Method for synthesizing tributyl citrate

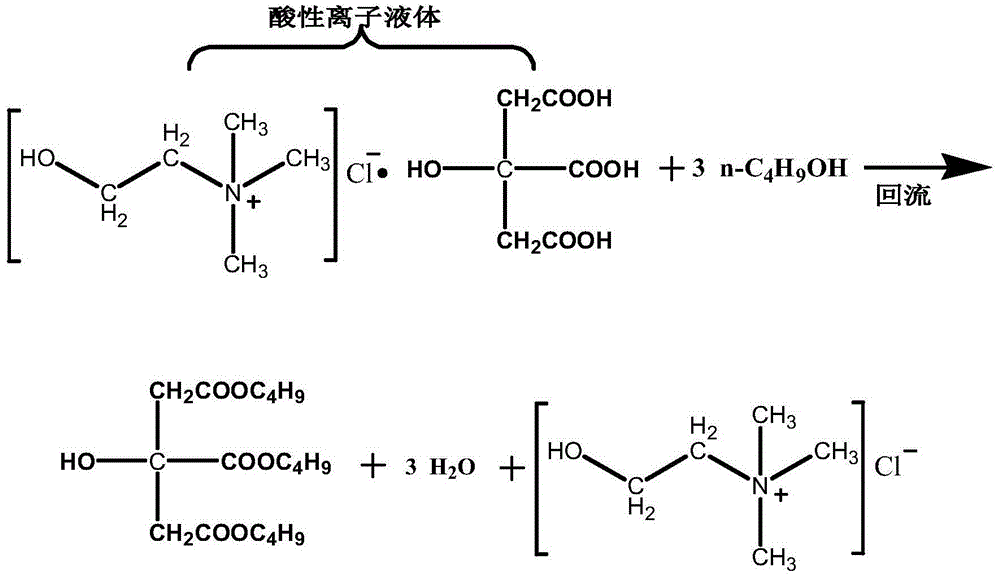

A technology of tributyl citrate and citric acid, applied in the preparation of carboxylate, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of high cost, toxicity and degradability of ionic liquids, and achieve short reaction time. , low cost, mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

