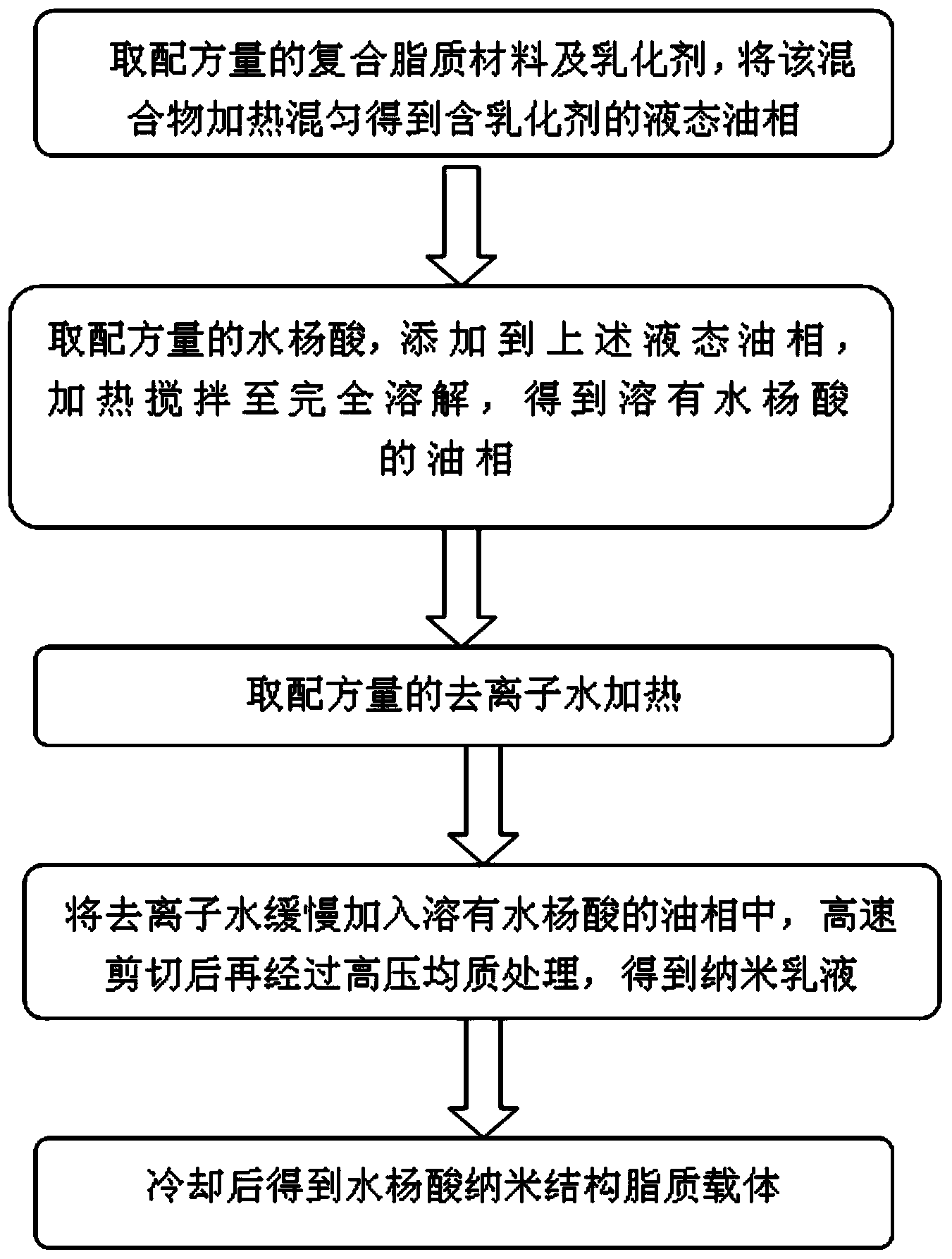

The invention discloses a salicylic acid nanostructured lipid carrier, which comprises the following components in percentage by mass: 1 to 5% of salicylic acid, 10 to 30% of composite lipid material, 5 to 15% of emulsifier, and the balance of deionized water, wherein the composite lipid material is a solid-liquid lipid material, a solid lipid material is one or more of glyceryl monostearate, shea butter, acetylated monoglyceride and spermaceti wax, and a liquid lipid material is one or more of glyceryl caprylate caprate, diethyl sebacate, castor oil, and isopropyl myristate. The invention also discloses a preparation method and application of the salicylic acid nanostructured lipid carrier. Salicylic acid is embedded by a nanostructured carrier technology, so that large amounts of free salicylic acid are not in direct contact with the skin to reduce the irritation of the salicylic acid, and the release of salicylic acid is favorably controlled, and salicylic acid can be ensured to be effective at the surface concentration by utilizing controlled release and sustained release.

Owner:SOUTHEAST UNIV

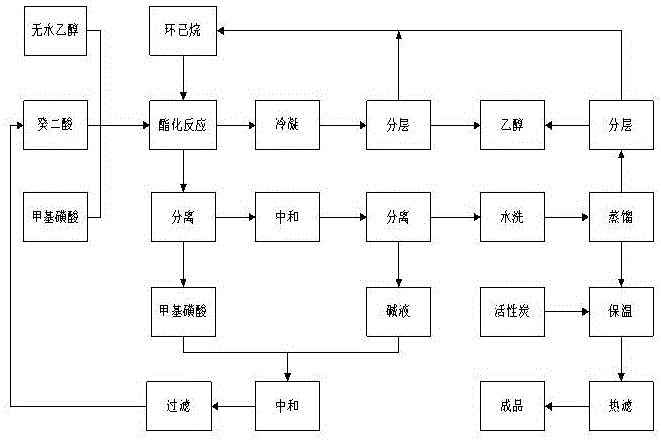

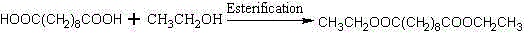

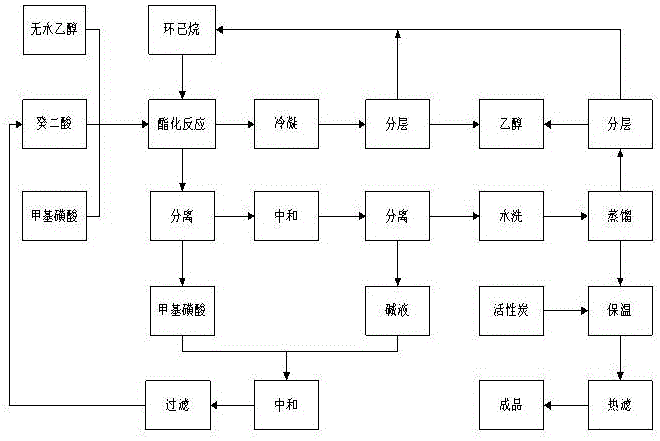

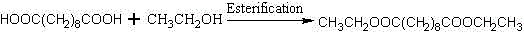

Preparation method of diethyl sebacate in presence of catalyst namely methyl sulfonic acid

ActiveCN105130814AReduce pollutionReduce consumptionOrganic compound preparationCarboxylic acid esters preparationPtru catalystDIETHYL SEBACATE

The invention discloses a preparation method of diethyl sebacate in the presence of a catalyst namely methyl sulfonic acid, and belongs to the field of catalytic synthesis of diethyl sebacate. According to the method, sebacic acid and anhydrous ethanol are taken as the raw materials, methyl sulfonic acid is taken as the catalyst, cyclohexane is taken as the water carrying agent, and after the reactions the reaction product is subjected to neutralization, water washing, distillation, and purification so as to obtain diethyl sebacate. Cyclohexane is taken as the water carrying agent, the reaction time is short, methyl sulfonic acid can be degraded, a product with a good appearance can be obtained without vacuum distillation, the acid / alkali using amount is little, the method is pollution-free; the product yield can reach at least 94% after one hour of reactions, the production cost is low, and the synthesis method is efficient and environment-friendly and can be applied to massive industrial production.

Owner:XUZHOU CURRENCY MAGNETOELECTRICITY

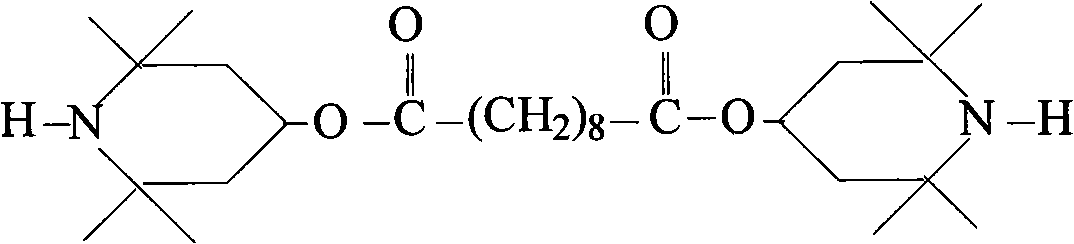

Light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and preparation method thereof

InactiveCN101665457AReduce pollutionEasy to separate and purifyOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsDibutyltin oxideDIETHYL SEBACATE

The invention discloses a light stabilizer bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and a preparation method thereof. Dimethyl sebacate and 2,2,6,6-tetramethyl-4-hydroxypiperidine are taken as raw materials, and then the raw materials react in the presence of catalyst to prepare bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate. The invention uses dimethyl sebacate and 2,2,6,6-tetramethyl-4-hydroxypiperidine as the raw materials to synthesize the bis(2,2,6,6-tetramethyl-4-piperidinyl)sebacate and adopts dibutyltin oxide as the catalyst, and thereby the separation and purification process issimplified, the reaction time is short, and the product yield is as high as more than 97 percent; the obtained product has high purity, reduced energy consumption, little environmental pollution andlow cost, and therefore, the invention is an ideal process for realizing industrial production.

