Patents

Literature

125results about How to "Evenly cooled" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

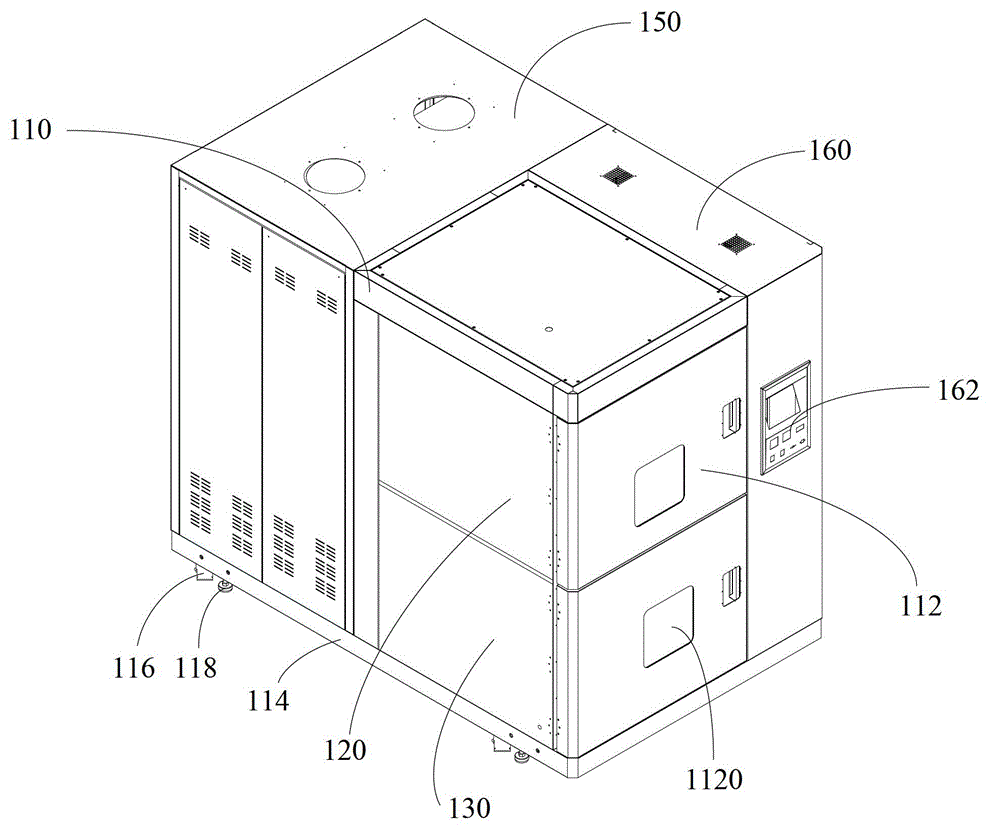

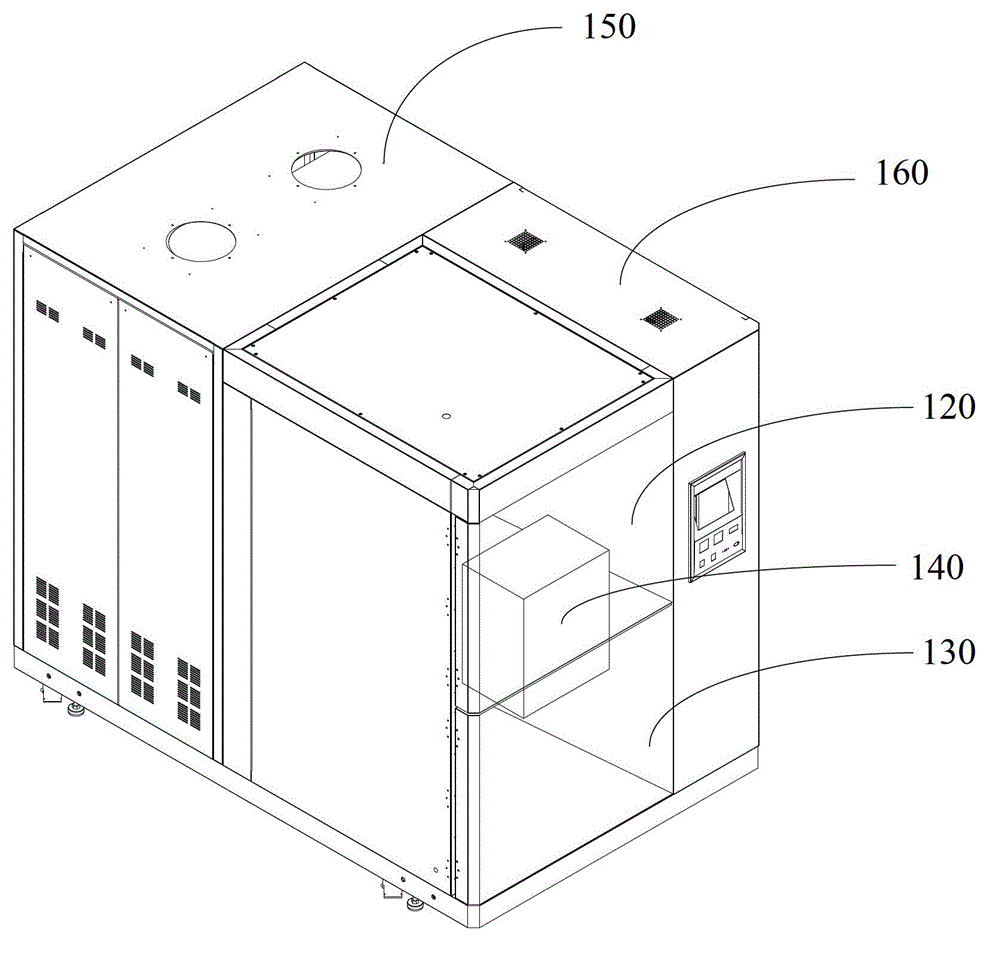

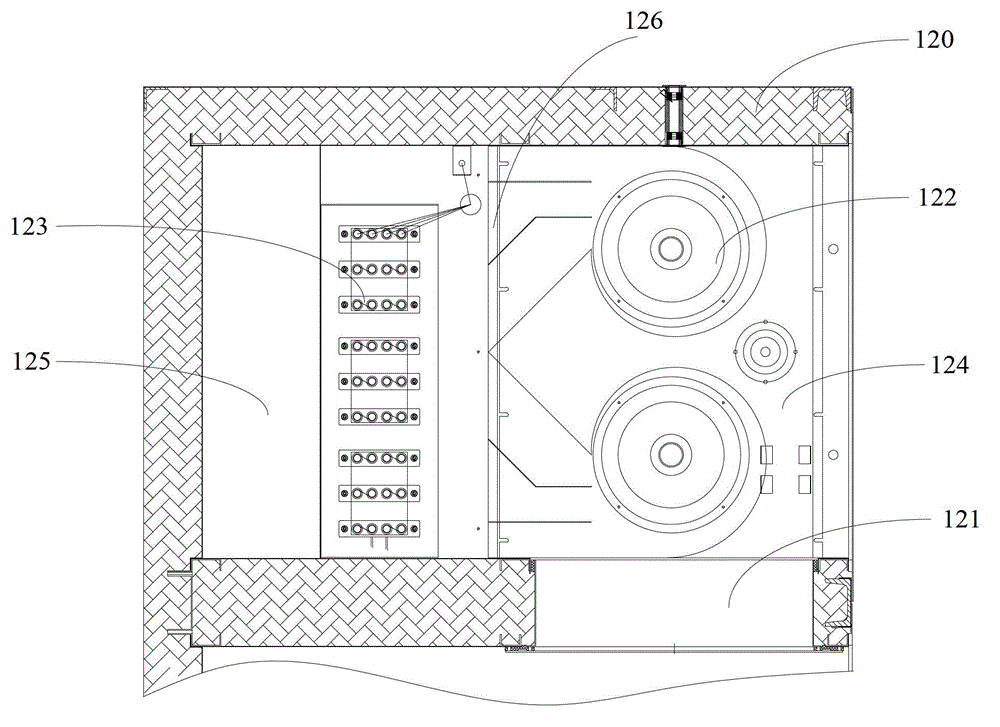

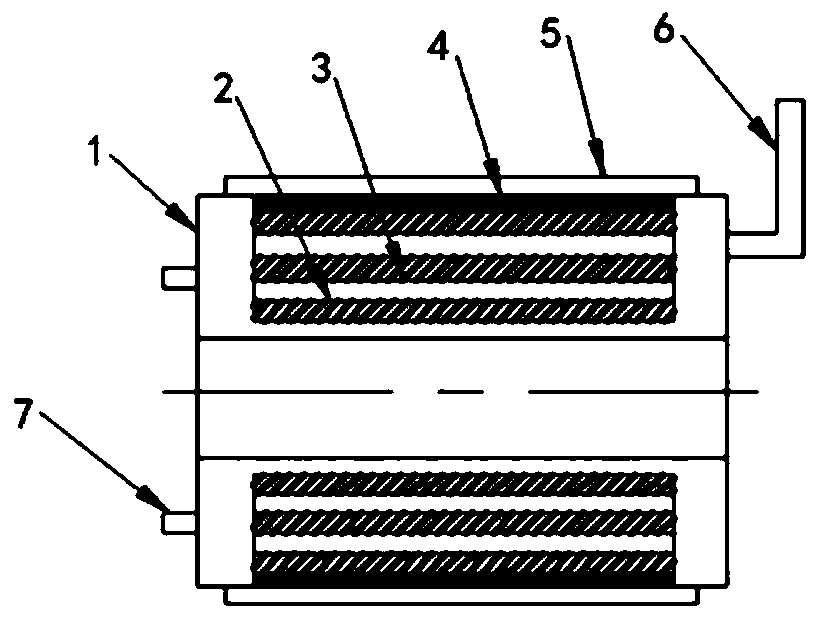

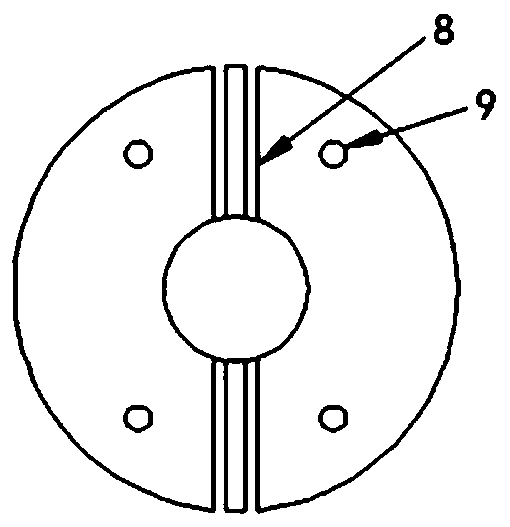

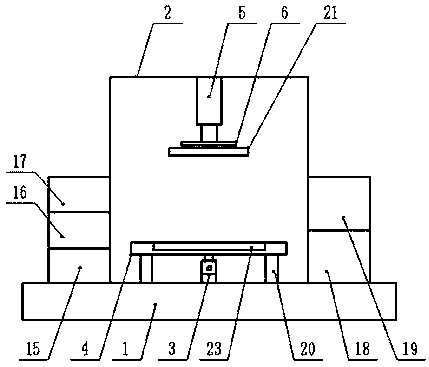

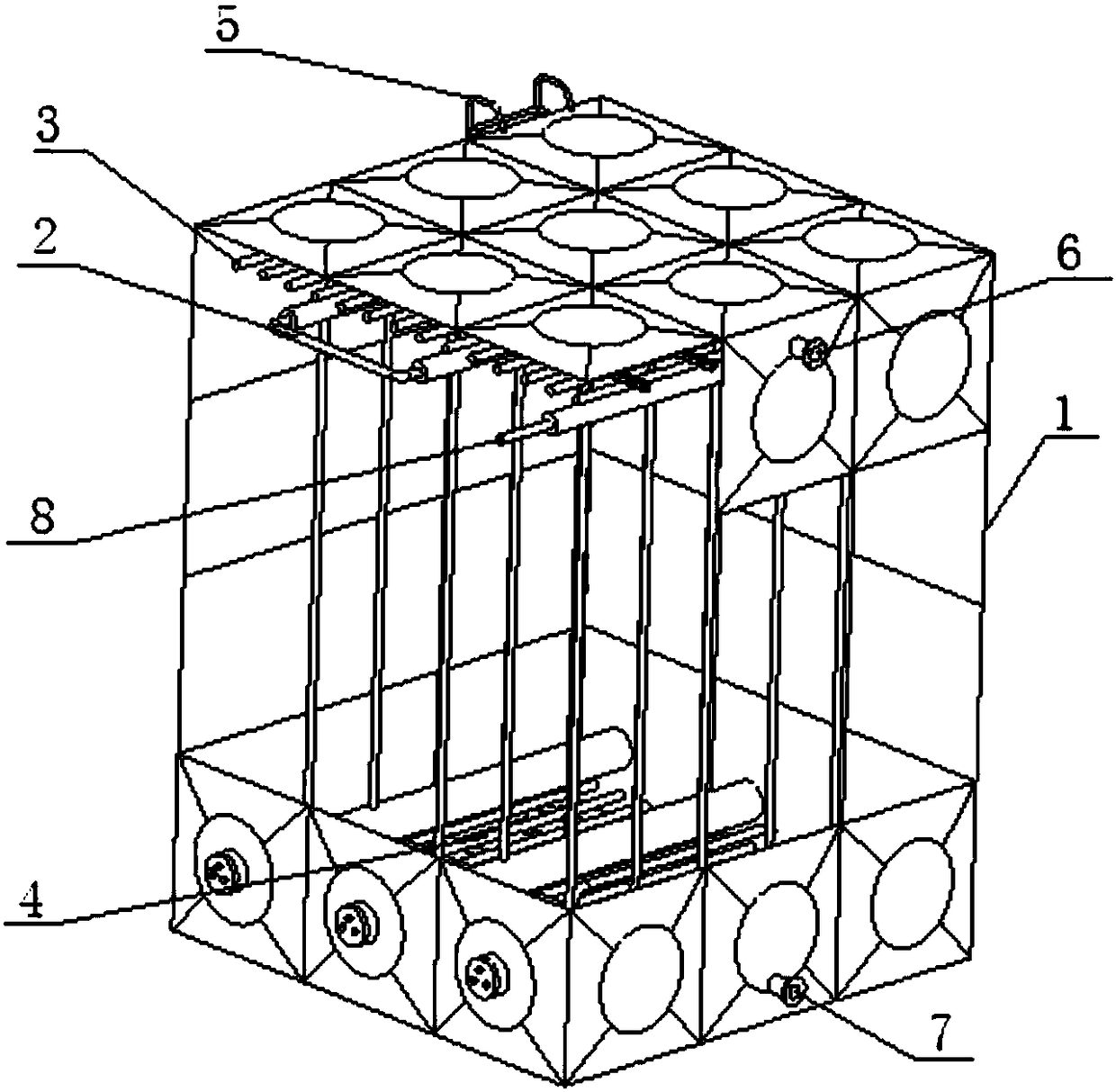

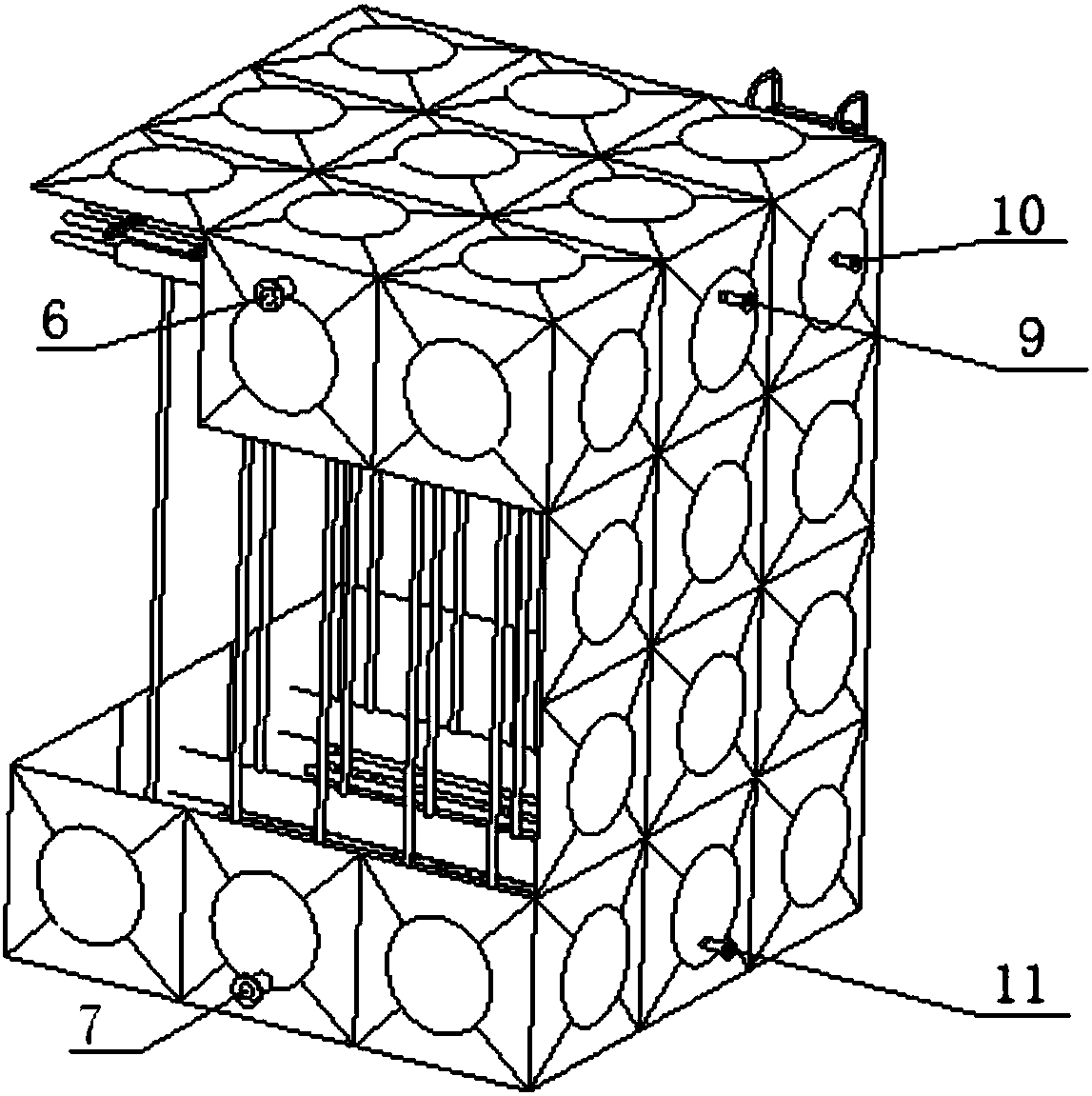

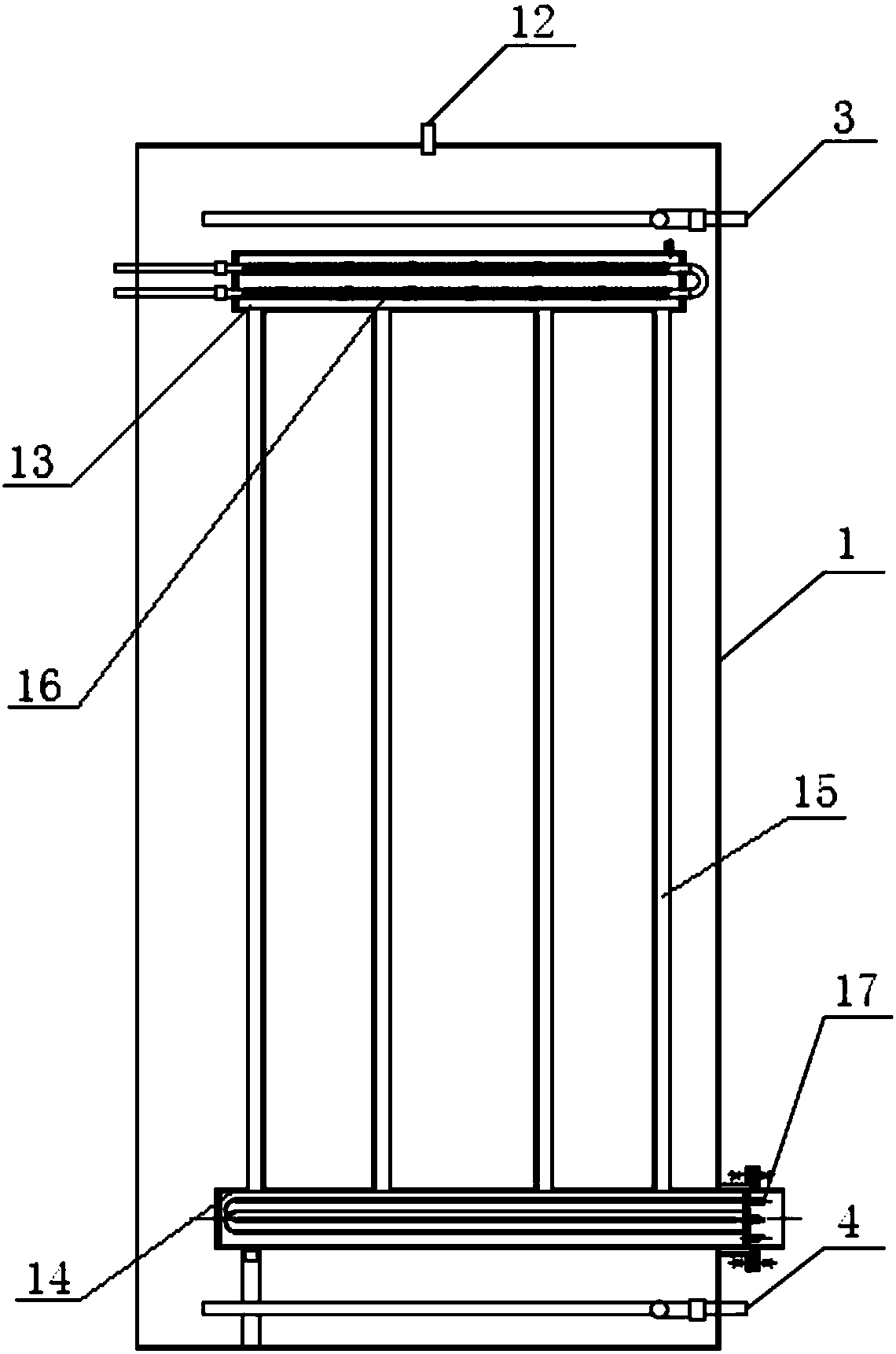

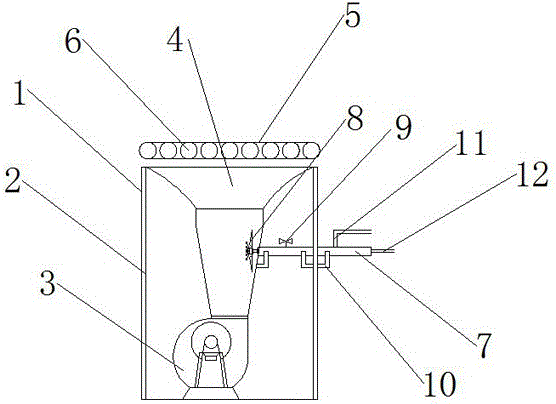

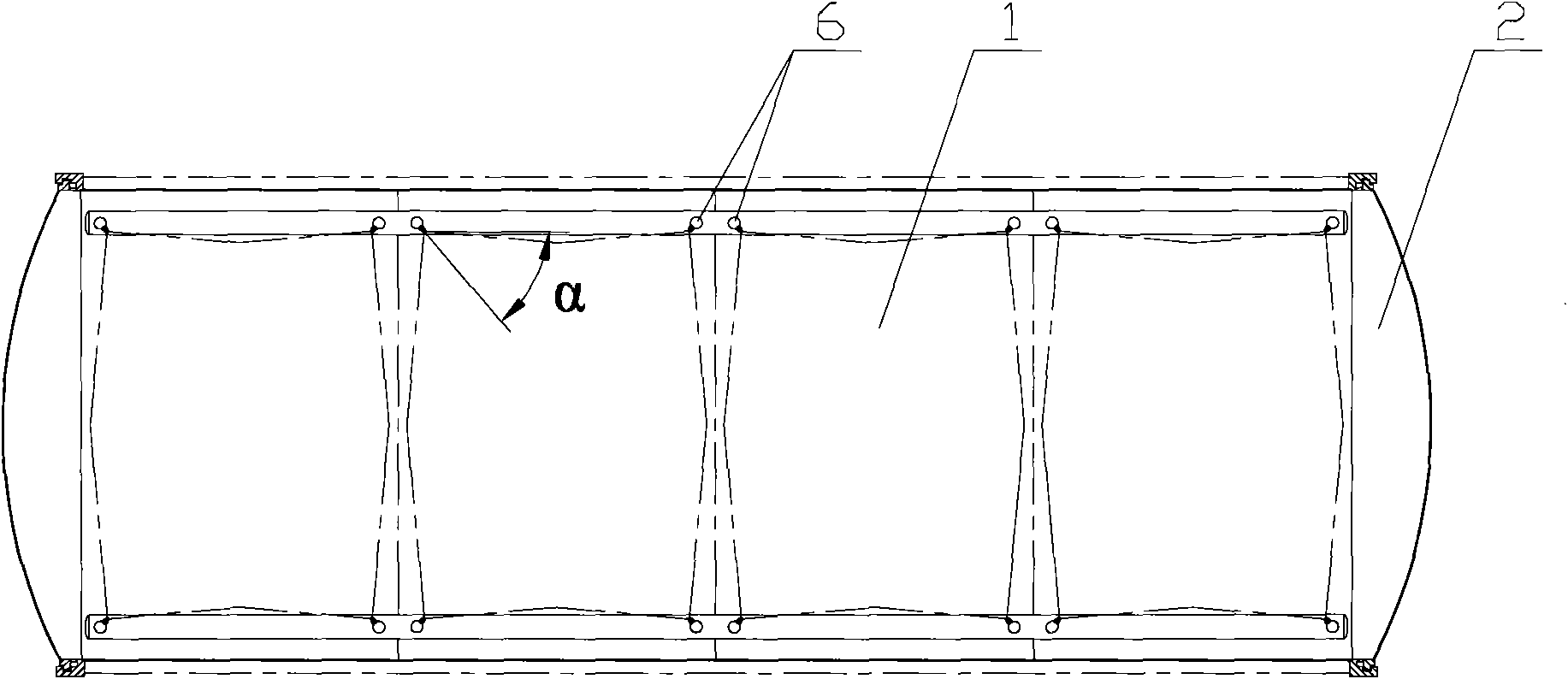

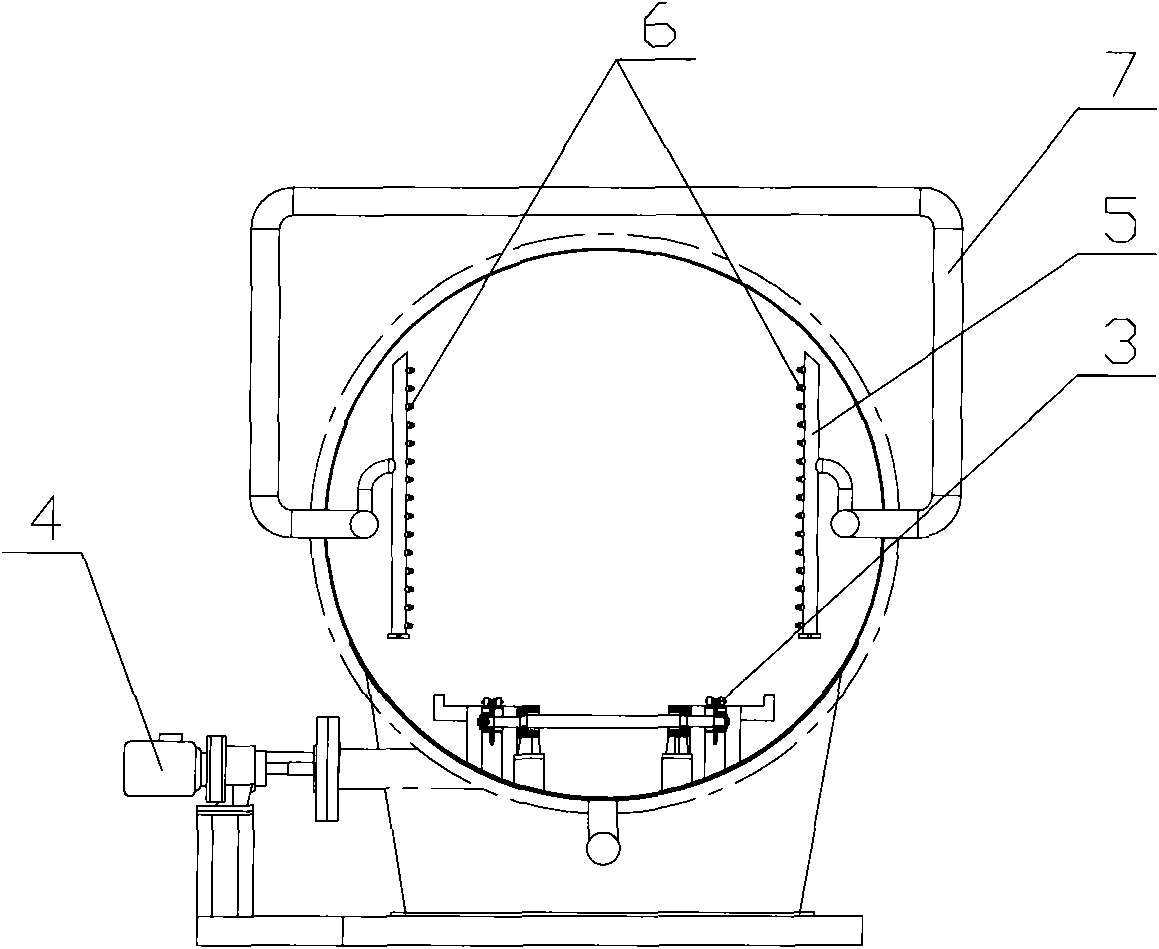

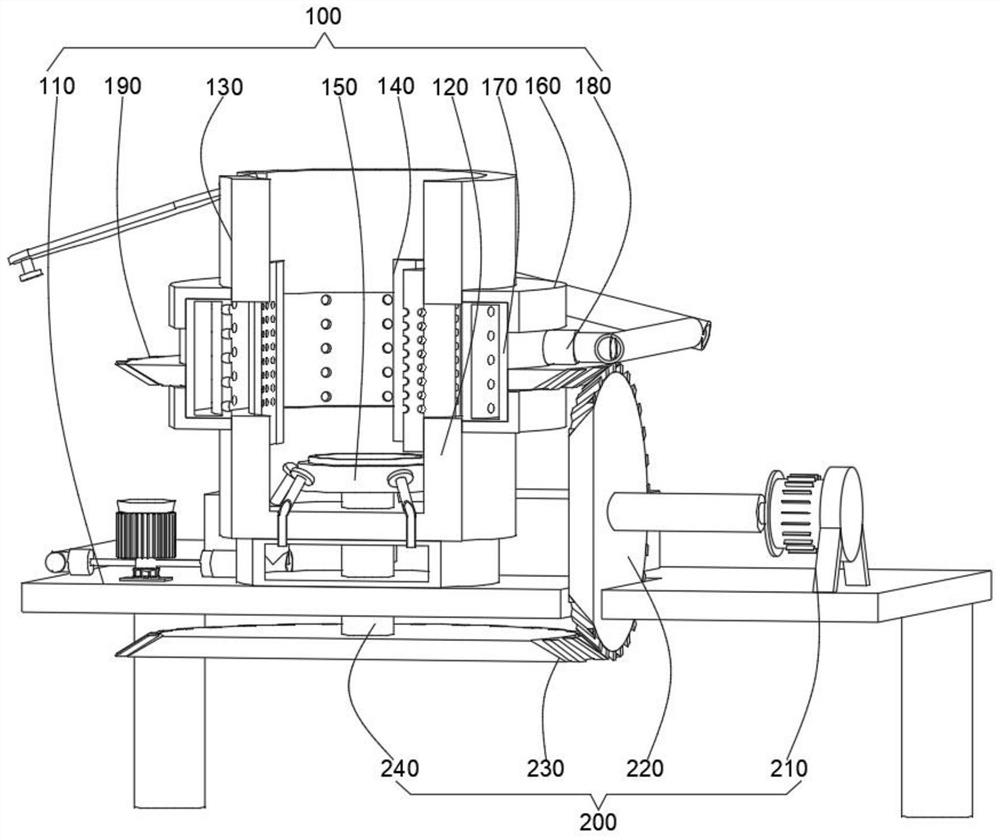

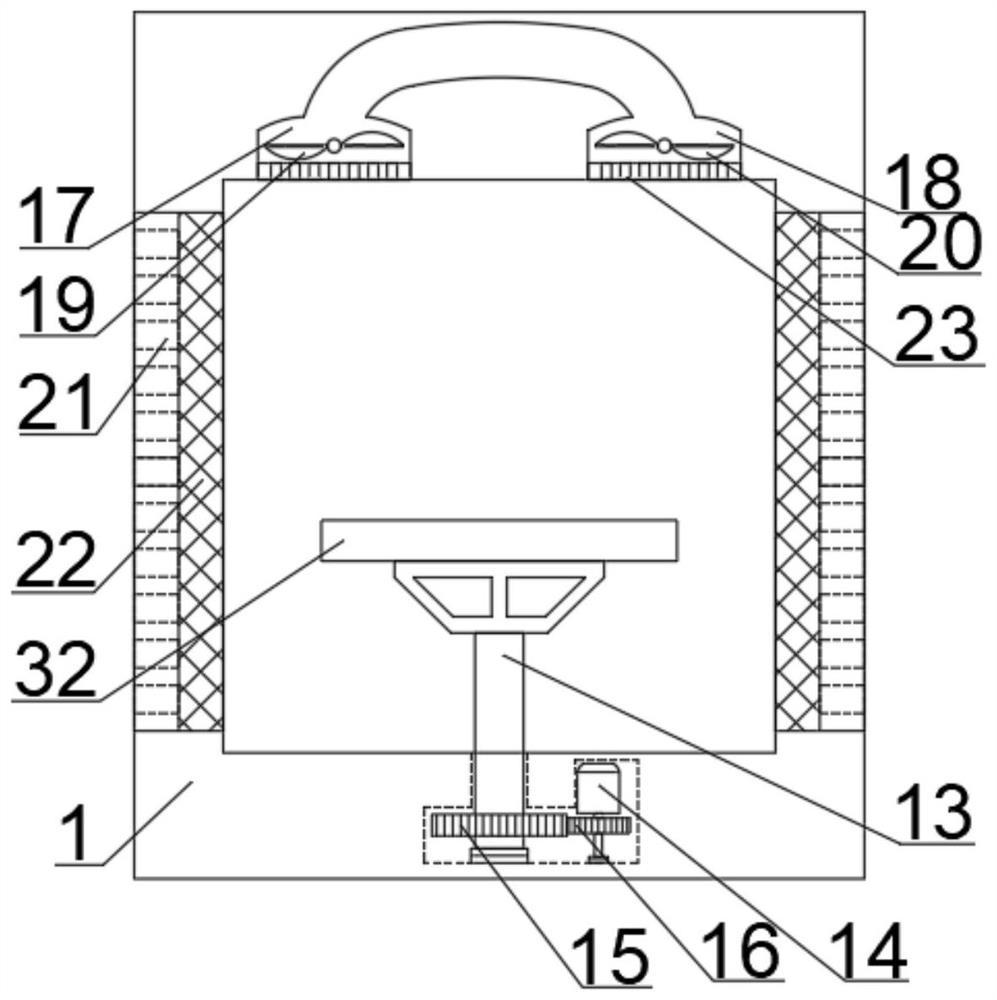

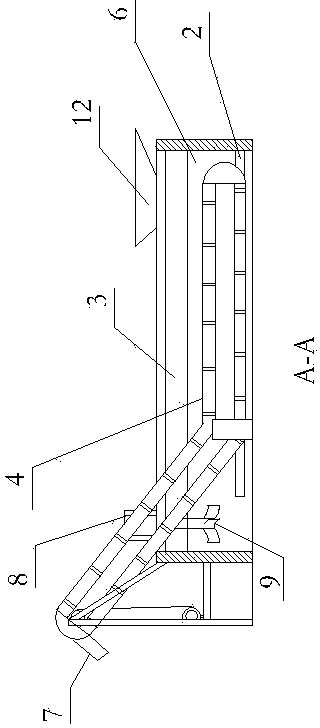

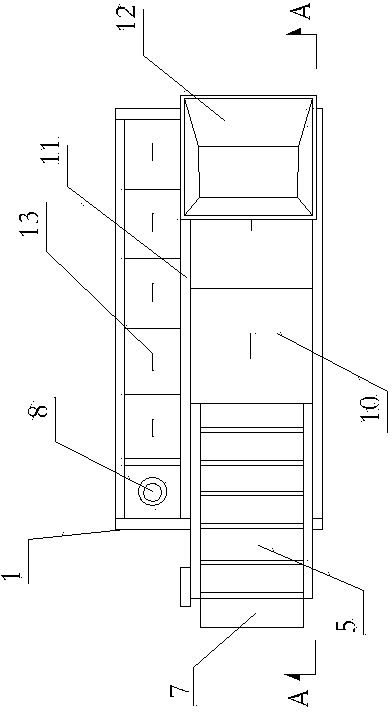

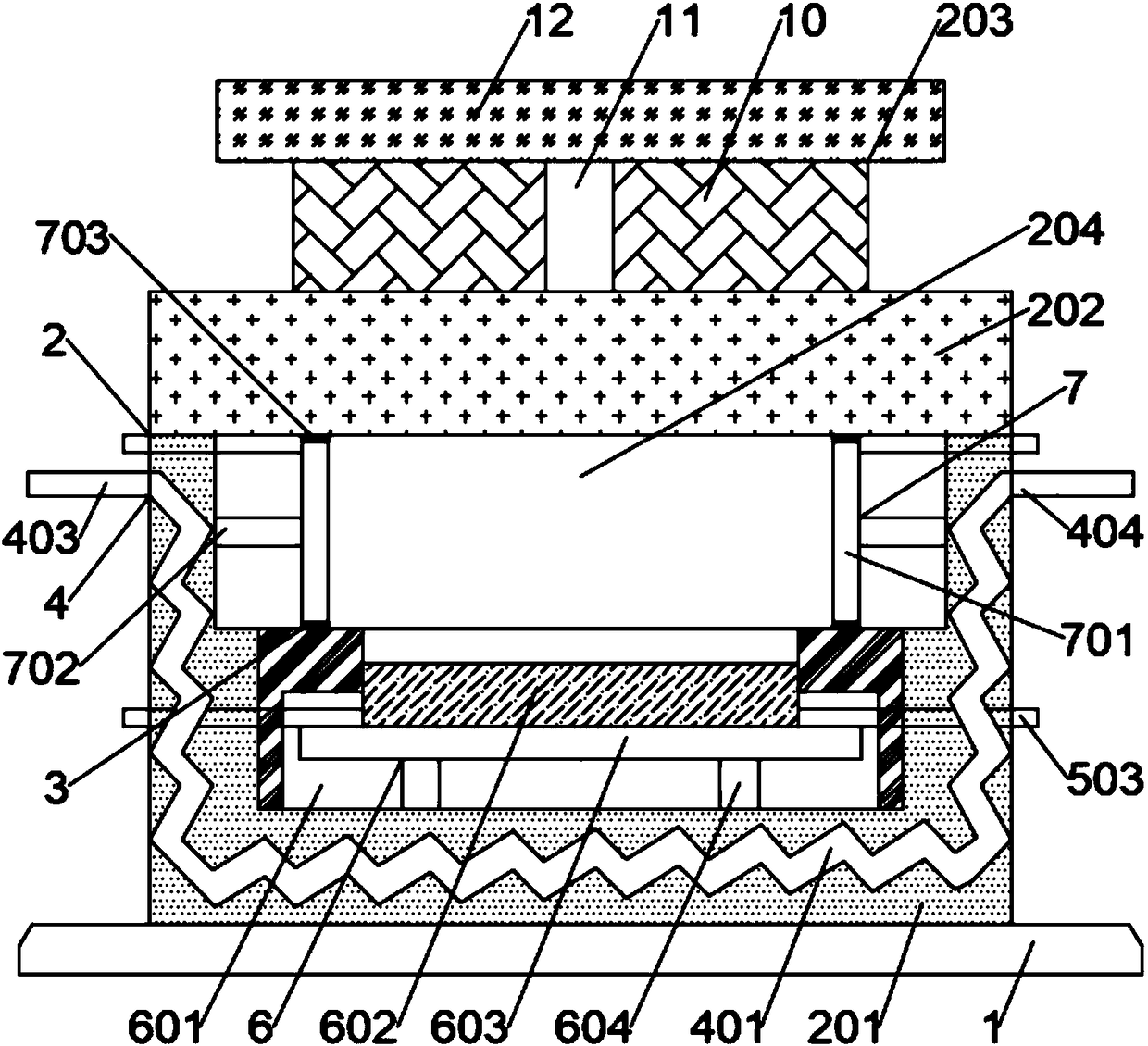

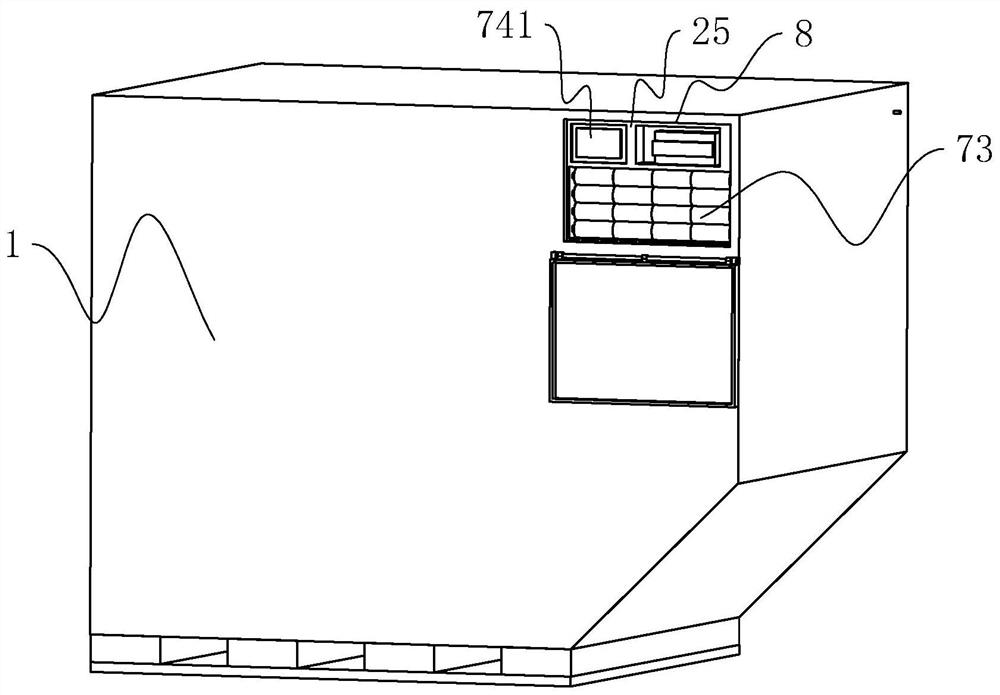

Two-box type impact testing box

The invention discloses a two-box type impact testing box. A hanging basket between a high-temperature box and a low-temperature box is moved to transfer a test sample and a room-temperature box does not need to be arranged, so that the defrosting time can be shortened, the consumption of electric quantity is reduced and the testing cost is saved; inner walls of the high-temperature box and the low-temperature box are respectively provided with a heating device and a refrigerating device; the