Patents

Literature

31results about How to "Improve the efficiency of esterification reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of biodiesel

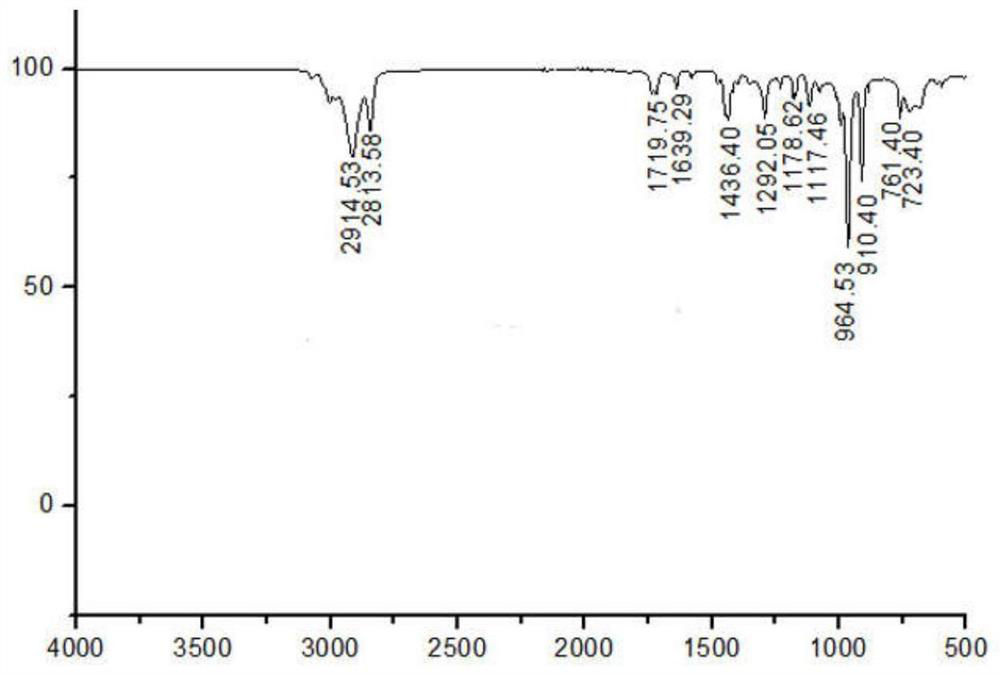

ActiveCN103468413AReduce moistureReduce impuritiesFatty acid esterificationFatty acids production/refiningWater bathsDistillation

The invention provides a production method of biodiesel. The production method comprises the steps of preprocessing of raw oil, esterification reaction, transesterification, dealcoholization, washing, distillation and deodorization, methanol distillation and recycling, glycerin purification and recycling and other steps. The production method has the advantages that the utilization rate of raw oil is high; few esterifying catalysts are needed; the catalytic activity is high; the esterification reaction is performed within a short time; a water-bath heating system is adopted, so that the temperature of heating a medium can be controlled effectively, and the generated unsaponifiable matters can be effectively decreased; in addition, the heat produced in reaction can be recycled, thus the energy consumption is reduced; the unreacted methanol can be recycled that the production cost is reduced. The biodiesel has acid value up to 0.5mgKOH / g and yield up to more than 92%, has the quality meeting BD100, and is suitable for industrial production.

Owner:四川惠盛新能源有限公司

Emulsifier for stabilizing food emulsion system and its preparation method

An emulsifier able to stabilize the emulsified food system is prepared from the starch of early long-grained non-glutinous rice, octylenyl succinyl oxide, water, and NaOH through mixing said starch with water, stirring, using NaOH to regulate pH value, adding octylenyl succinyl oxide within one hour while stirring, controlling temp while stirring, using NaOH to regulate pH value, using HCl to regulate the pH value of resultant, washing for removing HCl and residual oetylenyl succinyl oxide, centrifugal separation and spray drying.

Owner:ZHEJIANG UNIV

Emulsifier for stabilizing food emulsion system and its preparation method

InactiveCN100515222CIncrease viscosityContinuous ruptureFood preparationEmulsionOCTENYLSUCCINIC ACID

Owner:ZHEJIANG UNIV

Preparation method of starch octenyl succiniade under supercritical condition

ActiveCN102367280AGuaranteed food safetyPenetrate fastBulk chemical productionChemical synthesisOCTENYLSUCCINIC ACID

The invention discloses a preparation method of starch octenyl succiniade under the supercritical condition. The method comprises the following steps: simultaneously performing an oxidation reaction and an esterification reaction using starch as a raw material, hydrogen peroxide or sodium hypochlorite as an oxidant, ocentyl succinic anhydride as an esterifying agent and supercritical CO2 as a reaction medium under stirring to obtain an esterification product; and extracting the esterification product with supercritical CO2 to obtain the purified powdery starch octenyl succiniade of which viscosity is 5-25mPa.s (6%, 95 DEG C) and degree of substitution is 0.005-0.12. The invention provides an environmentally-friendly green chemical synthesis method; and the method has the advantages of lowimpurity content, high reaction efficiency, good product quality and the like.

Owner:GUANGXI UNIV

Esterification method for preparing biodiesel using waste oils and fats

ActiveCN103451027AWide range of acid values of raw materialsEquipment material requirements are lowFatty acid esterificationBiofuelsChemistryWaste oil

Provided is an esterification method for preparing biodiesel using waste oils and fats. Under the normal pressure condition, the mixture of methanesulfonic acid, ethanesulfonic acid or chlorosulfonic acid and erosion restraint agents is used as a catalyst, the using amount of the catalyst is little, the catalyst can be repeatedly used, erosion on equipment is small, through a demister arranged on the top of a reaction kettle, the utilization rate of raw oil and the yield coefficient of coarse methyl ester are improved, heat generated in the reaction process is used for preheating fine methyl alcohol and waste oils and fats, heat is circularly used, energy loss is reduced, methyl alcohol which is not reacted is recovered, and production cost is lowered. The acid value of raw materials of the esterification method is wide (15-180mgKOH / g), the reaction time is short, energy loss is little, production cost is low, the yield coefficient of coarse methyl ester is high, high-acid-value flora and fauna waste oils and fats are esterified in one time to be lower than 1mgKOH / g in acid value, the next transesterification can be directly carried out to prepare biodiesel, and the method is suitable for producing biodiesel in an industrial mode.

Owner:四川惠盛新能源有限公司

Method for preparing octenyl succinate starch ester

InactiveCN103739723APenetrate fastGuaranteed food safetyBulk chemical productionOctenyl succinateOCTENYLSUCCINIC ACID

The invention discloses a method for preparing octenyl succinate starch ester. The method is characterized in that the octenyl succinate starch ester is prepared by using starch as a raw material, using hydrogen peroxide or sodium hypochlorite as oxidant and using octenyl succinic anhydride as esterifying agent according to the following reaction process: A. respectively adding the starch, the oxidant and the esterifying agent into a supercritical reaction kettle, adding CO2 by using a high-pressure pump, and then, heating up to a supercritical temperature of 40-60 DEG C, wherein the supercritical pressure is 8.0-25 Mpa and the reaction time is 1-6 hours; B. carrying out an oxidation and esterification one-step synthesis reaction under the supercritical reaction conditions and a stirring condition; and C. after the oxidation and esterification one-step synthesis reaction, supercritical extracting the reactants to obtain powdery octenyl succinate starch ester.

Owner:LIUZHOU BOZE SCI & TECH

Synthetic method of polyglycerol-10 oleate

ActiveCN104496803AEasy to separate and purifyEfficient synthesis effectOrganic compound preparationCarboxylic acid esters preparationEsterification reactionON-glycerol

The invention relates to a synthetic method of polyglycerol-10 oleate. The synthetic method sequentially comprises the following steps: (1) carrying out polymerization reaction on glycerol under catalysis of a combined catalyst A to obtain polyglycerol-10, wherein the combined catalyst A is prepared from 5-55% of NaOH, 5-55% of KOH, 5-15% of MgO and 5-25% of Al2O3; and (2) carrying out esterification reaction on polyglycerol-10 and oleic acid under catalysis of a combined catalyst B to obtain the polyglycerol-10 oleate, wherein the combined catalyst B is prepared from 5-35% of NaOH, 25-85% of KOH, 5-15% of MgO and 5-25% of Al2O3. According to the synthetic method provided by the invention, the glycerol polymerization reaction and esterification reaction efficiencies can be greatly enhanced, so that polyglycerol-10 oleate is efficiently synthesized. The yield can be improved, and the product purity is improved.