Owner:南通惠康国际企业有限公司

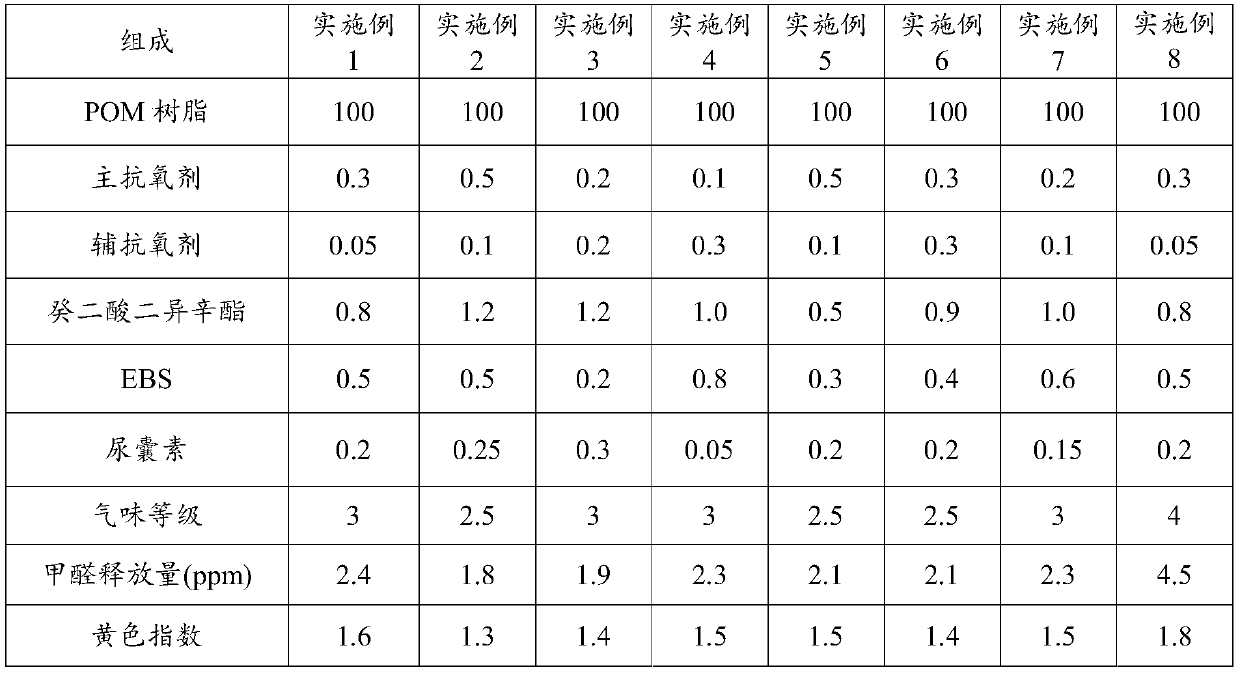

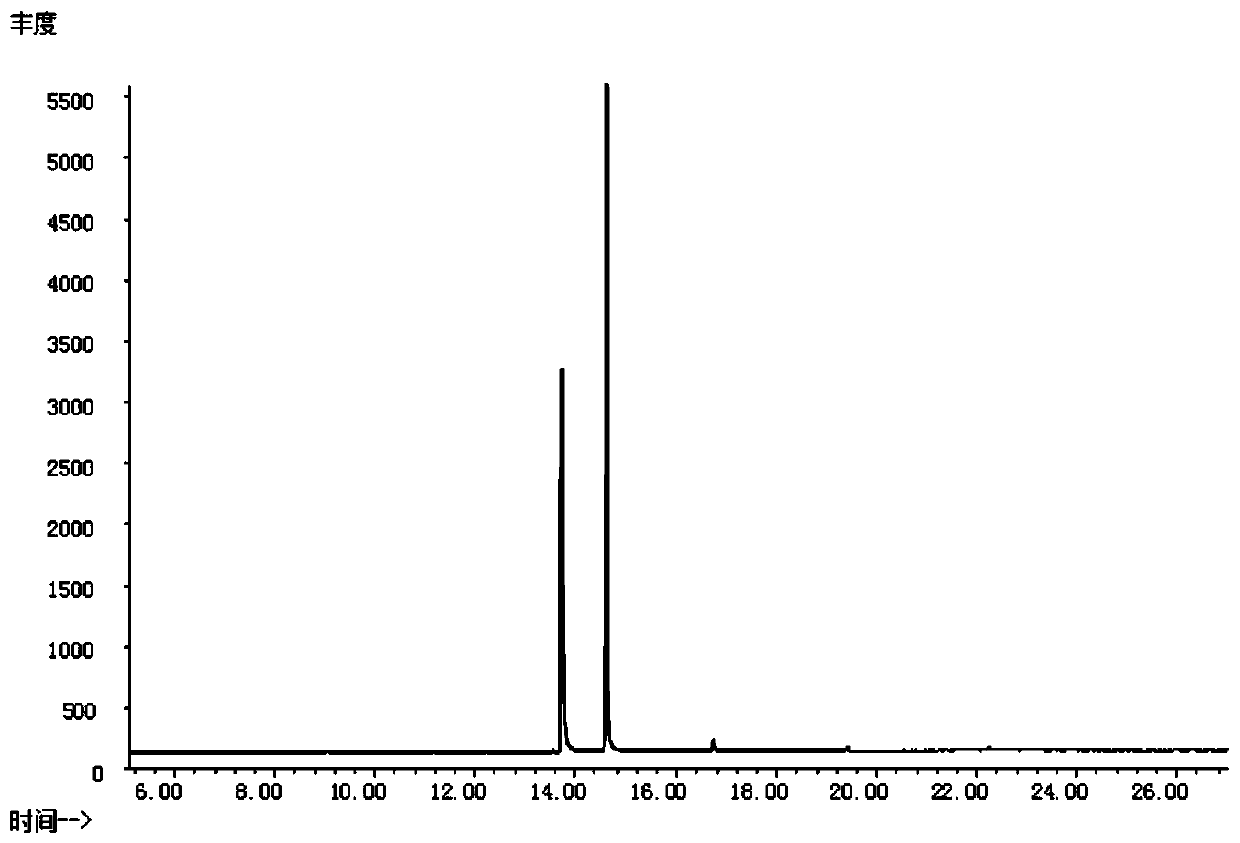

Method for preparing high-purity food standard product diethyl sebacate

InactiveCN106316850ASimple processMeet industrial productionOrganic compound preparationCarboxylic acid esters preparationDistillationDIETHYL SEBACATE

The invention relates to a method for preparing a high-purity food standard product diethyl sebacate. The method comprises the following steps: (1) selecting a raw material diethyl sebacate of which the purity content is not smaller than 98%; (2) adding the raw material diethyl sebacate into a saturated sodium chloride solution, performing stirring for 20-30 minutes, and allowing the stirred material to stand so as to separate a water phase; (3) adding a saturated potassium carbonate solution into the organic phase, performing heating to 40-50 DEG C, performing stirring for 25-30 minutes, performing heating to 50-60 DEG C, performing stirring for 25-30 minutes, and allowing the stirred material to stand so as to separate a water phase; and (4) performing water washing and drying, and performing reduced pressure distillation, thereby obtaining a standard product of which the content is 99.8% (GC), wherein the content of 99% (GC) is analytically pure. The method for preparing the high-purity food standard product diethyl sebacate, which is provided by the invention, is simple in process and good in operability, industrial production of companies can be met, self-operation of a laboratory can be met, the profit can be maximized, and the standard product does not need to be purchased with high price from the market.

Owner:TIANJIN GUANGFU TECH DEV

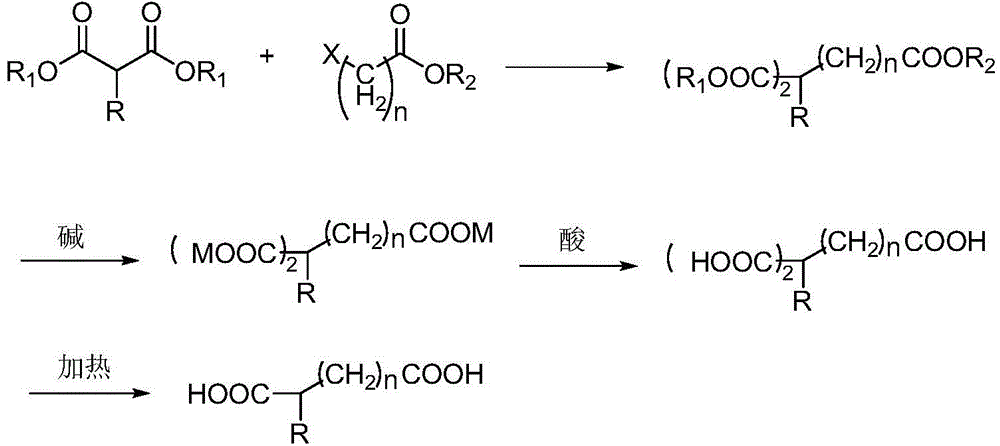

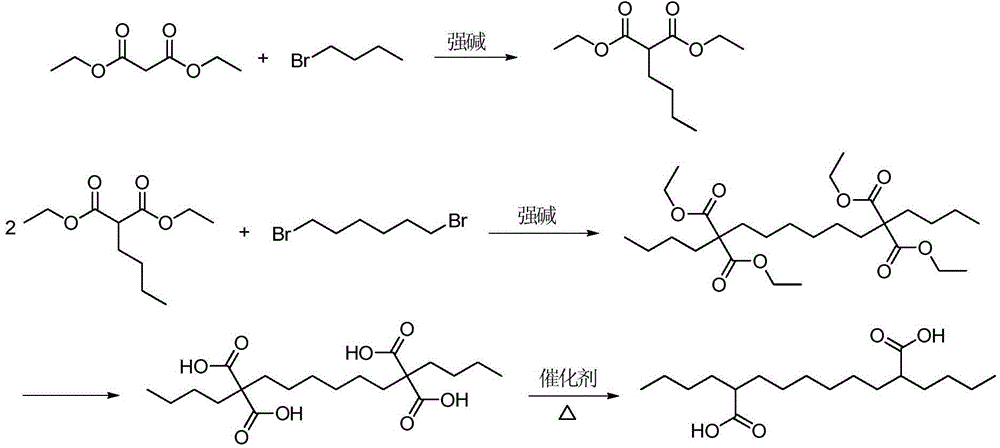

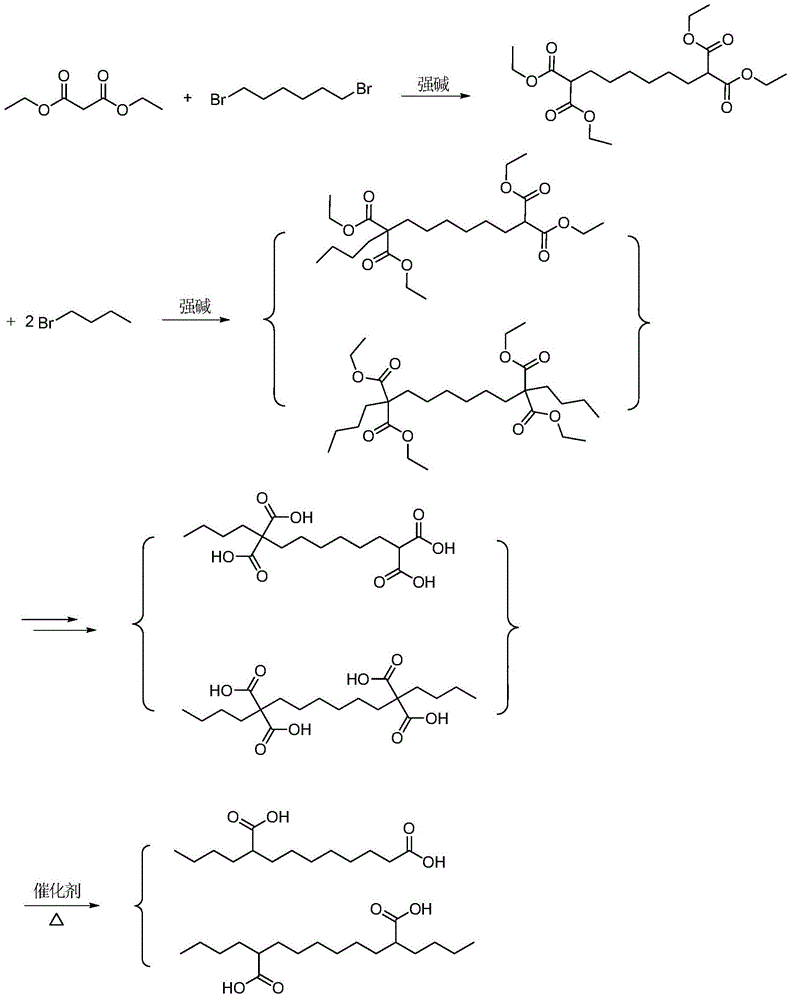

Co-production method for capacitance-grade 2-butylsebacic acid and 2, 9-butylsebacic acid