circulation of air flow is driven by an impeller; the air flow rapidly and circularly flows to realize the effect of rapidly heating the test sample or refrigerating the test sample; an impeller, one heating device, an evaporator, a regenerator and the like are all located on the side wall of the high-temperature box or the low-temperature box; a motor drives the impeller to rotate to drive the air flow to flow in the front and rear direction of the box body; the air flow can rapidly flow and the distribution of the air flow is uniform so as to reduce the formation of frost and realize a long-time defrosting-operation-free circulating continuous test; a driving device for moving the hanging basket is arranged in a refrigerator cabinet rather than in the low-temperature box, so as to avoid influences on the driving device by the low temperature and rapidly move the hanging basket; the safety is high.

Owner:GUANGZHOU CEPREI INSTR & EQUIP

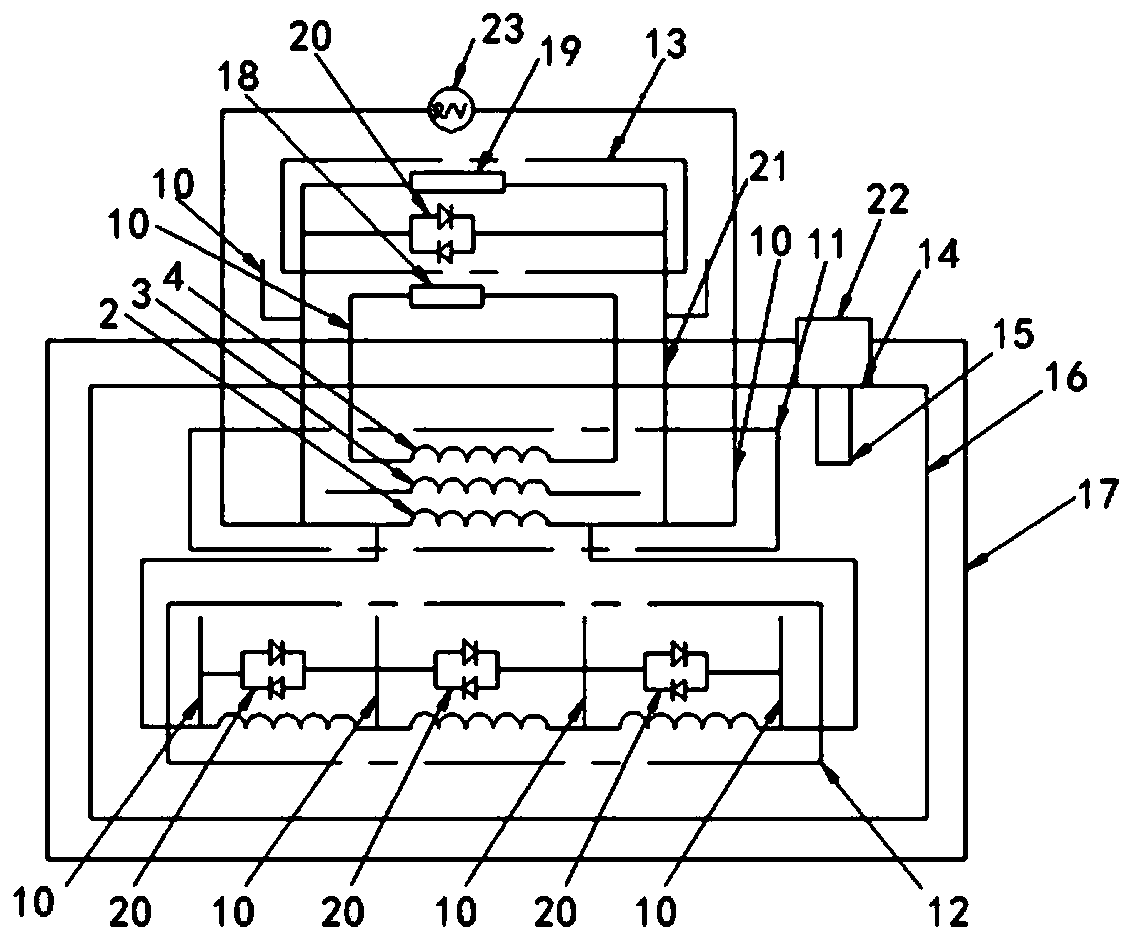

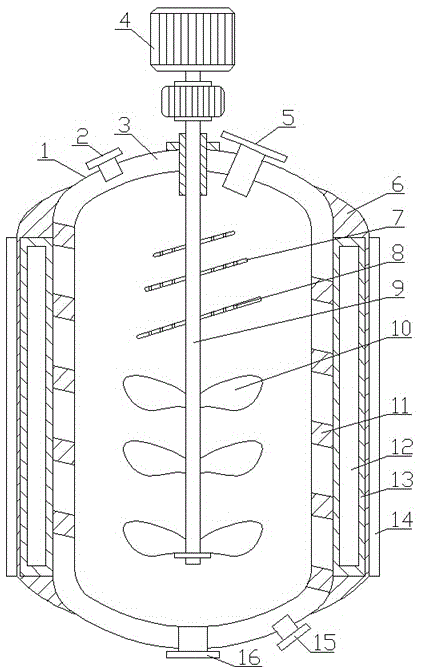

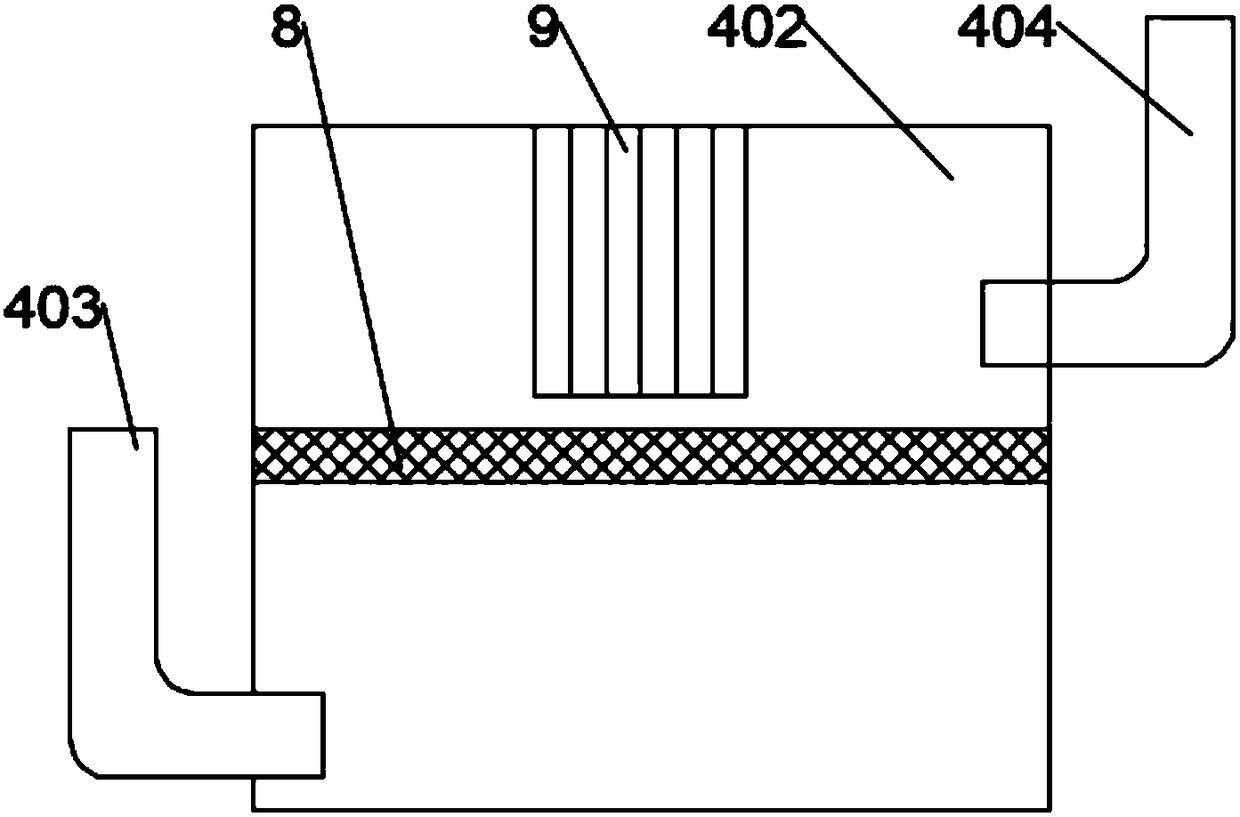

Superconducting switch for conduction cooling and superconducting magnet device thereof

InactiveCN110071713AEvenly cooledAvoid delayElectronic switchingSuperconducting magnets/coilsPower flowSuperconducting Coils

The invention discloses a superconducting switch for conduction cooling and a superconducting magnet device thereof. The superconducting switch comprises a switch framework, and a switch superconducting coil, a switch cold conduction coil and a switch heating coil which are wound on the switch framework, wherein the switch superconducting coil and the switch cold conducting coil are wound at intervals, a copper cable and a current lead are led out from the two ends of the switch superconducting coil respectively to form a four-wire method resistance measuring circuit, and whether the superconducting switch enters a quench or non-quench state is judged by detecting the coil resistance. The two ends of the switch cold conduction coil are thermally connected with a cold head of the superconducting magnet device, the switch heating coil is wound by being attached to the switch superconducting coil, and the copper cables are led out from the two ends of the switch heating coil and are usedfor conducting a current to heat the switch superconducting coil. According to the invention, the problem of low cooling efficiency of the conduction cooling superconducting switch, the problem of thereal-time detection of the cooling states of the superconducting switch and the main superconducting coil, and the problem of coil charging and discharging and coil protection of the conduction cooling superconducting switch used for conduction cooling of the superconducting magnet are solved.

