A kind of preparation method of NTAA modified cellulose film

A technology of cellulose film and microcrystalline cellulose, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

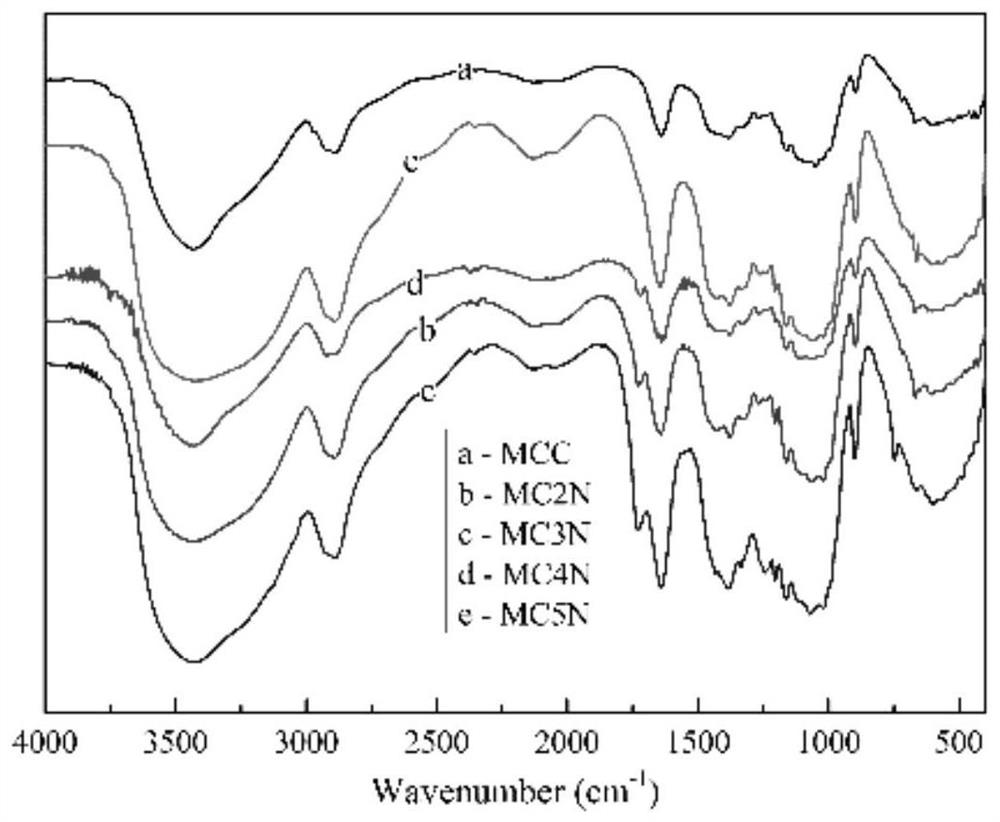

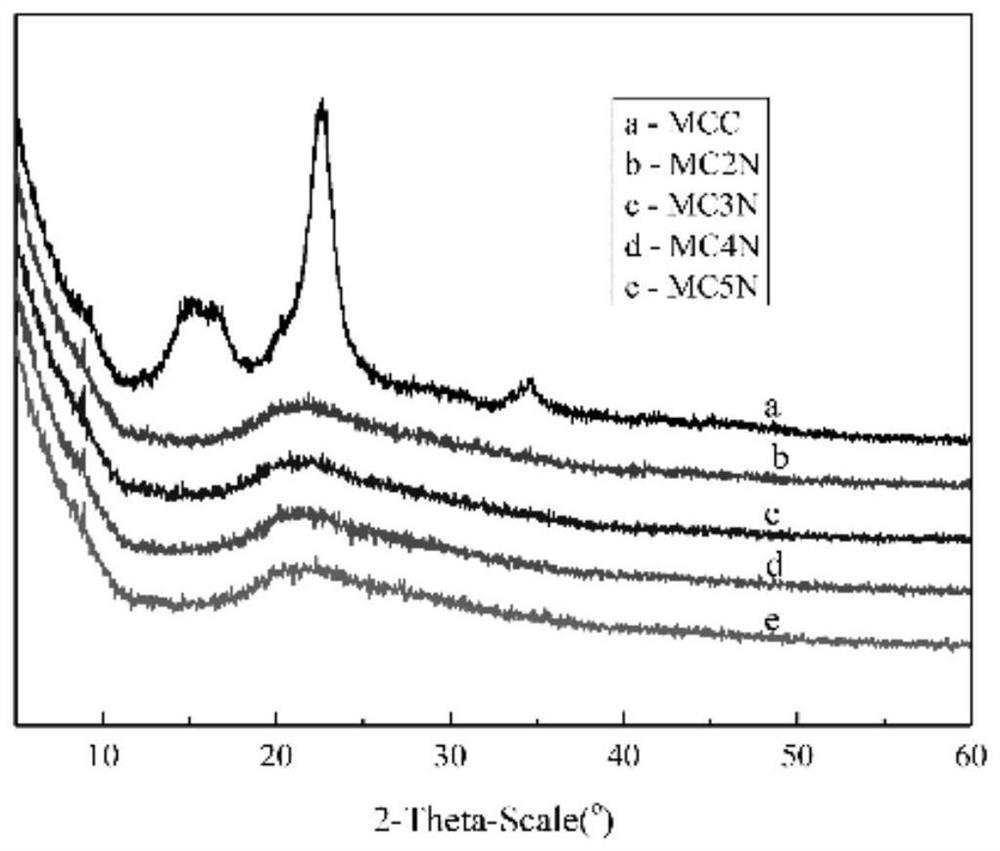

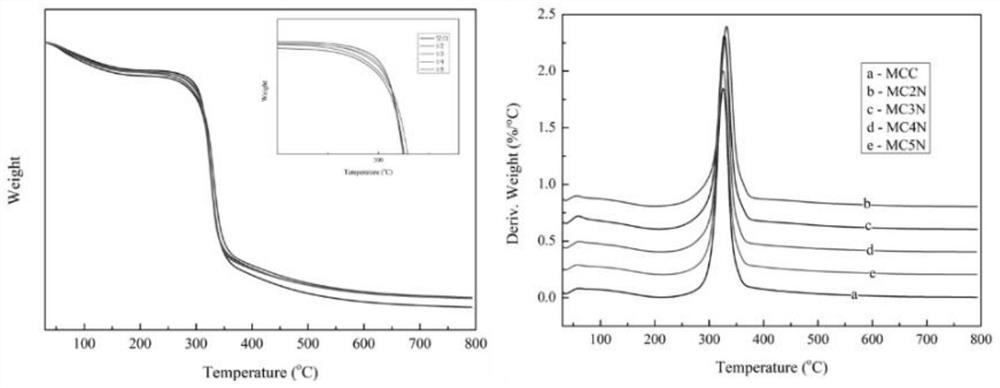

Method used

Image

Examples

Embodiment 1

[0044] Add 6mL of pyridine and 4g of nitrilotriacetic acid into a three-neck flask, stir at room temperature for 30min, then add 6mL of acetic anhydride dropwise, and heat at 65°C for 24h. After the reaction, the mixture was concentrated by distillation under reduced pressure, then washed with ether, triturated and filtered to obtain the target product. The resulting tan product was placed in a desiccator for later use.

Embodiment 2

[0046] 2 g of dry microcrystalline cellulose MCC and 25 mL of dimethylacetamide DMAc were mixed in a three-necked flask, and kept at 130 °C for 30 min. Then, 2 g of LiCl was added to the mixture and heating was continued for 10 minutes. Subsequently, the above mixture was stirred at room temperature for 12 h. Store the final clear cellulose solution in an airtight container in the refrigerator.

Embodiment 3

[0048] Weigh 10 g of the cellulose solution prepared in Example 2 and 5 g of NTAA respectively, and add them into the solution in the round bottom flask. The mixture was heated at 75 °C for 12 h.

[0049] Transfer 3.6g of the modified cellulose solution to a polytetrafluoroethylene mold (Φ=8cm), and place it at room temperature for 30min. The cast modified cellulose solution was soaked in acetone for 1 h and then washed with cold water for 6 h to completely remove the salt. The final wet modified cellulose membranes were freeze-dried on glass Petri dishes. Afterwards, the dried films were peeled off and stored in a desiccator with a relative humidity of ≤20%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com