Patents

Literature

52results about How to "Shorten the reaction time of esterification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

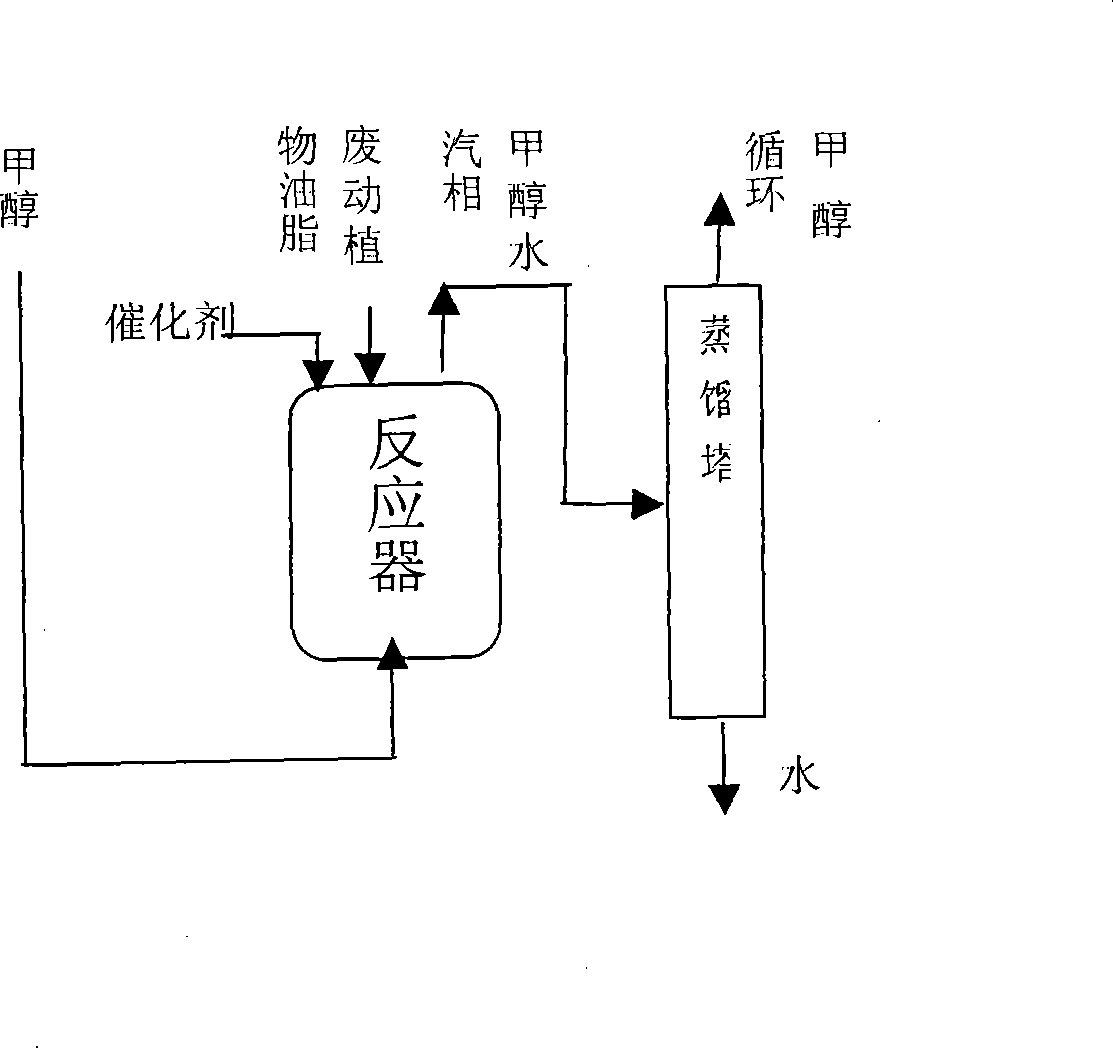

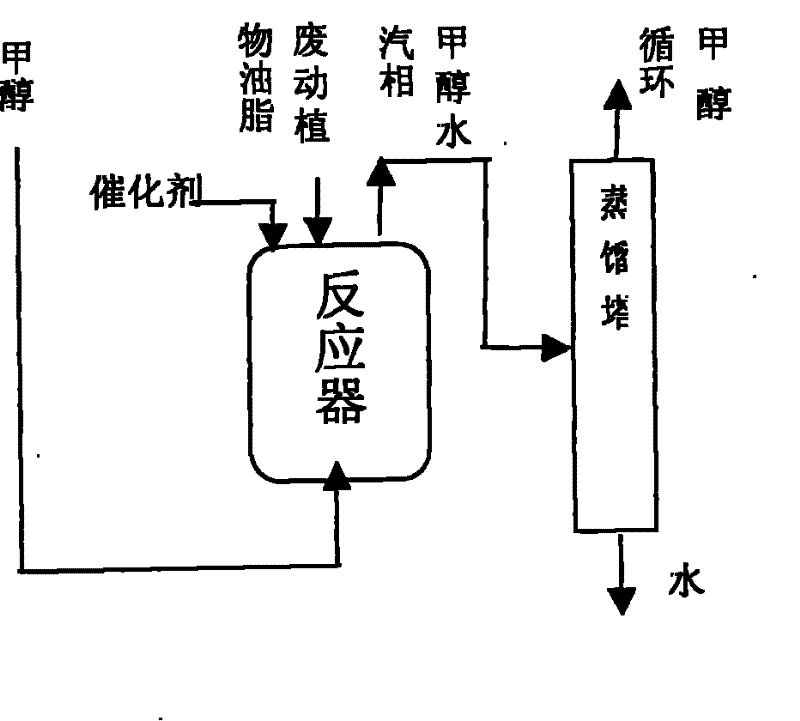

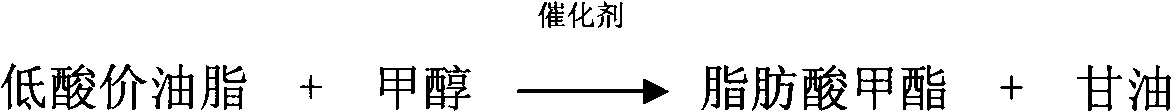

Method for preparing biological diesel oil from waste animals and plants grease

InactiveCN101148600AWell mixedReduce generationBiofuelsLiquid hydrocarbon mixture productionOil and greaseLiquid waste

The improved continuous esterification process of waste animal and vegetable oil and grease with low carbon alcohol to prepare biodiesel oil features that liquid low carbon alcohol is introduced into the liquid comprising liquid waste animal and vegetable oil and grease in 95-99.9 wt% and acid catalyst in 0.1-5 wt% to produce esterification reaction at normal pressure and the temperature from vaporizing temperature to 95 deg.c while the vapor mixture comprising the resultant, water vapor and low carbon alcohol vapor is discharged from the top of the reactor and separated in a fractionating tower to obtain product, separated water and liquid low carbon alcohol for reuse. The process has high reaction speed, high reaction conversion rate and other advantages, and the product has acid value capable of being controlled below 2 mgKOH / g.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

A kind of preparation method of high-purity glyceride type fish oil

ActiveCN102277237AOvercome deficienciesHigh purityFatty acid esterificationFish oilTG - Triglyceride

The invention discloses a preparation method of glyceride type fish oil, comprising the following steps: (1) taking 650-800g of glyceride type fish oil and 110-180g of alkali at weight ratio, dissolving alkali in 0.4-1.6L of water, evenly mixing in a reactor, and adding the glyceride type fish oil; (2) introducing nitrogen into the reactor until material is completely reacted; (3) cooling materials in the reactor to be below 25DEG C; (4) extracting by petroleum ether or n-hexane to obtain free polyunsaturated fatty acid; (5) adding the free polyunsaturated fatty acid into the reactor; (6) adding zinc powder into the reactor; (7) immediately pouring reaction liquid into crushed ice for quenching reaction; and (8) extracting a crude product subjected to quenching reaction by the petroleum ether or n-hexane, and washing an organic layer with saturated salt water to obtain the glyceride type fish oil. The preparation method disclosed by the invention has the advantages of short preparation time and low manufacture cost, the prepared glyceride type fish oil keeps high content of EPA (Eicosapntemacnioc Acid) and DHA (Docosahexaenic Acid) and also has high content of triglyceride.