Owner:广东添乐化妆品有限公司

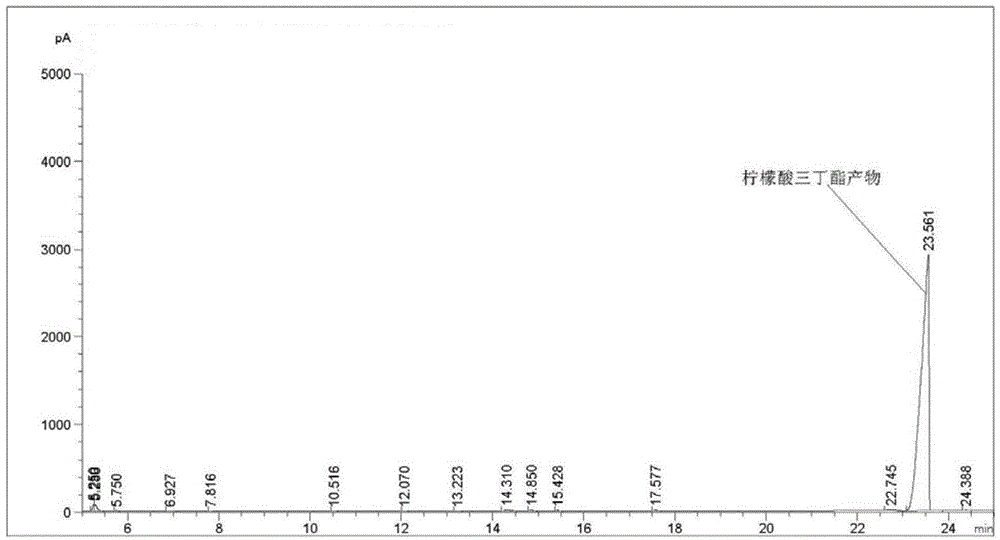

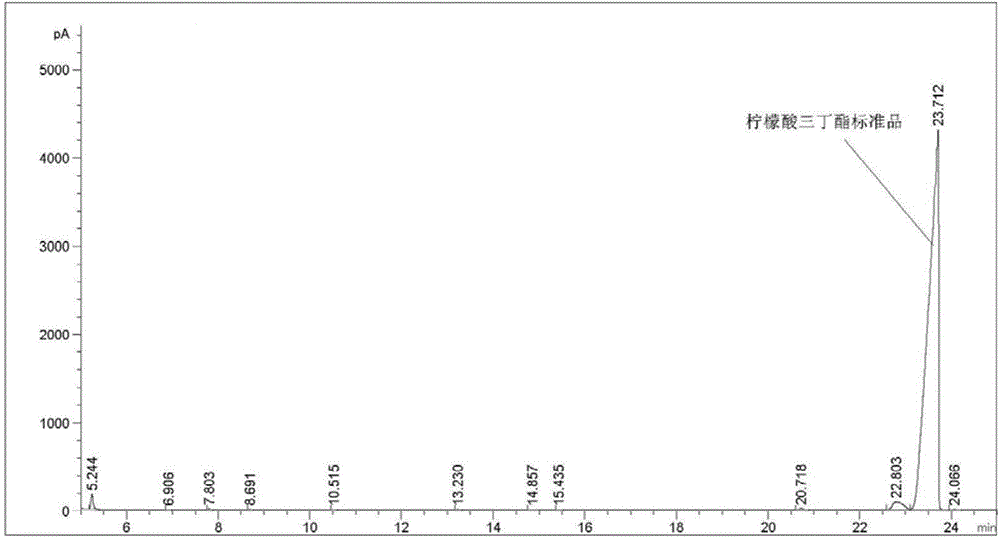

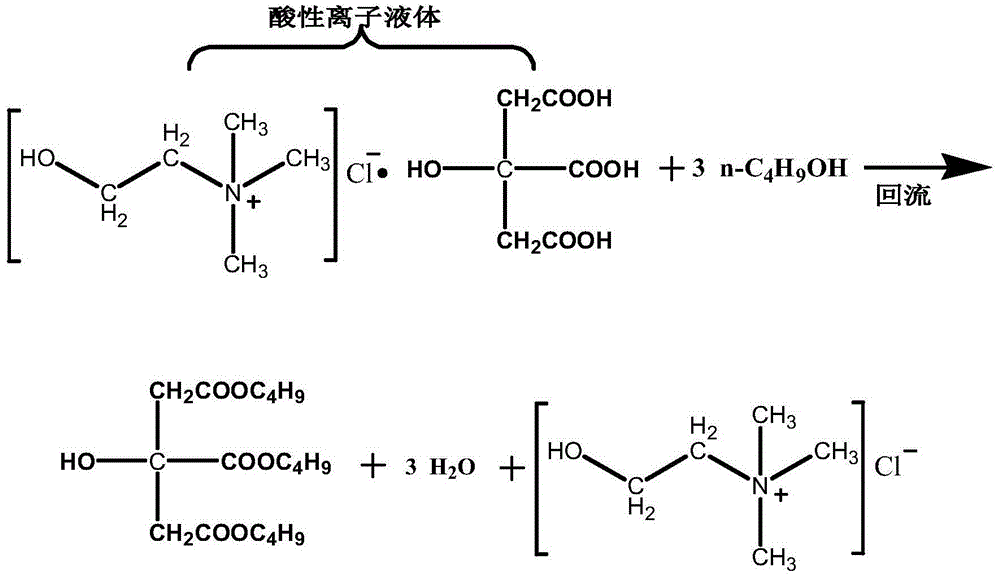

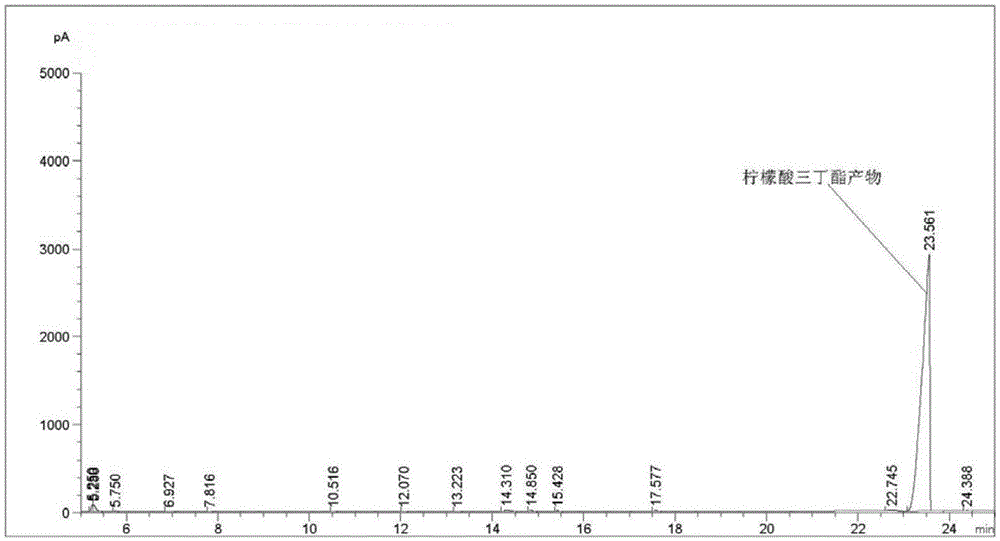

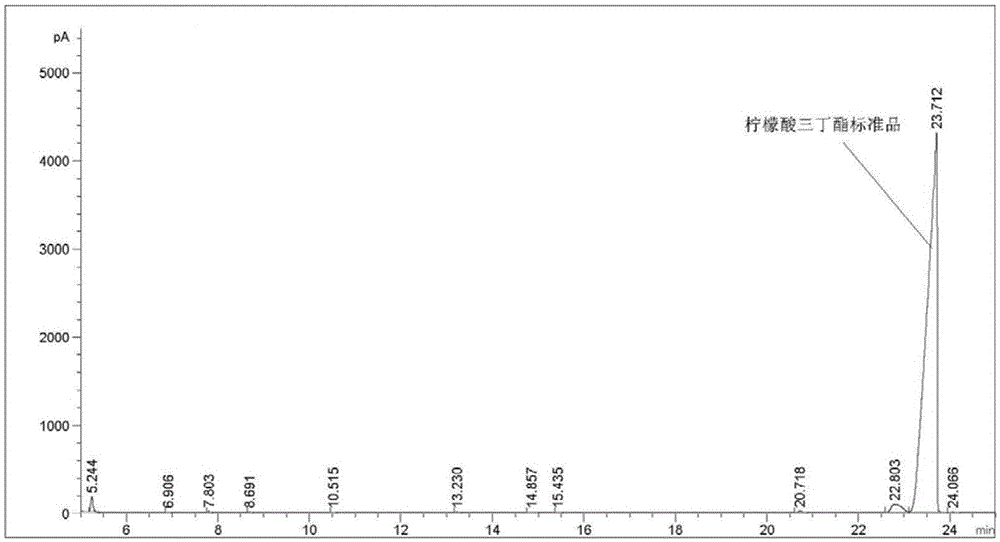

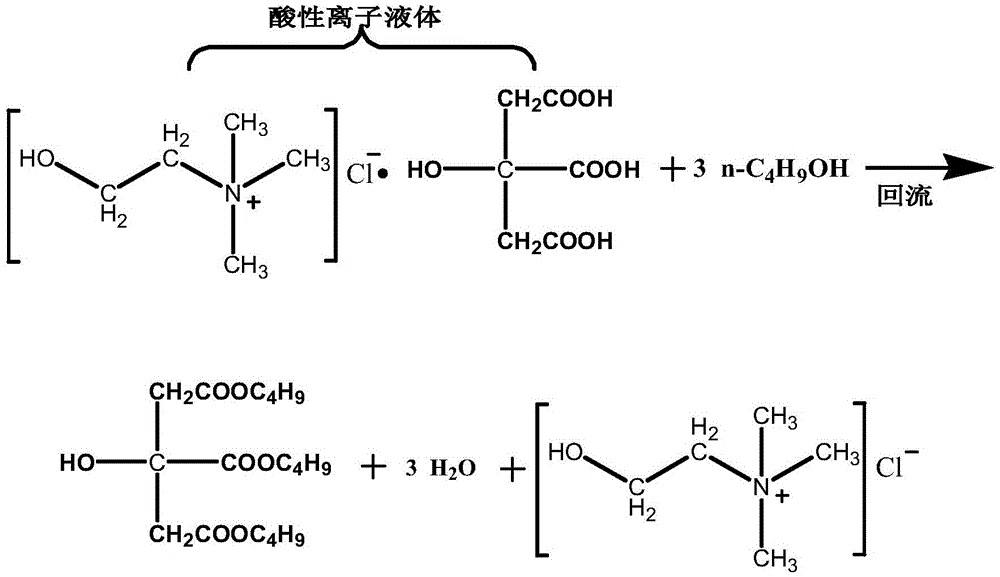

Method for synthesizing tributyl citrate

ActiveCN104447306ALow costImprove the efficiency of esterification reactionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsActivated carbonFiltration

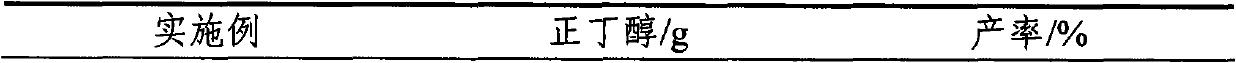

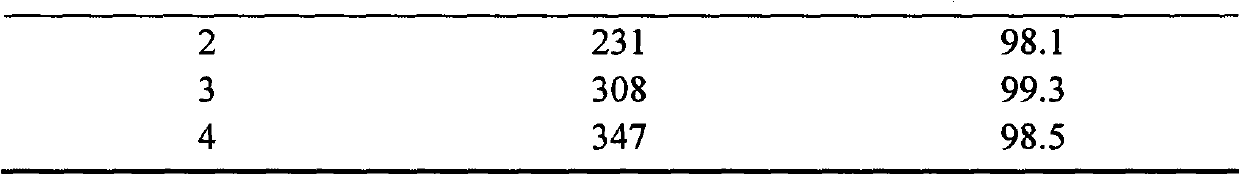

The invention discloses a method for synthesizing tributyl citrate. The method comprises the following steps: I, preparing a choline chloride acidic ionic liquid; II, performing esterification reaction; III, filtering the reaction system after reaction, thereby obtaining solid choline chloride and a liquid phase product; and IV, performing atmospheric distillation on the liquid phase product, washing residues generated after atmospheric distillation by using an alkali solution, adding activated carbon to decolor, filtering to remove the activated carbon, performing reduced pressure distillation on residues generated after filtration, and collecting fraction of 197-200 DEG C, thereby obtaining tributyl citrate. According to the method, choline chloride and citric acid are adopted to synthesize the acidic ionic liquid, the synthesized acidic ionic liquid is both a raw material and a catalyst, the acidic ionic liquid has esterification reaction with n-butyl alcohol to synthesize n-butyl alcohol, the efficiency of the esterification reaction is improved, the conversion rate can be greater than 90%, the choline chloride after esterification can be recycled and utilized, and the cost is low.

Owner:XIAN ORIGIN CHEM TECH

Method for preparing starch octenyl succinate under supercritical conditions

InactiveCN103724439APenetrate fastGuaranteed food safetyFood preparationBulk chemical productionOctenyl succinateOCTENYLSUCCINIC ACID

The invention discloses a method for preparing starch octenyl succinate under supercritical conditions, which is characterized by comprising the following steps by using starch as a raw material, oxydol or sodium hypochlorite as an oxidizer and octenyl succinic anhydride as an esterifying agent: A. respectively adding the starch, oxidizer and esterifying agent into a supercritical reaction kettle, adding CO2 with a high-pressure pump, heating to the supercritical temperature of 40-60 DEG C, and reacting under the supercritical pressure of 8.0-25 Mpa for 1-6 hours; B. under the supercritical reaction conditions, carrying out oxidization-esterification one-step synthesis reaction while stirring; and C. after the oxidization-esterification one-step synthesis reaction, carrying out supercritical extraction on the reaction product to obtain the powdery starch octenyl succinate.