ActiveCN104447277AHigh purityImprove electrochemical performanceOrganic compound preparationCarboxylic acid esters preparationElectrolytic agentOctanoic Acids

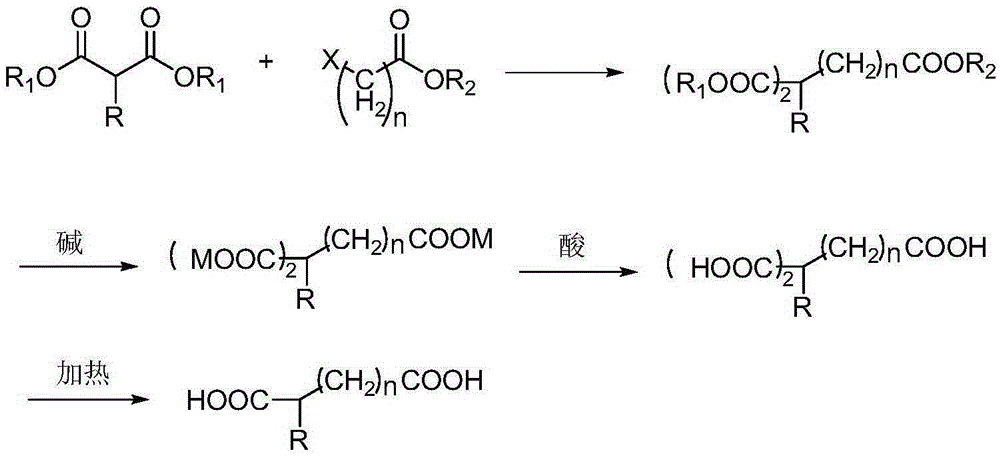

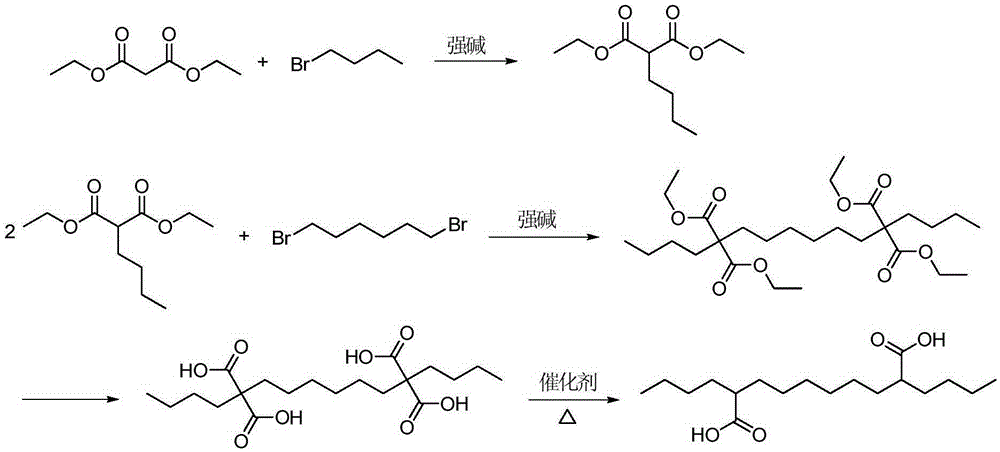

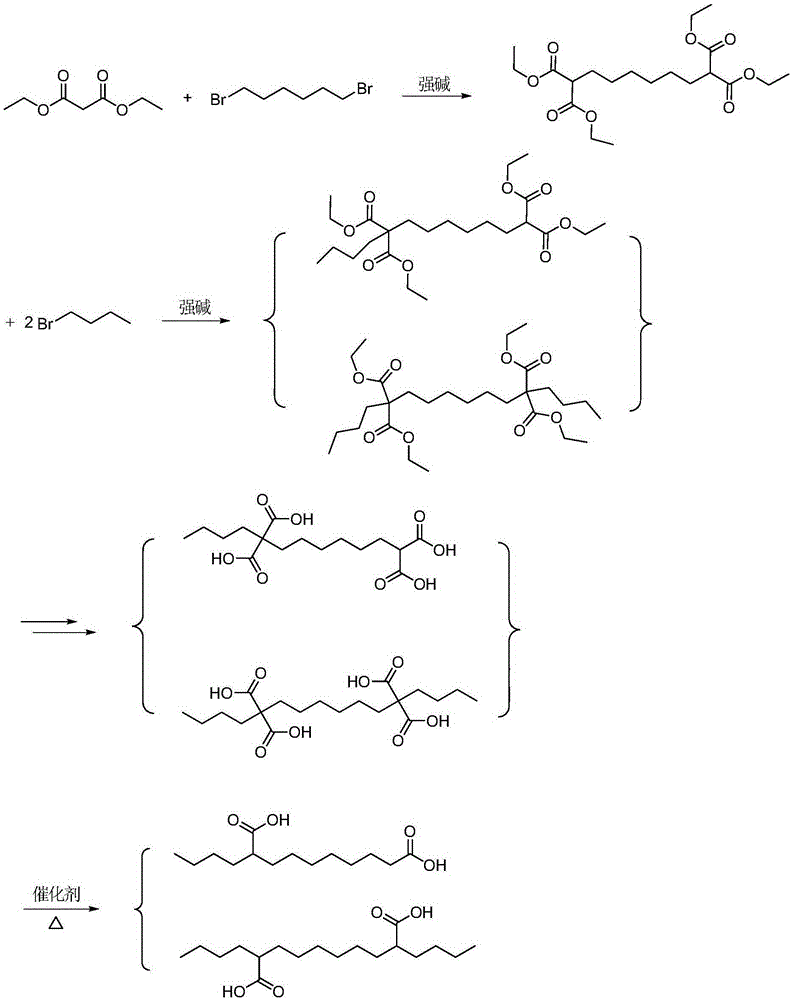

The invention relates to a co-production method for capacitance-grade 2-butylsebacic acid and 2, 9-butylsebacic acid. The co-production method comprises the steps of carrying out nucleophilic substitution reaction on diethyl malonate and 1, 6-dibromohexane serving as raw materials in a strong alkali solution to obtain 2, 9-bis(ethoxycarbonyl)-diethyl sebacate, then, enabling 2, 9-bis(ethoxycarbonyl)-diethyl sebacate to react with n-butyl bromide in the strong alkali solution, and distilling to obtain 2-butyl-2, 9-diethoxycarbonyldiethyl sebacate and 2, 9-dibutyl-2, 9-diethoxycarbonyldiethyl sebacate; and respectively saponifying, acidifying and carrying out decarboxylic reaction to obtain 2-butylsebacic acid and 2, 9-butylsebacic acid. Due to the improvement on a technological process, a byproduct, namely 2-butyl-8-thyoxyloctanoic acid is prevented from being generated, and high-purity 2-butylsebacic acid has more excellent electrochemical properties than 2-butyloctanedioic acid sold on the market, so that the oxidation efficiency of electrolyte is increased, and the co-production method has favorable market prospects.

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

Insulated heat conduction film for lithium ion battery

InactiveCN107799675AImprove securityInsulationSecondary cellsJackets/cases materialsDiethylene glycol monobutyl etherDibutyl sebacate

The invention discloses an insulated heat conduction film for a lithium ion battery. The insulated heat conduction film is used for covering the surface of a battery body. The insulated heat conduction film is prepared from the following ingredients including alkylolamide polyethylene oxide ester, inositol hexaphosphate, diethylene glycol monobutyl ether, dilauryl thiodipropionate, sodium secondary alkyl sulfonate, sodium hexametaphosphate, dibutyl sebacate, polytetrafluoroethylene, styrene and dibutyl phthalate. The insulation heat conduction film has dual attributes of insulation and heat conduction, and covers the surface of the battery body; the safety performance of the battery can be effectively improved.

Owner:SUZHOU GREEN POWER TECH CO LTD

Preparation method for adsorption material used for diethyl sebacate

InactiveCN108097220AStrong solvent resistanceStrong impact resistanceOrganic compound preparationOther chemical processesFiltrationDIETHYL SEBACATE

The invention relates to a preparation method of an adsorption material used for diethyl sebacate. The preparation method comprises the following steps: adding, by weight, vinylidene fluoride, diallylterephthalate, propylallyl disulfide, 6-(1'-tert-butyldimethylsilyloxyethyl)-2-(2''-tetrahydrofuryl)-penem-3-carboxylate, bis(pentamethylcyclopentene)titanium dichloride, dodecylbenzene sulphonic acid and water into reaction vessel; successively carrying out uniform mixing, heating and a reaction; and after completion of the reaction, subjecting a product of the reaction to filtration, washing and drying so as to obtain the adsorption material for diethyl sebacate.

Owner:孝感市锐思新材科技有限公司

Nano weather-resistant coating and preparation method thereof

InactiveCN104893448ATo meet the needs of weather resistanceImprove heat resistancePolyether coatingsDIETHYL SEBACATEPolyethylene glycol

The invention discloses a nano weather-resistant coating and a preparation method thereof. The nano weather-resistant coating comprises the following components in parts by weight: 9-17 parts of polytrifluorochloroethylene resin, 5-12 parts of polyvinylidene fluoride resin, 4-9 parts of tri-chloride-vinyl acetate resin, 3-8 parts of polyethylene glycol 6000, 3-7 parts of aluminum silicate, 3-5 parts of nano zirconium dioxide, 12-22 parts of 2-methyl-1-pentanol, 3-7 parts of diethyl sebacate and 5-10 parts of vinyl distearamide. The preparation method of the nano weather-resistant coating comprises the steps of crushing, mixing and the like. The prepared nano weather-resistant coating has the characteristic of good weather resistance.