Owner:TIANJIN UNIV

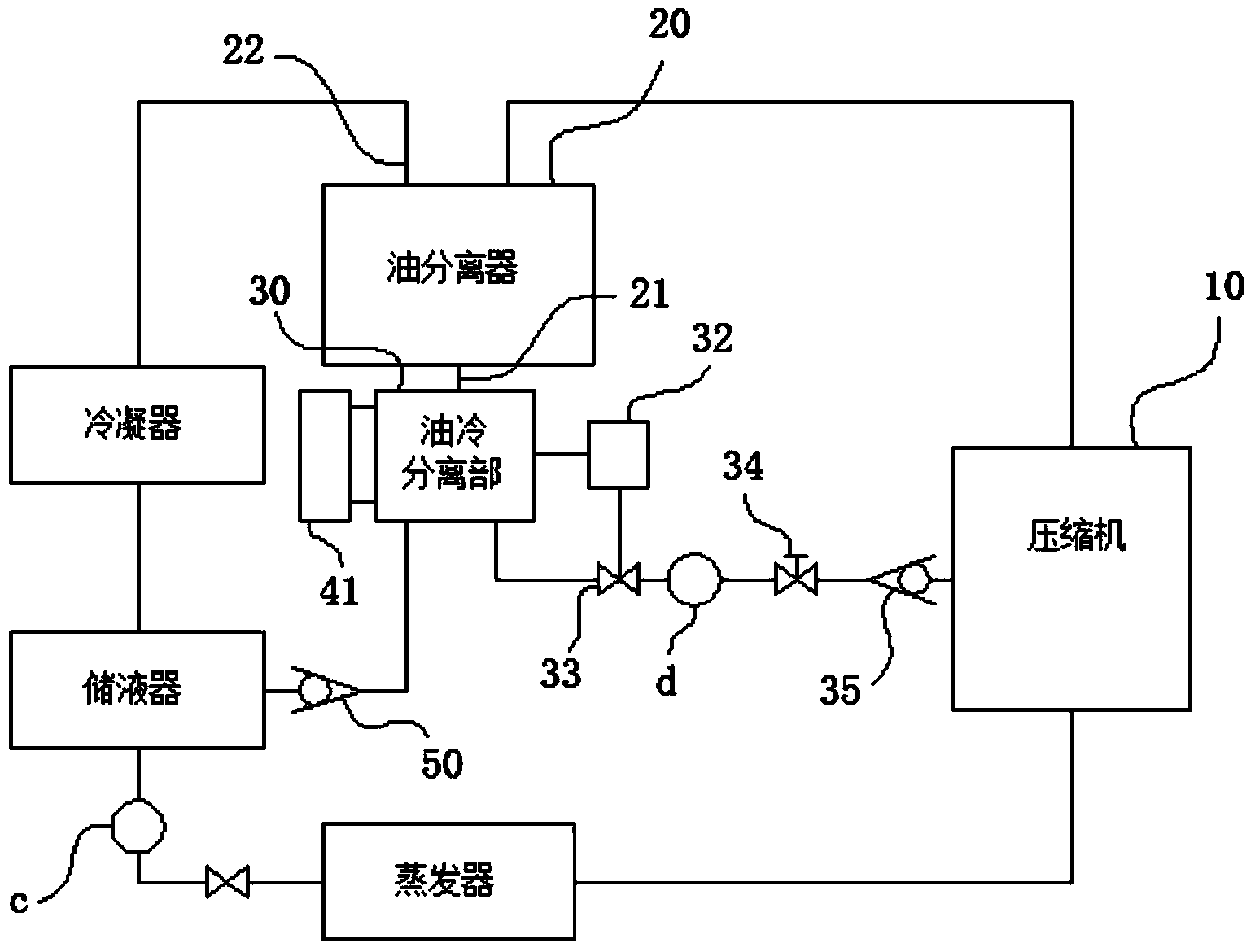

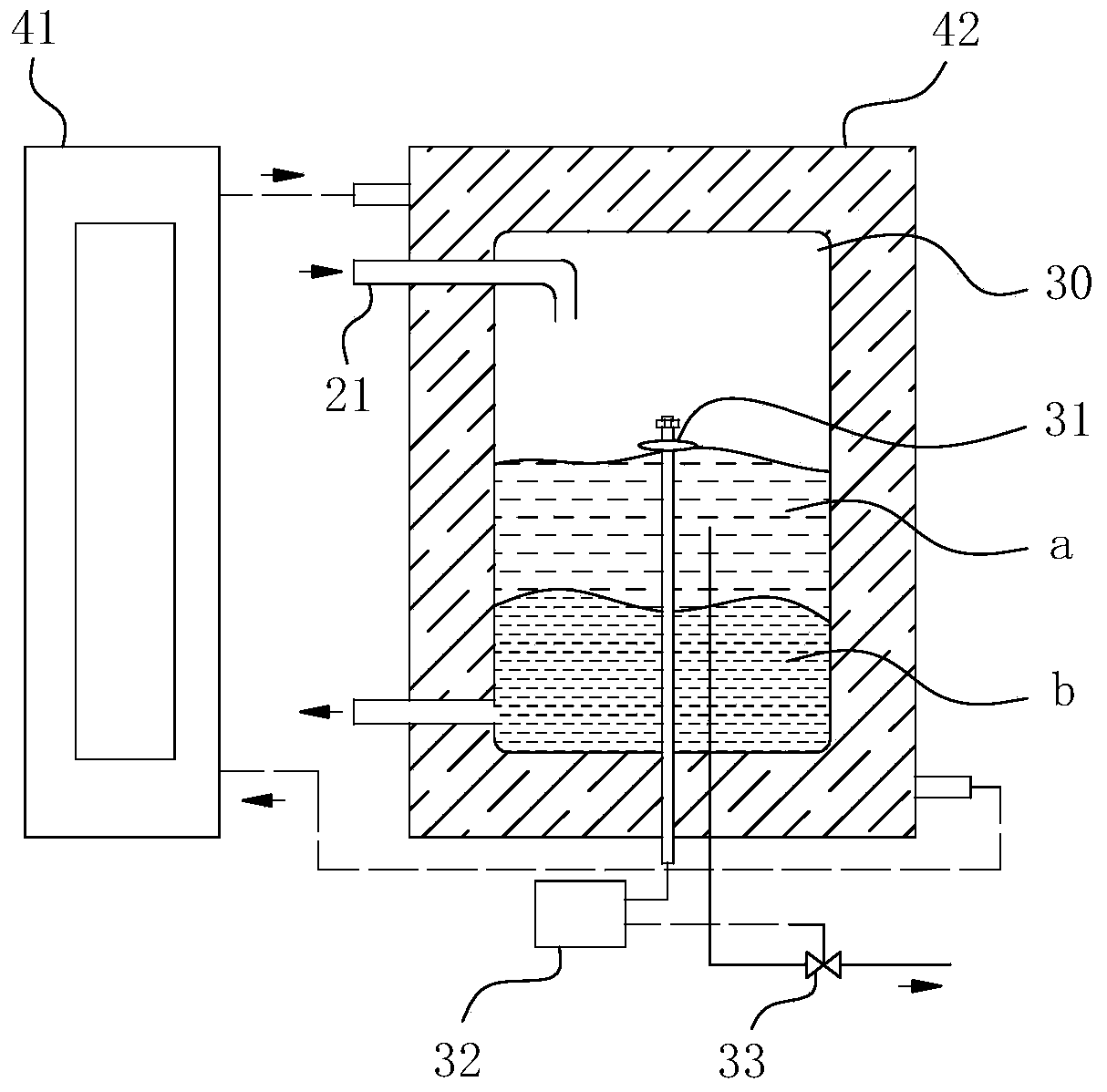

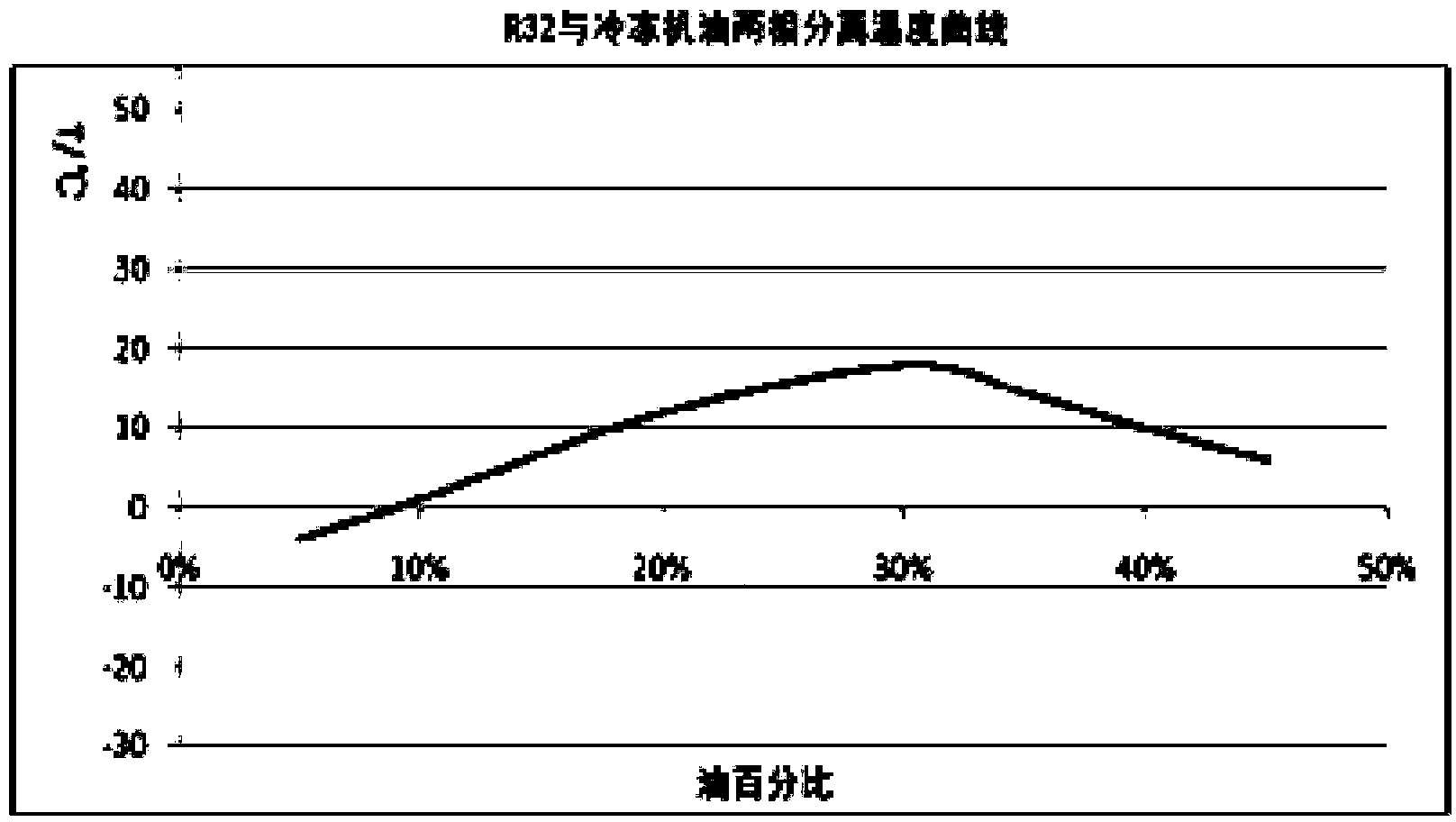

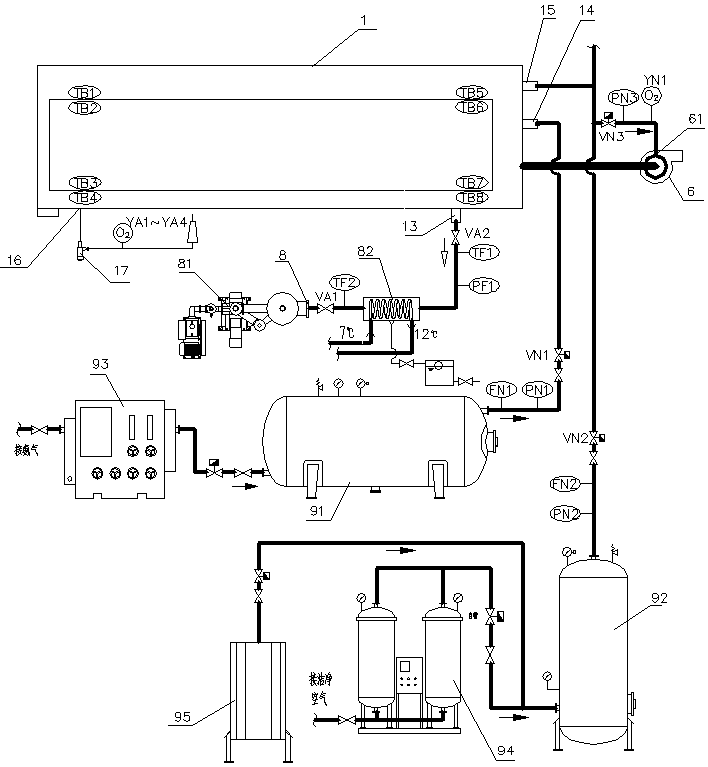

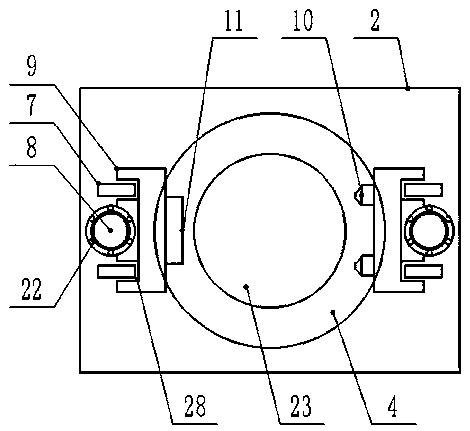

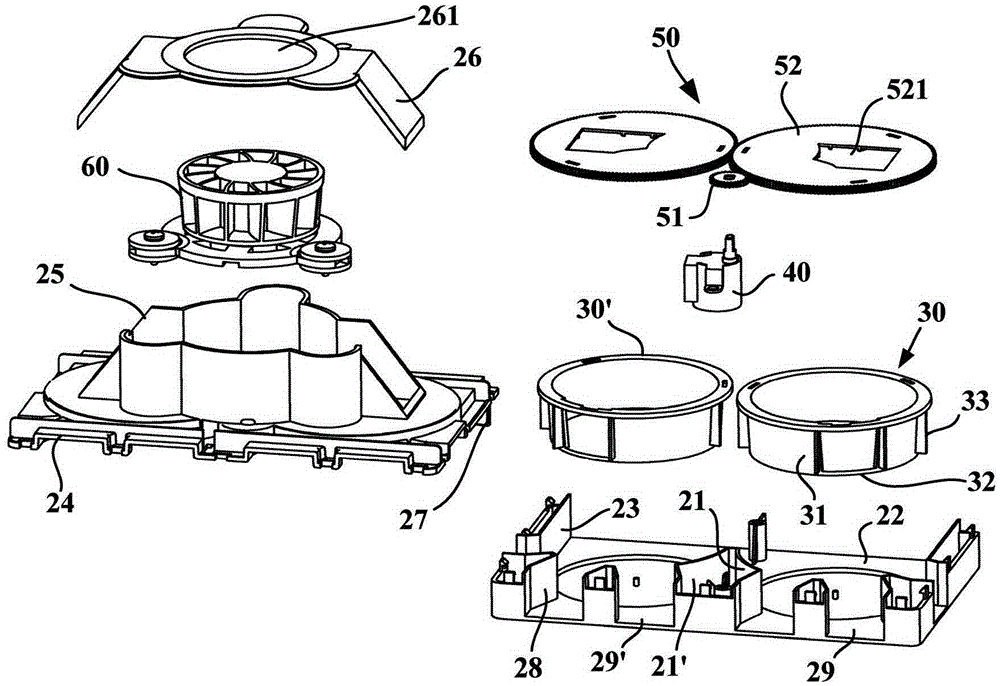

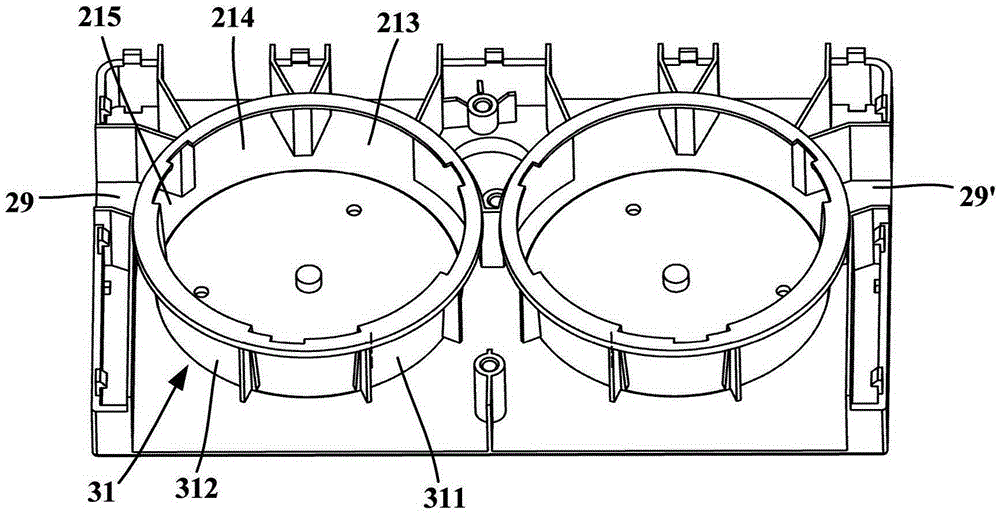

Refrigerant compressor oil circulation rate measuring and testing device based on intermiscibility

ActiveCN103939324AGuaranteed efficient separationImprove work efficiencyPump testingPositive-displacement liquid enginesOil separationEngineering

The invention belongs to the technical field of refrigeration, and particularly relates to a refrigerant compressor oil circulation rate measuring and testing device based on intermiscibility. The device comprises an oil separation assembly which is provided with an oil outlet end and a refrigerant outlet end, the refrigerant outlet end is at least communicated with a compressor air suction port end at least through a condenser, a liquid storage device and an evaporator to form a refrigerant loop, the oil outlet end is communicated with a compressor air suction oil return port to form an oil circulation loop, and flow meters are arranged on the oil circulation loop and the refrigerant loop. The device further comprises a refrigeration assembly, and liquid supply temperature of the refrigeration assembly is lower than the highest two-phase separation temperature of a refrigerant and refrigerator oil. The device improves work efficiency of a whole oil circulation system, meanwhile, values measured by the flow meters on the loops are more accurate, and finally precision of oil circulation flow rate measurement data of a refrigerant compressor is guaranteed.