Owner:LIUZHOU BOZE SCI & TECH

Method for preparing tributyl citrate through diatomite immobilized titanium sulfate used as catalyst

InactiveCN102584591ANot obviously corrosiveEasy to recyclePhysical/chemical process catalystsOrganic compound preparationEsterification reactionSolvent

The invention provides a method for preparing tributyl citrate through diatomite immobilized titanium sulfate used as a catalyst. According to the method, diatomite immobilized titanium sulfate is used as the catalyst, and citric acid and n-butyl alcohol take esterification reaction for synthesizing the tributyl citrate. The method has the advantages that the diatomite immobilized titanium sulfate is used as the catalyst, obvious corrosivity does not exist, in addition, the recovery and the repeated utilization are easy, and the activity is basically maintained unchanged; the esterification reaction efficiency is improved, and the product yield can reach 99.5 percent to the highest degree; reactants of the n-butyl alcohol are used as water-carrying agents, the use of noxious solvents such as methylbenzene and the like is avoided, and in addition, the aftertreatment process is simplified; and the esterification reaction condition is mild, the process is simple, and the method is suitable for industrial production.

Owner:BENGBU BBCA MEDICINE SCI DEV

Catalytic esterification method of oil with high acid value

InactiveCN101838591AEfficient removalIncrease contactFatty acid esterificationLiquid carbonaceous fuelsOil and greaseGlycerol

The invention discloses a catalytic esterification method of oil with a high acid value, relating to the esterification of higher fatty acid and providing a catalytic esterification method of oil with a high acid value. The method comprise the steps of: adding oil with a high acid value and an esterifying water carrying agent into a reactor and stirring, when reaching a preset reaction temperature, adding a catalyst, and reacting to obtain obtaining a reactant. The oil with the high acid value can be at least one selecting from waste oil, gleditsia sinensis lam, waste catering oil, hogwash oil, animal and plant oil containing the higher fatty acid and the higher fatty acid; the esterifying water carrying agent can be selected from low-carbon alcohol and can be added with glycerol; The low-carbon alcohol is distilled off in azeotropy with water, which ensures that the reaction balance moves to the right and a solid-acid catalyst has improved reaction efficiency and prolonged service life; the glycerol is used as an esterifying agent and can be subjected to reaction at higher temperature so as to improve esterification efficiency. Solid superacid is used as the catalyst with no sidereaction, easy separation with a product, reusability and low production cost; and moreover, the method has high reactivity, fast speed and mild conditions.

Owner:XIAMEN UNIV

Preparation method of C-potassium isoascorbiate

InactiveCN110294726AHigh purityHigh yieldSugar derivativesSaccharide compounds with non-saccharide radicalsFiberFiltration

The invention relates to a preparation method of C-potassium isoascorbiate. The preparation method of the C-potassium isoascorbiate comprises the following steps that a 2-keto-gluconic acid fermentation solution is taken, centrifugation is carried out, concentrated sulfuric acid is added into supernatant, then filtration is carried out to obtain acidified clear liquid, the acidified clear liquid is subjected to ultrafiltration by using a hollow fiber ultrafiltration device, ultrafiltrate with the molecular weight less than 50,000 is intercepted, and concentration is carried out to obtain a 2-keto-gluconic acid concentrated solution; an alcohol solvent and a solid super acidic catalyst are added for an esterification reaction, then an alkaline potassium ion donor is added for a conversion reaction, and purification is carried out to obtain the C-potassium isoascorbiate. The 2-keto-gluconic acid fermentation solution is pretreated, so that the purity of the raw material of the esterification reaction is higher, the yield of 2-keto-gluconic acid ester is higher, and the subsequent esterification reaction efficiency of the 2-keto-gluconic acid ester and the yield of the C isoascorbiate converted from the 2-keto-gluconic acid ester are higher.