Owner:SUZHOU DEXIANG DECORATION ENG

Boric acid glycerin polyester-doped aluminum eletrolytic capacitor electrolyte and preparation method thereof

InactiveCN107785171ASolve technical problemsLow costLiquid electrolytic capacitorsPolyesterDIETHYL SEBACATE

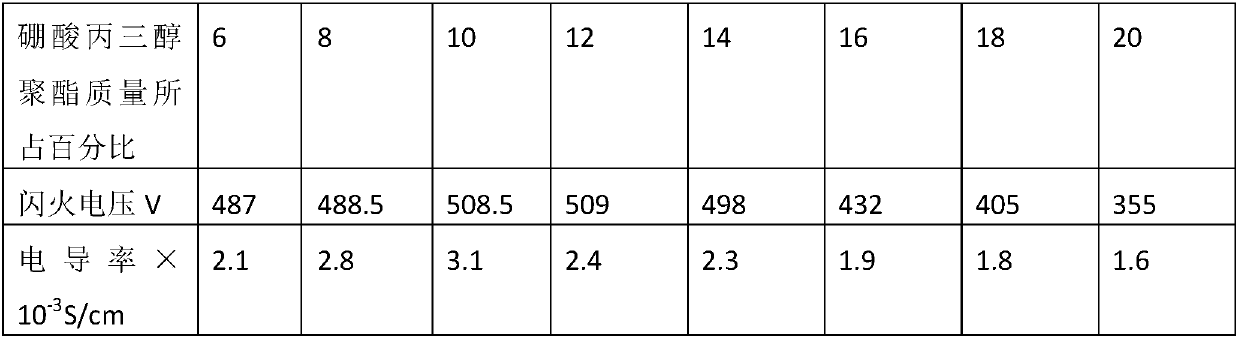

The invention discloses a boric acid glycerin polyester-doped aluminum eletrolytic capacitor electrolyte, which is prepared by the following raw materials, by mass percentage, 4% to 7% of ammonium sebacate, 50% to 75% of ethylene glycol, 17% to 24% of diethylene glycol, 1% to 5% of dioctyl sebacate, 1% to 10% of boric acid glycerin polyester, 2% to 3% of water, 0.2% to 0.5% of mannitol, 0.3% to 0.5% of ammonium hydrogen azelate, 0.8% to 1.2% of a binder, and 0.2% to 0.8% of ammonium pentaborate. The preparation method comprises the following steps: (1) the ethylene glycol, the water and the boric acid glycerin polyester are heated to 60 DEG C and the heat is preserved for 0.5 h; 2) the temperature rises to 60 DEG C to 85 DEG C, the diethylene glycol and the ammonium hydrogen azelate are added; 3) the temperature rises to 130 DEG C within a certain time and the heat is preserved for 1 h, and the ammonium sebacate, the mannitol, the binder, the ammonium pentaborate and the dioctyl sebacate are added; and 4) the temperature falls to 95 DEG C to 105 DEG C, the heat is preserved for 1 h, and cooling to a room temperature in the air is carried out to obtain the electrolyte. The electrolyte has high conductivity and high sparking voltage, the electrolyte can resist sparking voltage of 508.5 DEG C, and the conductivity reaches 3.1*10<-3>S / cm.

Owner:江苏泗阳欣宏电子科技有限公司

A kind of medical adhesive and preparation method thereof

ActiveCN104368030BLess irritatingEasy to addSurgical adhesivesAbsorbent padsBenzoyl peroxideDIETHYL SEBACATE

The invention provides a medicinal adhesive and a preparation method thereof. The medicinal adhesive comprises polyacrylate, tragacanth, polymethacrylate, squalane, benzoyl peroxide, rosin triglyceride, dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate. The preparation method of the medicinal adhesive comprises the following steps: firstly mixing polyacrylate, tragacanth, polymethacrylate and squalane, then adding benzoyl peroxide and rosin triglyceride, and stirring to obtain a mixture I; then mixing dimethyl sebacate, p-dihydroxybenzene, p-benzene methane sulfonic acid, dioctyl phthalate, tricalcium phosphate and sodium alginate to obtain a mixture II, and then mixing the mixture I and the mixture II, heating, insulating, and cooling to room temperature, so that the medicinal adhesive is obtained. The medicinal adhesive has the advantages of moderate curing speed, long stabilization time and strong bonding strength.

Owner:美迪科(上海)包装材料有限公司

Method for preparing adsorbent for diethyl sebacate purification

InactiveCN106111092AHigh purityImprove adsorption capacityOther chemical processesOrganic compound preparationSorbentCyclododecatriene

A preparation method of an adsorbent for purification of diethyl sebacate: add water and polyvinyl alcohol in a reactor, and stir to obtain an aqueous phase; in the reactor, methyl methacrylate, bicyclo[2.2. 1] Hepta-2,5-diene, monomer containing rare earth ruthenium, 1,5,9-cyclododecatriene, vinyl laurate, stir evenly to obtain an oil phase; add the oil phase solution to the Put it in a reaction kettle with prepared water phase, and then react at a suitable temperature. After the reaction, the reaction mixture is extracted with acetone and dried in vacuum to obtain an adsorbent for purifying diethyl sebacate.

Owner:王金明

Preparation method of biodegradable caster oil-based lubricant oil

InactiveCN105087124ARelieve pressureReduce manufacturing costAdditivesActivated carbonDIETHYL SEBACATE

The invention discloses a preparation method of biodegradable caster oil-based lubricant oil and belongs to the field of preparation by virtue of biotechnology. The preparation method of the biodegradable caster oil-based lubricant oil comprises the following steps: adding alkali for cracking caster oil, so as to obtain sebacic acid; then preparing a self-made phosphotungstic / silica catalyst, and esterifying in presence of the catalyst, so as to obtain flavescent di-iso-octyl sebacate; mixing the flavescent di-iso-octyl sebacate with caster oil in a mass ratio of 3:2, and adding a right amount of thickening agent for regulating viscosity; and then concentrating and dehydrating, and adsorbing with activated carbon, so as to finally obtain the biodegradable caster oil-based lubricant oil. Examples prove that the preparation method of the biodegradable caster oil-based lubricant oil has the advantages that no harm is caused to the surrounding environment in an operation process, the duration of usage is prolonged by more than 5 months after use compared with common lubricant oil, damages caused by machine fraction are reduced, and the service life of a machine is prolonged.

Owner:JIANGSU JINYU ENVIRONMENTAL ENG

A method of co-producing capacitor grade 2-butyl sebacic acid and 2,9-dibutyl sebacic acid

ActiveCN104447277BHigh purityImprove electrochemical performanceOrganic compound preparationCarboxylic acid esters preparationElectrolytic agentDIETHYL SEBACATE

Owner:JIANGSU GUOTAI SUPER POWER NEW MATERIALS

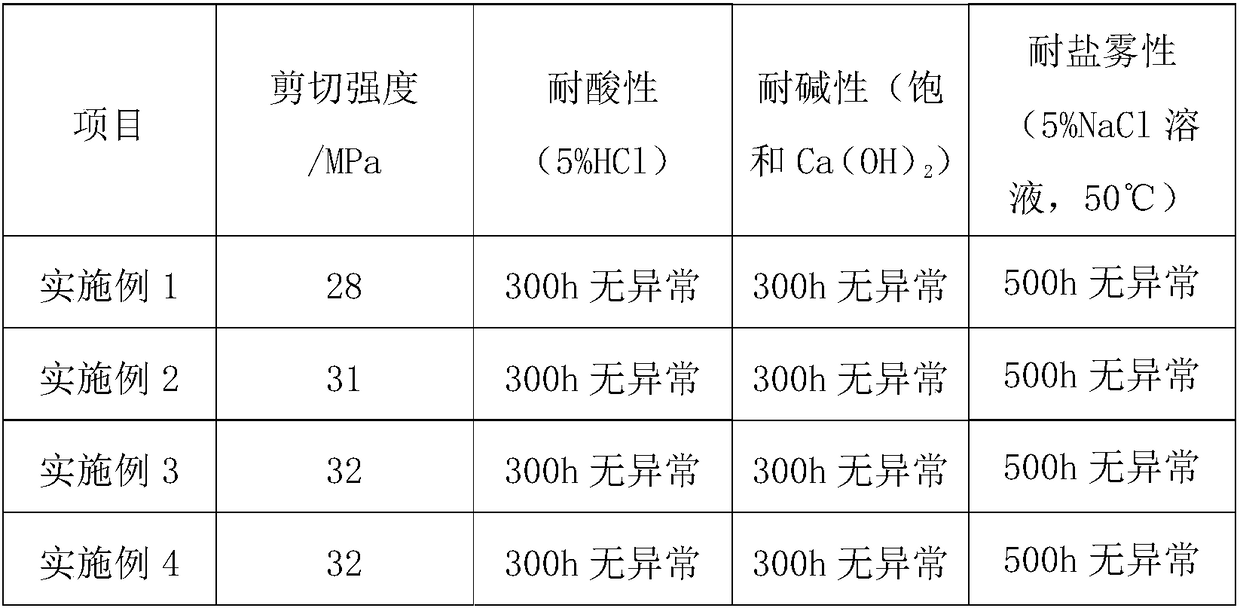

Glass adhesive and preparation method thereof

InactiveCN109181557AGood acid and alkali resistanceNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveAdhesiveDIETHYL SEBACATE

The invention discloses a glass adhesive and a preparation method thereof. The glass adhesive is prepared from ethyl cyanoacrylate, polyvinyl acetate, hydroxypropyl methylcellulose, stearic acid, pentamethyldiethylenetriamine, dimethyl sebacate, tricalcium phosphate, silica, glass frit, dioctyl phthalate and azodicarbonamide. The preparation method comprises the following steps: stirring and mixing the polyvinyl acetate, hydroxypropyl methylcellulose, dimethyl sebacate, tricalcium phosphate and glass frit to obtain a first mixture, adding the first mixture into a reactor, adding stearic acid and azodicarbonamide under a vacuum condition, and performing heating and stirring to obtain a first material; adding the ethyl cyanoacrylate, pentamethyldiethylenetriamine, silica and dioctyl phthalate to the first material, and performing heating and stirring under the protection of an inert gas to obtain the glass adhesive. The glass adhesive provided by the invention has the advantages of goodadhesion and good resistance to acids and alkalis.