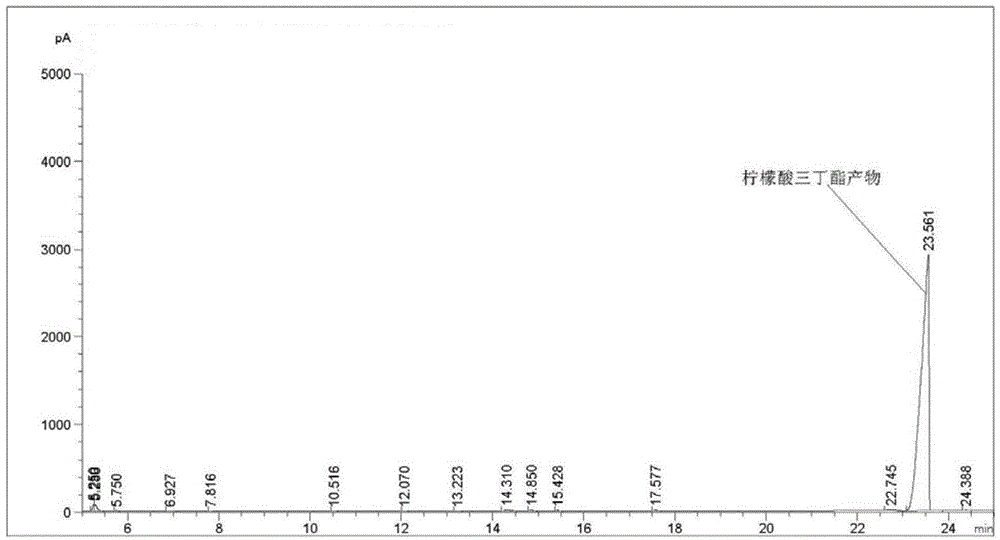

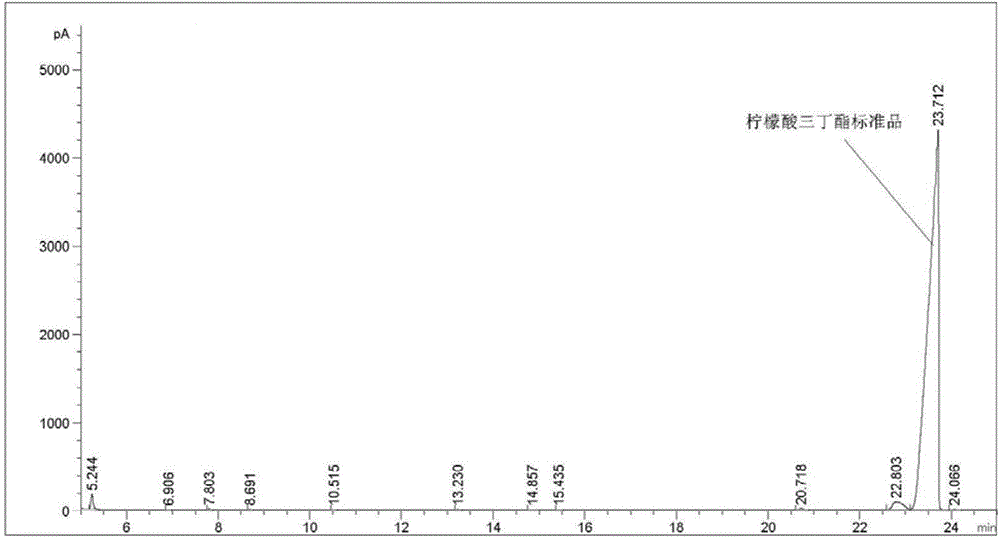

Image

Examples

Embodiment 1

[0028] Step 1. Preparation of choline chloride acidic ionic liquid: add 0.5 mol choline chloride to a 500 mL flask, then add 0.5 mol citric acid, and heat and stir for 1.5 hours at a temperature of 100°C under a nitrogen atmosphere , And obtain choline chloride acid ionic liquid after cooling;

[0029] Step 2. Esterification reaction: Add 2.0 mol of n-butanol and the choline chloride acid ionic liquid described in step 1 to a four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and water separator, and heat to reflux with stirring , The water produced by the reaction is separated from the water trap, and the reaction is stopped when the reaction reaches no water and then enters the water trap, and choline chloride precipitates out of the reaction system; the temperature of heating, reflux and stirring is 110°C, and the stirring rate 1500rpm;

[0030] Step 3. Separation of choline chloride: filter the reaction system after the reaction in step 2 to obt...

Embodiment 2

[0033] The methods of Example 2 and Example 3 are the same as Example 1, except that the molar amount of citric acid is 0.25 mol and 1 mol, respectively, and the molar amount of n-butanol is 1 mol and 4 mol, respectively, as shown in Table 1.

[0034] Table 1 Conversion rate and yield of Example 1 to Example 3

[0035] Example

Embodiment 4

[0037] Step 1. Preparation of choline chloride-based acidic ionic liquid: add 0.5 mol of choline chloride to a 500 mL flask, then add 0.25 mol of citric acid, and heat and stir under a nitrogen atmosphere at a temperature of 120°C for 1 hour. Obtain choline chloride acid ionic liquid after cooling;

[0038] Step 2. Esterification reaction: Add 1.0 mol of n-butanol and the choline chloride acid ionic liquid described in step 1 to a four-necked flask equipped with mechanical stirring, thermometer, reflux condenser and water separator, and heat to reflux with stirring , The water produced by the reaction is separated from the water trap, and the reaction is stopped when the reaction reaches no water and then enters the water trap, and choline chloride precipitates out of the reaction system; the temperature of heating, reflux and stirring is 160°C, and the stirring rate Is 800rpm;

[0039] Step 3. Separation of choline chloride: filter the reaction system after the reaction in step 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com