Owner:新拓洋生物工程有限公司

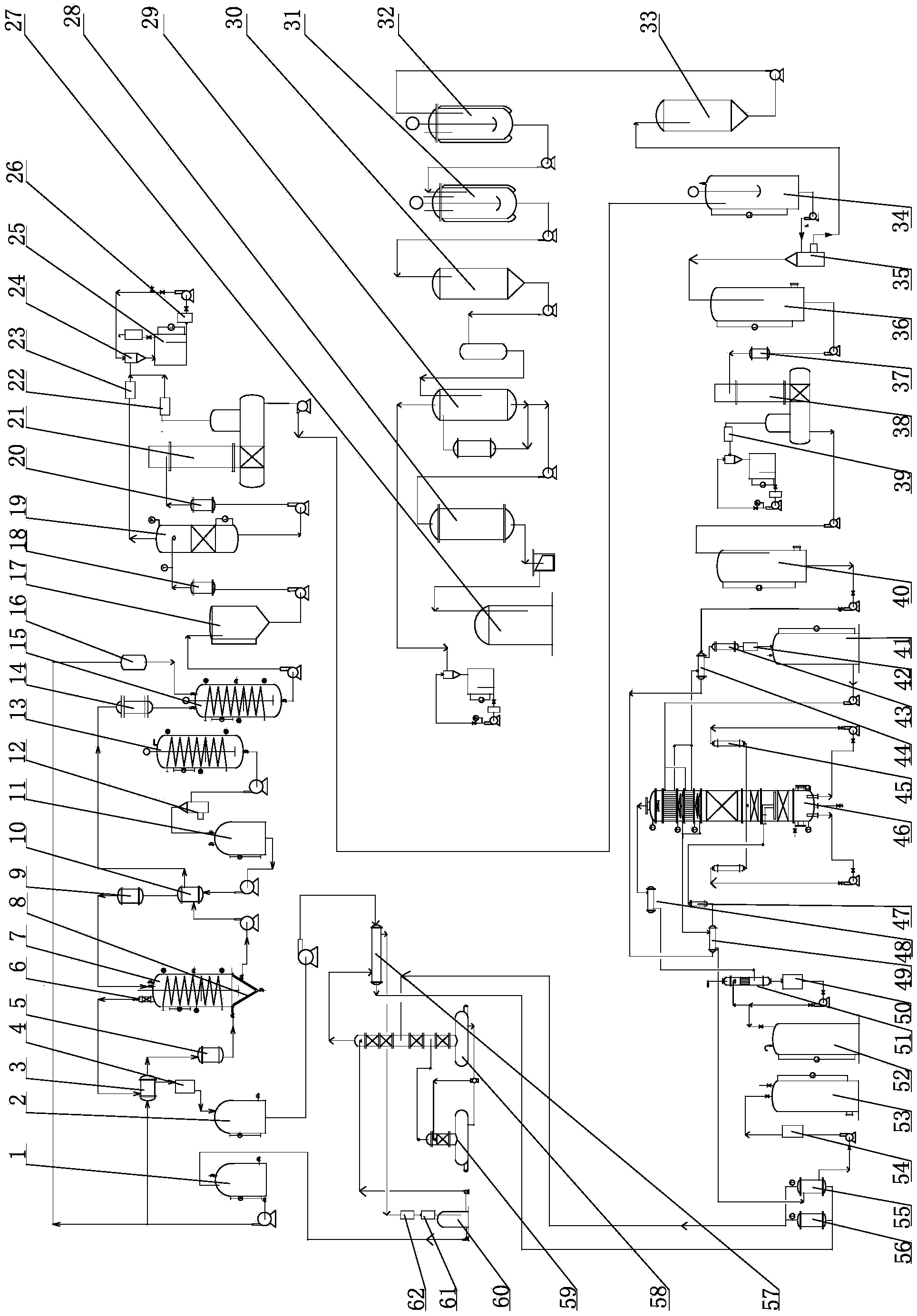

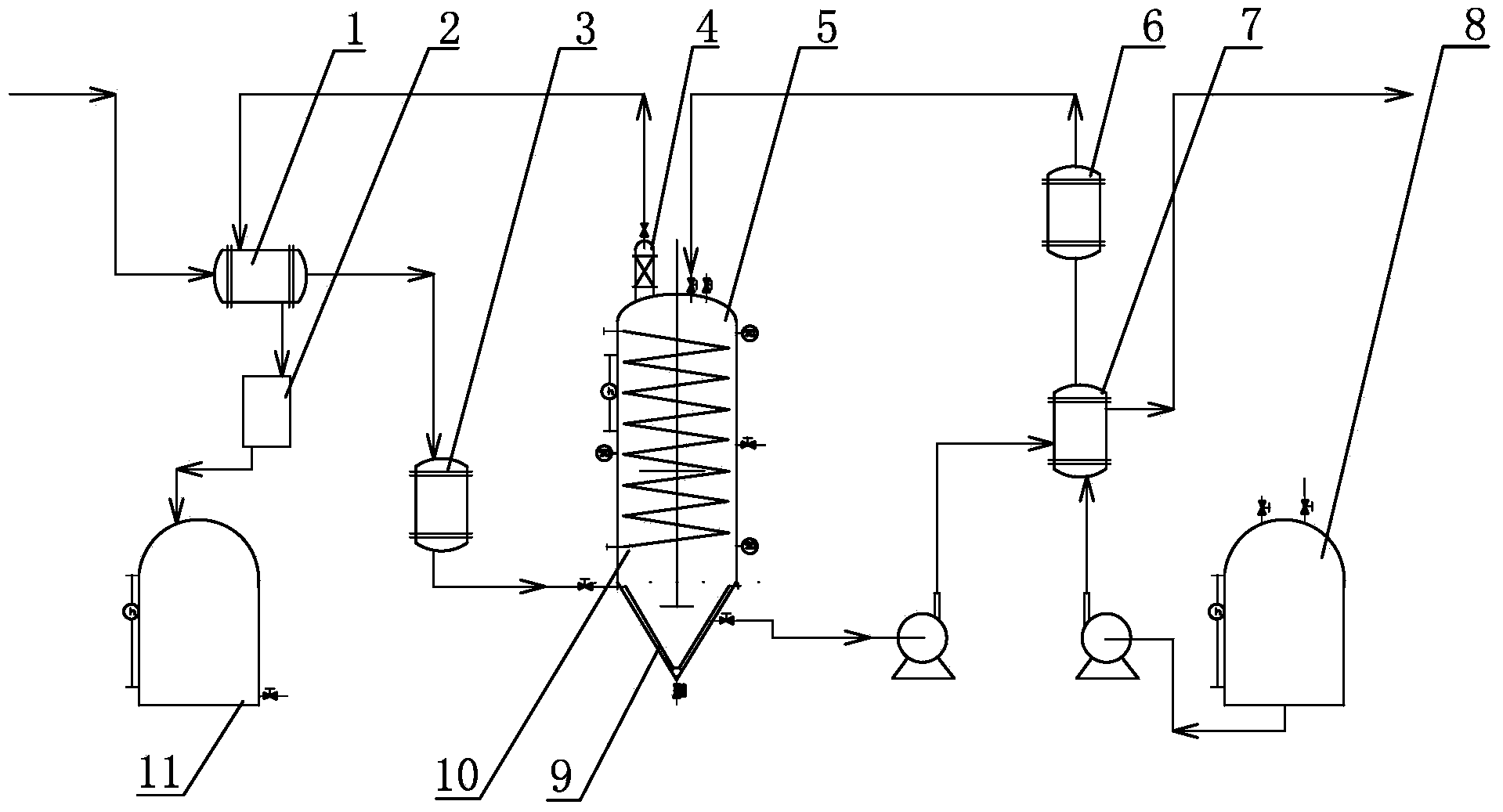

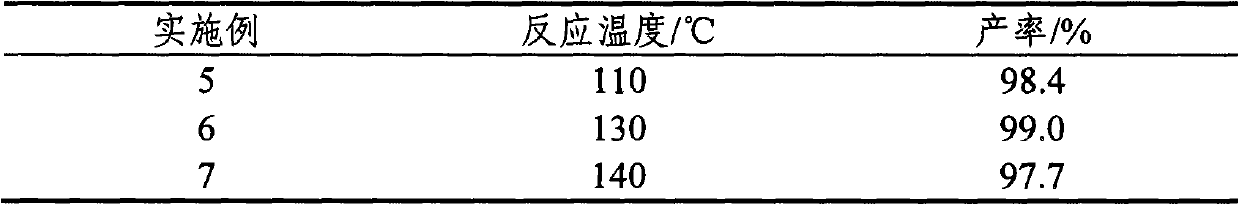

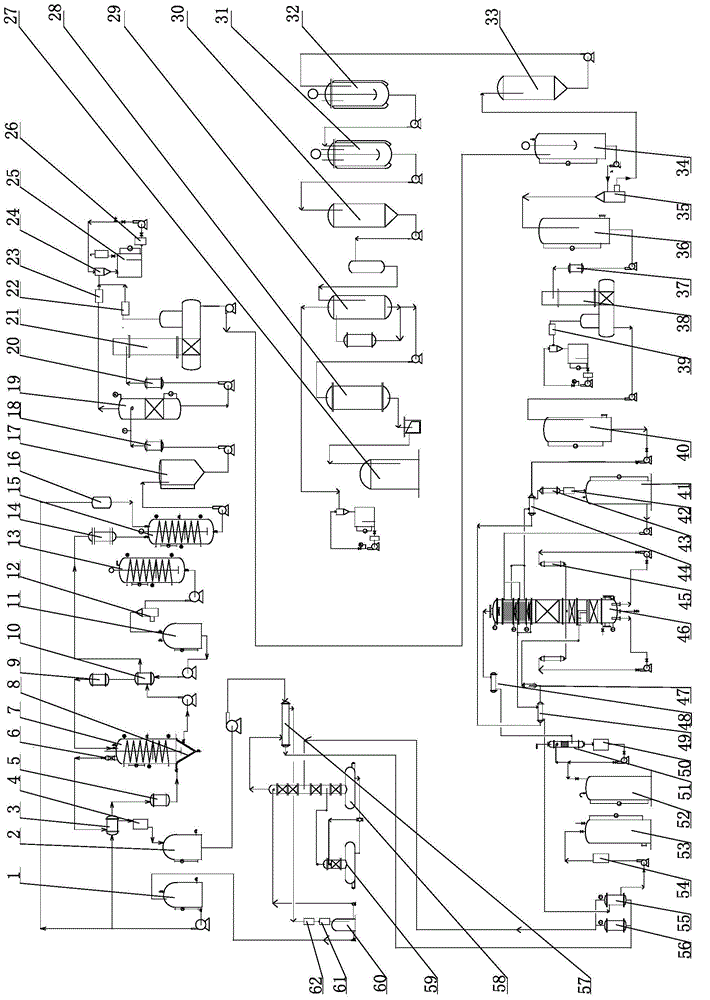

Device for producing biodiesel from waste edible oil

InactiveCN105602737ARealize rational utilizationEase the crisisFatty acid esterificationBiofuelsOil and greaseBiodiesel

The invention discloses a device for producing biodiesel from waste edible oil. The device comprises a solid-liquid separation tank (1), an oil-water separator (2), an impurity removal tank (3), an esterification tank (4), a phase splitter (7) and a rectification tank (9). The oil-water separator (2) is connected to the bottom of the solid-liquid separation tank (1) and connected with the impurity removal tank (3) through a liquid pump I (16), the bottom of the impurity removal tank (3) is connected with the esterification tank (4) through a liquid pump II (17), a phase splitter (7) is connected to the bottom of the esterification tank (4), the bottom of the phase splitter (7) is connected with a glycerinum collection tank (8) and a feed inlet of a vacuum pump (18) through a three-way pipe, a discharge outlet of the vacuum pump (18) is connected with the rectification tank (9), and the bottom of the rectification tank (9) is connected with a biodiesel collection tank (11). According to the device, waste edible oil can be converted into biodiesel, waste materials are changed into things of value, resources are reasonably utilized, and the problem of energy crisis can be effectively relieved.

Owner:薛晶

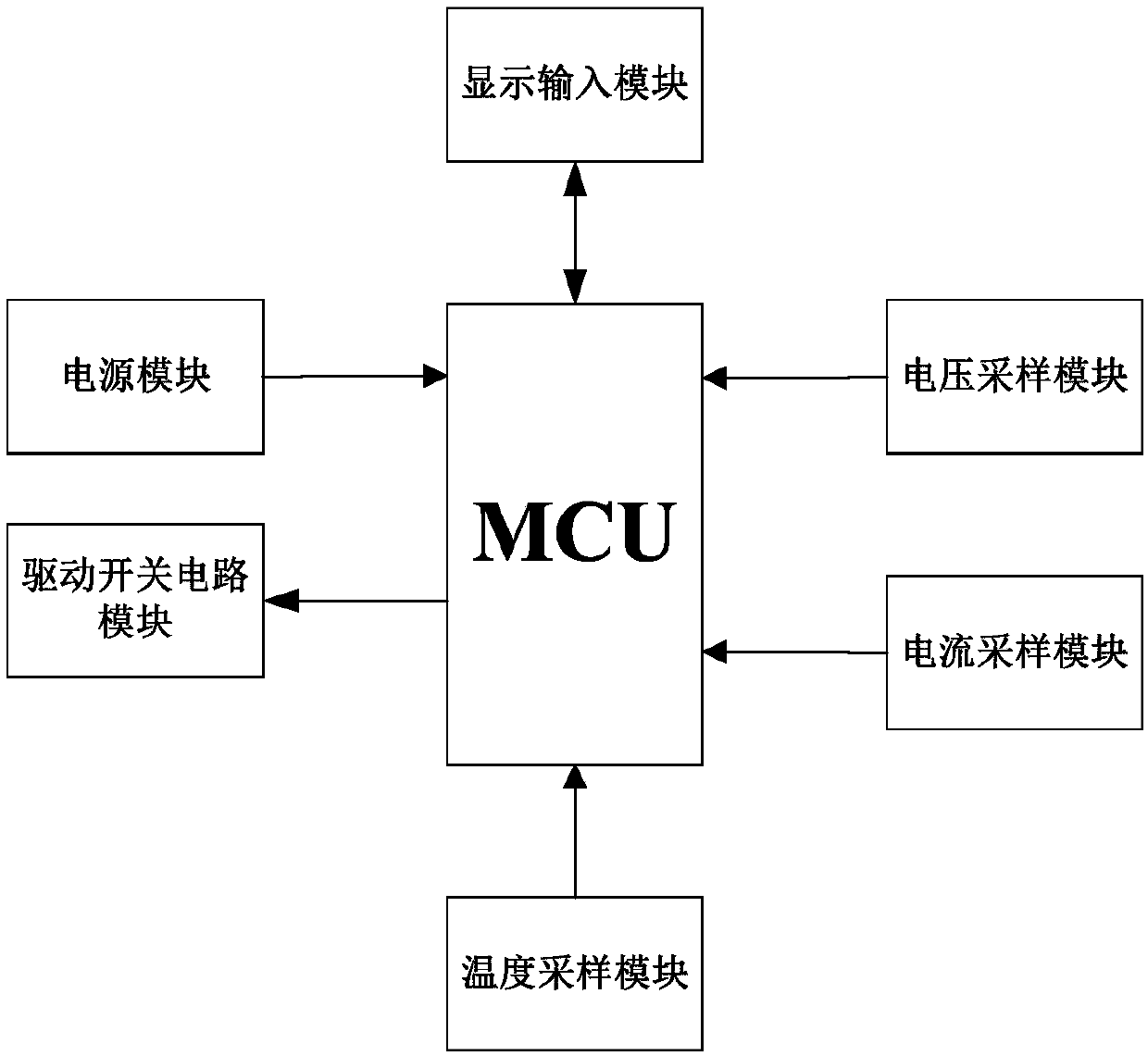

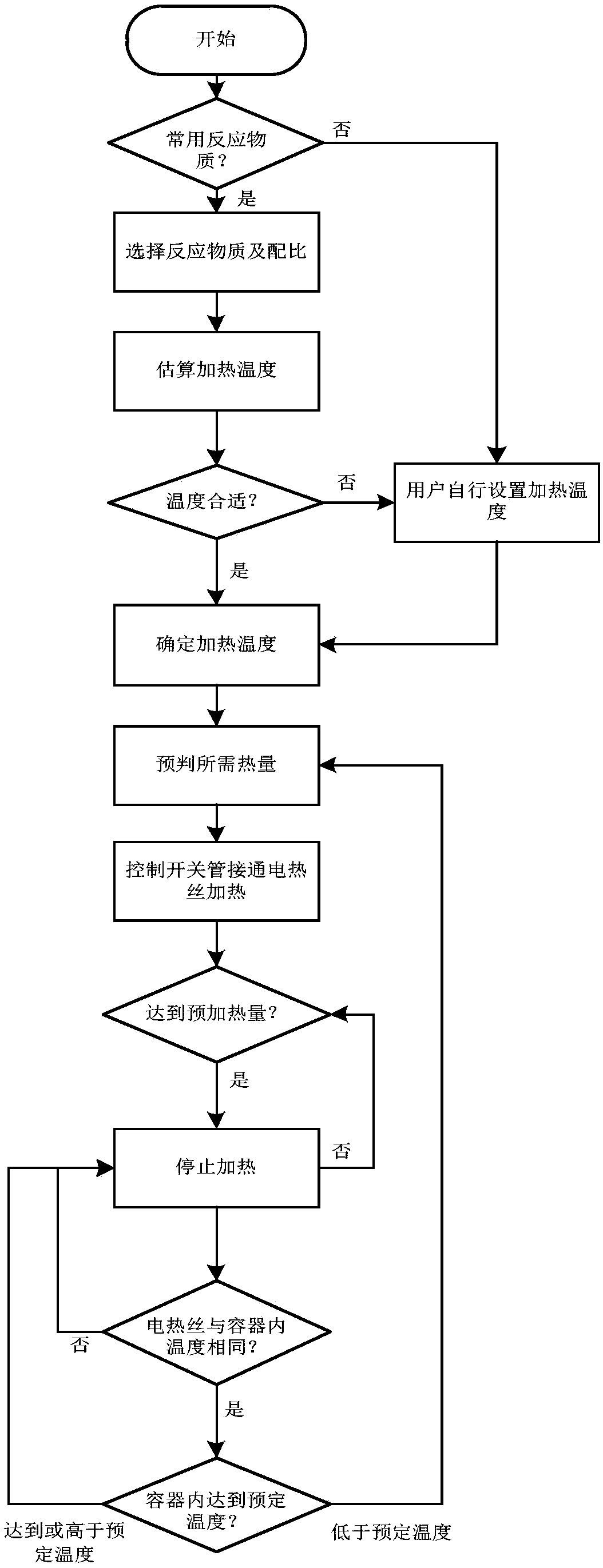

Multi-zone adaptive temperature control device applied to esterification reaction

InactiveCN109857171AAccurate and fast temperature controlHeating evenlyAuxillary controllers with auxillary heating devicesTemperature controlControl signal

The invention relates to a multi-zone adaptive temperature control device applied to esterification reaction. In the temperature control device, a temperature sampling module is connected with an MCUto collect the temperature of a tubular reactor and the temperature of a heating wire, and feed back the temperatures to the MCU; a current sampling module is connected with the MCU to collect the current of the heating wire and feeds back the current to the MCU; a voltage sampling module is connected with the MCU to collect the voltage of the heating wire and feeds back the voltage to the MCU; and a driving switch circuit module is connected with the MCU to receive a control signal of the MCU and controls ON / OFF of the heating wire. According to the type and characteristic, provided by a display input module, of the reaction substances, the temperature change trend in the tubular reactor is predetermined by combining the temperature of the reaction substance and the temperature of the heating wire, the driving switch circuit module controls the ON / OFF state of the heating wire, transition of temperature in the tubular furnace reactor is smooth, the temperature is controlled accuratelyand rapidly, heating is uniform, and the efficiency of esterification reaction is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Esterification method of pectin

InactiveCN107353359AImprove the efficiency of esterification reactionShorten the reaction time of esterificationChemistryGalacturonic acid

The invention belongs to the technical field of pectin and particularly relates to an esterification method of pectin. The esterification method comprises the steps as follows: firstly, pectin is dissolved in water, vacuum freeze drying is performed, and a pectin solid is obtained; the pectin solid obtained through vacuum freeze drying is dispersed in an alcoholic solution in the solid-liquid ratio being 1:(1-50), inorganic acid is added for an esterification reaction, filtration is performed, and esterified pectin is obtained; the alcoholic solution obtained after filtration can be used for the pectin esterification reaction repeatedly. The esterification method has the advantages that the operation is convenient, the alcoholic solution can be recycled repeatedly, and no pollution is caused. The method can be used for preparing pectin esterified products with the esterification degree being 20%-95%, and esterification groups linked with galacturonic acid units correspond to used alcohol types.

