Multi-zone adaptive temperature control device applied to esterification reaction

A technology of esterification reaction and temperature control device, which is applied in the direction of temperature control by electric method, temperature control, auxiliary controller with auxiliary heating device, etc., which can solve the temperature difference in the tubular reactor and the temperature fluctuation of the catalyst bed Large, affecting the yield of ester products and catalyst life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

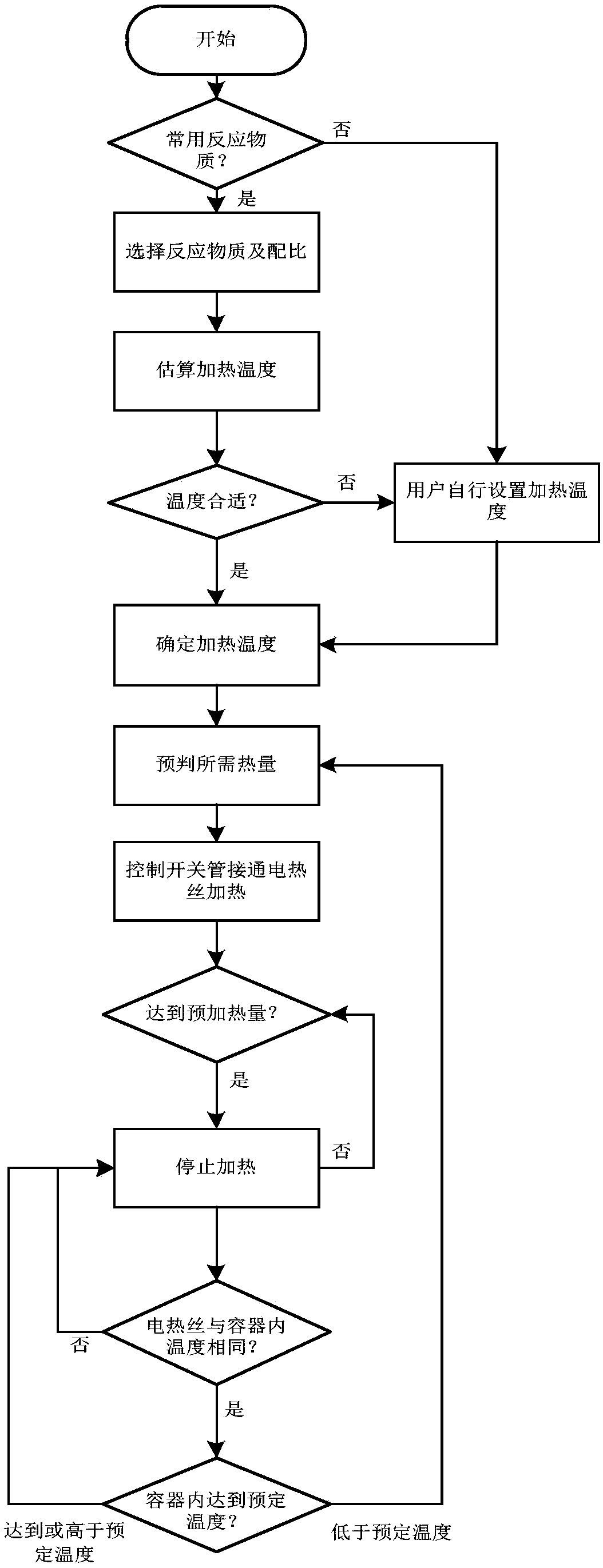

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

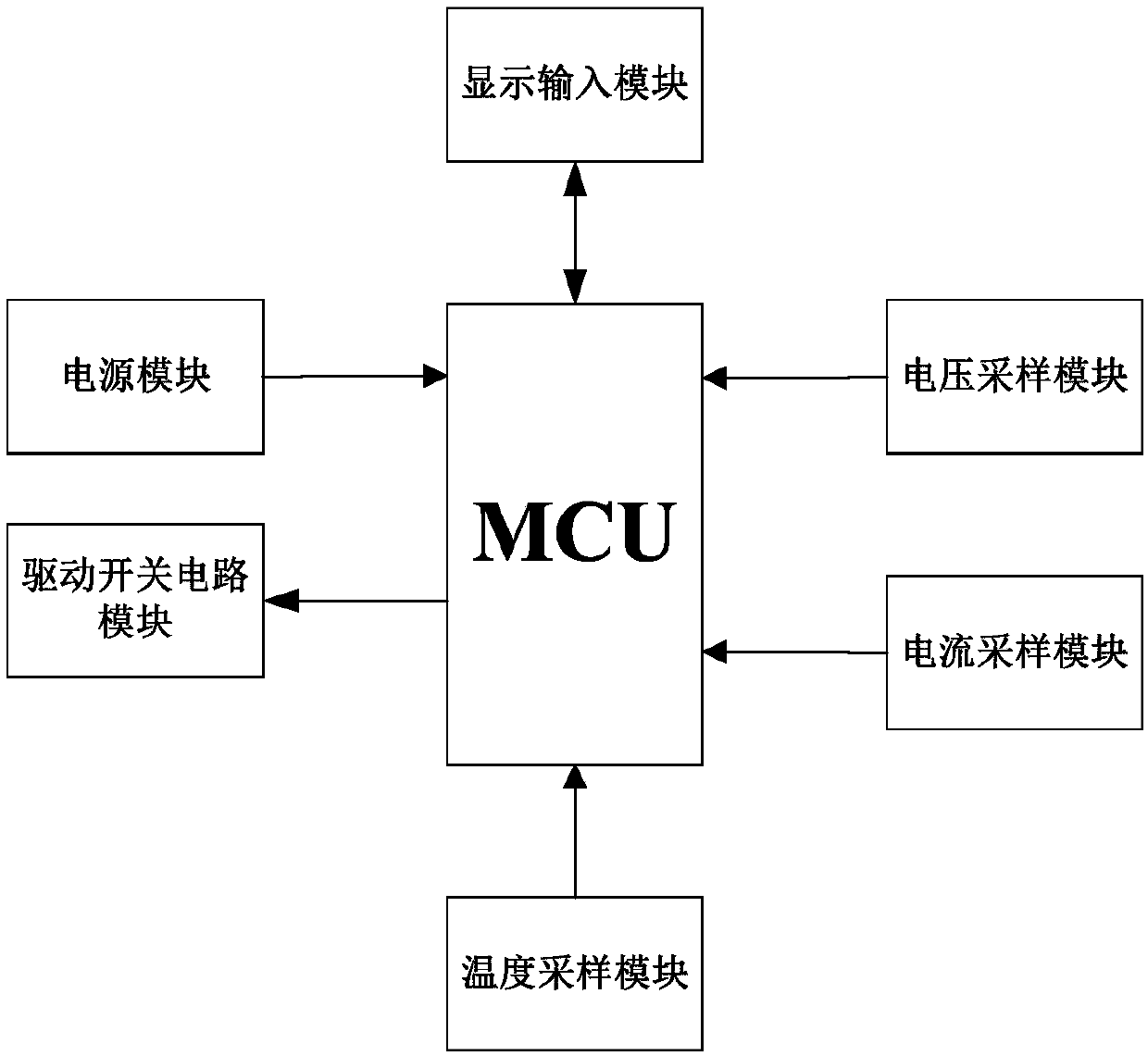

[0022] Such as figure 1 Shown is the hardware structural diagram of the present invention.

[0023] A multi-region self-adaptive temperature control device applied to esterification reaction of the present invention comprises an MCU (microcontroller) module, a temperature sampling module, a current sampling module, a voltage sampling module, a drive switch circuit module, a display input module and a power supply module; it is characterized in that the temperature sampling module is used to collect the temperature of the tubular reactor and the heating wire; the heating wire is a three-section independently controlled heating wire using direct current as a power supply; the current sampling module and The voltage sampling module is connected with the heating wire to collect the current and voltage of the heating wire; the MCU (micro-controlle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com