Owner:山东禹王制药有限公司

Synthetic method of phosphorus and nitrogen type fire retardant

The invention relates to a synthetic method of a phosphorus and nitrogen type fire retardant, which comprises the following steps of: reacting an assistant with phosphate materials to remove water out of the phosphate materials; reacting polyhydric alcohols with the phosphate materials with water removed to obtain an intermediate; and reacting the intermediate with melamine in a solvent to obtain the phosphorus and nitrogen type fire retardant, wherein the phosphate materials can be one or more than one of phosphoric acid, pyrophosphoric acid and polyphosphoric acid. Compared with the prior art, the synthetic method provided by the invention has the advantages of shortening the esterification reaction time and increasing yield of the phosphorus and nitrogen type fire retardant, improving the purity of the phosphorus and nitrogen type fire retardant and the production process is simple in process and clean and safe.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Preparation method of high purity butyl lactate

ActiveCN103102269AImprove conversion rateHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsHydrogen SulfateSodium bisulfate

The invention relates to a preparation method of high purity butyl lactate. The method is characterized by: taking industrial lactic acid and n-butyl alcohol as raw materials, and adopting benzene as a water-carrying agent, subjecting them to an esterification reaction in the presence of a catalyst, then carrying out vacuum distillation and refining, thus obtaining the high purity butyl lactate. Specifically, the catalyst is a composite catalyst of potassium hydrogen sulfate and ferric trichloride, or a composite catalyst of p-toluenesulfonic acid and sodium hydrogen sulfate. The method provided in the invention shortens the esterification reaction time, increases the yield of butyl lactate, simplifies refining operation, and is easy to realize industrialization.

