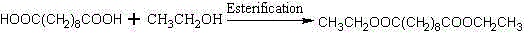

Preparation method of diethyl sebacate in presence of catalyst namely methyl sulfonic acid

A technology of diethyl sebacate and methanesulfonic acid, which is applied in the field of preparation of diethyl sebacate, can solve the problems of ineffective treatment of three wastes, complex catalyst preparation, long reaction time, etc., and achieve large-scale Industrial production, shortening the reaction time of esterification, and the effect of short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

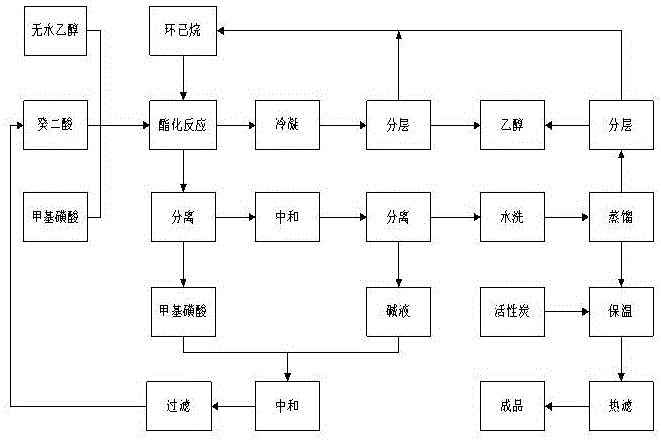

Method used

Image

Examples

Embodiment 1

[0027] The selected sebacic acid, absolute ethanol, methanesulfonic acid, and cyclohexane are 99.5% analytically pure products; activated carbon is used for medicine;

[0028] Add 50 mL of cyclohexane, 44.22 g of absolute ethanol I and 2 g of methanesulfonic acid into a three-necked round-bottomed flask equipped with an electric mixer, a thermometer, a condenser, and a water separator, and add 40.45 g of sebacic acid while stirring, and control the rotation speed. Heat to reflux at 450r / min, separate the water produced by the reaction from the water separator, stop heating at 84°C, cool down to 50°C, anhydrous ethanol II 11.06g, continue to heat and reflux to 84°C, stop heating, and reflux for 1h , lower the temperature to 50°C, stand still to remove methylsulfonic acid, and obtain material liquid I, which is added with 5% sodium hydroxide aqueous solution and stirred to neutralize unreacted sebacic acid, remove the alkali aqueous layer, and obtain Feed liquid II; alkaline wat...

Embodiment 2

[0030] The selected sebacic acid, absolute ethanol, methanesulfonic acid, and cyclohexane are 99.5% analytically pure products; activated carbon is used for medicine;

[0031] Add 50mL of cyclohexane, 44.22g of absolute ethanol I, 0.3g of fresh methanesulfonic acid and 1.7g of recovered methanesulfonic acid into a flask equipped with an electric mixer, a thermometer, a condenser, and a water separator, and add them under stirring. Sebacic acid 40.45g, the speed is controlled at 450r / min, heated to reflux, the water produced by the reaction is separated from the water separator, the heating is stopped at 84°C, the temperature is lowered to 50°C, absolute ethanol II is 11.06g, continue to heat and reflux to Stop heating at 84°C, reflux for 1 hour, cool down to 50°C, stand still to remove methanesulfonic acid to obtain material liquid I, add 5% sodium hydroxide aqueous solution to the material liquid I and stir to neutralize unreacted decane acid, remove the alkaline water layer ...

Embodiment 3

[0033] The selected sebacic acid, absolute ethanol, methanesulfonic acid, and cyclohexane are 99.5% analytically pure products; activated carbon is used for medicine;

[0034] Add 50 mL of cyclohexane, 44.22 g of absolute ethanol, and 2 g of methanesulfonic acid into a flask equipped with an electric mixer, a thermometer, a condenser, and a water separator, add 39 g of sebacic acid under stirring, and recover 3.0 g of sebacic acid ( Wet weight), the speed is controlled at 450r / min, heated to reflux, the water produced by the reaction is separated from the water separator, the heating is stopped at 84°C, the temperature is lowered to 50°C, and absolute ethanol is 11.06g, and the heating is continued to reflux to 84°C to stop Heating, total reflux for 1 hour, cooling down to 50°C, standing still to remove methanesulfonic acid to obtain material liquid I, adding 5% sodium hydroxide aqueous solution to material liquid I and stirring to neutralize unreacted sebacic acid, removing A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com