Owner:江苏耀兴安全玻璃有限公司

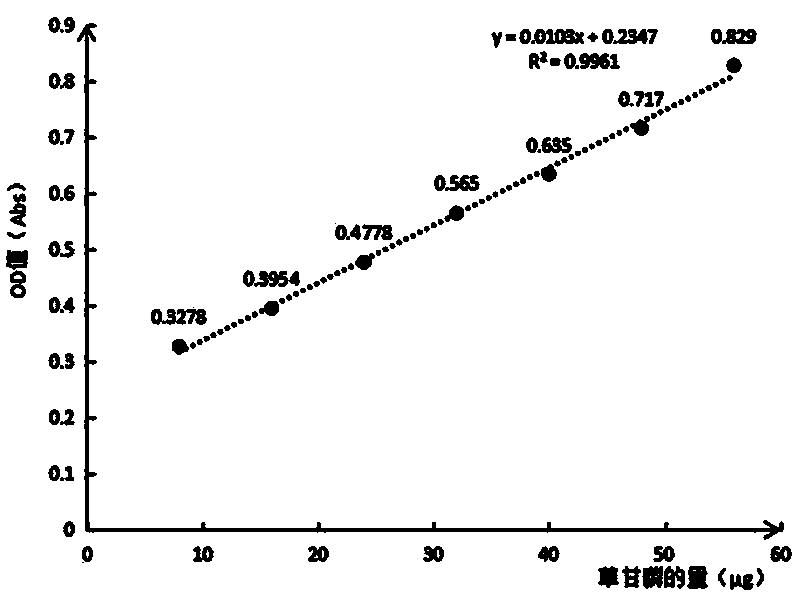

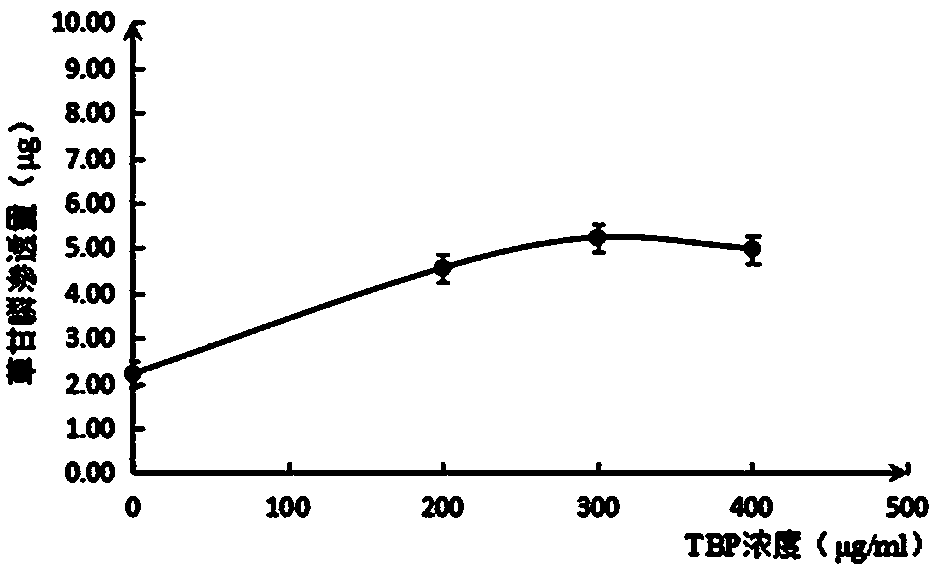

Pesticide auxiliary agents for improving glyphosate effect and use method thereof

InactiveCN110973124ASignificant synergyReduce the use effectBiocideAnimal repellantsDibutyl sebacateDIETHYL SEBACATE

The invention discloses pesticide auxiliary agents for improving the action effect of glyphosate. The pesticide auxiliary agents comprise tributyl phosphate (TBP), dibutyl sebacate (DBS) or diethyl sebacate (DES), wherein the concentration of tributyl phosphate is 200-400 [mu] g / ml, the concentration of dibutyl sebacate is 10-30 [mu] g / ml, and the concentration of diethyl sebacate is 40-60 [mu] g / ml. The pesticide auxiliary agents are simple in dosage form (the three pesticide auxiliary agents are all single dosage forms), can play a significant role in synergism of herbicide glyphosate in agricultural production, reduce the usage amount and production cost of glyphosate, and provide a new thought and lay a working foundation for research and development of efficient and environment-friendly pesticide assistants in the future.

Owner:郑州玄弘生物科技有限责任公司

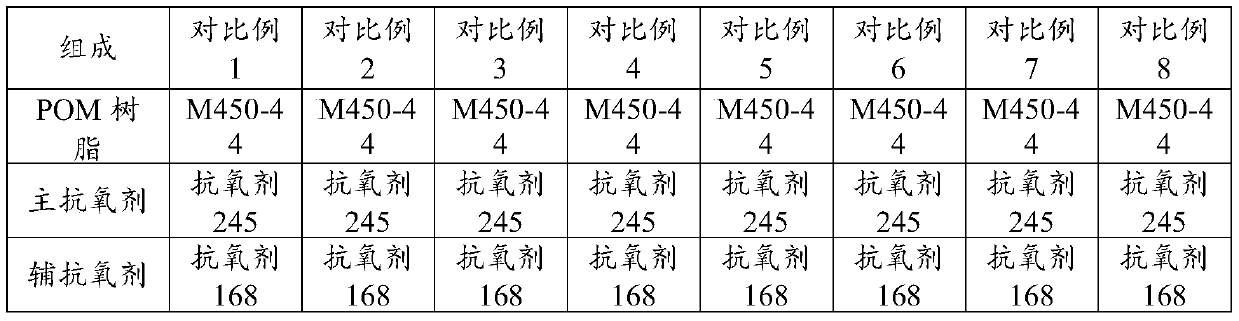

Polyformaldehyde composite low in formaldehyde emission and preparation method thereof

The invention discloses a polyformaldehyde composite low in formaldehyde emission. The polyformaldehyde composite is prepared from, by weight, 100 parts of POM resin, 0.1-0.5 part of a main antioxidant, 0.05-0.3 part of an auxiliary antioxidant, 0.5-1.2 parts of diiso-octyl sebacate, 0.2-0.8 part of N,N'-ethyl distearamide and 0.05-0.3 part of allantoin. According to the polyformaldehyde composite, N,N'-ethyl distearamide (EBS), the main antioxidant, the auxiliary antioxidant, the allantoin and the diiso-octyl sebacate are selected as a stable processing system of POM, and the polyformaldehydecomposite low in smell grade, low in formaldehyde emission and good in color stability is prepared. Meanwhile, the invention discloses a preparation method of the polyformaldehyde composite.

Owner:KINGFA SCI & TECH CO LTD

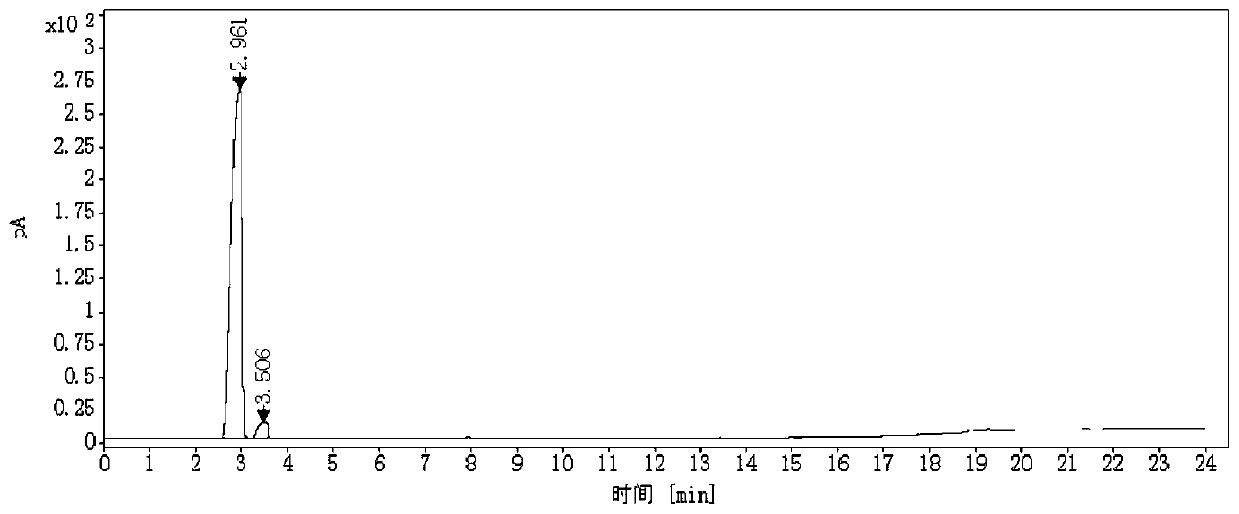

Method for detecting dibutyl sebacate and acetyl tributyl citrate in film material

PendingCN109781904AAchieve detection confirmationHigh sensitivityComponent separationDibutyl sebacateOrganic solvent

The invention relates to the technical field of chemical substance detection, in particular to a method for detecting dibutyl sebacate and acetyl tributyl citrate in a film material. The method comprises: weighing a to-be-detected film material and carrying out extraction by using an organic solvent to obtain an extracting solution; and detecting the extracting solution by using gas chromatography-mass spectrometer. The method is operated simply and easily; the result is accurate and reliable; the potential safety hazard in the film material can be discovered timely to realize an early warningeffect; and a technical support is provided for the risk monitoring of membrane material packaging products in China. The method has the broad application prospects and great economic and social values.

Owner:SHANDONG INST FOR PROD QUALITY INSPECTION

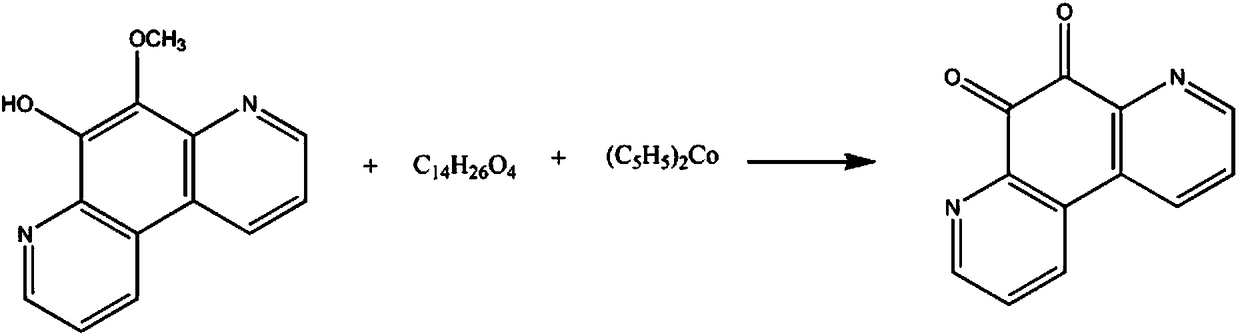

Synthetic method for anti-amebic-dysentery drug phanquone

InactiveCN108239088AAvoid high demands on corrosion resistanceReduce manufacturing costOrganic chemistryDIETHYL SEBACATEPotassium

The invention discloses a synthetic method for the anti-amebic-dysentery drug phanquone. The synthetic method comprises the following steps: adding 5-hydroxy-6-methoxy-4,7-diazaphenanthrene and a potassium chloride solution into a reaction vessel, raising a solution temperature, controlling a stirring speed, and carrying out a reaction; and adding a sodium sulfate solution, raising the solution temperature, then adding a diethyl sebacate solution, adding cobaltocene powder in batches within a certain period of time, carrying out a reaction, lowering the temperature, adjusting a pH value, thencarrying out washing with a benzyl chloride solution a plurality of times, then carrying out washing with a 2,3-dimethylbutane solution a plurality of times, carrying out recrystallization in a 2,4-dichlorotoluene solution, and then carrying out dehydration with a dehydrating agent so as to obtain the finished phanquone.