Owner:JIANGNAN UNIV

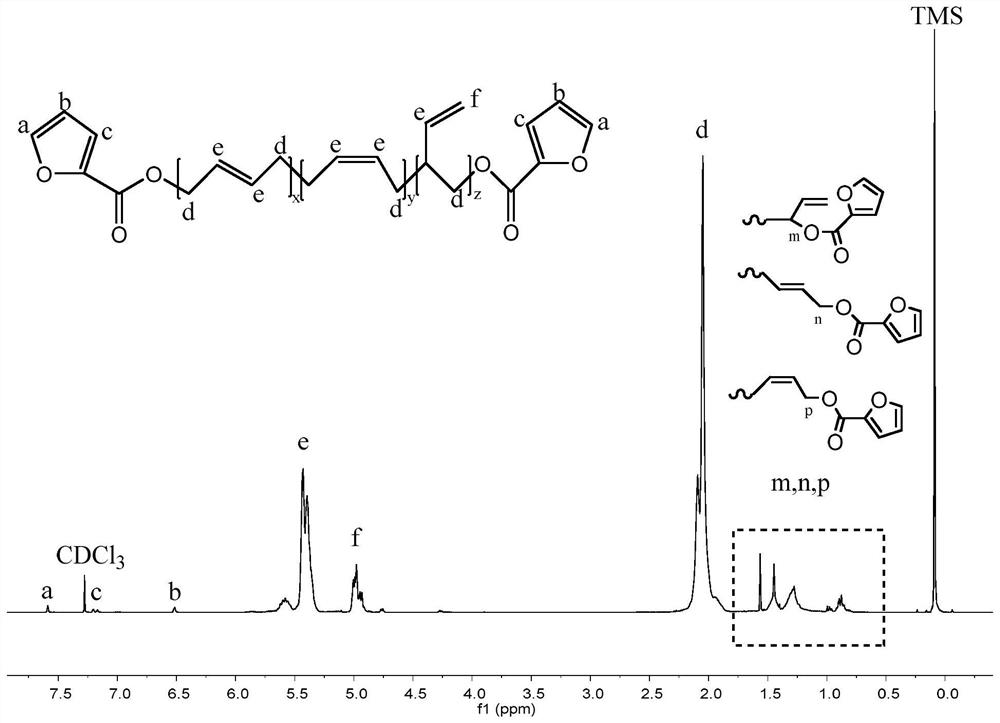

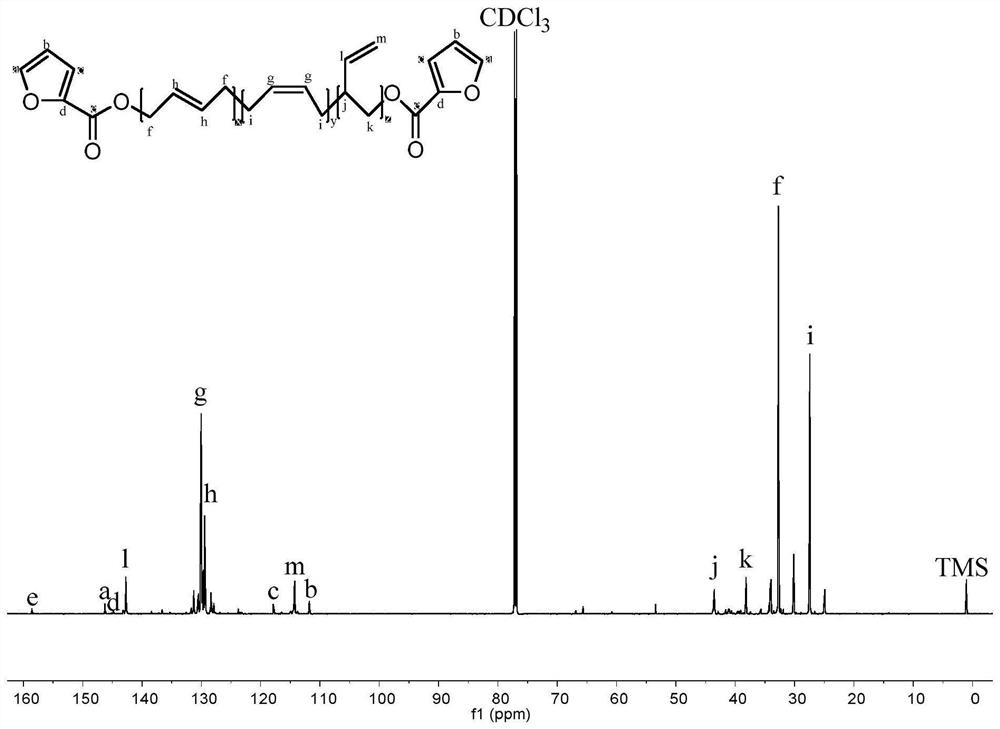

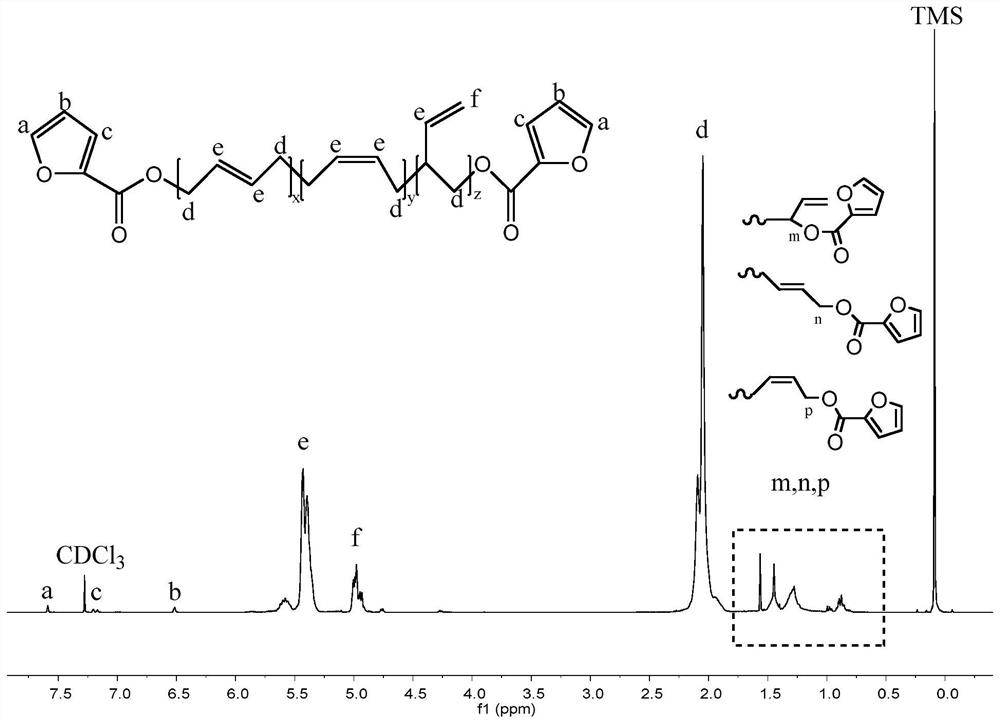

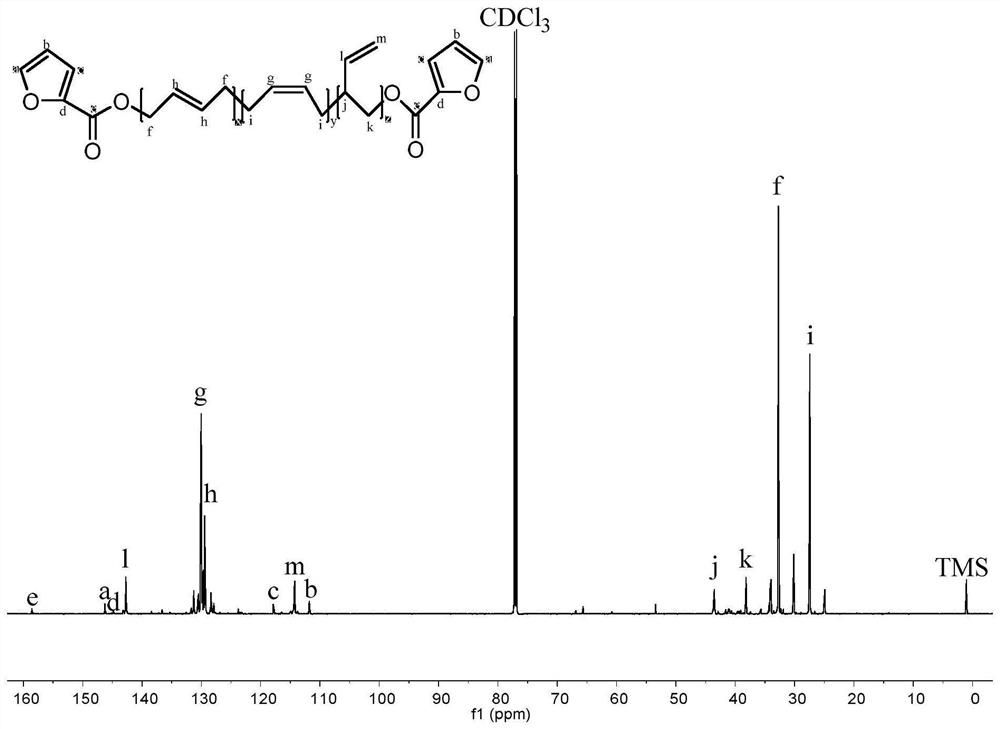

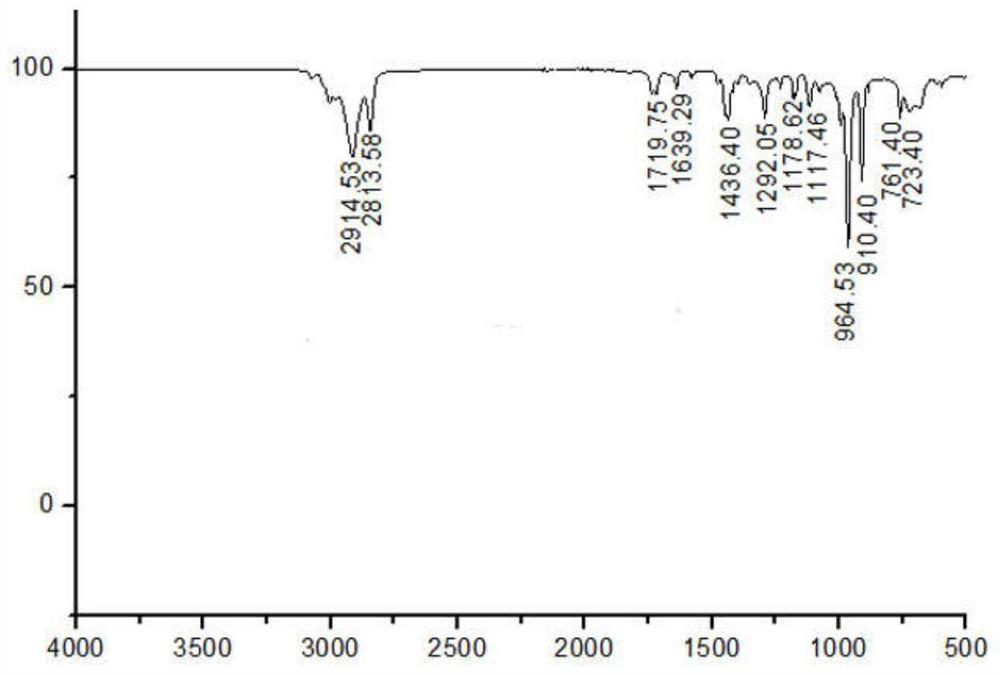

A kind of method for preparing terminal 2-furanoate group polybutadiene

ActiveCN112625151BGood catalyticImprove the efficiency of esterification reactionFuranPolymer science