Owner:HEFEI GENERAL MACHINERY RES INST +1

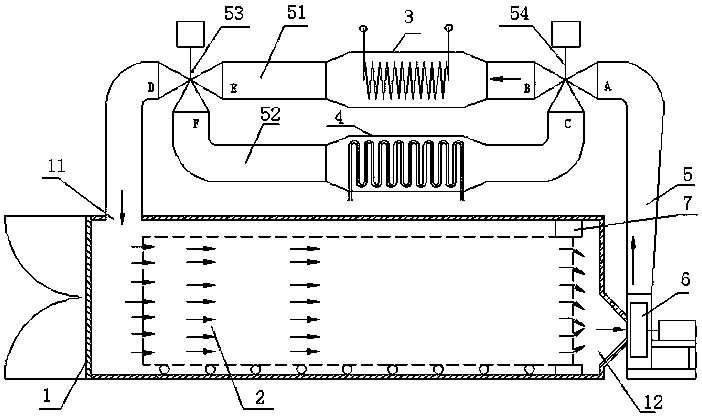

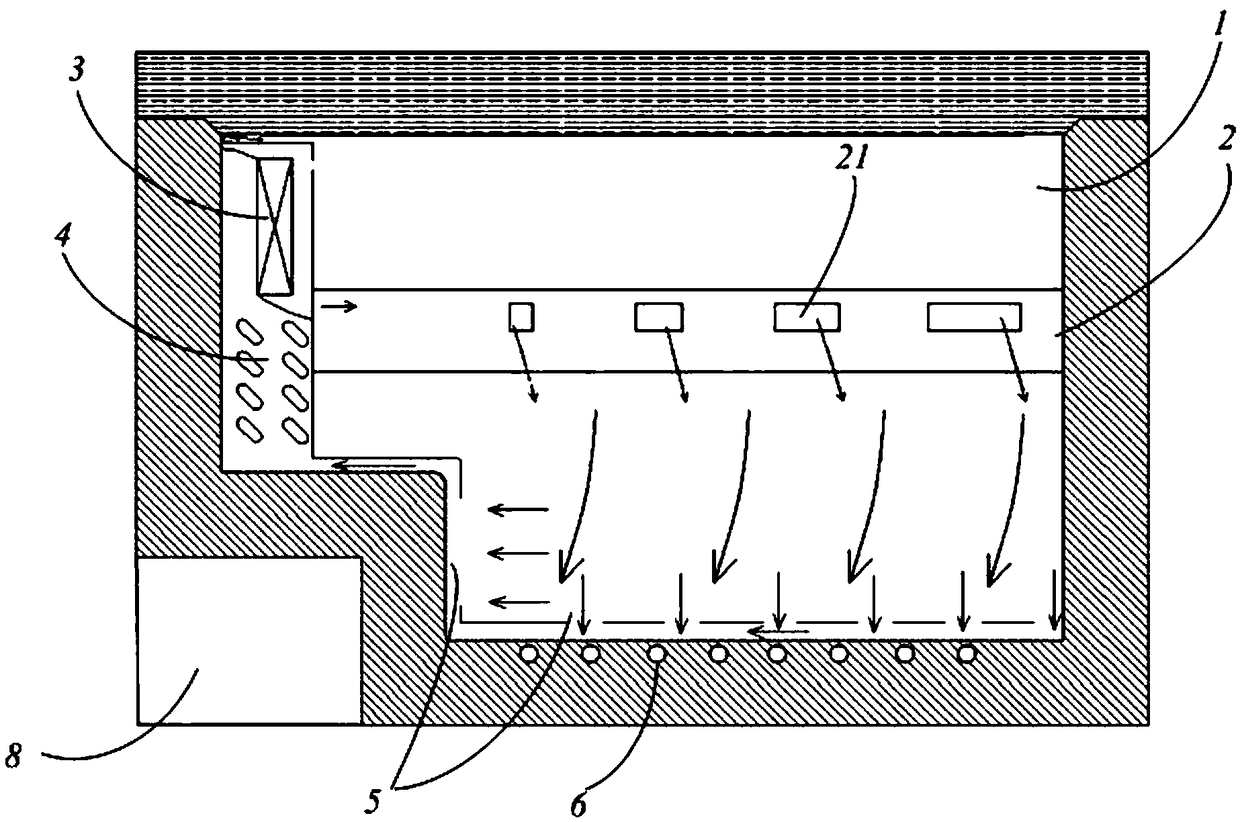

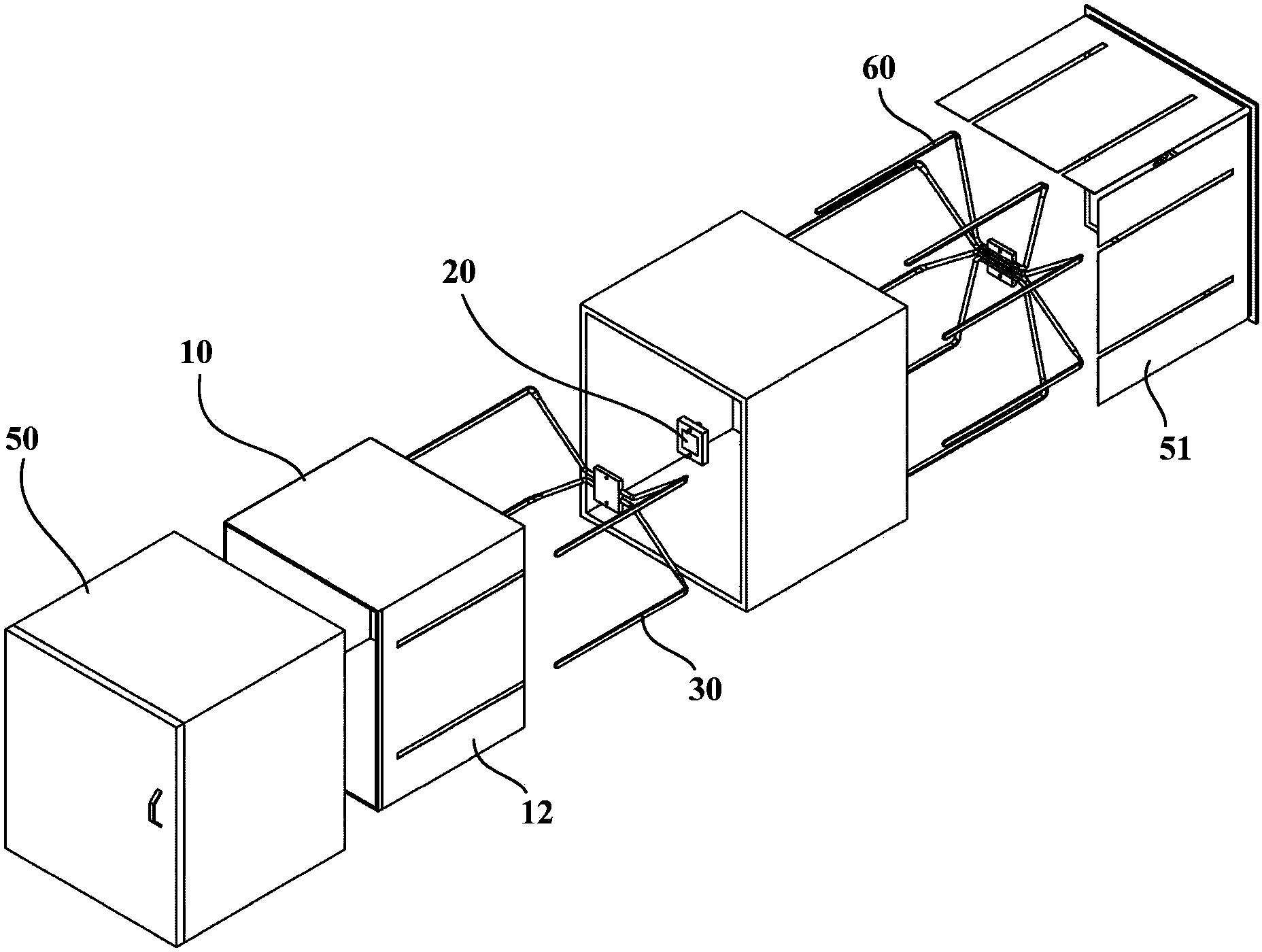

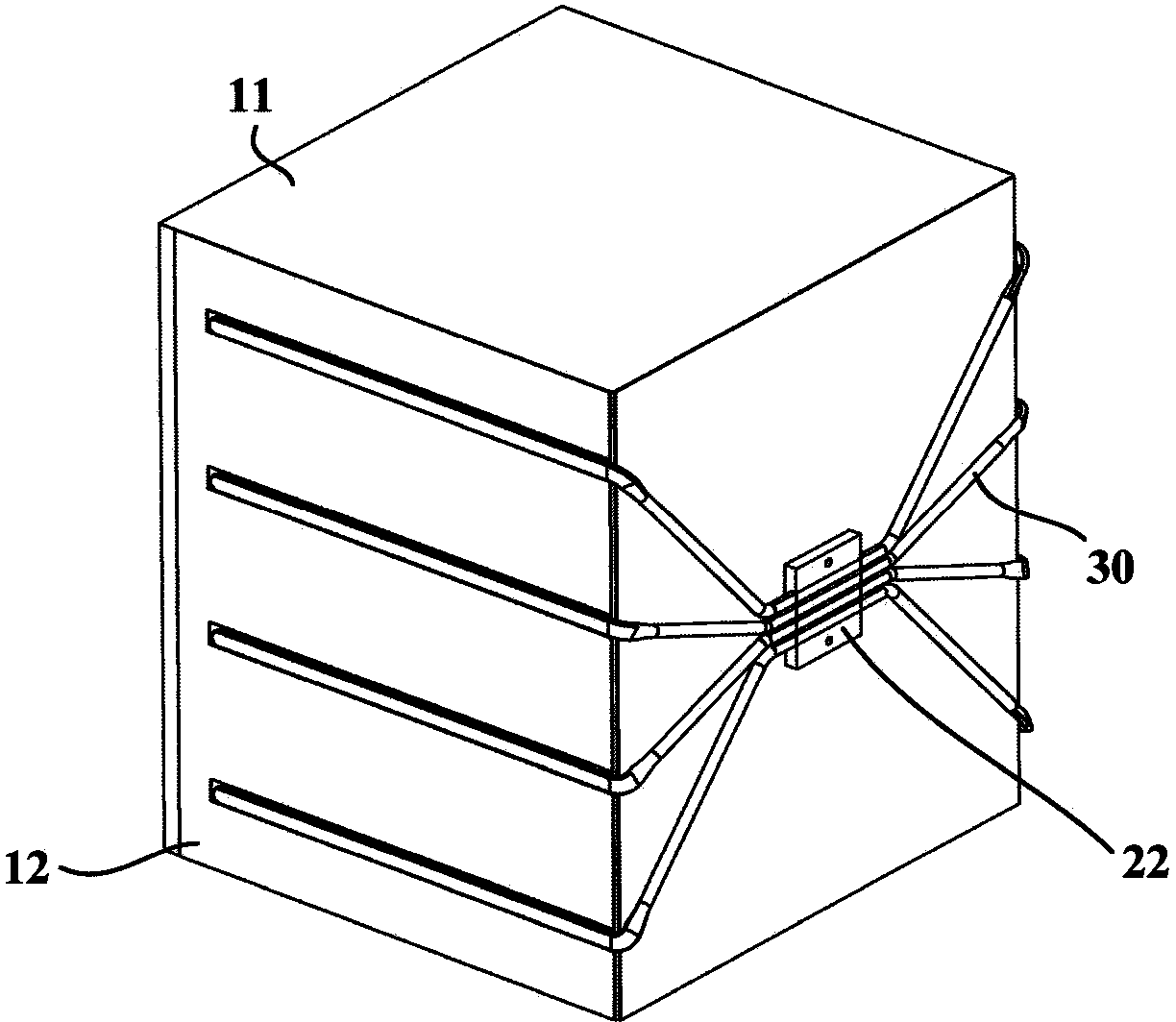

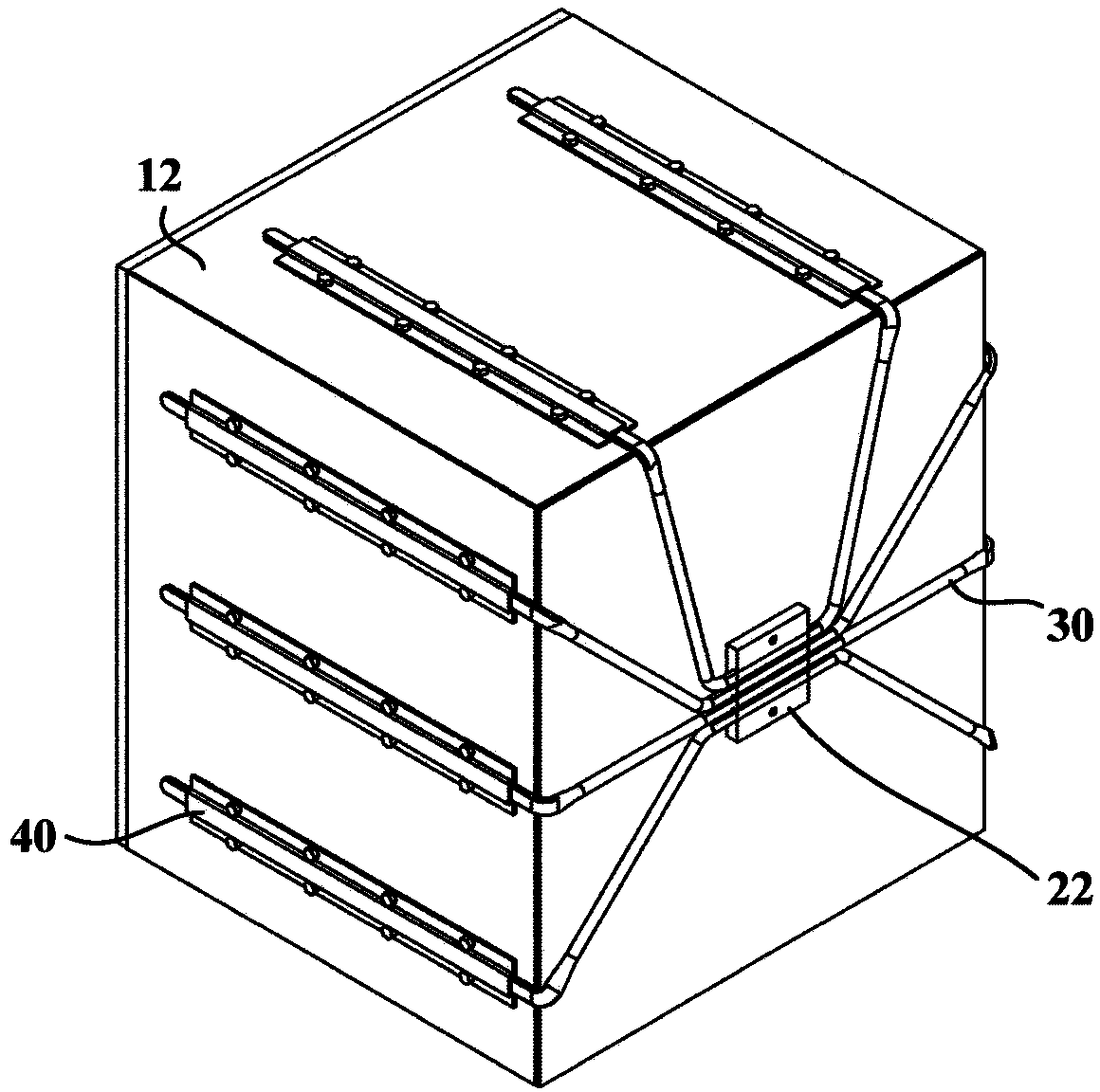

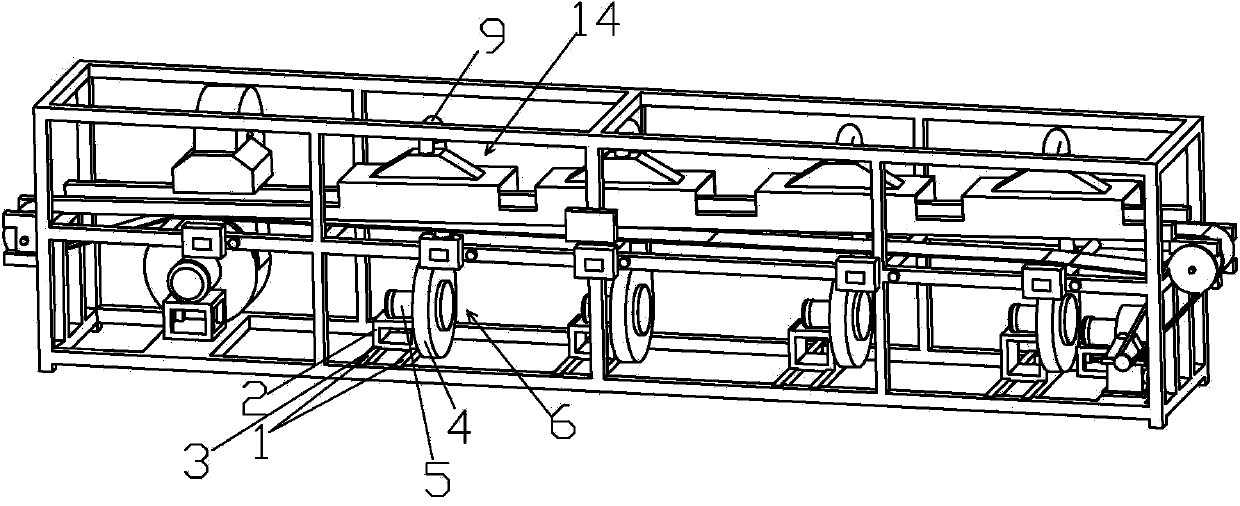

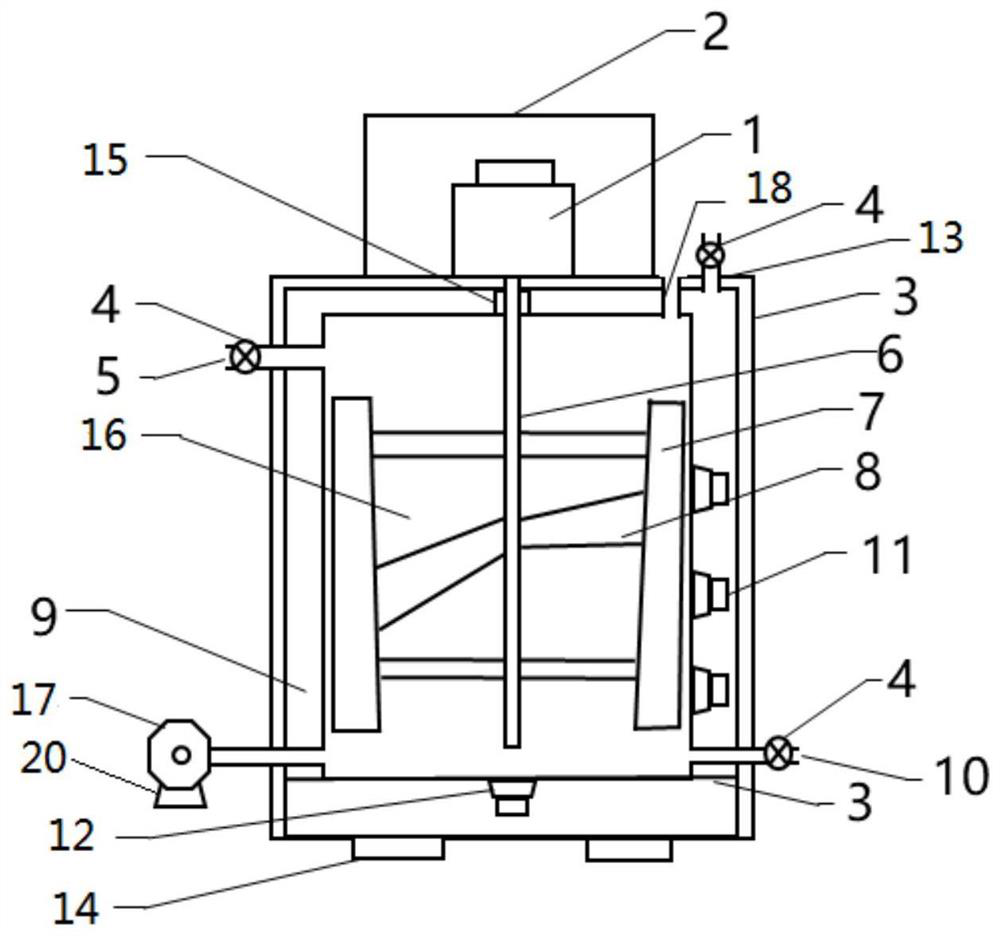

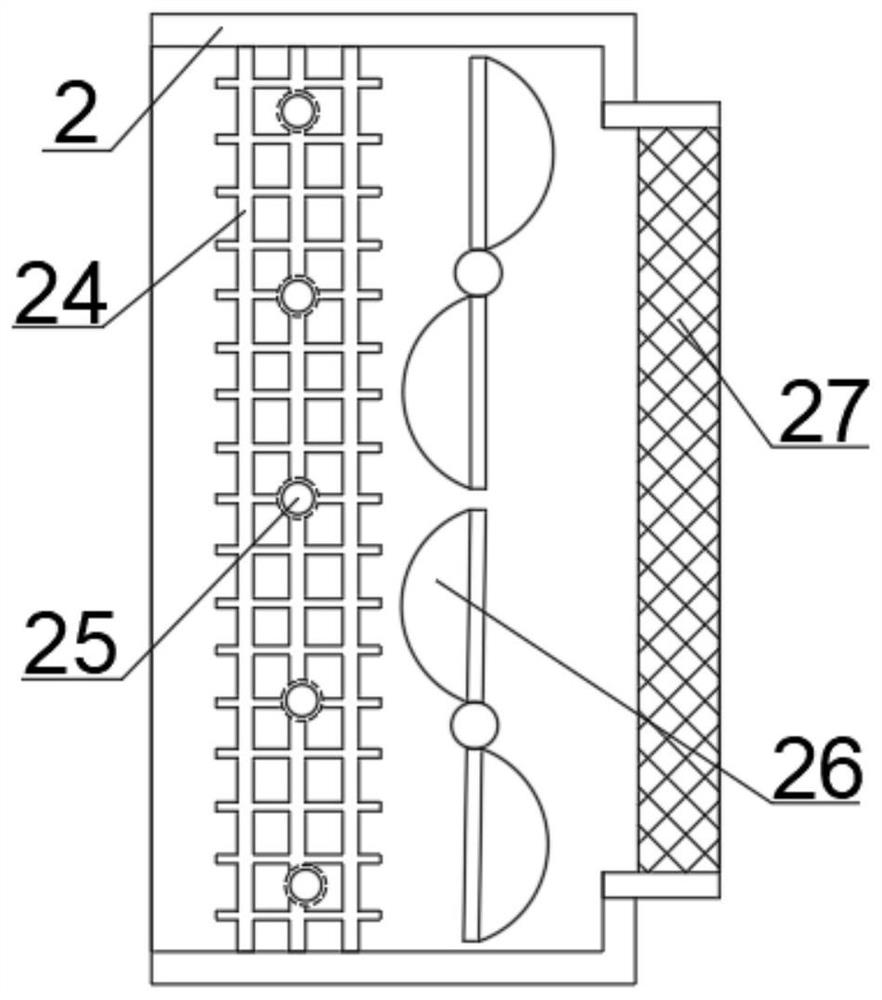

Brazing system carrying out heating/cooling by using gas as medium

InactiveCN108213630AReduce processing timeImprove efficiencySoldering apparatusMetal working apparatusVacuum pumpingShielding gas

A brazing system carrying out heating / cooling by using gas as a medium comprises a furnace body, a vacuum pumping system and a gas supply system, wherein a workpiece is arranged in a furnace chamber of the furnace body, a gas inlet and a gas outlet are arranged on the furnace body, and the outer part of the furnace body is provided with a circulating pipeline which is connected between the gas inlet and the gas outlet of the furnace body; a heating part and / or a cooling part are / is arranged on the circulating pipeline, and the heating part and / or the cooling part guides hot gas or cold gas into an inner cavity of the workpiece via the circulating pipeline through a power device so as to carry out circulating heating or cooling on the workpiece; a vacuum opening and a protective gas input opening are further arranged on the furnace body; the vacuum pumping system is connected with the vacuum opening and used for enabling the workpiece to be in an oxygen-free environment; and the gas supply system comprises a protective gas storage tank, and is connected with the protective gas input opening and used for conveying protective gas for the furnace body. The brazing system has the advantages of high efficiency, light weight, high safety, uniform workpiece heating or cooling, wide application range and the like.