Owner:CHENGDU QIANYE LONGHUA PETROLEUM ENG TECH CONSULTING

Salicylic acid nanostructured lipid carrier and its preparation method and application

InactiveCN103860387BGuaranteed to workPromote hydrationCosmetic preparationsToilet preparationsACETYLATED MONOGLYCERIDEIrritation

Owner:SOUTHEAST UNIV

External preparation containing rapamycin

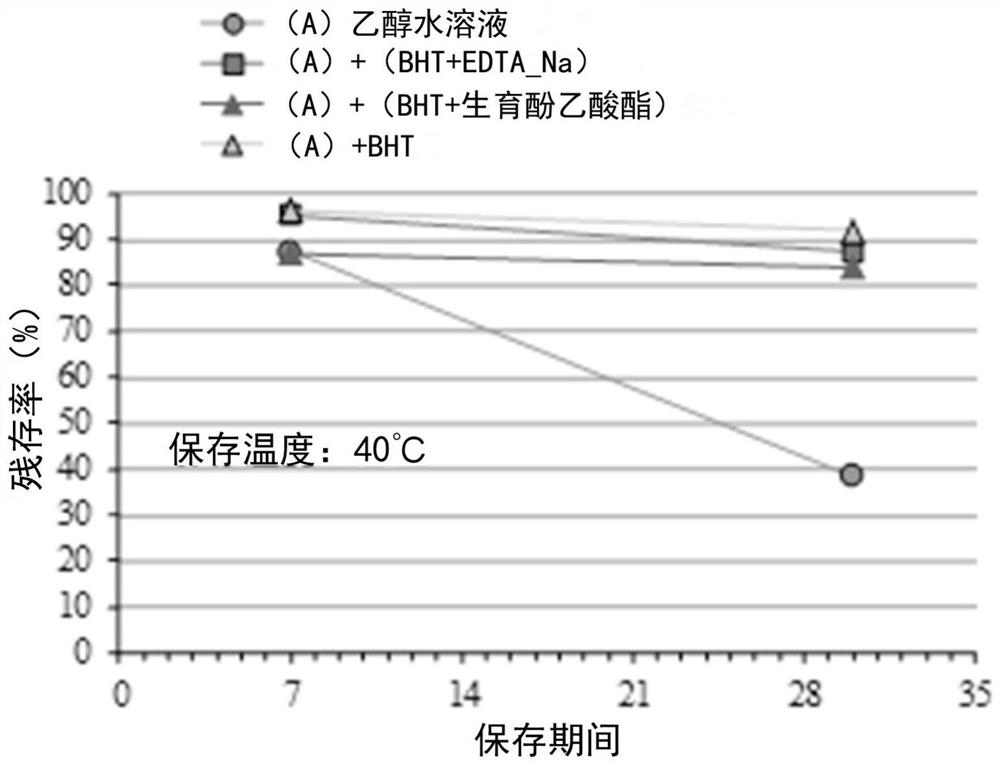

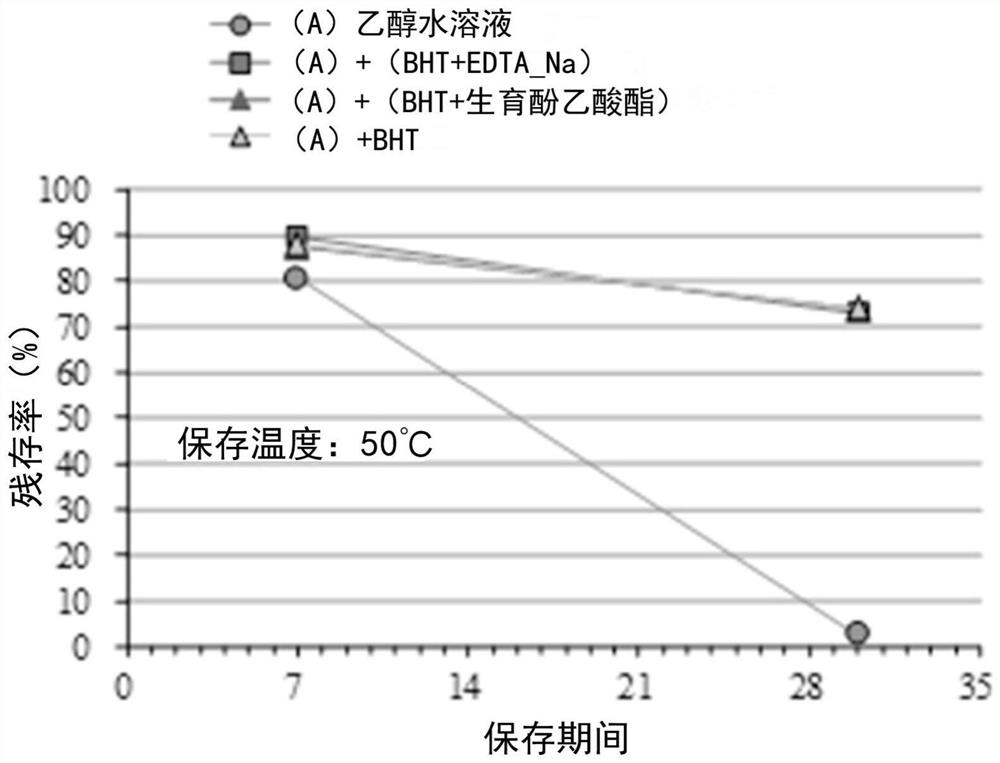

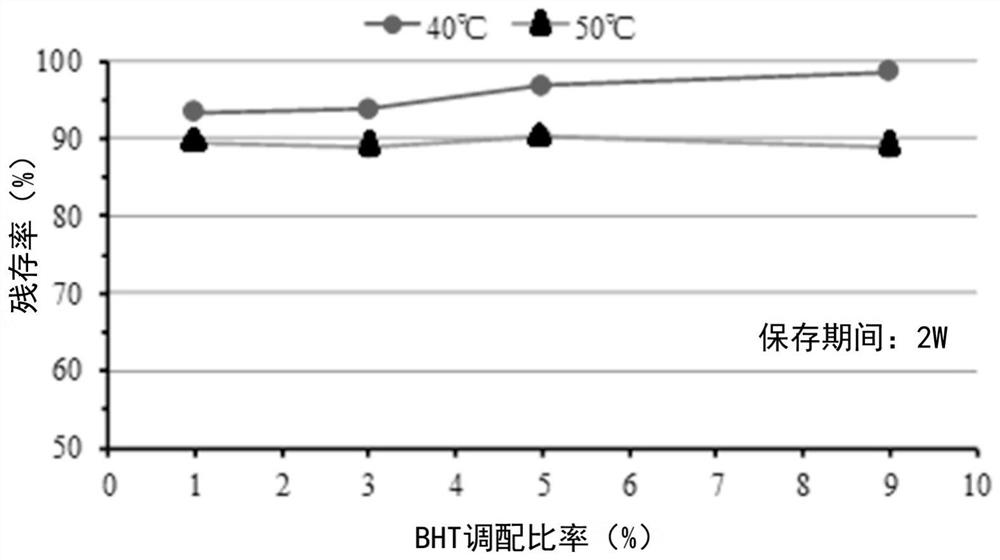

PendingCN114585350AProcess stabilityWill not precipitateHydroxy compound active ingredientsAerosol deliveryPolymer scienceDIETHYL SEBACATE

The present invention addresses the problem of providing a rapamycin-containing external preparation which has excellent stability and is effective in the treatment of skin diseases. Provided is an external preparation containing (a) rapamycin, (b) at least one substance selected from the group consisting of ethylene glycol salicylate, diethyl sebacate, and glyceryl triacetate, and (c) propylene glycol and / or polyethylene glycol, also provided are: an external preparation which further contains an antioxidant; and an external preparation which further contains a lipophilic solvent solution of an antioxidant.

Owner:NOBELPHARMA CO LTD

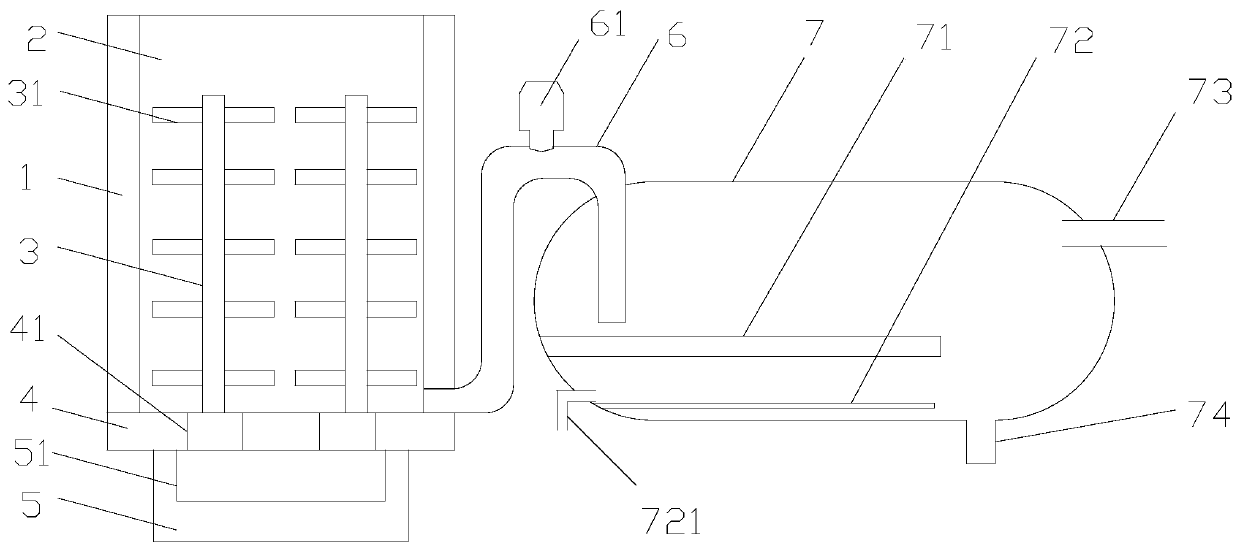

Anti-emulsification type neutralization device for preparing dioctyl sebacate

PendingCN110449107AIncrease the time of full contactEffective distributionChemical/physical/physico-chemical stationary reactorsDIETHYL SEBACATERetention time

The invention provides an anti-emulsification type neutralization device for preparing dioctyl sebacate. The anti-emulsification type neutralization device is characterized by comprising neutralization stirrers, a transfer pipe and a neutralization separator, wherein the bottom of a neutralization reaction chamber is provided with a plurality of stirrers, one side of the lower portion of the neutralization reaction chamber is provided with a transfer pipe, the other end of the transfer pipe is connected with the neutralization separator, and an oil-water distributor and a sand flushing deviceare arranged inside the neutralization separator. Compared with the prior art, by increasing the volume of the neutralization reaction chamber, the full contact time of a catalyst and an alkali liquoris increased, the catalyst is effectively hydrolyzed, so that the catalyst is easier to separate, the oil-water distributor can effectively distribute oil and water, the retention time of the oil andthe water is increased, the sediment at the bottom can be washed by installing a sand flushing device through regular water flow, and the sludge sediment can be prevented from occupying the effectivevolume. An auxiliary bottle filled with a demulsifier is arranged in the transfer pipe, and the demulsification phenomenon can be effectively eliminated by adding 10-20 ppm of demulsifier into a material.