The invention provides a method for preparing polybutadiene with 2-furanoic acid ester group, comprising the following steps: adding hydroxyl-terminated polybutadiene, 4-dimethylaminopyridine and an organic solvent into a reactor, stirring at room temperature fully Mix well; cool the mixture to 0°C, slowly add 2-furoyl chloride, then stir the reaction, the reaction temperature is 0°C~room temperature, and the reaction time is 1h~48h; the mixture is washed, dried, concentrated organic phase, and separated and purified by column chromatography Obtain product terminal 2-furanoate group polybutadiene. In the present invention, while using 4-dimethylaminopyridine as an acid-binding agent, the efficiency of the esterification reaction can be effectively improved, and the 2-furoyl chloride has high reactivity and low cost, and avoids the use of dicyclohexylcarbodiimide. The reaction operation and post-treatment in the invention are simple and safe, the yield is stable in the scale-up preparation process, and has great industrial application potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A method for preparing starch percarbonate under supercritical conditions

ActiveCN106519051BIncrease chances of effective contactImprove solubilityBulk chemical productionCarbonate esterCarboxylic acid

The invention relates to a method for preparing starch high carbonate ester under a supercritical condition. Starch is taken as a raw material, C8-C18 carboxylic acid or acid anhydride of the C8-C12 carboxylic acid is taken as an esterification modifying agent, caustic alkali is taken as a catalyst, an accessory ingredient of which the mass is 0.1-0.2 time of the mass of the starch is added into a supercritical CO2 media, and the starch high carbonate ester is prepared through supercritical esterification reaction. The degree of substitution of a starch high carbonate ester product is 0.01-0.50, and the reaction efficiency of an esterifying agent is 55-90%.

Owner:GUANGXI UNIV

Production method of biodiesel

ActiveCN103468413BReduce moistureEfficient separationFatty acid esterificationFatty acids production/refiningWater bathsDistillation

Owner:四川惠盛新能源有限公司

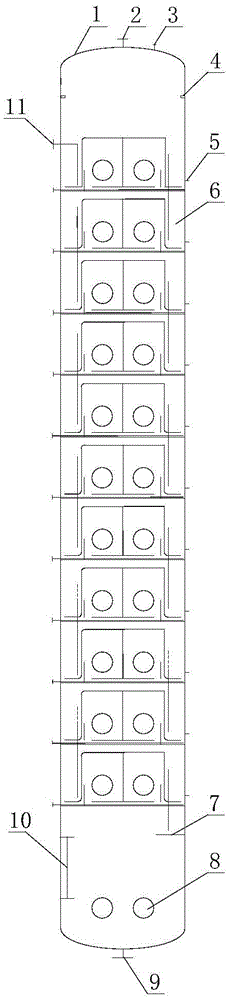

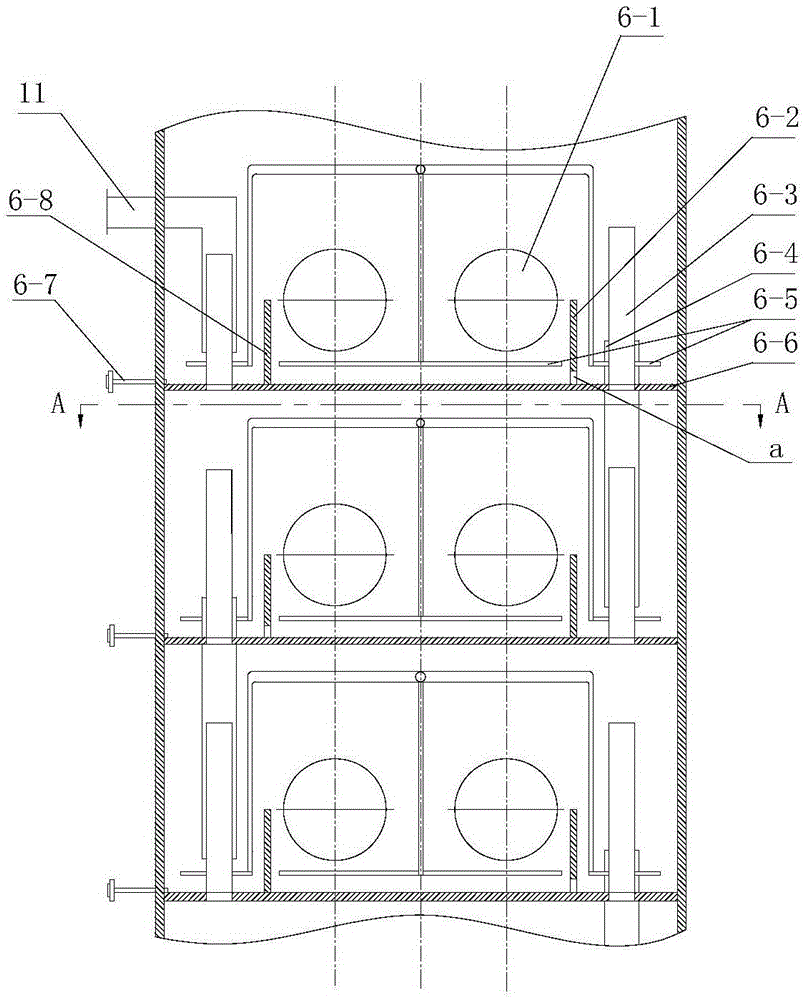

Biodiesel continuous esterification reaction tower

The invention provides a biodiesel continuous esterification reaction tower. A methyl alcohol outflow tube, a top pressure meter and a demister are arranged on the top of a reaction tower shell, a feed tube and 8-15 tower sections communicated with the feed tube are arranged in the middle of the reaction tower shell, temperature monitors are arranged on the outer walls of the tower sections, and a liquid baffle, tower bottom heaters, a liquid level and a diesel outflow tube are arranged at the bottom of the reaction tower shell. The biodiesel continuous esterification reaction tower has the advantages of being reasonable in design, continuous in esterification reaction, high in esterification reaction efficiency and raw material utilization rate and the like, and can be used for preparing biodiesel.