Owner:JIANGSU YIDA CHEM

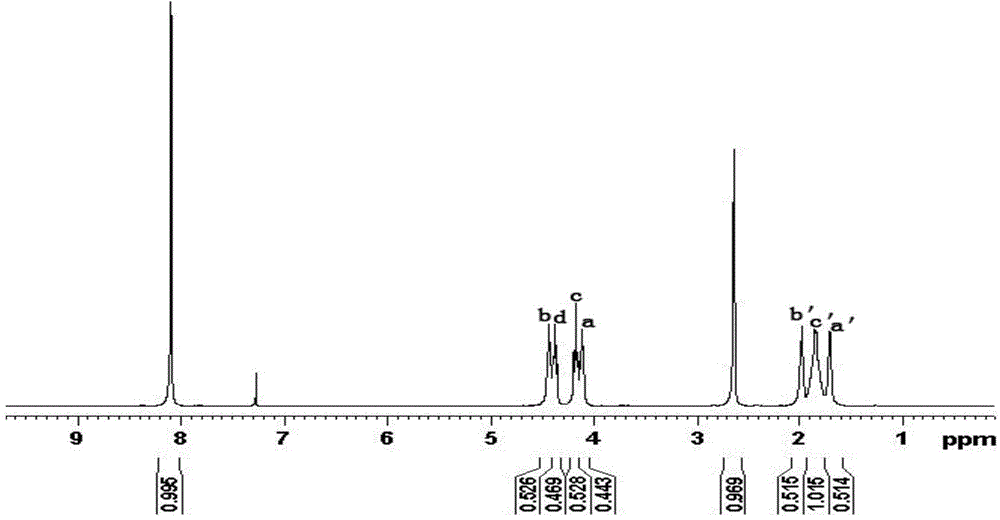

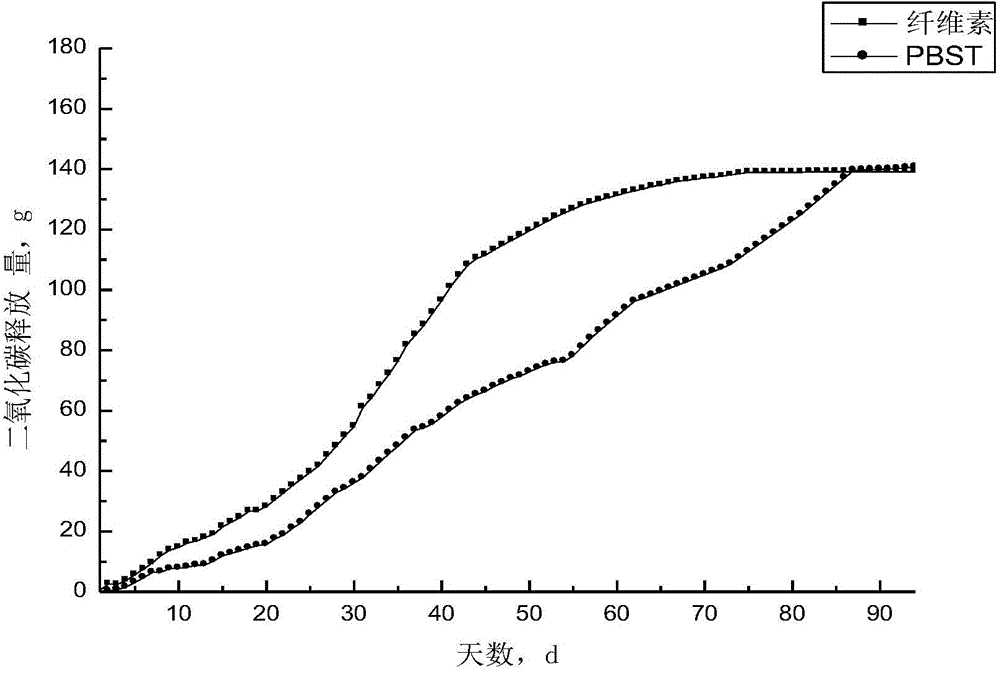

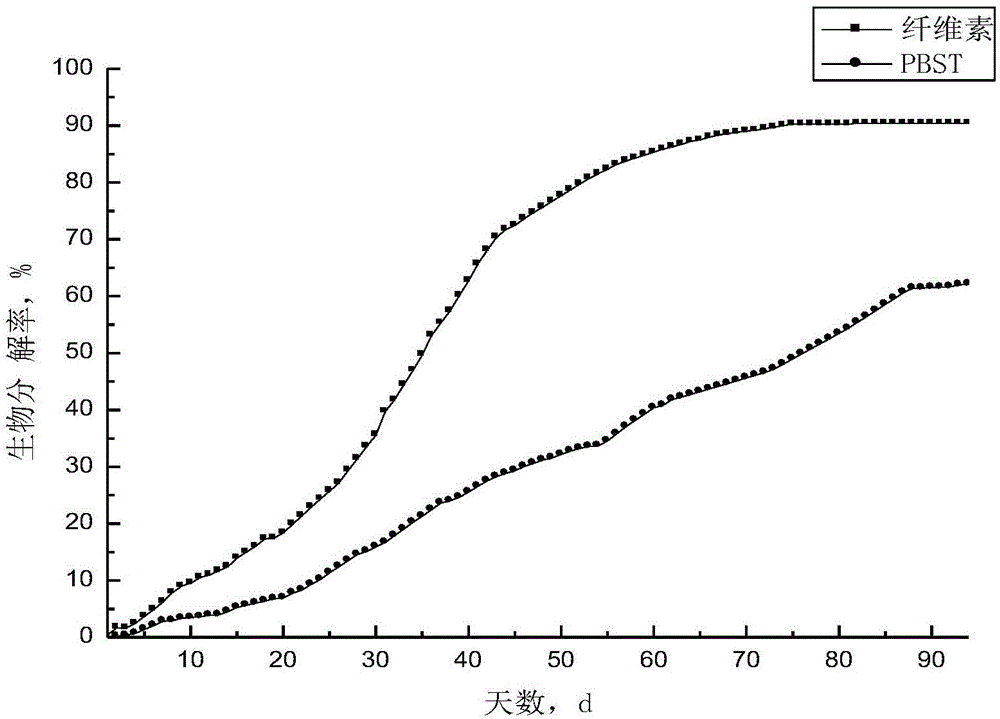

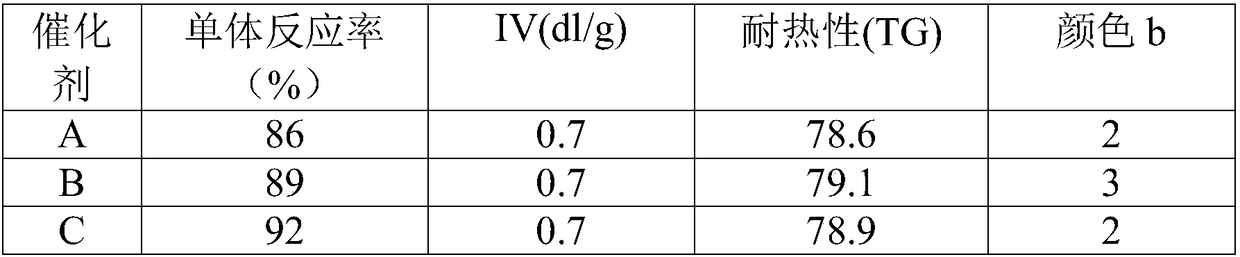

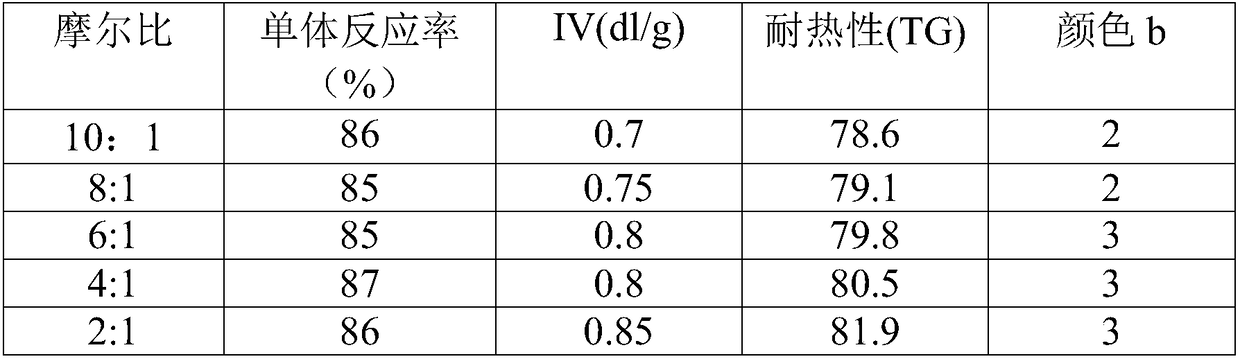

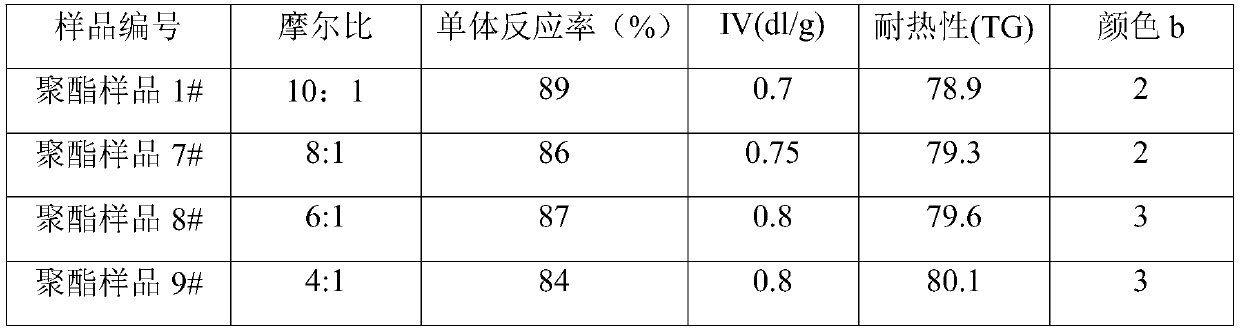

A preparing method of aliphatic/aromatic copolyester

The invention relates to a preparing method of aliphatic / aromatic copolyester. The method includes: subjecting raw material monomers comprising an aromatic diacid, an aliphatic (alicyclic) diacid and an aliphatic (alicyclic) dihydric alcohol to esterification at 150-230 DEG C under the function of a titanium catalyst and a synergistic catalyst; subjecting the reaction system to prepolymerization at 230-260 DEG C under a vacuum degree of 200-300 Pa for 1-2 h; and subjecting products of the prepolymerization to polycondensation at 240-270 DEG C under a vacuum degree not more than 200 Pa for 3-5 h to obtain the aliphatic / aromatic copolyester. The preparing method adopts a direct esterification method and omits a transesterification method, thus avoiding production of methanol that is a byproduct and reducing environment pollution. The preparing method obviously shortens the esterification time, simplifies processes and equipment, and provides technical support for continuous industrial production of the aliphatic / aromatic copolyester.

Owner:CHINA PETROLEUM & CHEM CORP +1

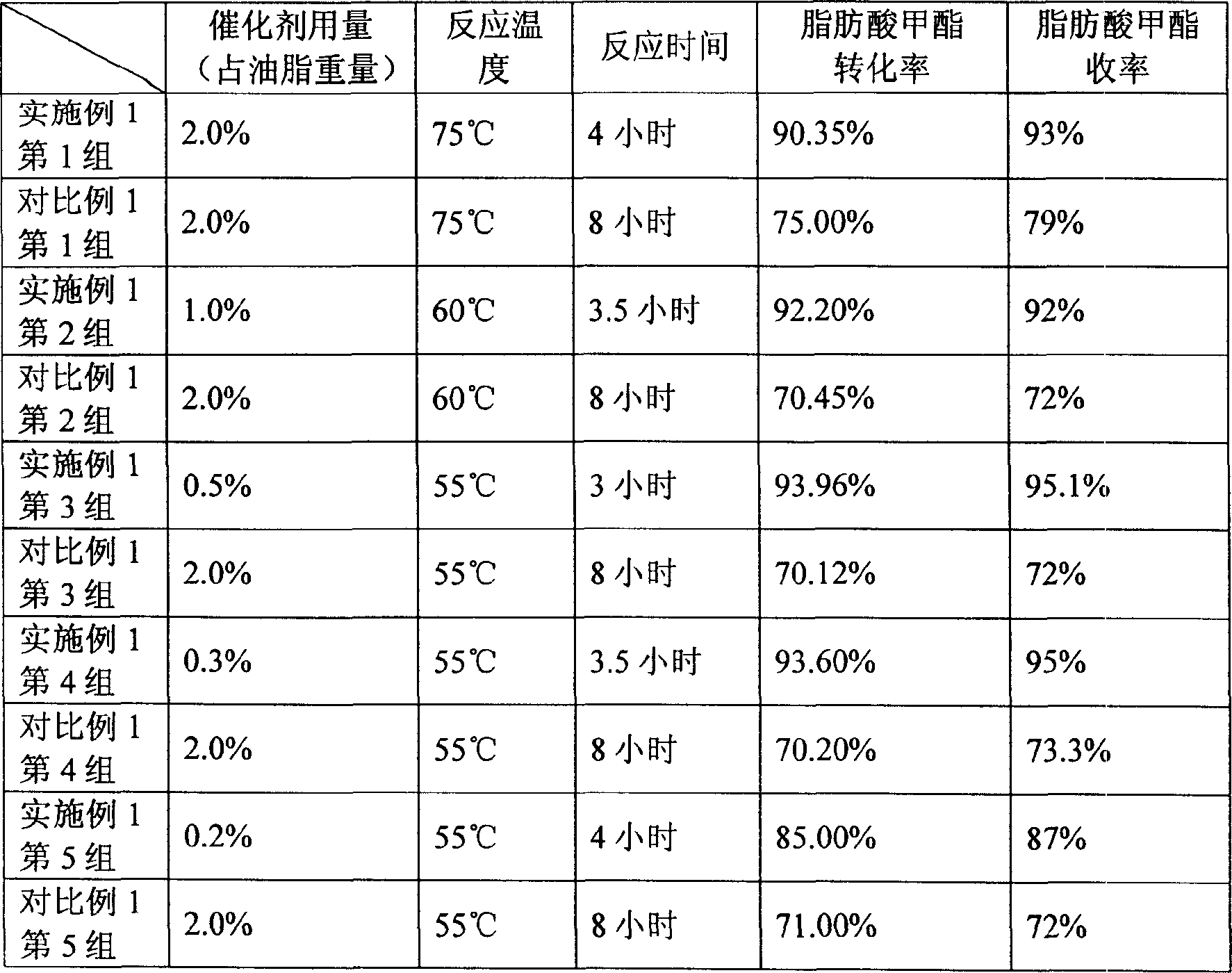

Esterification catalyst for preparing biological diesel oil by animal plant lipid and application method