Owner:ZHEJIANG GREAT CHEM SCI & TECH

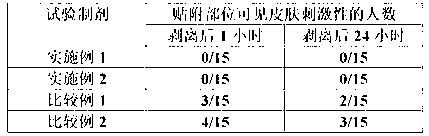

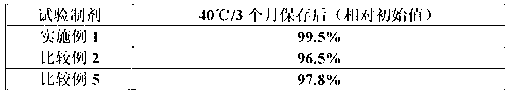

Felbinac-containing external patch

ActiveUS9833417B2Excellent drug release performanceReduce skin irritationBiocideNervous disorderStyrene-isoprene-styrene block copolymerMedicine

Provided is a felbinac-containing external patch which can exhibit high drug release properties, low skin irritation, and high drug stability, wherein felbinac having an average particle diameter of 5 μm or more and less than 100 μm is dispersed and mixed in an adhesive base including a styrene-isoprene-styrene block copolymer, an alicyclic saturated hydrocarbon resin, a softener, and diethyl sebacate, and does not contain L-menthol. Specifically, in the felbinac-containing external patch, 0.1 to 10% by weight of felbinac having an average particle diameter of 5 μm or more and less than 100 μm is dispersed and mixed in an adhesive base including 10 to 30% by weight of a styrene-isoprene-styrene block copolymer, 10 to 50% by weight of an alicyclic saturated hydrocarbon resin, 10 to 75% by weight of a softener, and 0.1 to 10% by weight of diethyl sebacate.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

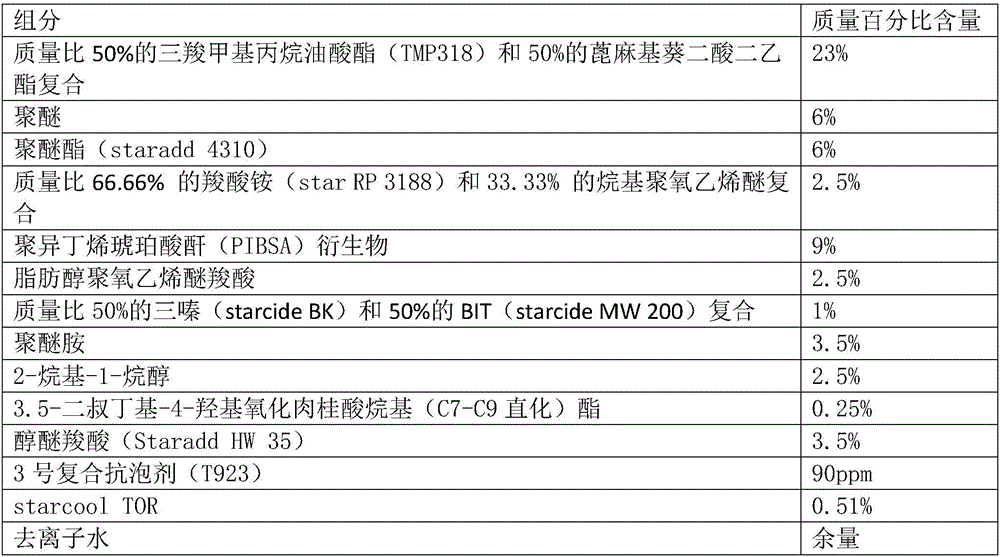

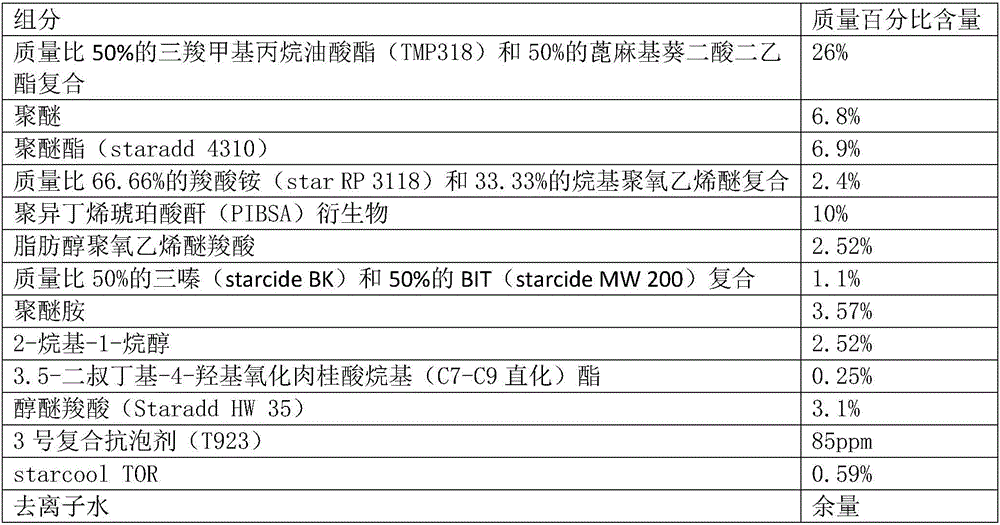

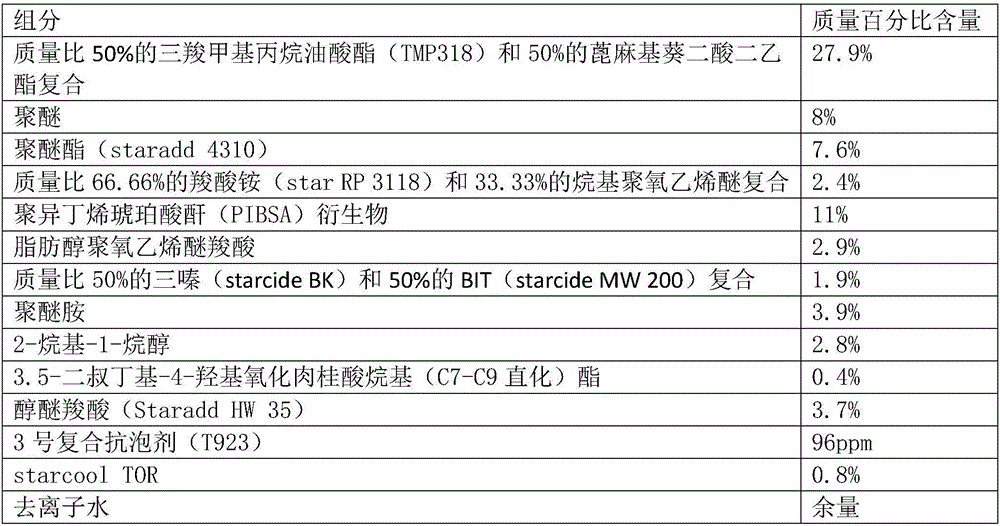

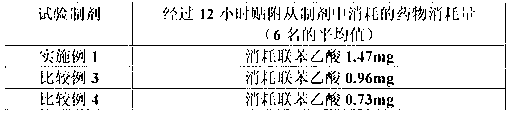

Castor-oil plant base environment-friendly cutting fluid composition

InactiveCN106520294AImprove cooling effectImprove the lubrication effectLubricant compositionMass ratioAntioxidant

The invention discloses a caster-oil plant base environment-friendly cutting fluid composition. By mass ratio, 50% of trimethylolpropane oleic acid ester TMP318 and 50% of caster-oil plant base diethyl sebacate are adopted to be combined to serve as base oil, and multiple composite additives are matched. The caster-oil plant base environment-friendly cutting fluid composition comprises an extreme pressure agent, an anti-wear agent, an antirust agent, an emulsion agent, a hard water stabilizer, an antibacterial corrosion prevention agent, a PH stabilizer, a coupling agent, an antioxidant, a co-emulsifier, a defoaming agent, deionized water and a cuttings settling agent. The composition has good cooling performance, lubricating performance, bearing capability, friction and vibration reducing performance, cleaning performance, a cuttings discharge function, antirust performance, anti-oxidization and anti-corrosion performance, defoaming performance and decay resistance, is weak in odor and free of irritation, has a good antimicrobial property, is not prone to smelliness or rancidification and has long service life, and residual liquid is easy to treat.

Owner:GUANGXI UNIV

Refining agent for synthesizing di-n-butyl sebacate and preparation method thereof

InactiveCN102249910ALow priceLess investmentOrganic compound preparationCarboxylic acid esters preparationActivated carbonFiltration

The invention relates to a refining agent for synthesizing di-n-butyl sebacate and a preparation method thereof. The method for synthesizing di-n-butyl sebacate comprises the steps of esterification, water washing, dealcoholization, refining and filtration, wherein the refining agent used in the refining step is prepared by mixing potassium carbonate, magnesium hydroxide, activated carbon and magnesium sulfate according to a certain ratio. The invention facilitates the industrial production and improves the production efficiency; as the high-vacuum refining step is omitted in the production process, the investment of high-vacuum pump equipment is avoided, thereby saving the equipment investment, lowering the production cost and improving the market competitiveness of the product; the refining agent is prepared by mixing potassium carbonate, magnesium hydroxide, activated carbon and magnesium sulfate according to a certain ratio, and each component is low in price and easy to purchase; the product quality and long-term storage stability of the product is simultaneously ensured; the preparation method is simple to implement and convenient to operate; and the investment of production equipment is saved, and the production efficiency is improved.

