Device for producing biodiesel from waste edible oil

A biodiesel and waste oil technology, applied in biofuel, petroleum industry, fatty acid esterification, etc., can solve the problems of incomplete utilization of catering waste oil, difficulty in industrialized production, and low biodiesel output, and achieve The effect of alleviating the energy crisis, high production efficiency, and improving the efficiency of esterification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

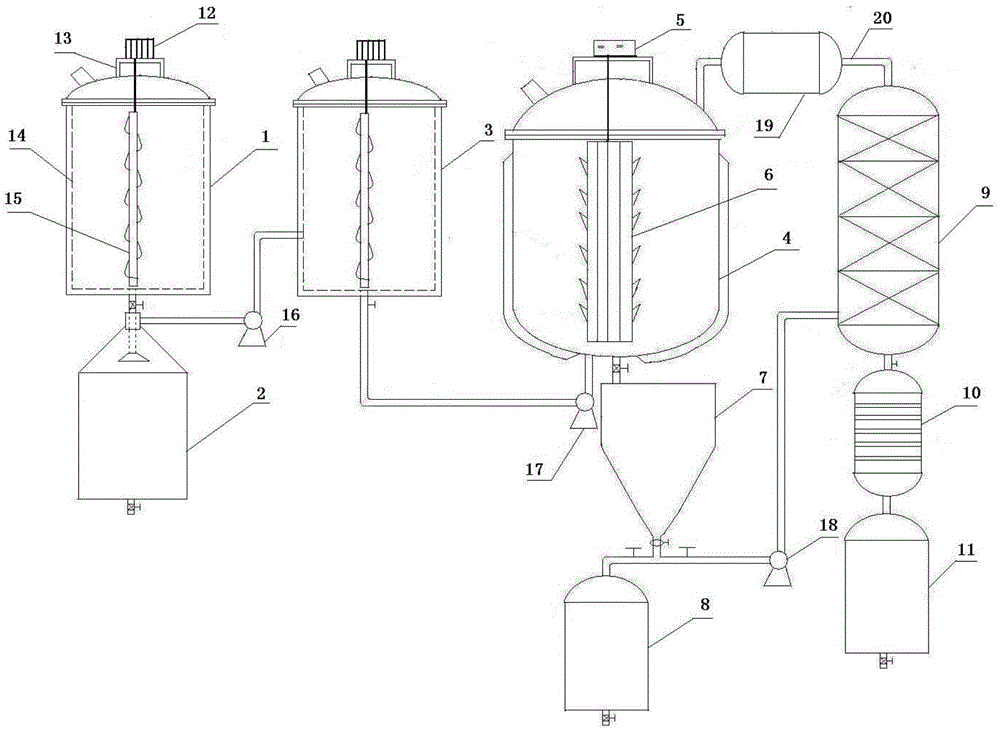

[0021] As shown in Figure 1, the device for producing biodiesel by using waste catering oils and fats includes a solid-liquid separation tank 1, an oil-water separator 2, an impurity removal tank 3, an esterification tank 4, a phase separator 7 and a rectification tank 9 The bottom of the solid-liquid separation tank 1 is connected to the oil-water separator 2, and the oil-water separator 2 is connected to the impurity removal tank 3 through the liquid pump I16, and the above solid-liquid separation tank 1 and the impurity removal tank 3 are respectively provided with stirring motors 12 , the stirring motor 12 is respectively fixed on the solid-liquid separation tank 1 and the impurity removal tank 3 through the bracket 13, and the stirring motor 12 is also connected with the stirring shaft 15 respectively, and the bottom of the impurity removal tank 3 is connected with the esterification by the liquid pump II17 The tank 4 is connected, and the bottom of the esterification tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com