InactiveCN1793288AHigh yieldReduce manufacturing costBiofuelsLiquid hydrocarbon mixture productionOil and greaseReaction temperature

The invention relates to esterifying reaction catalyst used animal and vegetable grease to manufacture biological diesel oil. It belongs to using anima and vegetable grease to manufacture biological diesel oil technique field. The catalyst includes A, B, and C three components; the A can be one or many of cadmium sulfate, zinc sulphate, or aluminium sulphate; the B is sulfuric acid quadric-ammino combine copper; the C is chromic oxide and aluminium sulfide. The invention also offers the manufacturing method. The esterifying reaction catalyst can effectively control the reaction direction to make the reversible reaction toward producing fatty acid methyl ester to make fatty glyceride esterifying ratio reach above 90%. Compared with the catalyst and application method, the invention can reduce catalyst reaction temperature, shorten catalyst reaction time, reduce end product processing program, and effectively increase biological diesel oil production quality, and reduce the fabrication cost.

Owner:赵金玉

Preparation method of low-melting-point PBT copolyester fiber

InactiveCN109576813ALow modulusIncrease elasticityMonocomponent copolyesters artificial filamentAdhesiveEsterification reaction

The invention provides a preparation method of a low-melting-point PBT copolyester fiber, which comprises the following steps: butanediol is used as a raw material, a direct esterification method is adopted, dibasic acid and dihydric alcohol monomers with the molar ratio of 1:1.5-1:2.5 are simultaneously added, esterification, prepolymerization and polymerization reaction are carried out under theaction of a catalyst, and the PBT copolyester with the melting point ranging from 140 DEG C to 190 DEG C is prepared, wherein the esterification reaction and the prepolymerization reaction are carried out in two stages. The prepared PBT polyester is subjected to melt spinning after being dried, and is subjected to oiling, balancing, winding and drafting after being cooled. According to the preparation method of the low-melting-point PBT copolyester fiber,, dibasic acid and dihydric alcohol monomers are simultaneously added in the polymerization process of the PBT, and the esterification and prepolymerization reaction processes are carried out in stages, so that the melting point of the PBT is reduced, the fluidity of the PBT melt is improved, the toughness of the PBT is increased, the impact strength is improved, the prepared low-melting-point PBT polyester fiber has the advantages of low modulus, high elasticity and good hand feeling, and can also be used as a substitute adhesive torealize the bonding function.

Owner:SINOPEC YIZHENG CHEM FIBER +1

Microalgae biodiesel production method

InactiveCN106221888AWidely distributedIncrease biomassFatty acid esterificationBiofuelsBiodieselVegetable oil

The invention discloses a microalgae biodiesel production method. The production method comprises the following steps of inoculating nannochloropsis oculata to a culture medium, irradiating through a red-blue dual-color LED light supplementing lamp for 8 to 14 hours per day, cultivating for 6 to 8 days at a temperature of 24 to 26 DEG C, and collecting nannochloropsis oculata cells; performing a wall breaking process on the collected nannochloropsis oculata cells through ultrasonic wave, then extracting through an organic solvent to obtain microalgae grease, and then adding the microalgae grease, methyl alcohol and a zeolite molecular sieve catalyst into to a reactor according to a mass ratio of 1 : (5 to 7) : (0.01 to 0.03) to perform esterification reaction, so as to obtain an esterification product; then separating and purifying the esterification product to obtain the biodiesel. According to the production method, the nannochloropsis oculata which is short in production period, wide in distribution, strong in photosynthesis and high in grease content is utilized as a raw material, so that the problem of vegetable oil and fat raw materials in biodiesel development is solved. The production method also has the advantages of being simple in preparation technology, high in catalytic efficiency, high in grease extraction rate, high in product yield, and the like, and also lays a good foundation for industrialization and scale of the biodiesel.

Owner:南宁华侨投资区政孙贸易有限公司

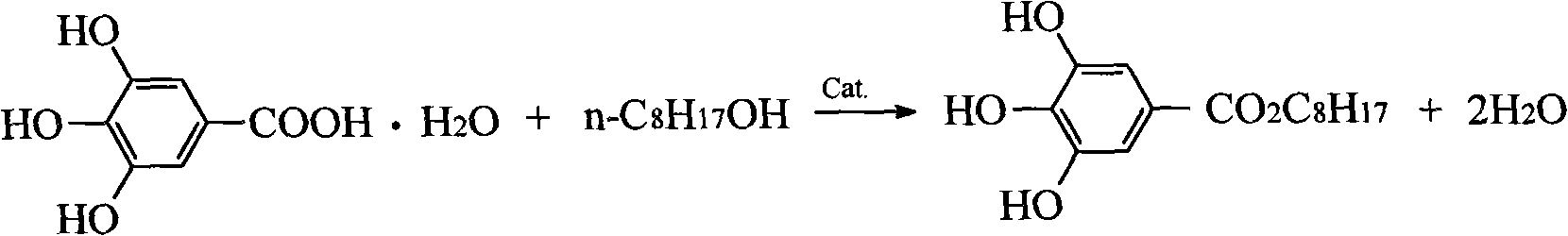

Overdosed esterification production technology for n-octyl gallate

InactiveCN101781214AShorten the reaction time of esterificationHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationGallic acid esterDistillation

The invention discloses overdosed esterification production technology for n-octyl gallate, which comprises the following steps: reacting gallic acid raw materials with n-octyl alcohol for an esterification reaction in the presence of an organic sulfonic acid catalyst; vaporizing and concentrating the filtrate under reduced pressure; adding cyclohexane for recrystallization; washing the filtrate by using purified water until the PH is between 6.0 and 7.0; and performing vacuum drying to obtain the end product of n-octyl gallate. The overdosed esterification production technology for the n-octyl gallate has the advantages of obviously shortening the esterification reaction time, having high reaction conversion rate, saving the high temperature distillation process under reduced pressure and reducing the damage to reaction products due to high temperature. The n-octyl alcohol is a reactant and a solvent used for the reaction, and the production cost is reduced.

Owner:JIURUI BIOLOGY & CHEM CO LTD

Production process of high-purity alpha-ethyl linolenate

ActiveCN104693033AYield maximizationIncrease productionOrganic compound preparationCarboxylic acid esters separation/purificationPerilla oilEthyl ester

The invention discloses a production process of high-purity alpha-ethyl linolenate, and belongs to the field of chemistry. The process is characterized in that esterification reaction is adopted, raw materials include perilla oil, the perilla oil is saponified, acidified and washed to obtain fatty acid containing alpha-linolenic acid, the esterification reaction is directly carried out by adopting the washed fatty acid containing the alpha-linolenic acid, the esterification reaction is carried out at one time and carried out in a reaction device, the reaction device is connected with a water distribution device, azeotrope of ethanol and water is simultaneously evaporated into the water distribution device during the esterification reaction in a period of time, and the urine enveloping purification is carried out for the alpha-ethyl linolenate in a product after the esterification reaction. By adopting the production process, the production process of the alpha-ethyl linolenate is simplified, the productivity is greatly improved, the production time is shortened, and the production efficiency is improved.