Owner:陕西合盛生物柴油技术开发有限公司

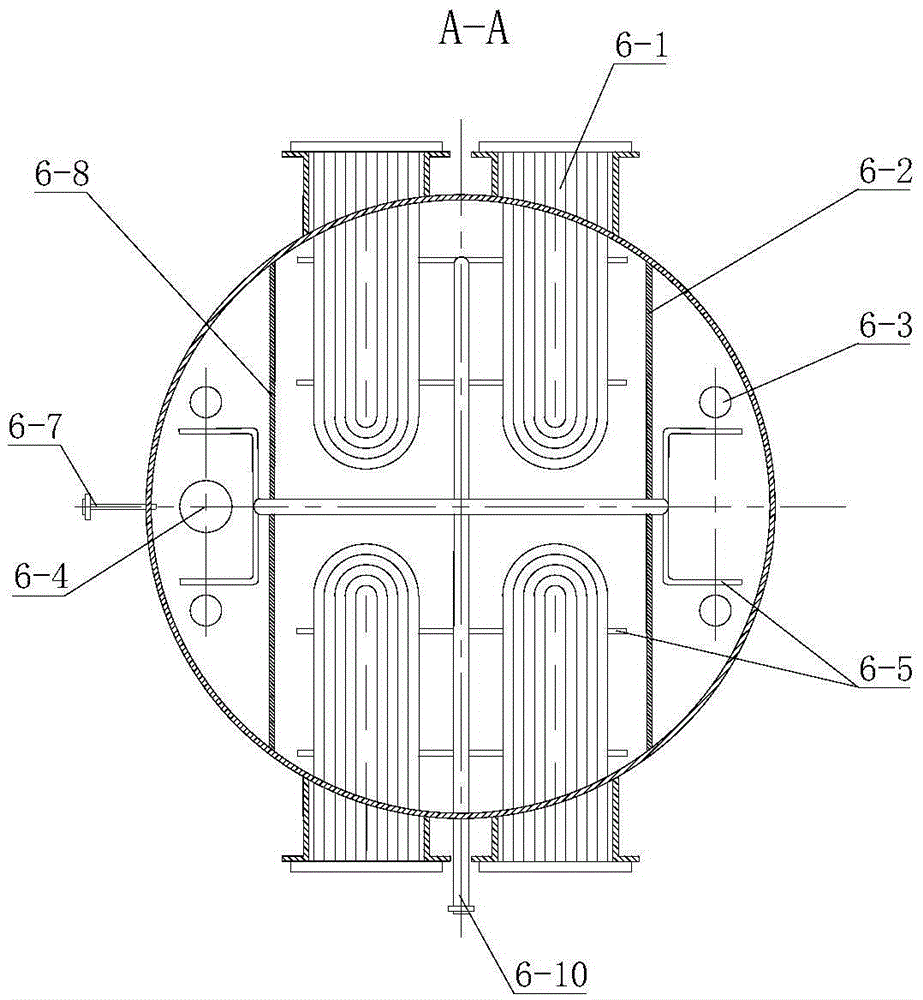

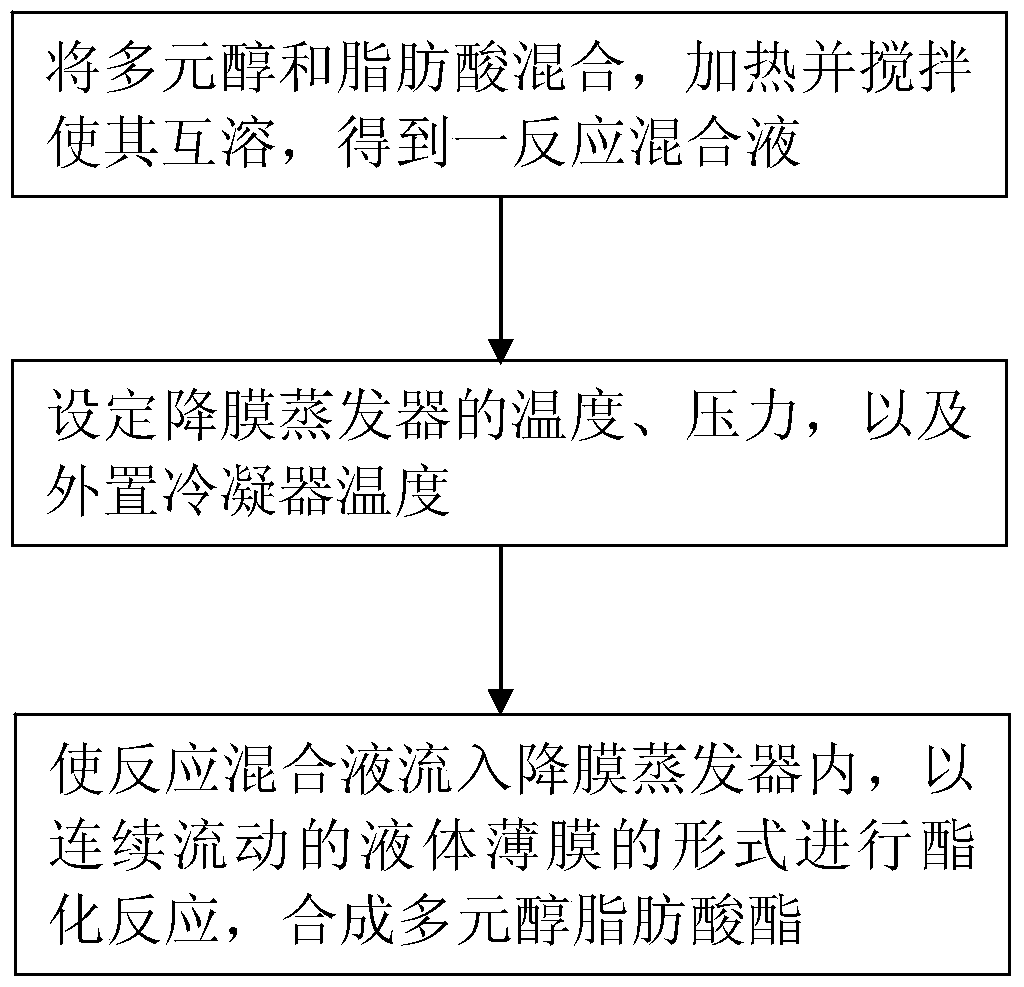

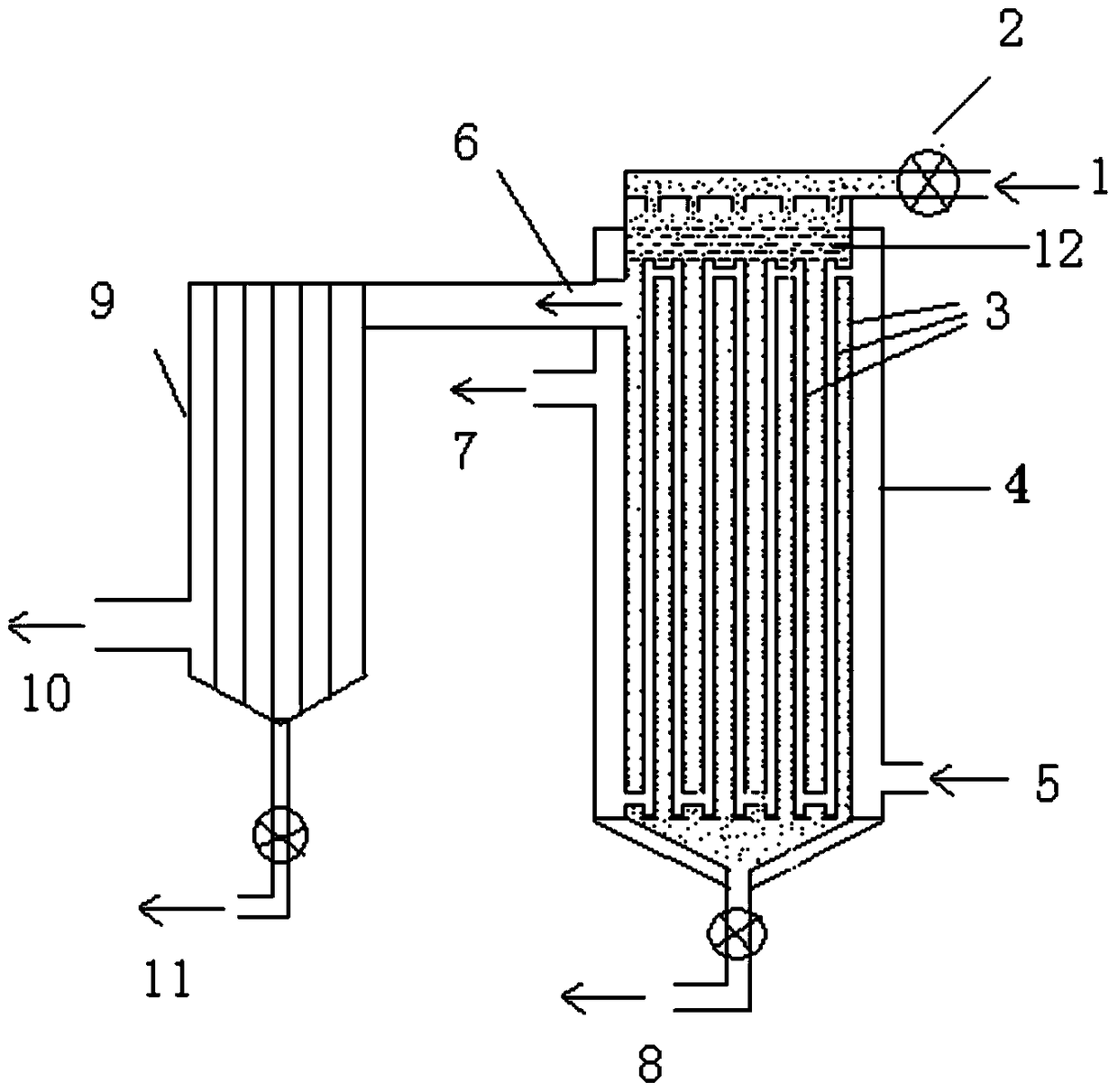

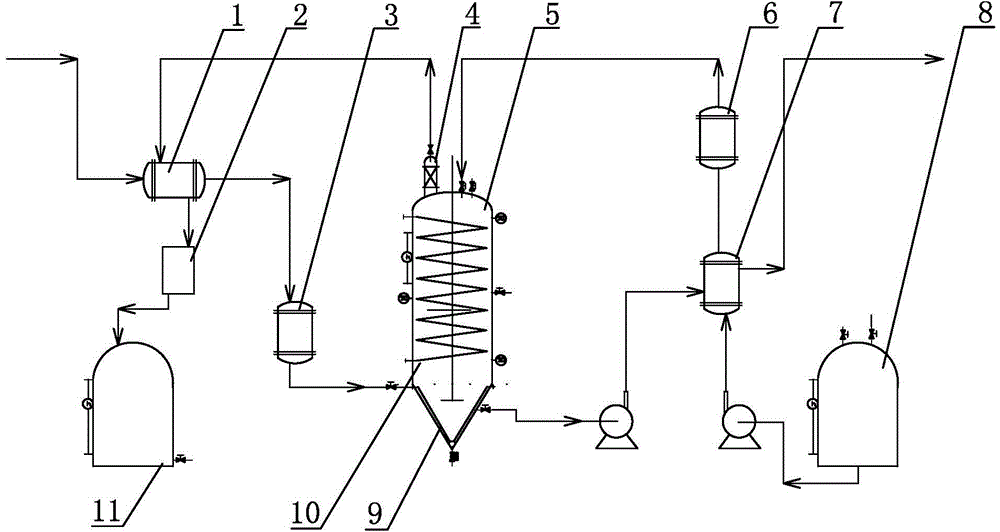

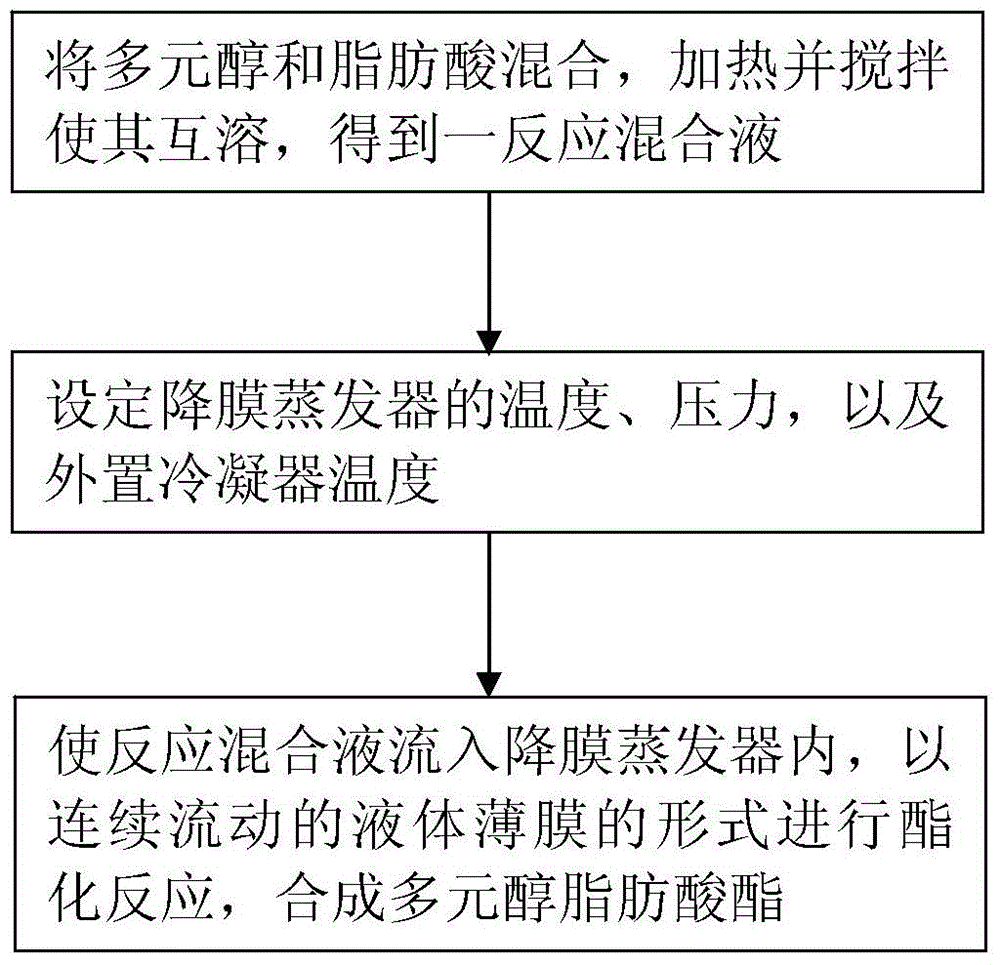

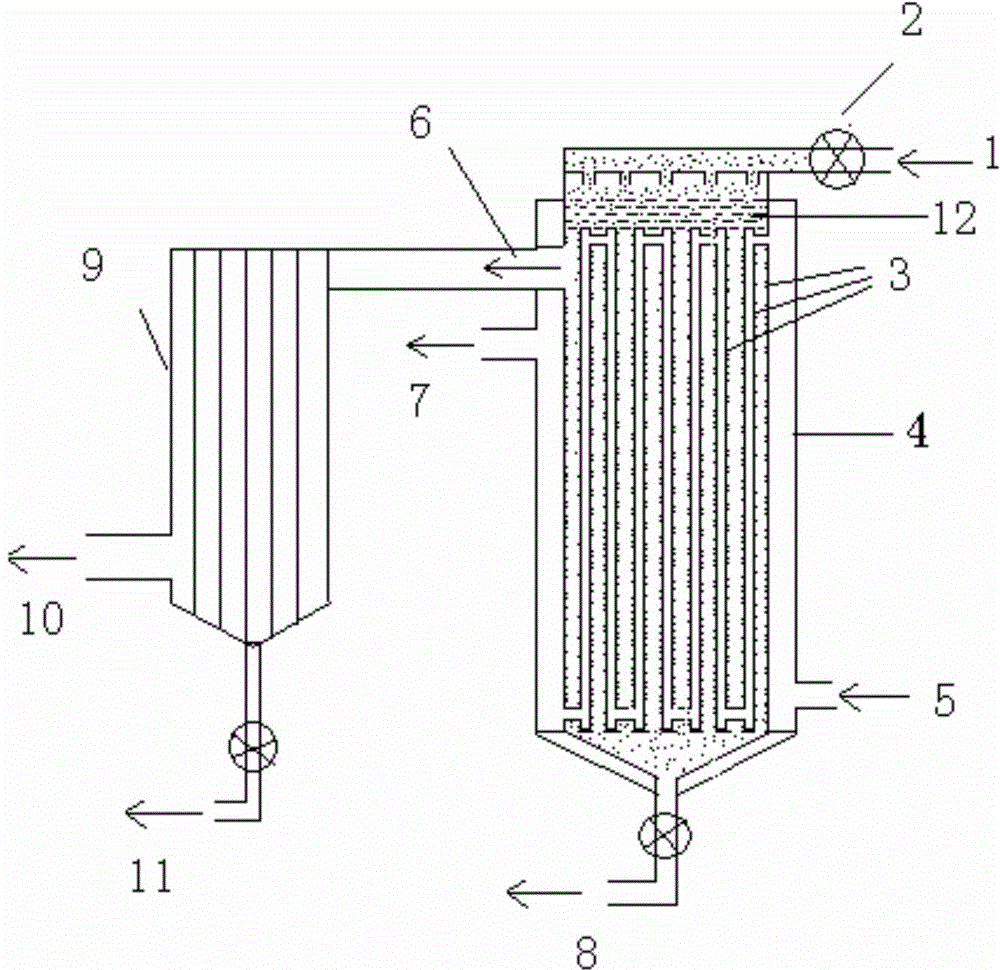

Method for Synthesizing Polyol Fatty Acid Ester Using Falling Film Evaporator

ActiveCN105732369BContinuous productionPromote escapeOrganic compound preparationCarboxylic acid esters preparationPolyolContinuous flow

The invention discloses a method for synthesizing polyol fatty acid ester by adopting a falling-film evaporator. The method comprises the following steps: mixing polyol and fatty acid in accordance with that the mole ratio of hydroxyl to carboxyl is 1: (1 to 1.6), carrying out heating and stirring so as to mutually dissolve the polyol and the fatty acid and obtain a reaction mixture solution; setting the temperature of the falling-film evaporator to 180 DEG C to 250 DEG C, setting the pressure to 5KPa to 60KPa, and setting the external condenser temperature to -20 DEG C to 30 DEG C; and enabling the reaction mixture solution to flow into the falling-film evaporator so as to form a continuous flowing liquid film, carrying out heating, and then, carrying out an esterification reaction so as to synthesize the polyol fatty acid ester. According to the method disclosed by the invention, the technical effects of high efficiency, environment-friendliness and environmental protection can be achieved.

Owner:PETROCHINA CO LTD

Esterification method for preparing biodiesel using waste oils and fats

ActiveCN103451027BA wide range of acid valuesReduce dosageFatty acid esterificationBiofuelsEthanesulfonic acidAlcohol

Provided is an esterification method for preparing biodiesel using waste oils and fats. Under the normal pressure condition, the mixture of methanesulfonic acid, ethanesulfonic acid or chlorosulfonic acid and erosion restraint agents is used as a catalyst, the using amount of the catalyst is little, the catalyst can be repeatedly used, erosion on equipment is small, through a demister arranged on the top of a reaction kettle, the utilization rate of raw oil and the yield coefficient of coarse methyl ester are improved, heat generated in the reaction process is used for preheating fine methyl alcohol and waste oils and fats, heat is circularly used, energy loss is reduced, methyl alcohol which is not reacted is recovered, and production cost is lowered. The acid value of raw materials of the esterification method is wide (15-180mgKOH / g), the reaction time is short, energy loss is little, production cost is low, the yield coefficient of coarse methyl ester is high, high-acid-value flora and fauna waste oils and fats are esterified in one time to be lower than 1mgKOH / g in acid value, the next transesterification can be directly carried out to prepare biodiesel, and the method is suitable for producing biodiesel in an industrial mode.

Owner:四川惠盛新能源有限公司

A kind of synthetic method of polyglycerol-10 oleate

ActiveCN104496803BHigh polymerization efficiencyEfficient synthesisOrganic compound preparationCarboxylic acid esters preparationEsterification reactionON-glycerol

The invention relates to a synthetic method of polyglycerol-10 oleate. The synthetic method sequentially comprises the following steps: (1) carrying out polymerization reaction on glycerol under catalysis of a combined catalyst A to obtain polyglycerol-10, wherein the combined catalyst A is prepared from 5-55% of NaOH, 5-55% of KOH, 5-15% of MgO and 5-25% of Al2O3; and (2) carrying out esterification reaction on polyglycerol-10 and oleic acid under catalysis of a combined catalyst B to obtain the polyglycerol-10 oleate, wherein the combined catalyst B is prepared from 5-35% of NaOH, 25-85% of KOH, 5-15% of MgO and 5-25% of Al2O3. According to the synthetic method provided by the invention, the glycerol polymerization reaction and esterification reaction efficiencies can be greatly enhanced, so that polyglycerol-10 oleate is efficiently synthesized. The yield can be improved, and the product purity is improved.

Owner:广东添乐化妆品有限公司

A kind of method of synthesizing tributyl citrate

ActiveCN104447306BLow costImprove the efficiency of esterification reactionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsFiltrationDistillation

The invention discloses a method for synthesizing tributyl citrate. The method comprises the following steps: I, preparing a choline chloride acidic ionic liquid; II, performing esterification reaction; III, filtering the reaction system after reaction, thereby obtaining solid choline chloride and a liquid phase product; and IV, performing atmospheric distillation on the liquid phase product, washing residues generated after atmospheric distillation by using an alkali solution, adding activated carbon to decolor, filtering to remove the activated carbon, performing reduced pressure distillation on residues generated after filtration, and collecting fraction of 197-200 DEG C, thereby obtaining tributyl citrate. According to the method, choline chloride and citric acid are adopted to synthesize the acidic ionic liquid, the synthesized acidic ionic liquid is both a raw material and a catalyst, the acidic ionic liquid has esterification reaction with n-butyl alcohol to synthesize n-butyl alcohol, the efficiency of the esterification reaction is improved, the conversion rate can be greater than 90%, the choline chloride after esterification can be recycled and utilized, and the cost is low.