Owner:张跃

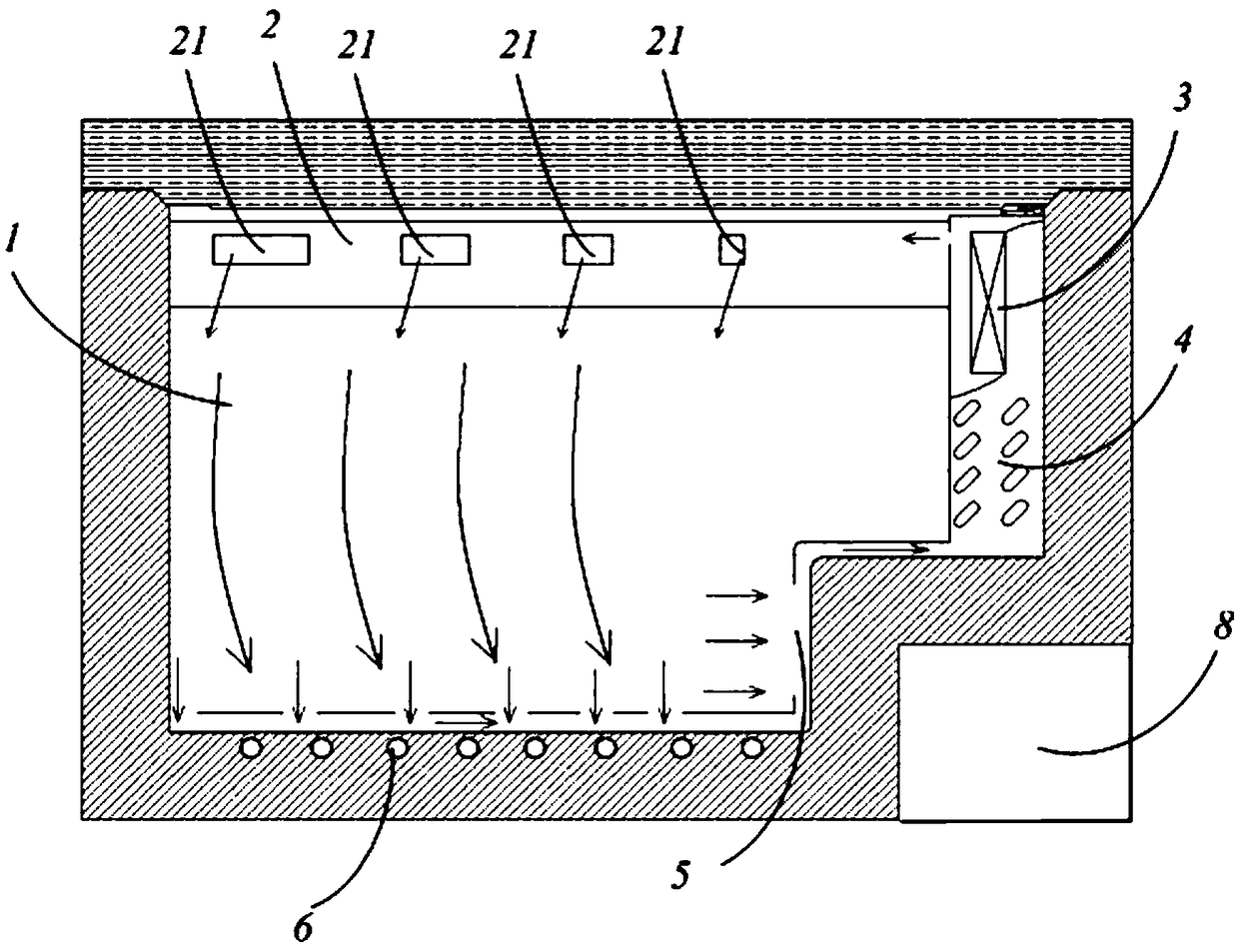

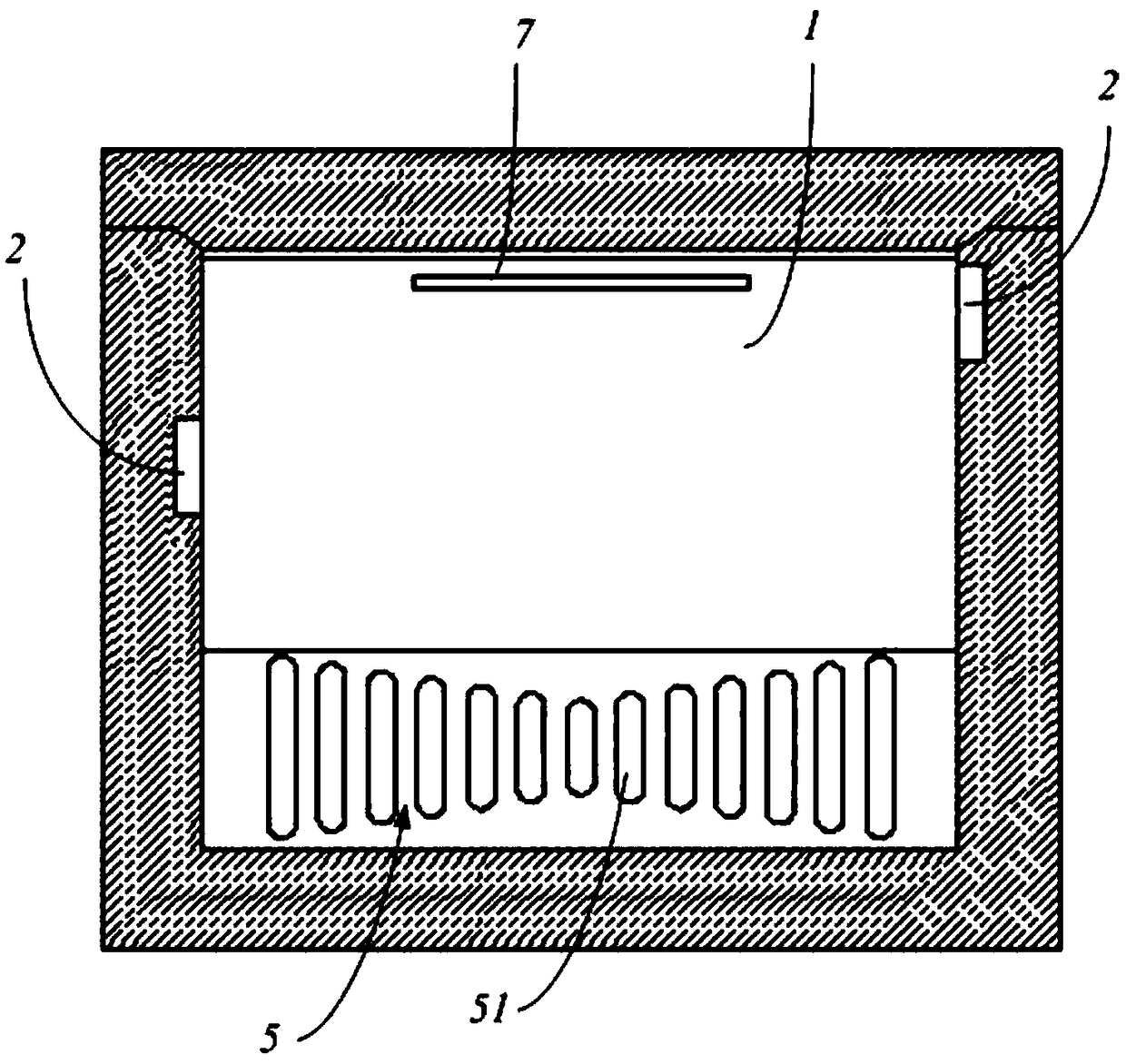

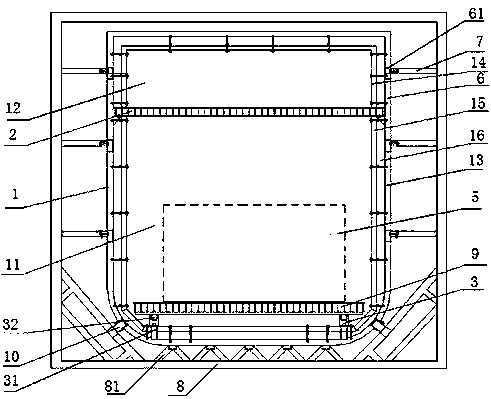

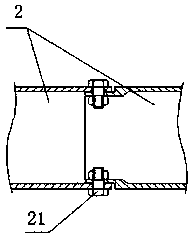

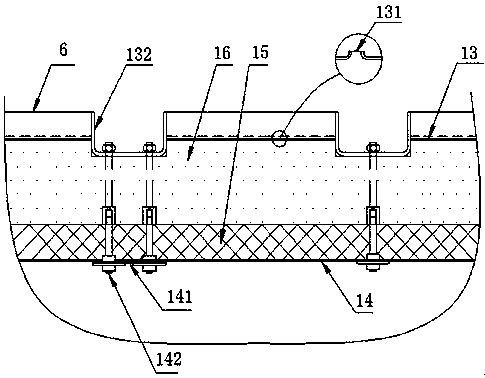

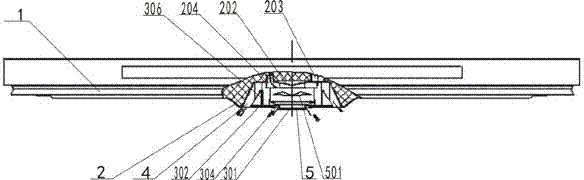

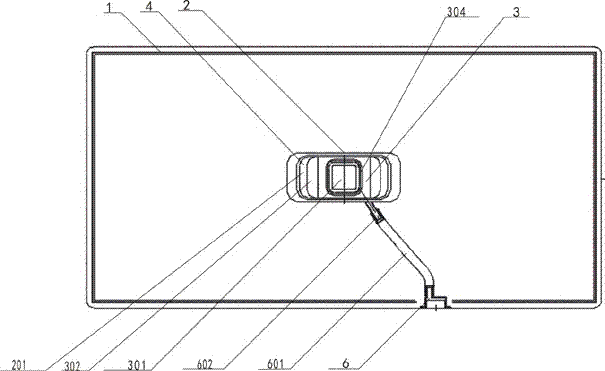

Horizontal air cooling refrigeration cabinet

InactiveCN109307393AEvenly cooledLighting and heating apparatusDomestic refrigeratorsCold airRefrigeration

The invention provides a horizontal air cooling refrigeration cabinet. The horizontal air cooling refrigeration cabinet comprises a storage chamber, and an air cooling refrigeration system for providing cold air to the storage chamber; side exhaust ways are arranged on two opposite side walls of the storage chamber, and communicate with an air way of the air cooling refrigeration system to providethe cold air to the storage chamber; the side exhaust way on the first side wall of the two side walls is arranged at the middle part of the first side wall; the side exhaust way on the second side wall is arranged at the top of the second side wall; the side exhaust ways on the first and second side walls are provided with air outlets capable of blowing out the cold air to the inclined lower side; and a direct cooling evaporator is arranged at the bottom of the storage chamber. The horizontal air cooling refrigeration cabinet can uniformly cool stored matters in the storage chamber.

Owner:QINGDAO HAIER SPECIAL ICEBOX

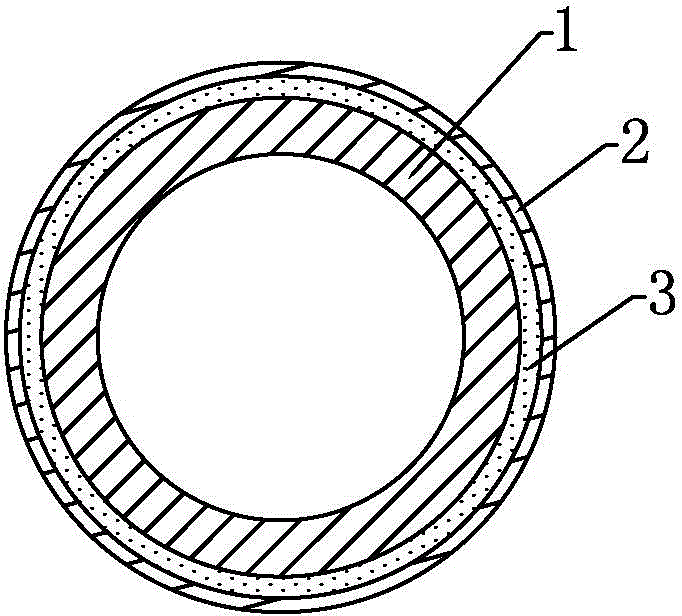

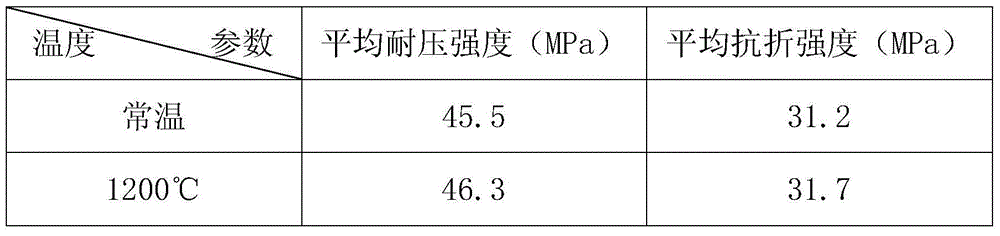

Thermal shock resistant ceramic tube mold and preparation method thereof

The invention belongs to the field of metallurgy casting and smelting, and particularly discloses a thermal shock resistant ceramic tube mold and a preparation method thereof. The thermal shock resistant ceramic tube mold comprises an inner ceramic tube mold, wherein an outer steel-made tube mold layer sleeves the outer side of the inner ceramic tube mold; a self-flowing thermal-resistant casting material is filled between the inner ceramic tube mold and the inner ceramic tube mold; the inner ceramic tube mold is made of the following raw materials in percentage by weight: 40-50% of carbon silicon micro powder, 20-25% of silicon powder, 20-25% of primary aluminum nitride powder, 2-5% of graphite micro powder, 2-3% of zirconium oxide micro powder, 0.5-1% of yttrium oxide micro powder, 0.2-0.5% of absolute ethyl alcohol and 3-4% of an adhesive. The thermal shock resistant ceramic tube mold is high in pressure resistance, good in breaking strength, good in high temperature corrosion resistance and long in service life; when nodular cast iron tubes are produced by using the thermal shock resistant ceramic tube mold, the production procedures can be reduced, the energy is saved, the equipment maintenance expense is reduced, and the production cost is lowered, so that the nodular cast iron pipe thermal shock resistant ceramic tube mold has great significance for the metallurgy tube industry and has wide application prospect and popularization values.

Owner:山东坤能环保科技有限公司

Semiconductor cooling refrigerator and manufacturing method for same

ActiveCN104344630AImprove cooling efficiencyImprove cooling effectLighting and heating apparatusDomestic refrigeratorsCooling effectEvaporation

The invention relates to a semiconductor cooling refrigerator and a manufacturing method for the same. The semiconductor cooling refrigerator comprises an inner container, a semiconductor module and at least one cold-end heat tube for transferring the cold of the semiconductor module to the inner container, wherein the inner container of the semiconductor cooling refrigerator particularly comprises a graphite film layer which is arranged on at least a part of the outer surface of a substrate layer of the inner container to dissipate the cold of at least a part of an evaporation section of each cold-end heat tube to the outer surface of the substrate layer of the inner container. In addition, the invention further provides the manufacturing method for the semiconductor cooling refrigerator. According to the semiconductor cooling refrigerator and the manufacturing method for the same, the graphite film layer is arranged on at least a part of the outer surface of the substrate layer of the inner container, and can be used for uniformly dissipating the cold of at least a part of the evaporation section of each cold-end heat tube to the outer surface of the substrate layer of the inner container, so that the cooling uniformity of a storage room is achieved, and the cooling efficiency and cooling effects of the semiconductor cooling refrigerator are remarkably improved.