Owner:HENAN LINUO BIOCHEM CO LTD

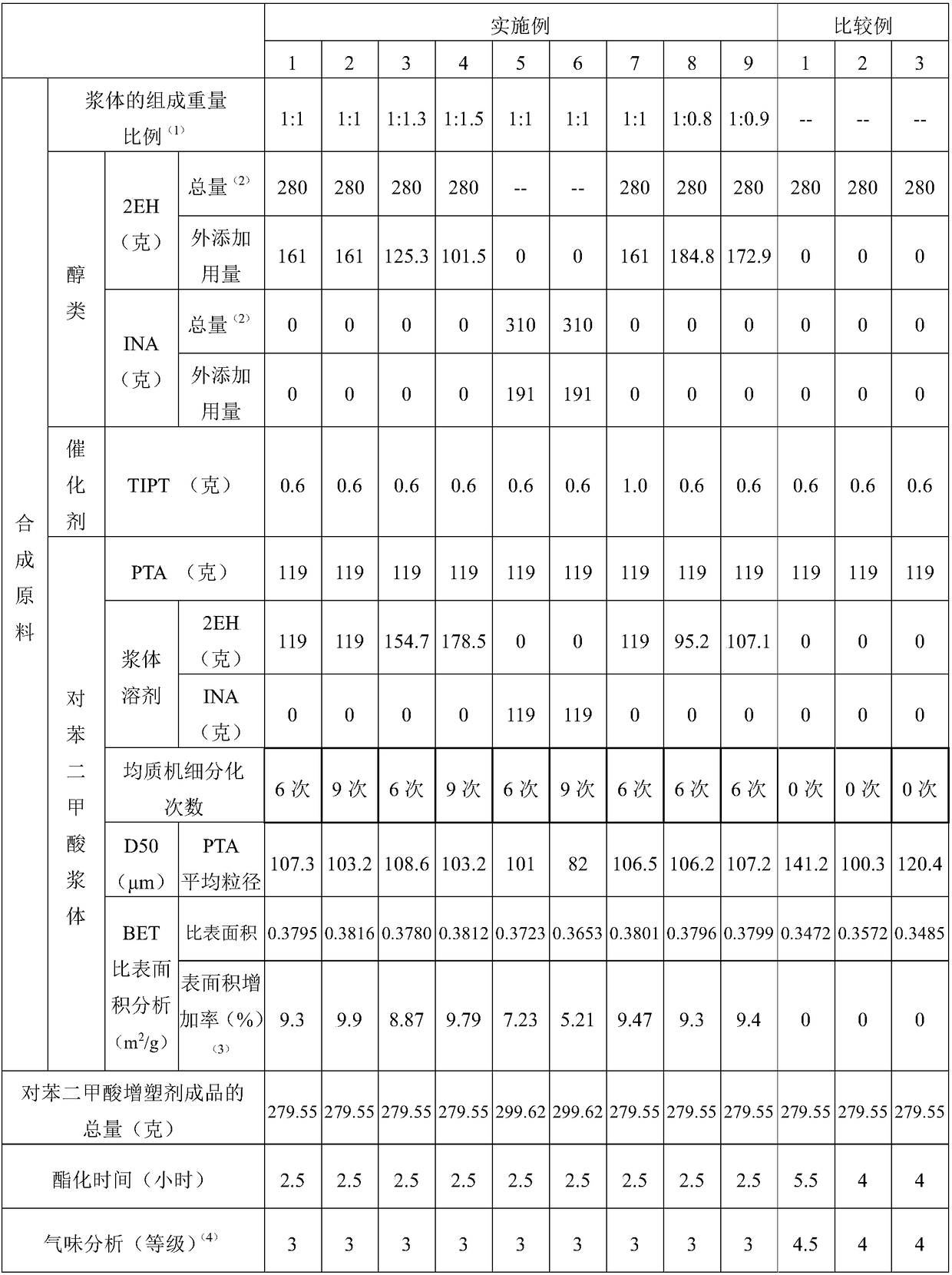

A method for improving the reaction efficiency of a terephthalate plasticizer

ActiveCN108640837AShorten the reaction time of esterificationIncrease productionOrganic compound preparationCarboxylic acid esters preparationAlcoholMetal catalyst

The invention provides a method for improving the reaction efficiency of a terephthalate plasticizer. A homogenizer is used to refine PTA in a mixture containing the PTA and C6-C10 alcohol multiple times to a grain size of 80-110 [mu]m. Esterification reaction is performed in the presence of a titanium metal catalyst. Compared with the conventional producing method, the method has the advantages that the esterification reaction time is at least shortened by more than 37.5%, the purity of a terephthalate plasticizer finished product synthesized through esterification is more than 99.5%, the physical properties such as acid value, hue, refractive index and the like all meet standards, and the product has a low odor characteristic.

Owner:NANYA PLASTICS CORP

Method for inhibiting side reaction of tetrahydrofuran in polymerizing process

The invention relates to a method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process. According to the method, in the process of preparing a polymer by using terephthalic acid and 1,4-butanediol as main raw materials, ester, titanium-silicon-cobalt composite catalyst dispersant and pH regulator are generated by adding the terephthalic acid and dihydric alcohol in the esterifying stage, the molar ratio of the terephthalic acid to the 1,4-butanediol is controlled to be 1:(1.05-1.10) to inhibit the side reaction of tetrahydrofuran, so that the content of tetrahydrofuranin the polymer is less than or equal to 10wt%; the dispersing medium in the titanium-silicon-cobalt composite catalyst dispersant is 1,4-butanediol, and the titanium-silicon-cobalt composite catalystis prepared by combining a titanium-silicon composite catalyst and a cobalt catalyst, and the titanium-silicon composite catalyst is prepared from a silicon catalyst-supported titanium catalyst. According to the method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process, the final product has concentrated molecular weight distribution, few byproduct and high quality, andhas a great application prospect.

Owner:DONGHUA UNIV

Method for preparing biological diesel oil from waste animals and plants grease

InactiveCN101148600BWell mixedReduce generationBiofuelsLiquid hydrocarbon mixture productionOil and greaseLiquid waste

The improved continuous esterification process of waste animal and vegetable oil and grease with low carbon alcohol to prepare biodiesel oil features that liquid low carbon alcohol is introduced into the liquid comprising liquid waste animal and vegetable oil and grease in 95-99.9 wt% and acid catalyst in 0.1-5 wt% to produce esterification reaction at normal pressure and the temperature from vaporizing temperature to 95 deg.c while the vapor mixture comprising the resultant, water vapor and low carbon alcohol vapor is discharged from the top of the reactor and separated in a fractionating tower to obtain product, separated water and liquid low carbon alcohol for reuse. The process has high reaction speed, high reaction conversion rate and other advantages, and the product has acid value capable of being controlled below 2 mgKOH / g.

Owner:JIANGSU ZHONGSHENG GAOKE ENVIRONMENTAL CO LTD

Heterogeneous catalyst and application of same to preparation of polyester

The invention relates to preparation of a hydrophobically-modified transition metal oxide-immobilized organosilicone sphere catalyst and application of the catalyst to preparation of polyester. According to the invention, dibasic acid and dihydric alcohol are used as monomers and a hydrophobically-modified transition metal oxide-immobilized organosilicone sphere is used as a catalyst, so polyesteris prepared under mild conditions. The catalyst used in the preparation can effectively reduce esterification time, lower polycondensation temperature, decrease the loss of raw materials and reduce the probability of occurrence of side reactions of a system.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of method suppressing THF side reaction in polymerization process

The invention relates to a method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process. According to the method, in the process of preparing a polymer by using terephthalic acid and 1,4-butanediol as main raw materials, ester, titanium-silicon-cobalt composite catalyst dispersant and pH regulator are generated by adding the terephthalic acid and dihydric alcohol in the esterifying stage, the molar ratio of the terephthalic acid to the 1,4-butanediol is controlled to be 1:(1.05-1.10) to inhibit the side reaction of tetrahydrofuran, so that the content of tetrahydrofuranin the polymer is less than or equal to 10wt%; the dispersing medium in the titanium-silicon-cobalt composite catalyst dispersant is 1,4-butanediol, and the titanium-silicon-cobalt composite catalystis prepared by combining a titanium-silicon composite catalyst and a cobalt catalyst, and the titanium-silicon composite catalyst is prepared from a silicon catalyst-supported titanium catalyst. According to the method for inhibiting the side reaction of tetrahydrofuran in a polymerizing process, the final product has concentrated molecular weight distribution, few byproduct and high quality, andhas a great application prospect.