Owner:XIAN ORIGIN CHEM TECH

Method for preparing 2-furancarboxylic acid ester-terminated polybutadiene

The invention provides a method for preparing 2-furancarboxylic acid ester-terminated polybutadiene. The method comprises the following steps: adding hydroxyl-terminated polybutadiene, 4-dimethylaminopyridine and an organic solvent into a reactor, and conducting sufficient stirring at room temperature to realize uniform mixing; cooling a mixture to 0 DEG C, slowly adding 2-furoyl chloride, and then conducting stirring for a reaction at a reaction temperature of 0 to room temperature for 1-48 hours; and washing the mixture, conducting drying, concentrating an organic phase, and carrying out column chromatography separation and purification to obtain the product, namely 2-furancarboxylic acid ester-terminated polybutadiene. According to the invention, while 4-dimethylaminopyridine is used as an acid-binding agent, esterification reaction efficiency can be effectively improved; the reaction activity of 2-furoyl chloride is high, the cost of 2-furoyl chloride is low, and the use of dicyclohexylcarbodiimide is avoided; and reaction operation and post-treatment are simple, convenient and safe, yield is stable in an amplified preparation process, and the method has great industrial application potential.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Catalytic esterification method of oil with high acid value

InactiveCN101838591BImprove reaction efficiencyExtend your lifeFatty acid esterificationLiquid carbonaceous fuelsOil and greaseGlycerol

Owner:XIAMEN UNIV

Synthesis method of neopentyl glycol dibenzoate

PendingCN113402386AImprove the efficiency of esterification reactionHigh yieldOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsBenzoic acidPtru catalyst

The invention discloses a synthesis method of neopentyl glycol dibenzoate, which comprises the following steps: adding water into solid neopentyl glycol for dissolving or introducing water vapor for liquefying to obtain a neopentyl glycol solution; mixing the neopentyl glycol solution, a catalyst and benzoic acid, introducing nitrogen, evaporating water, then raising the temperature to 160-255 DEG C, carrying out esterification reaction for 5-10 hours, and after the esterification reaction is finished, carrying out decoloration, neutralization, water washing, dehydration, filtration and cooling to obtain neopentyl glycol dibenzoate. Water is added as a medium, and a two-step esterification method is used, so that the color number of a product can be reduced, and the esterification reaction efficiency is improved; the method is simple in process, short in production period, high in product yield, small in color number, energy-saving, environment-friendly and easy to realize industrialization.

Owner:武汉亿科德精细化工有限公司

Method for synthesizing polyol fatty acid ester by adopting falling-film evaporator

ActiveCN105732369AContinuous productionPromote escapeOrganic compound preparationCarboxylic acid esters preparationPolyolContinuous flow

The invention discloses a method for synthesizing polyol fatty acid ester by adopting a falling-film evaporator. The method comprises the following steps: mixing polyol and fatty acid in accordance with that the mole ratio of hydroxyl to carboxyl is 1: (1 to 1.6), carrying out heating and stirring so as to mutually dissolve the polyol and the fatty acid and obtain a reaction mixture solution; setting the temperature of the falling-film evaporator to 180 DEG C to 250 DEG C, setting the pressure to 5KPa to 60KPa, and setting the external condenser temperature to -20 DEG C to 30 DEG C; and enabling the reaction mixture solution to flow into the falling-film evaporator so as to form a continuous flowing liquid film, carrying out heating, and then, carrying out an esterification reaction so as to synthesize the polyol fatty acid ester. According to the method disclosed by the invention, the technical effects of high efficiency, environment-friendliness and environmental protection can be achieved.

Owner:PETROCHINA CO LTD

Preparation method of starch octenyl succiniade under supercritical condition

ActiveCN102367280BGuaranteed food safetyPenetrate fastBulk chemical productionChemical synthesisImpurity

The invention discloses a preparation method of starch octenyl succiniade under the supercritical condition. The method comprises the following steps: simultaneously performing an oxidation reaction and an esterification reaction using starch as a raw material, hydrogen peroxide or sodium hypochlorite as an oxidant, ocentyl succinic anhydride as an esterifying agent and supercritical CO2 as a reaction medium under stirring to obtain an esterification product; and extracting the esterification product with supercritical CO2 to obtain the purified powdery starch octenyl succiniade of which viscosity is 5-25mPa.s (6%, 95 DEG C) and degree of substitution is 0.005-0.12. The invention provides an environmentally-friendly green chemical synthesis method; and the method has the advantages of lowimpurity content, high reaction efficiency, good product quality and the like.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com