Owner:HAIER SMART HOME CO LTD

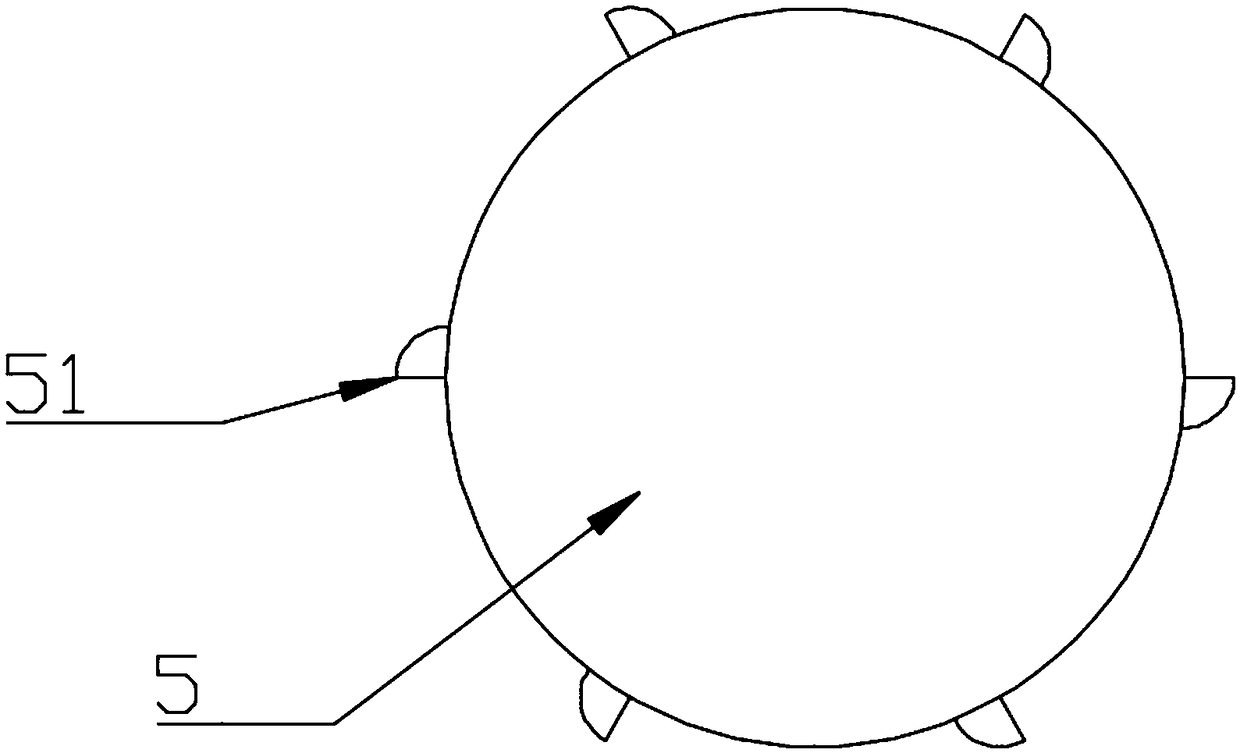

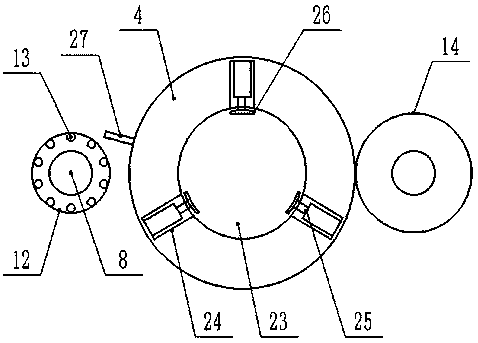

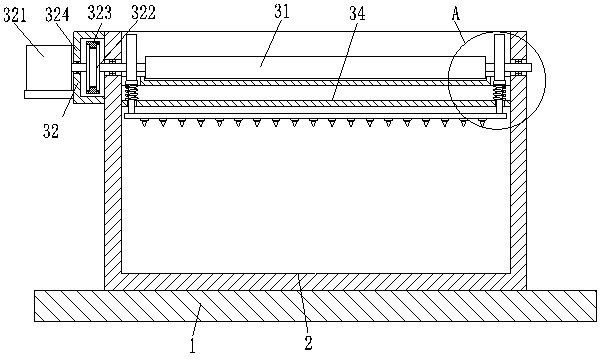

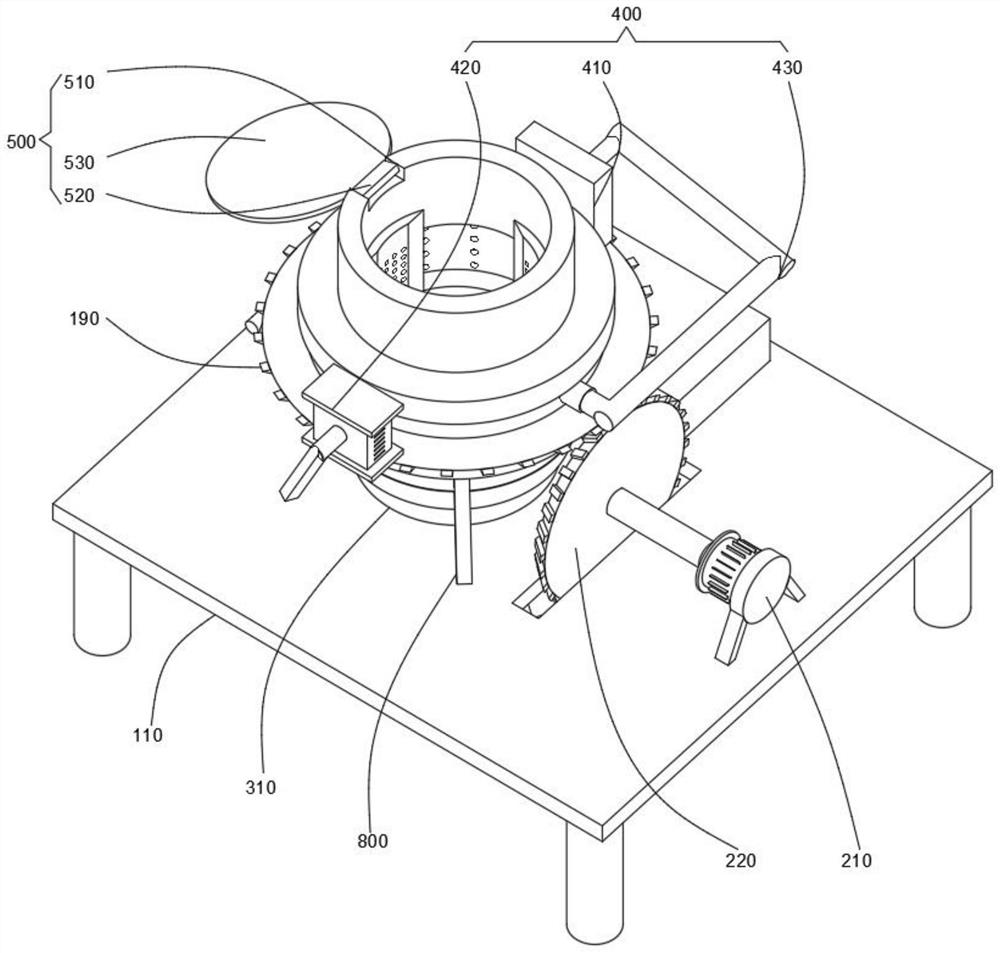

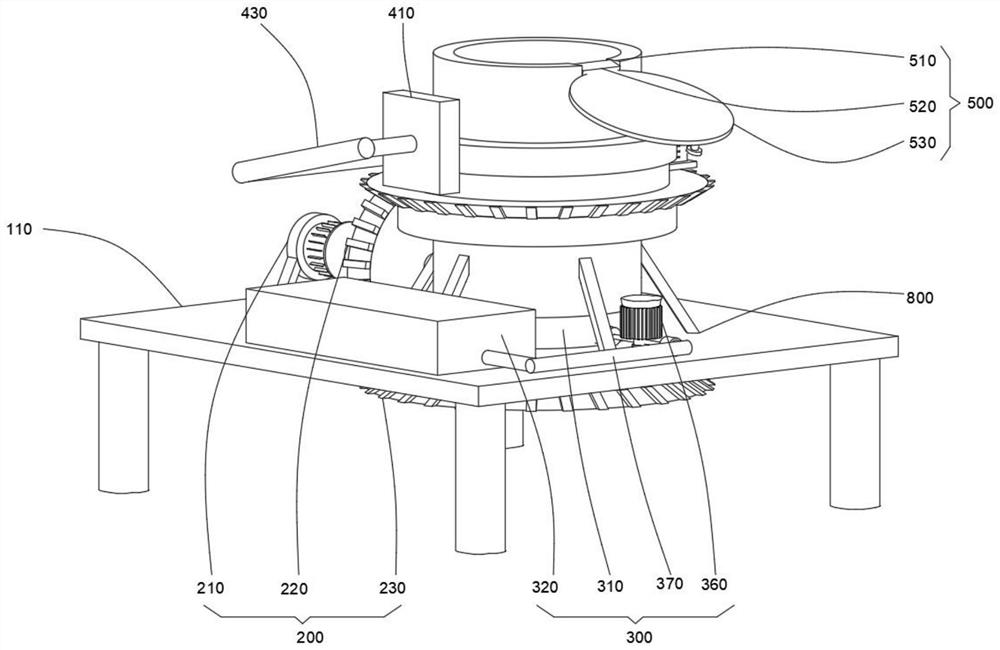

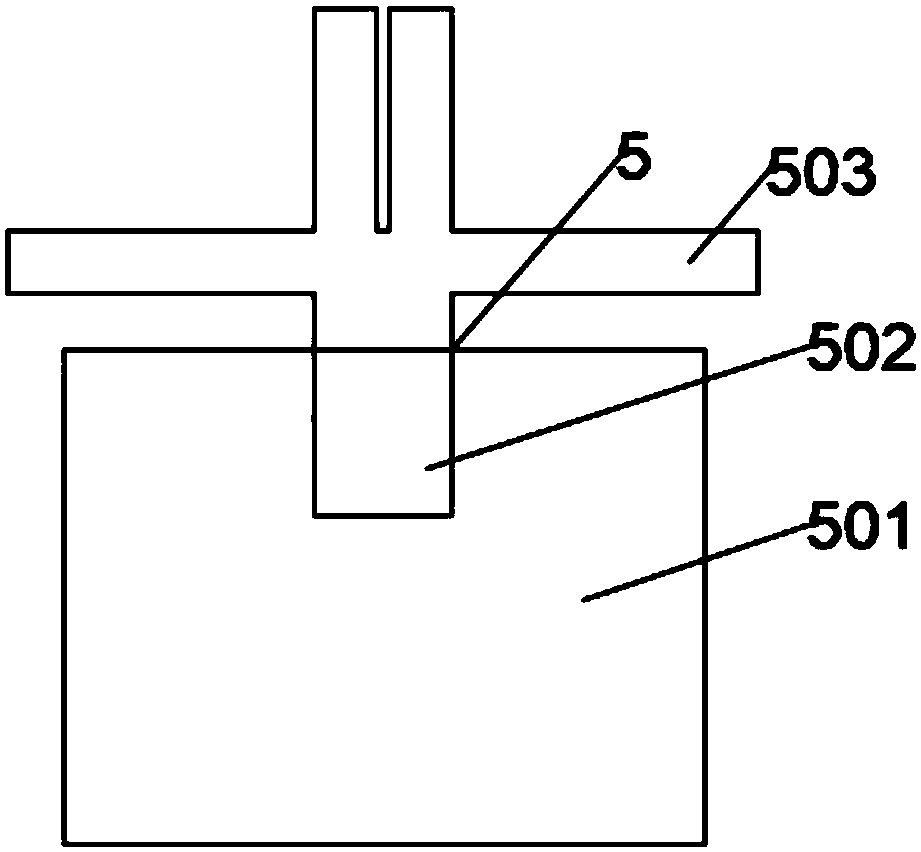

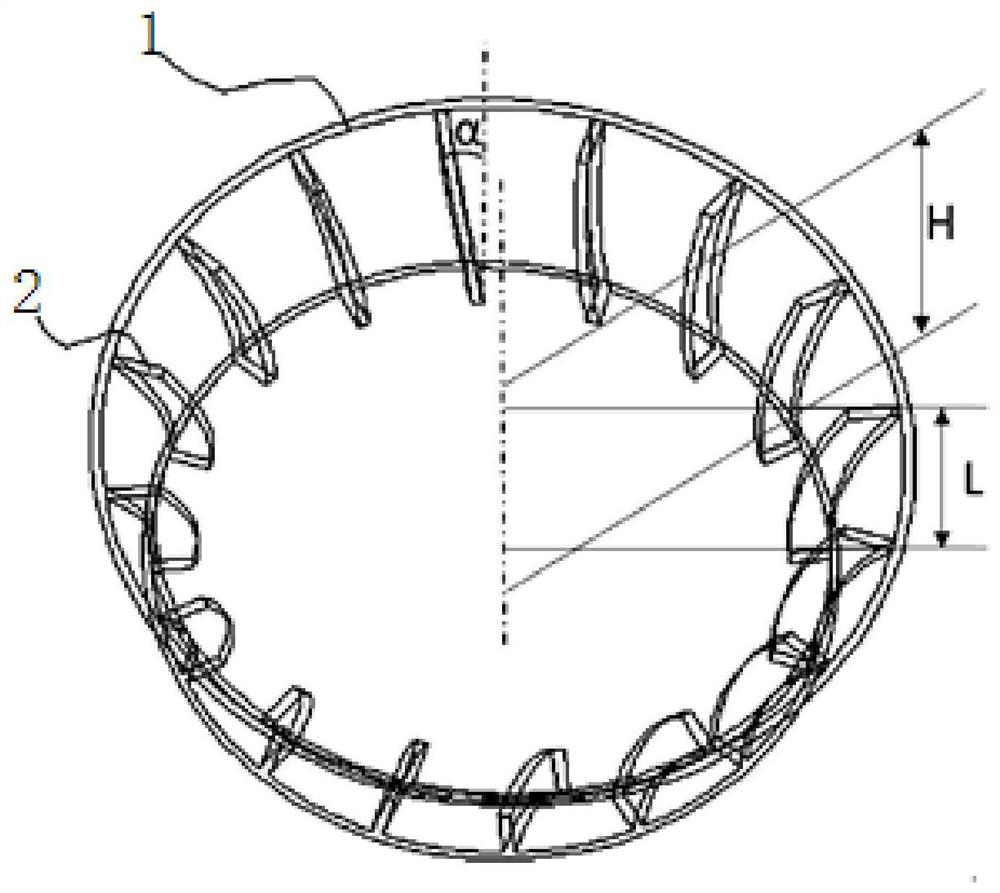

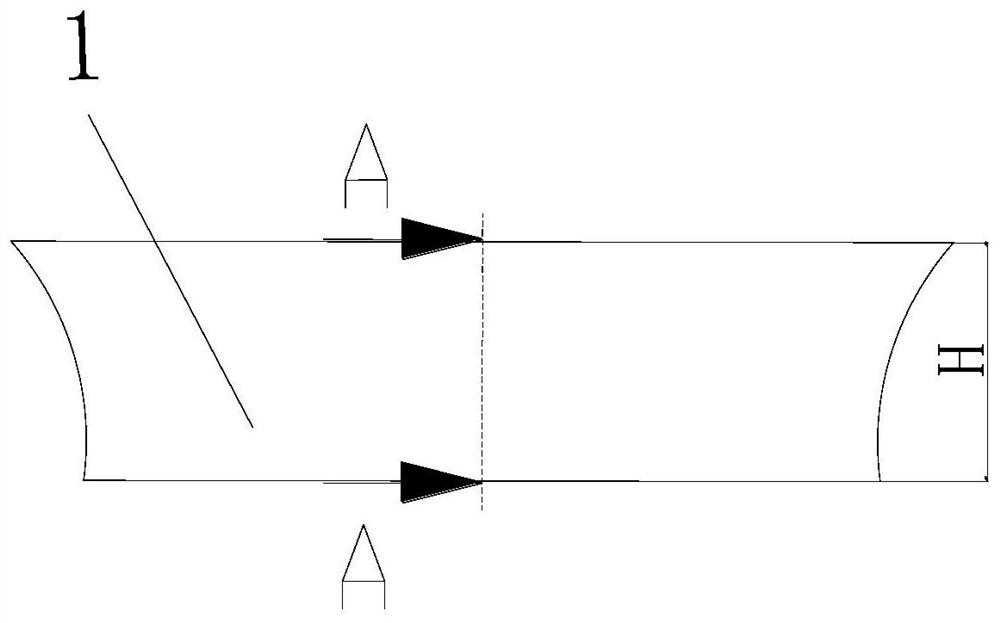

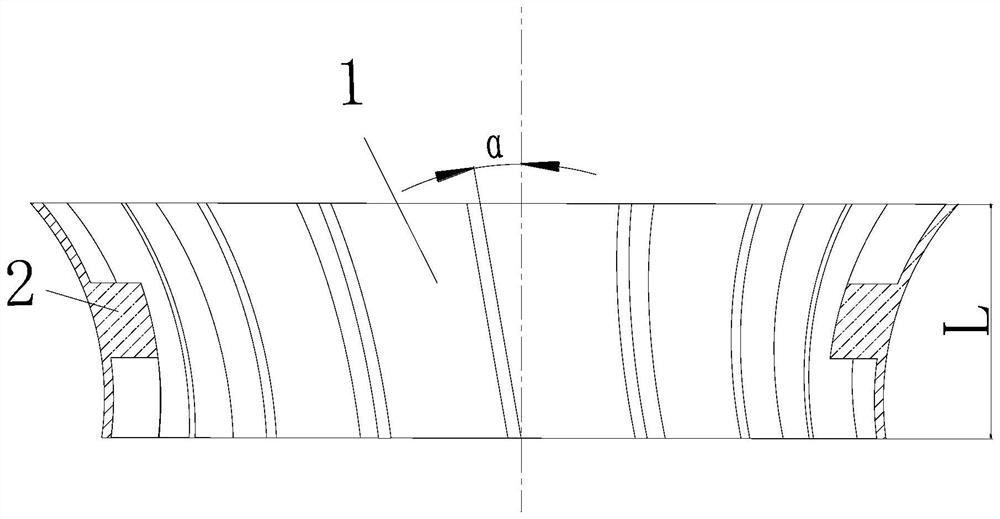

Roller subzero treatment device

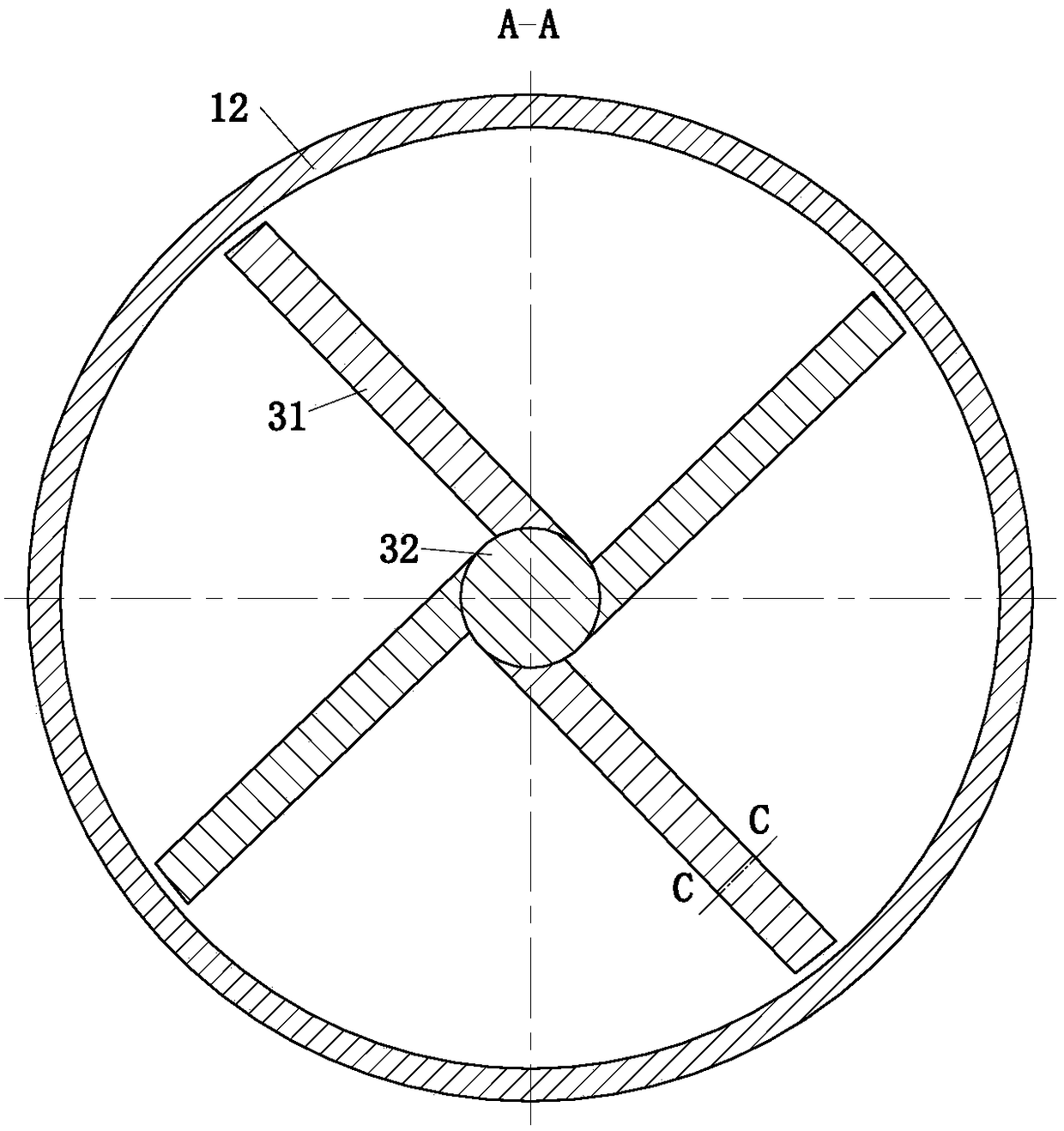

PendingCN109504846APrevent direct sprayEvenly dispersedFurnace typesHeat treatment furnacesImpellerNitrogen

The invention discloses a roller subzero treatment device comprising a precipitation pipe and a blowing device. Nitrogen precipitated at the bottom is blown into a subzero box again, use of liquid nitrogen is reduced, and meanwhile movement of gas in the subzero box is also facilitated. A shielding cover is arranged, so that nitrogen is guided while liquid nitrogen direct injection is prevented, and nitrogen is dispersed more evenly. In addition, a driving device drives a gas inlet barrel to rotate, nitrogen is guided to a roller through the gas inlet barrel, the roller is further cooled evenly, and subzero quality is improved. Meanwhile an impeller is arranged on the outer wall of the gas inlet barrel and is rotated with driving force of the gas inlet barrel, movement of gas in the subzero box is facilitated, gas is distributed more evenly, in addition additional power is not needed, and cost is lowered.

Owner:JIANGSU RUNFU MECHANICAL ROLL MFG

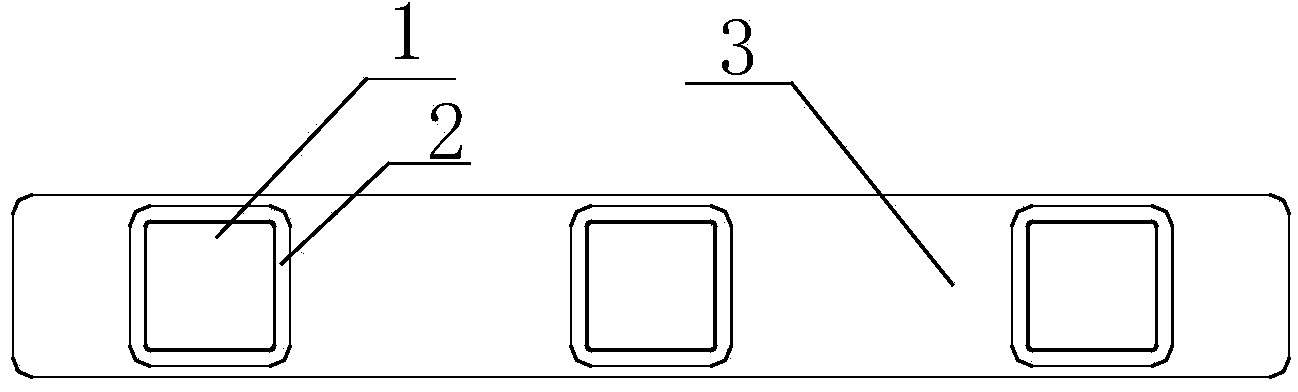

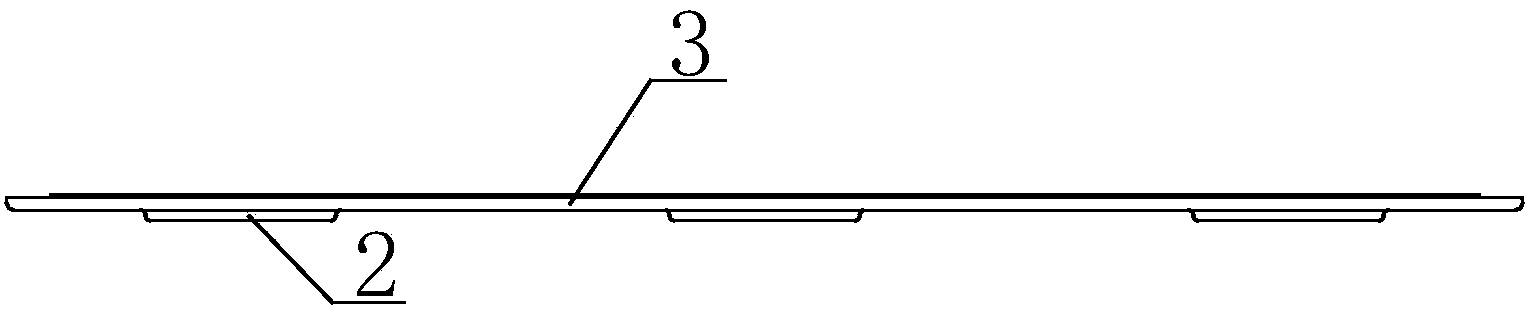

Suspension type refrigerator magnetic attraction storage rack and refrigerator

InactiveCN104374151ASave spaceEvenly cooledLighting and heating apparatusSupportBiological cellRefrigerator car

The invention provides a suspension type refrigerator magnetic attraction storage rack and a refrigerator, and belongs to the field of refrigerator manufacturing. The suspension type refrigerator magnetic attraction storage rack comprises a plastic slot, a plurality of evenly-arranged magnet slots are formed in the plastic slot, and strong magnets are arranged in the magnet slots. The magnetic slots coat the peripheries of the strong magnets, and the middles of the strong magnets protrude out of the magnetic slots. The strong magnets are square and are in a sheet shape. Beverages, beer, cans and other objects with iron covers can be attracted through the strong magnets, and are suspended and hung in the refrigerator, the utilization space of the refrigerator is saved, the stored objects are cooled evenly and are convenient to take, the strong magnets have the attraction function, magnetism of the strong magnets can activate active molecules of biological cells, the refrigeration capacity of the refrigerator is matched, freshness and nutrition are locked lastingly, the structure of the cells is not damaged, the new survival environment of the biological cells is guaranteed and reproduced to the maximum extent, and it is guaranteed that vegetables and fruits in a refrigeration chamber are unchanged in taste for a short time and are as fresh as before.