Owner:DONGHUA UNIV

Method for preparing biodiesel from microalgae

ActiveCN106318480AWidely distributedIncrease biomassFatty acid esterificationBiofuelsBiodieselVegetable oil

The invention discloses a method for preparing biodiesel from microalgae. The method comprises steps as follows: a culture medium is inoculated with haematococcus pluvialis, the haematococcus pluvialis is irradiated with a red and blue LED light-compensating lamp for 8-10 h every day and cultured at 23-25 DEG C for 7-8 d, and haematococcus pluvialis cells can be collected; the collected haematococcus pluvialis cells are subjected to wall breaking treatment with ultrasonic waves, extraction is performed with an organic solvent, microalgae oil is obtained, the microalgae oil, methanol and a zeolite molecular sieve catalyst are added to a reactor in the weight ratio being 1:(3-5):(0.01-0.03) for an esterification reaction, an esterification product is obtained, separated and purified, and the biodiesel can be obtained. According to the method, the haematococcus pluvialis which is short in production cycle, wide in application range, high in photosynthesis and high in oil content is taken as a raw material, and the problem of vegetable oil raw materials in the biodiesel development process is solved. Meanwhile, the method has the advantages that the preparation process is simple, the catalytic efficiency is high, the oil extraction rate is high, the product yield is high and the like, and a good foundation is laid for industrialization and mass production of biodiesel.

Owner:黄艳红

Method for preparing microalgae biodiesel through esterification reaction

InactiveCN106281641AWidely distributedIncrease biomassFatty acid esterificationBiofuelsMolecular sieveBiodiesel

The invention discloses a method for preparing microalgae biodiesel through an esterification reaction. The method comprises the following steps that a culture medium is inoculated with chaetoceros gracilis, the culture medium is irradiated with a red-blue light LED light supplementing lamp for 12 h per day to 16 d per day, the chaetoceros gracilis is cultured for 5 days to 8 days at the temperature of 26 DEG C to 28 DEG C, and then chaetoceros gracilis cells can be collected; the collected chaetoceros gracilis cells are subjected to wall-breaking treatment through ultrasonic waves and then extracted through an organic solvent to obtain microalgae grease, the microalgae grease, methyl alcohol and a zeolite molecular sieve catalyst are added into a reactor according to the mass ratio of 1:(6-8):(0.01-0.03) to be subjected to the esterification reaction to obtain an esterification product, the esterification product is separated and extracted, and then the biodiesel can be obtained; According to the method, the chaetoceros gracilis which is short in production period, wide in distribution and high in photosynthesis and grease content is taken as the raw material, and therefore the problems existing in vegetable grease raw materials in biodiesel development are solved; meanwhile, the advantages of being simple in preparation technology, high in catalytic efficiency, grease extraction rate and product yield and the like are achieved, and a foundation is laid for biodiesel industrialization and scale.

Owner:南宁华侨投资区政孙贸易有限公司

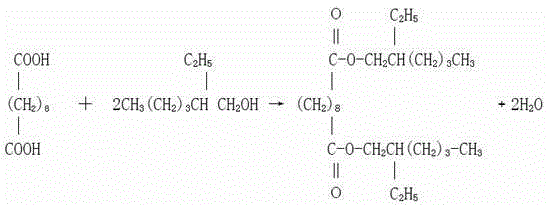

Preparation method for cold-resistant plasticizer dioctyl sebacate

InactiveCN105399625AHigh yieldShorten the reaction time of esterificationOrganic compound preparationCarboxylic acid esters separation/purificationPlasticizerDistillation

The invention relates to a preparation method for a cold-resistant plasticizer dioctyl sebacate, and belongs to the field of PVC auxiliary agents. The preparation method comprises the following steps: esterification, dealcoholysis, neutralization, distillation, adsorption and press filtration. The technical scheme employs 2-ethylhexanol and sebacic acid as raw materials and employs one or more titanates as a catalyst for esterificatoin, and then excessive 2-ethylhexanol is removed; then neutralization is performed, and a dioctyl sebacate crude product is prepared; and then the dioctyl sebacate crude product is subjected to reduced-pressure distillation, adsorption and press filtration, the high-quality high-yield high-purity cold-resistant plasticizer dioctyl sebacate product is prepared. The product quality reaches super grade standard.

Owner:ANHUI XIANGFENG NEW MATERIALS

Method for preparing biodiesel by taking algae as raw materials

ActiveCN106281483AWidely distributedIncrease biomassFatty acid esterificationBiofuelsVegetable oilBiodiesel

The invention discloses a method for preparing biodiesel by taking algae as raw materials. The method comprises the following steps that a culture medium is inoculated with pavlova viridis, irradiation is conducted through a red and blue LED fill light for 10 h / d to 16 h / d, culturing is conducted for 8 d to 10 d at the temperature of 25 DEG C to 27 DEG C, and then pavlova viridis cells can be collected; the collected pavlova viridis cells are added into a high-speed ball mill to be crushed and then extracted with an organic solvent to obtain microalgal oil, 1 part by weight of microalgal oil, 5-7 parts by weight of methanol and 0.03-0.05 part by weight of zeolite molecular sieve catalyst are added into a reactor to generate an esterification reaction, esterification products are obtained and then separated and purified, and the biodiesel is obtained. According to the method, by taking the pavlova viridis which is short in production cycle, wide in distribution, high in photosynthesis and high in oil content as the raw material, the problems existing in vegetable oil raw materials in boidiesel development are solved. Meanwhile, the method further has the advantages of being simple in preparation technolog, high in catalytic efficiency, high in oil extraction ratio, high in product yield and the like, and a good foundation is laid for industrialization and large scale of the biodiesel.

Owner:黄艳红

Biodiesel production method

InactiveCN106147994AWidely distributedIncrease biomassFatty acid esterificationBiofuelsMolecular sieveBiodiesel

The invention discloses a biodiesel production method which comprises the following steps: inoculating crypthecodinium cohnii to a medium; irradiating for 10-14h per day with a red-blue double-color LED fill light; culturing for 6-7 days at 23-26 DEG C to obtain organic crypthecodinium cohnii cells; performing wall breaking treatment of the collected crypthecodinium cohnii cells, and extracting with an organic solvent to obtain microalgae oil; adding the microalgae oil, methanol and a zeolite molecular sieve catalyst into a reactor according to a mass ratio of 1:(5-7):(0.01-0.04) for an esterification reaction to obtain an esterified product; and separating and purifying the esterified product to obtain the biodiesel. In the method disclosed by the invention, by adopting the crypthecodinium cohnii with short production cycle, wide distribution, strong photosynthesis and high oil content as a raw material, the problems of vegetable oil raw material in biodiesel development are solved. The method also has the advantages of simple preparation technology, high catalysis efficiency, high oil extraction rate, high product yield and the like and lays a good foundation for the industrial and large-scale production of biodiesel.

