Emulsifier for stabilizing food emulsion system and its preparation method

An emulsifier and food technology, applied in food preparation, food science, application, etc., can solve the problems of unsustainable stability of food emulsion system, weak emulsification effect, no emulsification effect, etc., so as to achieve difficult and continuous rupture , the effect of large cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] EIRSSOS: Early Indica Rice Starch 1000kg

[0026] Octenyl succinic anhydride 30kg

[0027] Water 3500kg

[0028] Catalyst NaOH 0.525kg

[0029] Preparation method: mix 1000kg early indica rice starch (dry basis) with 3500kg water, stir at 3000 rpm (1 meter diameter of stirring blade) for 2 hours to make an emulsion, adjust the pH value of the emulsion to 8.0 with 0.525kg NaOH, and then add 30kg Add OSA within 1 hour, and keep stirring at 3000 rpm (1 meter in diameter of stirring blade) during this period. Thereafter, the esterification reaction was carried out for 6 hours. During the esterification reaction, stirring was maintained at 3000 rpm (the diameter of the stirring blade was 1 meter), the temperature was maintained at 30-32° C., and the pH value was maintained at 8.0 with 1M NaOH. After the reaction, adjust the pH value of the reaction solution to 7.0 with 1M HCl, then wash away NaCl and unreacted OSA with water, centrifuge at 3000 ...

Embodiment 2

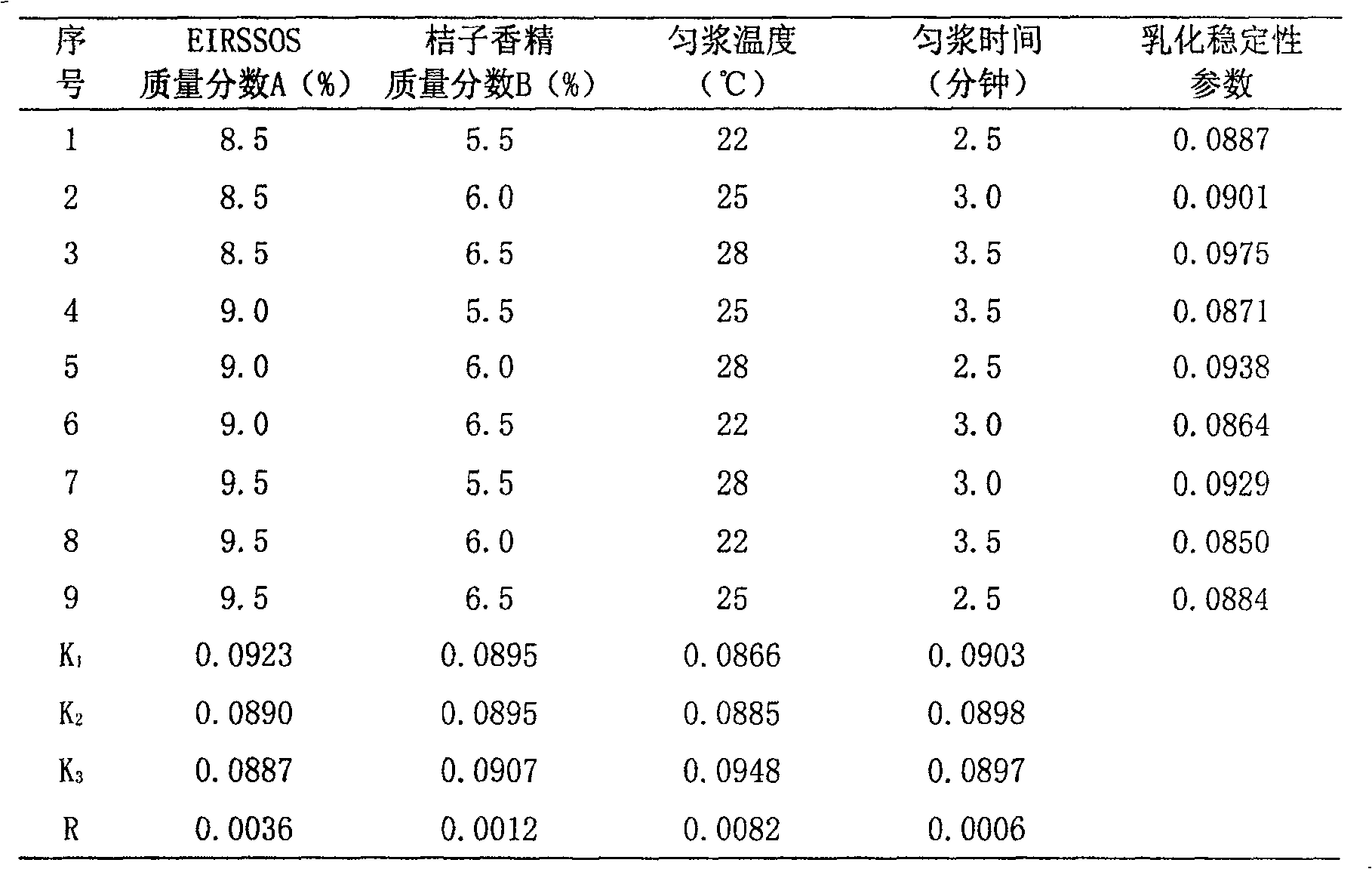

[0030] Example 2: Application of EIRSSOS in almond milk ice cream milky gel system

[0031] Comparison of the stabilizing effect of EIRSSOS with gelatin, xanthan gum, locust bean gum and carrageenan on the opacity gel system of almond milk ice cream. The formula of almond milk ice cream is: 10 parts of almond milk, 6 parts of skimmed evaporated milk powder, 7 parts of margarine, 14 parts of granulated sugar, 8 parts of starch syrup, 0.1 part of almond essence, and 54.9 parts of water. Add 10g each of EIRSSOS, gelatin, xanthan gum, locust bean gum, and carrageenan to 1000g of ice cream. The stability of almond milk ice cream is as follows:

[0032] Proportion

Embodiment 3

[0033] Embodiment 3: EIRSSOS substitution degree determination

[0034] Product performance is determined by the degree of substitution, and high substitution reaction efficiency helps reduce costs.

[0035] Determination of degree of substitution: Accurately weigh 2.0g of EIRSSOS and place it in a 250mL beaker, wet it with 10mL of pure isopropanol, add 15mL of 2.5mol / L hydrochloric acid in isopropanol, stir magnetically for 30 minutes, then add 50mL of 90% ( Prepared by weight percentage) isopropanol solution, and continued to stir for 10 minutes. The sample was transferred to a Buchner funnel, washed with 90% isopropanol until there was no Cl- (checked with 0.1 mol / L silver nitrate). Then transfer the sample into a 500mL beaker, add distilled water to 300mL, bathe in boiling water for 20 minutes, add 2 drops of phenolphthalein, and titrate with 0.1mol / L NaOH while hot until pink. The formula for calculating the degree of substitution (DS) is as follows: degree of substitut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com