Owner:TIANJIN CHEM REAGENT RES INST

Felbinac-containing external patch

ActiveCN103269696AFacilitated releaseSkin irritationOrganic active ingredientsNervous disorderIrritationDIETHYL SEBACATE

Provided is a felbinac-containing external patch that shows a high drug release property and also low skin irritation, and is capable of exerting high drug stability. This felbinac-containing external patch is characterized in that L-menthol is not contained, and felbinac having an average particle size of 5 [mu]m or more but less than 100 [mu]m is dispersed to mix with an adhesive base that is composed of styrene-isoprene-styrene block copolymer, alicyclic saturated hydrocarbon resin, softener, and diethyl sebacate, specifically, 0.1 to 10% by weight of felbinac having an average particle size of 5 [mu]m or more but less than 100 [mu]m is dispersed to mix with an adhesive base that is composed of 10 to 30% by weight of styrene-isoprene-styrene block copolymer, 10 to 50% by weight of alicyclic saturated hydrocarbon resin, 10 to 75% by weight of softener, and 0.1 to 10% by weight of diethyl sebacate.

Owner:TEIKOKU SEIYAKU KK TEIKOKU SEIYAKU CO LTD

A kind of method that methanesulfonic acid catalysis prepares diethyl sebacate

ActiveCN105130814BReduce pollutionReduce consumptionOrganic compound preparationCarboxylic acid esters preparationAnhydrous ethanolDIETHYL SEBACATE

Owner:XUZHOU CURRENCY MAGNETOELECTRICITY

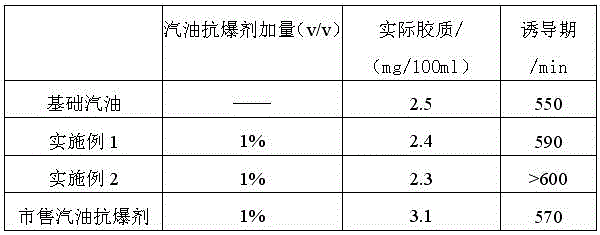

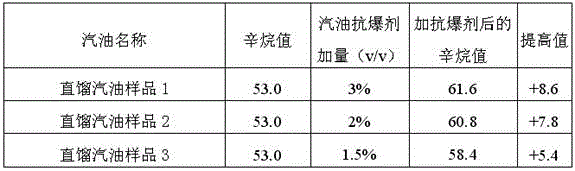

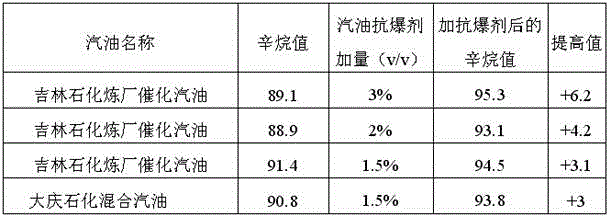

Gasoline antiknock agent and preparation method thereof and antiknock gasoline

ActiveCN105219457BBoost octaneImprove qualityLiquid carbonaceous fuelsFuel additivesDIETHYL SEBACATEO-Cresol

The invention provides a gasoline antidetonant, a preparing method thereof and antiknock gasoline. The gasoline antidetonant is prepared from 5-methylene cyclopentadiene, Dipropyl aminomethyl o-cresol, tertiary butanol and poly-isobutenyl amide di-iso-octyl sebacate in a weight ratio of 2-4:2-4:1-3:1. The gasoline antidetonant provided by the invention has excellent antiknock performance, does not contain metal and reduces pollution to the environment and harm to a human body, the gasoline antidetonant is simple in production process and low in cost. The antiknock gasoline comprising the gasoline antidetonant has excellent antiknock performance and is non-toxic and environment-friendly.

Owner:吉化集团油脂化工有限公司

Quick preparation method of di-n-hexyl sebacate

InactiveCN106518665AAvoid investmentLess investmentOrganic compound preparationCarboxylic acid esters separation/purificationRefluxAlcohol

The invention relates to a quick preparation method of di-n-hexyl sebacate. The method includes the following steps: (1) an esterification reaction step: putting sebacic acid, n-hexyl alcohol and concentrated sulfuric acid into a reaction kettle, stirring, heating to carrying out boiling reaction, keeping a boiling reflux state, and separating water; (2) a water washing step: adding water into the mixture after the esterification reaction, stirring evenly, standing to layer, and removing an aqueous layer; (3) a dealcoholization step: dealcoholizing the mixture after the water washing, to obtain a crude product di-n-hexyl sebacate; and (4) a refining step and a filtration step to obtain the di-n-hexyl sebacate product. The preparation method of di-n-hexyl sebacate has the advantages of convenient operation, simple and feasible operation, and easy realization of industrialized production, and improves the production efficiency.

Owner:TIANJIN CHEM REAGENT RES INST

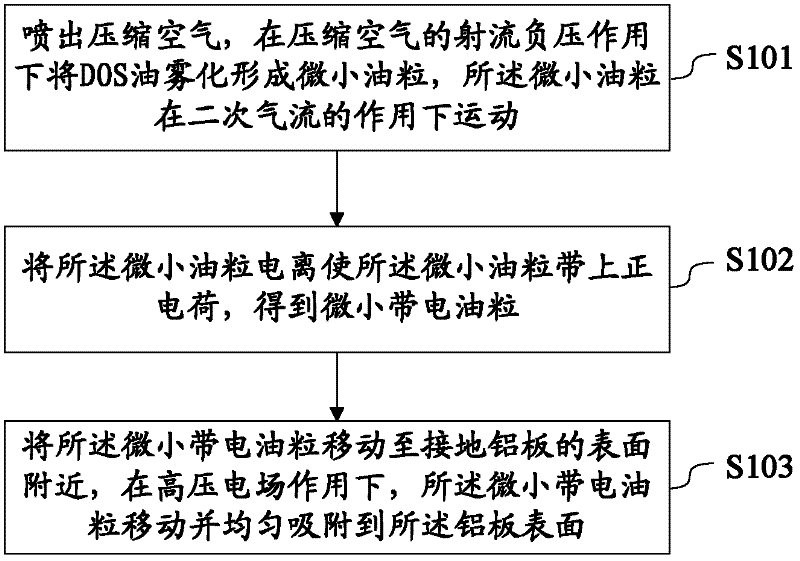

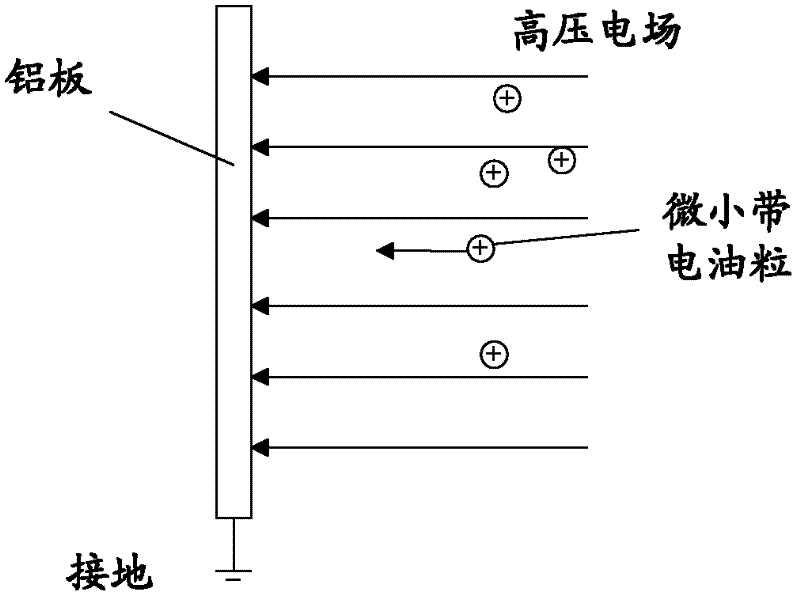

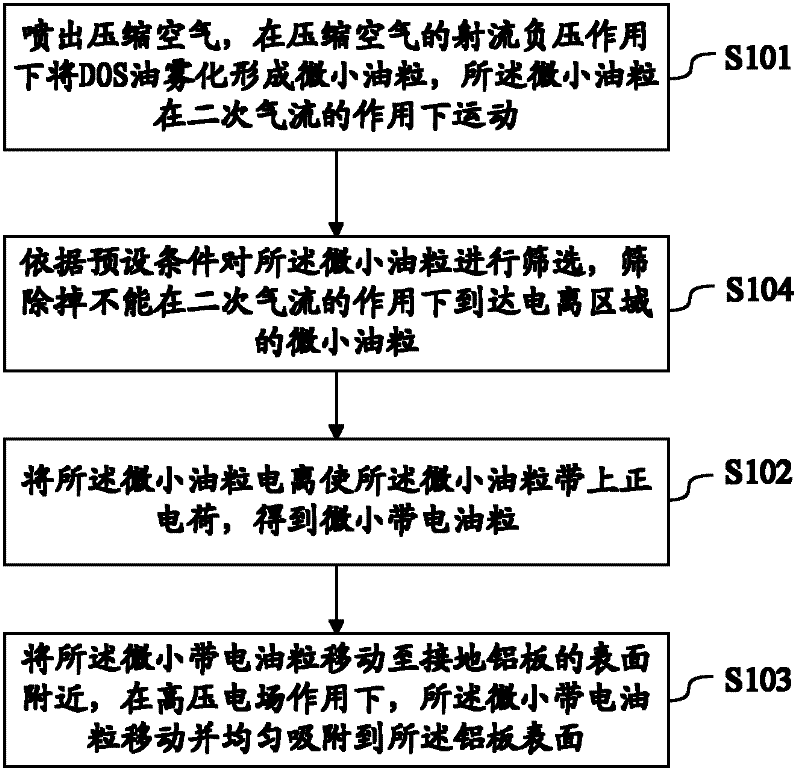

Electrostatic DOS (dioctyl sebacate) oil spraying method

InactiveCN102527595AReduce manufacturing costLiquid spraying plantsLiquid surface applicatorsDIETHYL SEBACATEHigh pressure

The invention provides an electrostatic DOS (dioctyl sebacate) oil coating method. The electrostatic DOS oil spraying method includes spraying out compressed air, atomizing DOS oil to form tiny oil particles under effects of jetting negative pressure of the compressed air and leading the tiny oil particles to move under effects of secondary airflow; ionizing the tiny oil particles to lead the tiny oil particles to have positive charge and obtaining tiny charged oil particles; and delivering the tiny charged oil particles to a place nearby a surface of a grounded aluminum plate, leading the tiny charged oil particles to move and be uniformly absorbed on the surface of the aluminum plate located at a high-voltage electric field under effects of the high-voltage electric field, and accordingly achieving the purpose of coating the DOS oil on the surface of the aluminum plate. The electrostatic DOS oil spraying method is applied to a DOS oil coating work procedure in belt production, the content, the chemical ingredients and the state of the DOS oil are identical to those of DOS oil on a final product of a traditional DOS oil roll coating method, but in the method, releasing agent and a baking step are omitted, and accordingly production cost is lowered.

Owner:SOUTHWEST ALUMINUM GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com