Owner:南宁华侨投资区政孙贸易有限公司

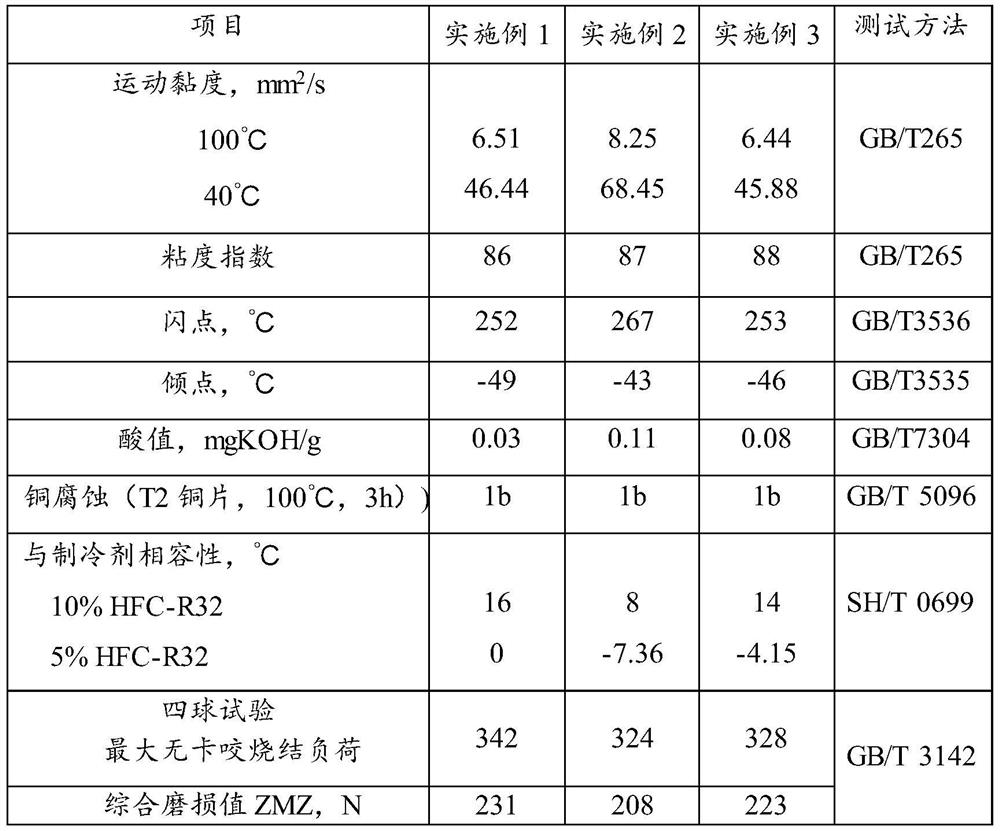

Pentaerythritol ester base oil and preparation method thereof

ActiveCN113173849AImprove performanceOptimize the esterification processOrganic compound preparationCarboxylic acid esters preparationPolymer sciencePtru catalyst

The invention provides a pentaerythritol ester base oil and a preparation method thereof. The preparation method comprises the following steps: a) mixing isocaprylic acid and pentaerythritol to obtain a mixture; and b) adding a catalyst into the mixture obtained in the step a), carrying out primary esterification reaction, supplementing fatty acid to carry out second esterification reaction to obtain pentaerythritol crude ester, and refining to obtain the pentaerythritol ester base oil. Compared with the prior art, the preparation method provided by the invention adopts specific raw materials, and the pentaerythritol ester base oil is prepared under specific steps and conditions; and according to the preparation method, the esterification process is optimized, the esterification reaction time can be shortened, and meanwhile, the prepared pentaerythritol ester base oil has good compatibility with a refrigerant on the basis that various properties are good.

Owner:CHINA PETROLEUM & CHEM CORP

Method for preparing biodiesel by catalysis of nano magnetic sulphonated coal

InactiveCN101353589AEasy to separateFast gatheringBiofuelsLiquid hydrocarbon mixture productionBiodieselSolid acid

The invention provides a method for preparing biodiesel by the catalysis of nano magnetic sulfonated coal. The method comprises the following steps: esterification is carried out to high acid value grease and glycerin at temperature of 120-180DEG C by virtue of the catalysis of nano magnetic sulfonated coal and the acid value is reduced to less than 3 to form low acid value grease; and then under the function of magnetic fields, the low acid value grease is quickly separated from catalyst and reacts with methanol at temperature of 60 DEG C for 10min under the action of strong base catalyst and cosolvent; and finally the reaction product continuously separates out the biodiesel and coarse glycerin under the action of a rotary vane centrifuge. The catalyst of nano magnetic sulfonated coal has strong paramagnetism and can quickly gather and is separated from a reaction product under the action of the magnetic field with the intensity of 0.7-0.8T, and the reaction product is refined to obtain pale yellow biodiesel through general ester exchange reaction. The method of the invention solves the problem that solid-acid dissociation happens in the process of esterification, shortens the esterification time of high acid value grease and reduces the corrosion of acid catalyst against equipment.

Owner:泰州市环科生物新能源有限公司

A green process for preparing sterol fatty acid esters

InactiveCN101434639BPromotes thorough mixingHeating up fastOrganic compound preparationCarboxylic acid esters preparationSterolAntioxidant

The invention relates to a green process for preparing sterol fatty acid ester. Use phytosterols, fatty acids or / and fatty acid esters, and antioxidants as raw materials. After mixing the raw materials evenly, heat and melt in vacuum or microwave radiation. After the above mixture is melted, add a catalyst. The amount of the catalyst added is 1% of the total weight of the reactants. 0.2% to 8%, after further thorough mixing, the esterification reaction is carried out for 3-20 hours at a temperature of 30-150 ° C, normal pressure or vacuum heating conditions of 10-100 Pa, or the esterification reaction is carried out by microwave radiation for 5-20 hours. For 30 minutes, the heating intensity of microwave radiation is 20W / mL~200W / mL, and the product after esterification reaction is separated, purified, and dried to obtain the sterol fatty acid ester product. Not only can the processing and reaction time be significantly shortened, the separation and purification steps can be simplified, the production efficiency can be improved, energy consumption can be saved, and the product has high biological activity and strong safety.

Owner:INST OF OIL CROPS RES CHINESE ACAD OF AGRI SCI

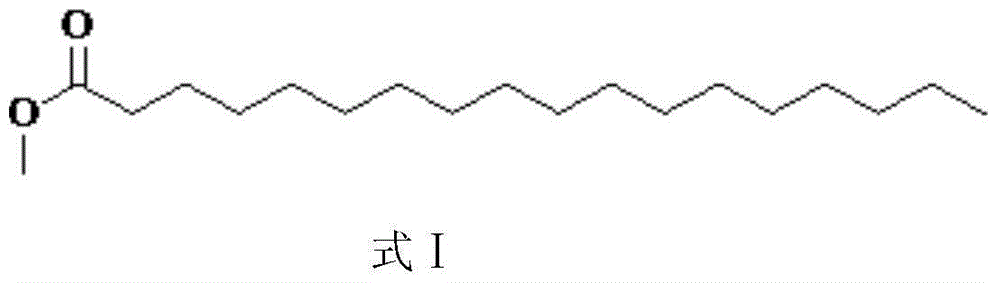

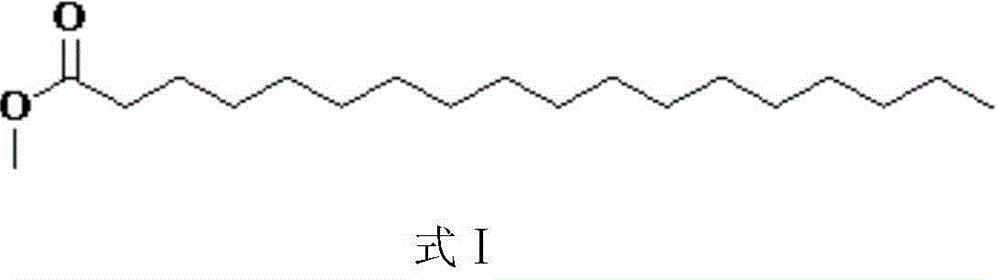

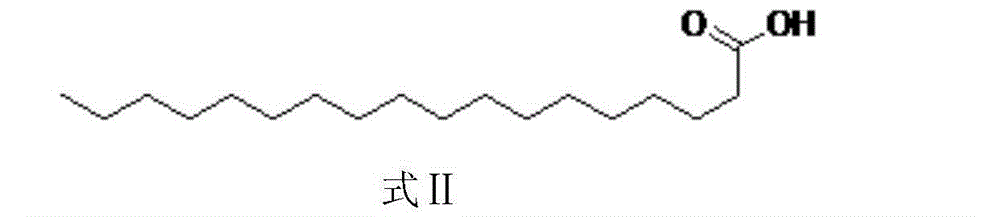

Preparation method of methyl stearate

InactiveCN104058957AShorten the reaction time of esterificationHigh reaction conversion rateOrganic compound preparationCarboxylic acid esters preparationChemical synthesisEsterification reaction

The invention relates to the field of chemical synthesis, and discloses a preparation method of methyl stearate. By using concentrated sulfuric acid as a catalyst and carbon black as a wave-absorbing agent, stearic acid and absolute methanol are subjected to esterification reaction under the microwave radiation heating conditions to obtain the methyl stearate. The preparation method disclosed by the invention effectively shortens the esterification reaction time and enhances the reaction conversion rate.

Owner:QINGDAO DONGFANG RECYCLING ENERGY +1

Esterification method of pectin

InactiveCN107353359AImprove the efficiency of esterification reactionShorten the reaction time of esterificationChemistryGalacturonic acid

The invention belongs to the technical field of pectin and particularly relates to an esterification method of pectin. The esterification method comprises the steps as follows: firstly, pectin is dissolved in water, vacuum freeze drying is performed, and a pectin solid is obtained; the pectin solid obtained through vacuum freeze drying is dispersed in an alcoholic solution in the solid-liquid ratio being 1:(1-50), inorganic acid is added for an esterification reaction, filtration is performed, and esterified pectin is obtained; the alcoholic solution obtained after filtration can be used for the pectin esterification reaction repeatedly. The esterification method has the advantages that the operation is convenient, the alcoholic solution can be recycled repeatedly, and no pollution is caused. The method can be used for preparing pectin esterified products with the esterification degree being 20%-95%, and esterification groups linked with galacturonic acid units correspond to used alcohol types.

Owner:JIANGNAN UNIV

A kind of method that utilizes microalgae to prepare biodiesel

ActiveCN106318480BWidely distributedIncrease biomassFatty acid esterificationBiofuelsVegetable oilBiodiesel

The invention discloses a method for preparing biodiesel from microalgae. The method comprises steps as follows: a culture medium is inoculated with haematococcus pluvialis, the haematococcus pluvialis is irradiated with a red and blue LED light-compensating lamp for 8-10 h every day and cultured at 23-25 DEG C for 7-8 d, and haematococcus pluvialis cells can be collected; the collected haematococcus pluvialis cells are subjected to wall breaking treatment with ultrasonic waves, extraction is performed with an organic solvent, microalgae oil is obtained, the microalgae oil, methanol and a zeolite molecular sieve catalyst are added to a reactor in the weight ratio being 1:(3-5):(0.01-0.03) for an esterification reaction, an esterification product is obtained, separated and purified, and the biodiesel can be obtained. According to the method, the haematococcus pluvialis which is short in production cycle, wide in application range, high in photosynthesis and high in oil content is taken as a raw material, and the problem of vegetable oil raw materials in the biodiesel development process is solved. Meanwhile, the method has the advantages that the preparation process is simple, the catalytic efficiency is high, the oil extraction rate is high, the product yield is high and the like, and a good foundation is laid for industrialization and mass production of biodiesel.

Owner:黄艳红

Quaternary ammonium salt catalyst, application thereof and isosorbide modified polyester

The invention discloses a quaternary ammonium salt catalyst, which is prepared by the following steps: adding metal chloride into a solution containing quaternary ammonium salt, aging, and filtering to obtain a solution containing the quaternary ammonium salt catalyst. The metal complex modified quaternary ammonium salt designed and synthesized by the invention can effectively shorten the esterification reaction time, reduce the polycondensation reaction temperature, reduce the raw material loss and reduce the system side reaction occurrence probability in the preparation process of modified polyester. The isosorbide modified polyester prepared by utilizing the catalyst is good in heat resistance, high in intrinsic viscosity and excellent in chromaticity, and an efficient way is provided for efficient preparation of the modified polyester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

A kind of preparation method of NTAA modified cellulose film

ActiveCN108003363BAvoid lostShorten the reaction time of esterificationOther chemical processesWater contaminantsPhysical chemistryMethylene radical

The invention provides a preparation method of an NTAA modified cellulose membrane and an application of NTAA in adsorption of methylene blue. A DMAc / LiCl system commonly used in preparation of a cellulose membrane is directly used as a solvent of NTAA modified cellulose, an intermediate complex step of purifying modified cellulose is omits, the esterification time of cellulose and NTAA is shortened by 1 / 2, and the esterification rate is improved. The 12 h adsorption rate of the prepared modified cellulose membrane to adsorb a methylene blue solution with the pH of 6 reaches 85% or more, and the adsorbing capacity is not significantly reduced after multiple times of adsorption and desorption.

Owner:北京国素生态科技集团有限公司

Preparation method for microalgae biodiesel

InactiveCN106190536AWidely distributedIncrease biomassFatty acid esterificationBiofuelsMolecular sieveBiodiesel

The invention discloses a preparation method for microalgae biodiesel. The preparation method comprises the following steps: inoculating monallanthus salina into a culture medium, performing irradiation for 10-15h / day by virtue of a red-blue bicolor LED light supplement lamp, performing culture for 10 to 11 days at 25 to 28 DEG C, and collecting monallanthus salina cells; performing ultrasonic wall breaking treatment on the collected monallanthus salina cells, performing extraction to obtain monallanthus salina oil by virtue of an organic solvent, adding the monallanthus salina oil, methanol and a zeolite molecular sieve catalyst into a reactor according to a mass ratio of 1:(4-6):(0.01-0.03), performing esterification reaction to obtain an esterification product, and separating and purifying the esterification product to obtain the biodiesel. According to the method, the monallanthus salina which is short in production period, wide in distribution, strong in photosynthesis and high in oil content is taken as a raw material, so that problems of a plant oil raw material during biodiesel development are solved; in addition, the method also has the advantages of simple preparation process, high catalysis efficiency, high oil extraction rate, high product yield and the like, and a good foundation is laid for industrialization and large-scale production of the biodiesel.

Owner:南宁华侨投资区政孙贸易有限公司

Method for producing biodiesel from microalgae oil

InactiveCN106367446AWidely distributedIncrease biomassFatty acid esterificationBiofuelsMolecular sieveBiodiesel

The invention discloses a method for producing biodiesel from microalgae oil. The method comprises the following steps: inoculating a culture medium with scenedesmus ovalternus, irradiating the culture medium by virtue of a red-blue double-color LED light-compensating lamp for 10-16h / day, conducting culture at 23-25 DEG C for 9-10 days and collecting scenedesmus ovalternus cells; and conducting wall-breaking treatment on the collected scenedesmus ovalternus cells by virtue of ultrasonic wave and extracting the scenedesmus ovalternus cells by virtue of an organic solvent so as to obtain the microalgae oil, adding the microalgae oil, methanol and a zeolite molecular sieve catalyst to a reactor according to a mass ratio of 1 to (6-8) to (0.02-0.05) and conducting an esterification reaction so as to obtain an esterification product, and separating and purifying the esterification product so as to obtain the biodiesel. The method provided by the invention, which adopts the scenedesmus ovalternus which is short in production cycle, wide in distribution, strong in photosynthesis and high in oil content as a raw material, can solve the problem on a plant oil raw material in biodiesel development. Meanwhile, the method also has the advantages of being simple in preparation process, high in catalysis efficiency, high in oil extracting rate, high in product yield and the like, so that a good foundation is laid for the industrial and large-scale production of the biodiesel.

Owner:南宁华侨投资区政孙贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com