Owner:AUCMA

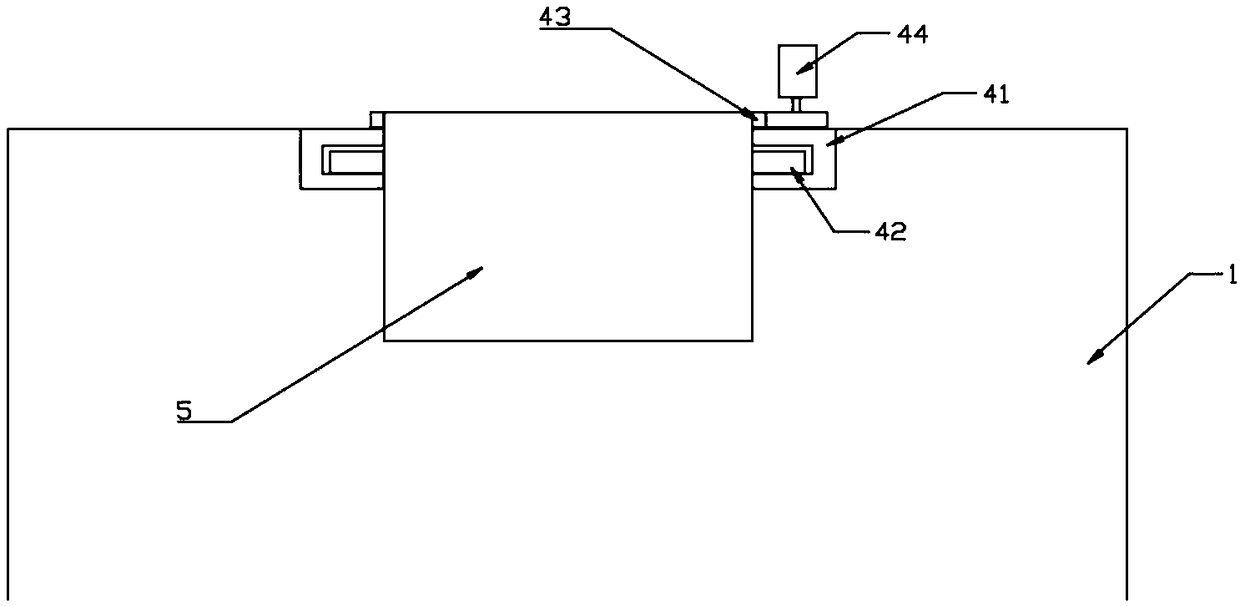

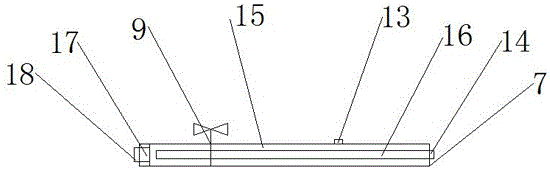

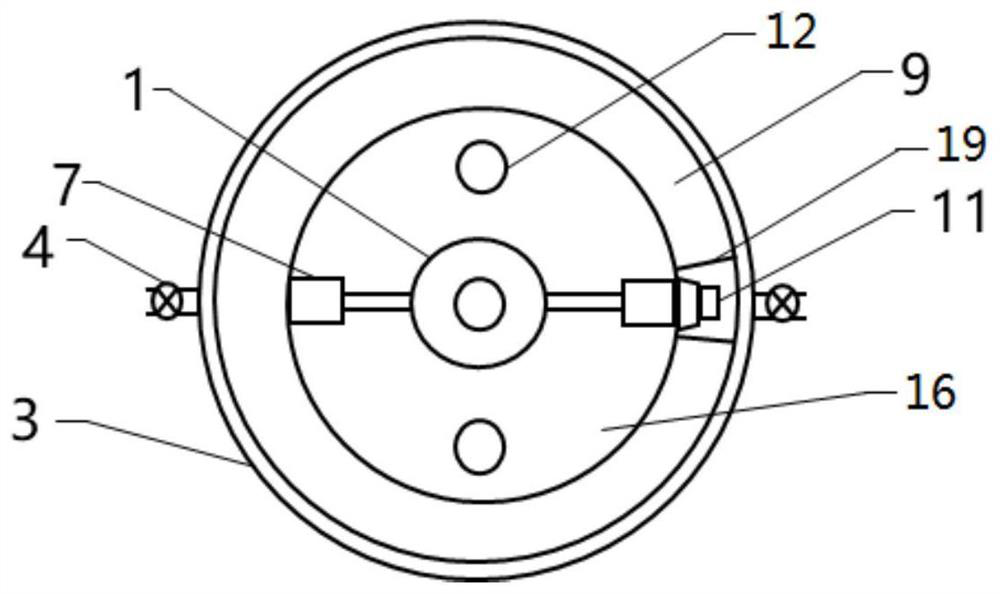

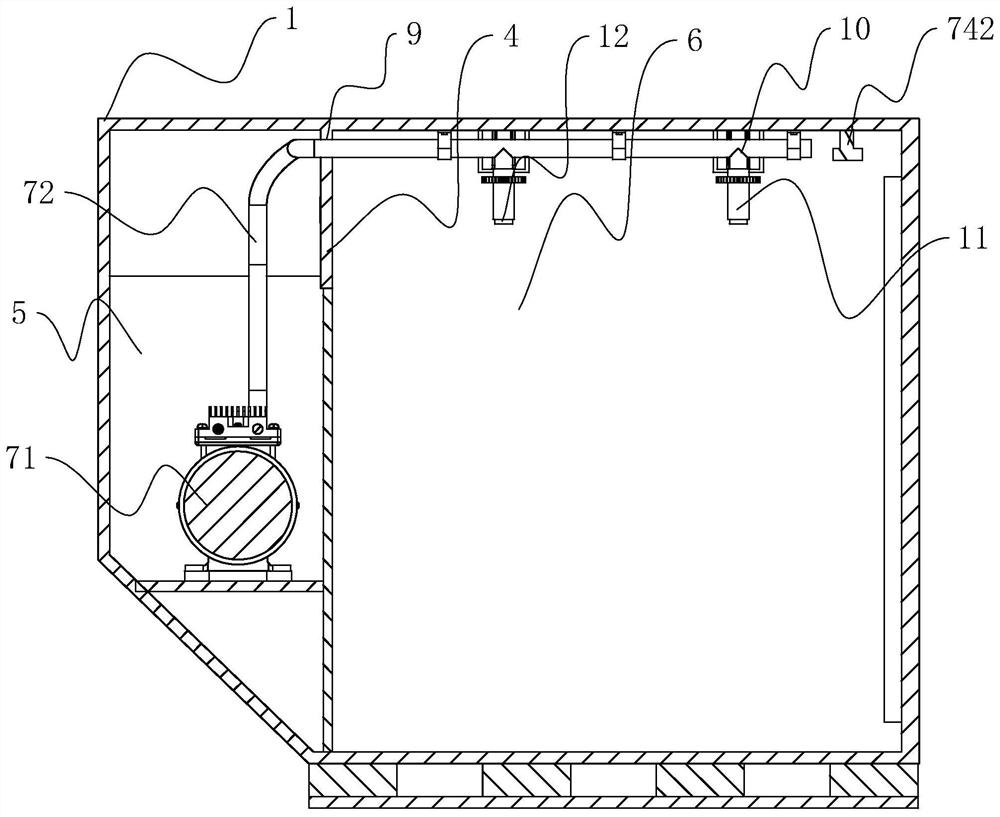

Detection device for pressure container

PendingCN109253915AHeating or cooling evenlyAchieve stress resistanceAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using tensile/compressive forcesSpray nozzleEngineering

The invention discloses a detection device for a pressure container. The detection device comprises a base seat and a detection box body, wherein the detection box body is internally provided with a transmission motor, a support table, a lifting air cylinder, a lifting table, and vertical guide rails, wherein a screw lever is arranged in the middle between the vertical guide rails, the screw leveris externally connected with slide bases, the slide base at one side is externally provided with a spray nozzle, the slide base at the other side is externally provided with a detection probe, a rotary round disk is sheathed at the bottom of the screw lever at the same side as the detection probe, the upper end edge of the rotary round disk is provided with a drive block, a rotary gear is sheathed at the bottom of the screw lever at the same side as the spray nozzle, and an electric control component, a pressure detector, an ultrasonic flaw detector, a heating room and a refrigerating room are arranged beside the detection box body at the upper end of the base seat.

Owner:南京通用化工设备技术研究院

Air cooling device for connecting rod

ActiveCN103555917AIncrease the air supply areaEvenly cooledFurnace typesHeat treatment process controlEngineeringAir cooling

The invention discloses an air cooling device for a connecting rod. The air cooling device comprises an air blower; a horn mouth which is vertically arranged downwards is formed at a fan hole of an air outlet pipe of the air blower; the air blower comprises an air blower body and a motor which is vertical to the air blower body; a fan bracket is arranged beside the motor; the fan bracket comprises two sliding rails which are arranged in parallel at interval; the sliding rails are arranged along the directions vertical to the axis of the motor; a support seat is arranged on the sliding rails in a sliding way, is in a rectangle shape and is internally hollow; two nicks are respectively formed in the two sides of the bottom surface of the support seat along the length directions of the sliding rails; the support seat is blocked between the two sliding rails by the nicks. According to the air cooling device, the motor of the air blower can be supported by a bracket; when the air blower moves to the specific location, the bracket is moved to the corresponding position, and the motor of the air blower is arranged on the bracket; the horn mouth is formed at an air outlet of the air blower, so that the air supply area is enlarged.

Owner:湖州优研知识产权服务有限公司

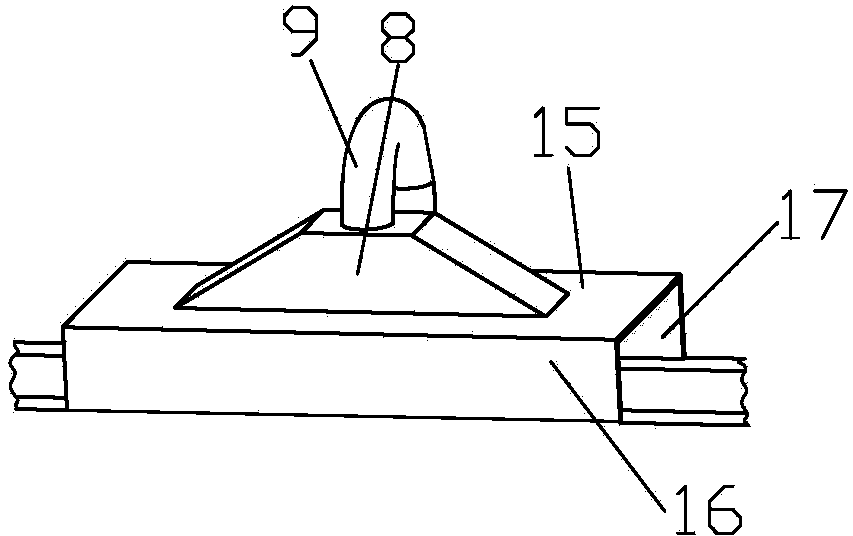

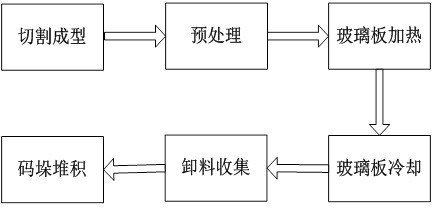

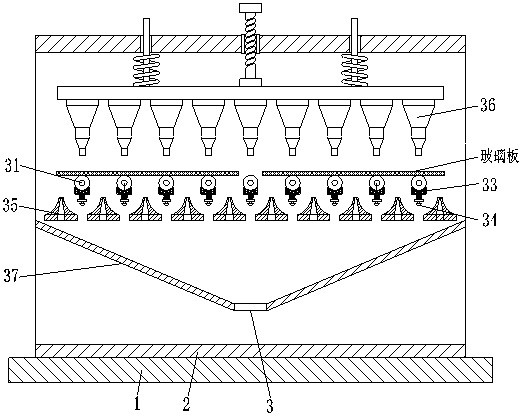

Tempered glass production and processing technology

InactiveCN111943490AAdjustable spacingGuaranteed cooling effectGlass transportation apparatusCleaning using toolsSlagCooling effect

The invention relates to a tempered glass production and processing technology which comprises a bottom plate, a support frame and a cooling device; the support frame is mounted at the upper end of the bottom plate, the section of the support frame is of a U-shaped structure, and the cooling device is mounted in the support frame. The invention solves the problems that when existing equipment cools a glass plate, the distance between a cooling mechanism and the glass plate cannot be effectively adjusted, consequently, the cooling effect of the glass plate is poor and uneven, and the glass plate is liable to break; when the glass plate is cooled and burst, the broken glass slag cannot be rapidly cleaned, manual cleaning is needed after a machine is stopped, and therefore the problems that tempered glass is poor in preparation effect, low in efficiency and the like are solved.

Owner:李明珍

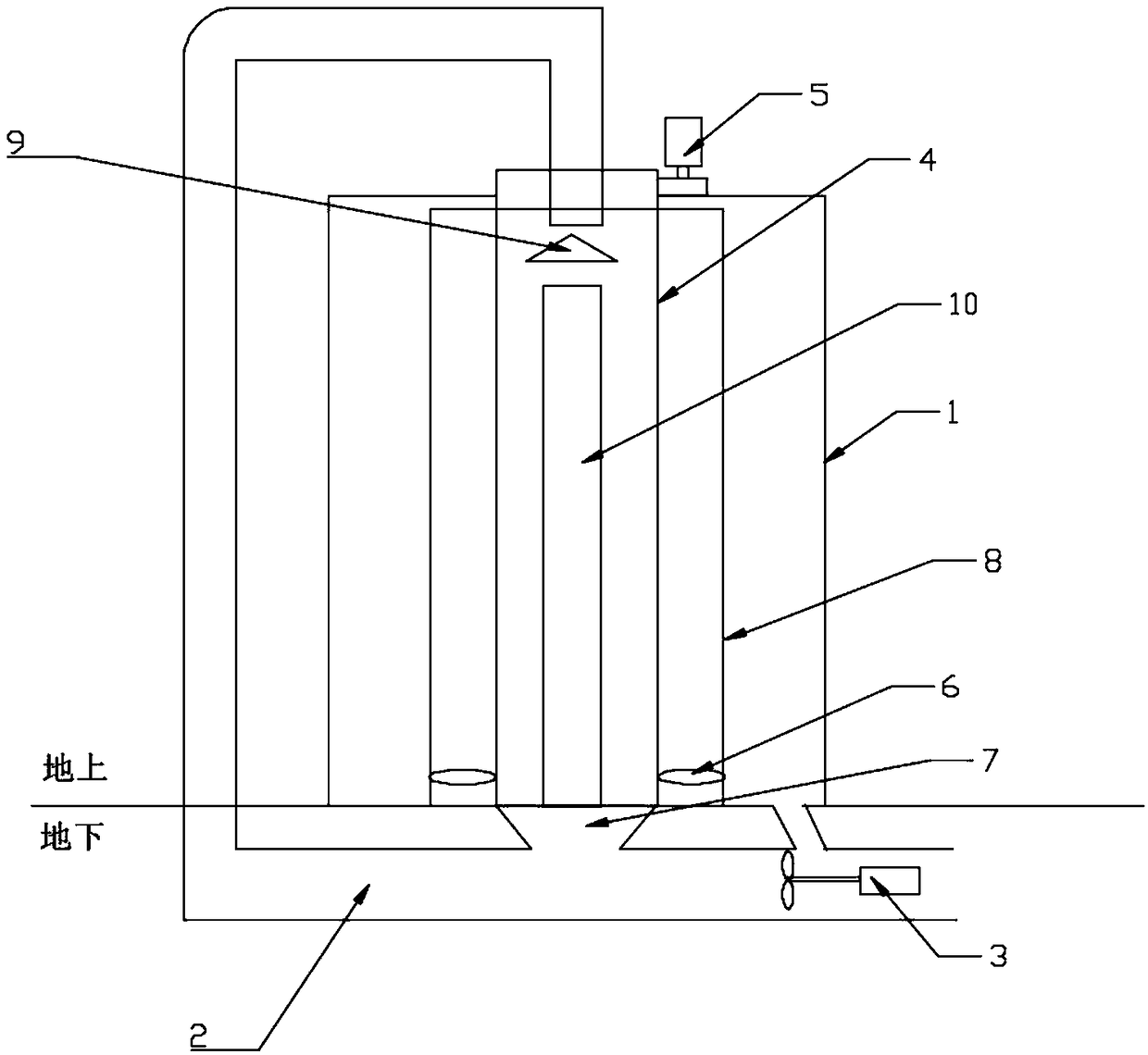

Device integrating cold accumulation and heat accumulation

ActiveCN108332591AAchieve uniform temperature coolingEvenly heatedHeat storage plantsEngineeringRefrigeration

The invention discloses a device integrating cold accumulation and heat accumulation. The device integrating cold accumulation and heat accumulation comprises an energy accumulation tank body. The energy accumulation tank body is internally provided with a heat pipe temperature equilibrium heat exchange device, an upper water distributor and a lower water distributor. The upper water distributor is arranged on the upper portion of the energy accumulation tank body, and the lower water distributor is arranged on the lower portion of the energy accumulation tank body. According to the device integrating cold accumulation and heat accumulation, the energy accumulation tank body is internally provided with the heat pipe temperature equilibrium heat exchange device, the process of cold accumulation and cold release and the process of heat accumulation and heat release can be achieved, and temperature equilibrium refrigeration and temperature equilibrium heating can be conducted on a mediuminside the energy accumulation tank body; and meanwhile, the energy accumulation tank body is internally provided with the upper water distributor and the lower water distributor, and the medium inside the energy accumulation tank body is further heated or cooled uniformly. In addition, under the same cold supply and heat supply external condition, the device integrating cold accumulation and heataccumulation and a corresponding cold accumulation and heat accumulation system thereof are smaller in occupied area, lower in initial investment, higher in operating efficiency, longer in service life and more convenient to maintain.

Owner:邬志军

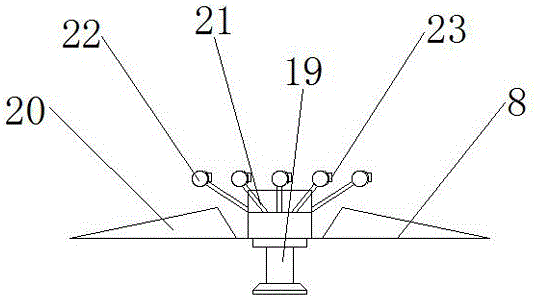

Atomization air cooling device for high-carbon steel production

PendingCN107525322AImprove stabilityPlay the role of diversionDomestic cooling apparatusLighting and heating apparatusRotational axisCarbon steel

The invention discloses an atomization air cooling device for high-carbon steel production. A frame body is arranged on the outer side of a device body, a fan is arranged at the bottom of the frame body, a fixing frame is arranged on one side of the frame body, a gas-liquid mixing pipe is arranged on the top of the fixing frame, the other end of the gas-liquid mixing pipe is provided with a water outlet, one end of the water outlet is provided with a base, one end of the base is provided with an atomization spray head, the bottom end of the atomization spray head is provided with a rotary bearing, the top of the rotary bearing is provided with a spray rod, the top of the spray rod is provided with a spray ball, one side of the spray ball is provided with a nozzle, blades are arranged on the periphery of the rotary bearing, the top of the atomization spray head is provided with an air outlet, the top of the air outlet is provided with a roller bed, and the top of the roller bed is provided with steel materials. One side of the spray ball is provided with the nozzle, the overall structure of the nozzle is in the design of a horn shape, the spray range is wide, the effect is good, and the cooling speed of the steel materials can be conveniently improved.

Owner:德清宏晨铸造有限公司

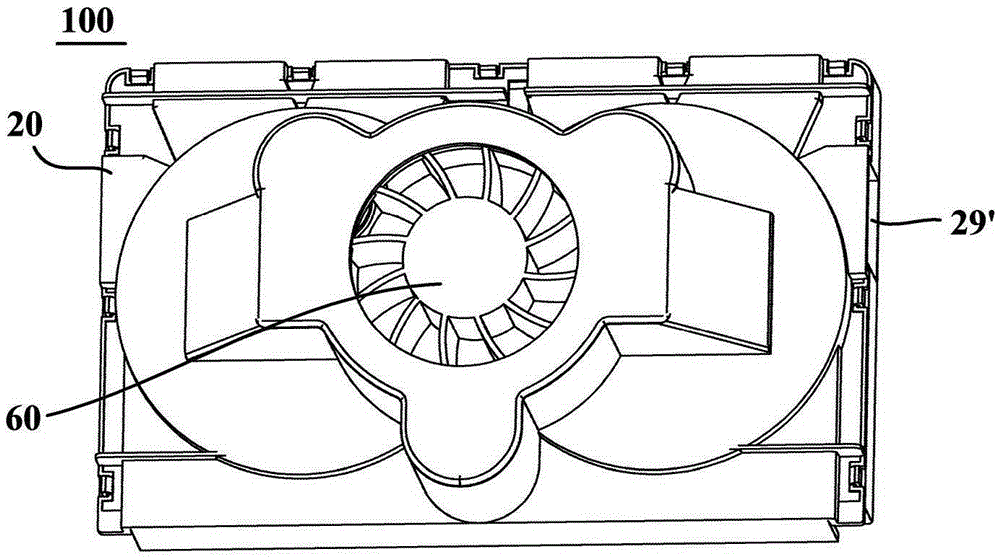

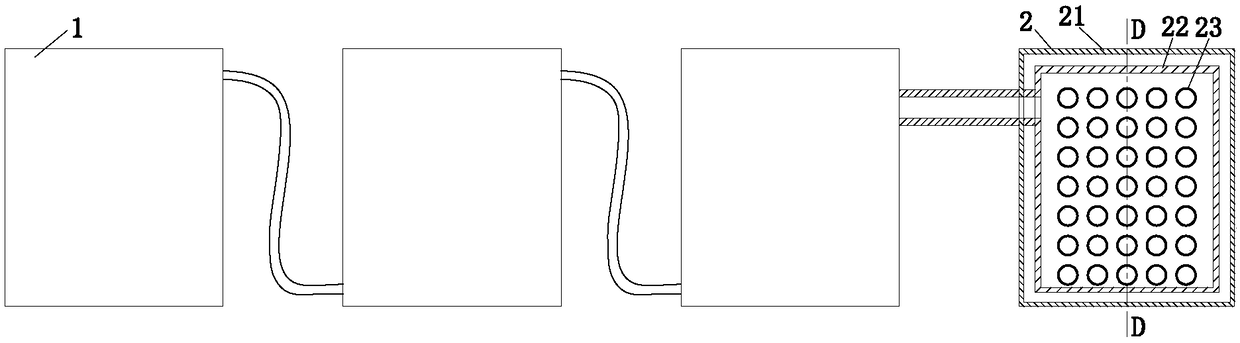

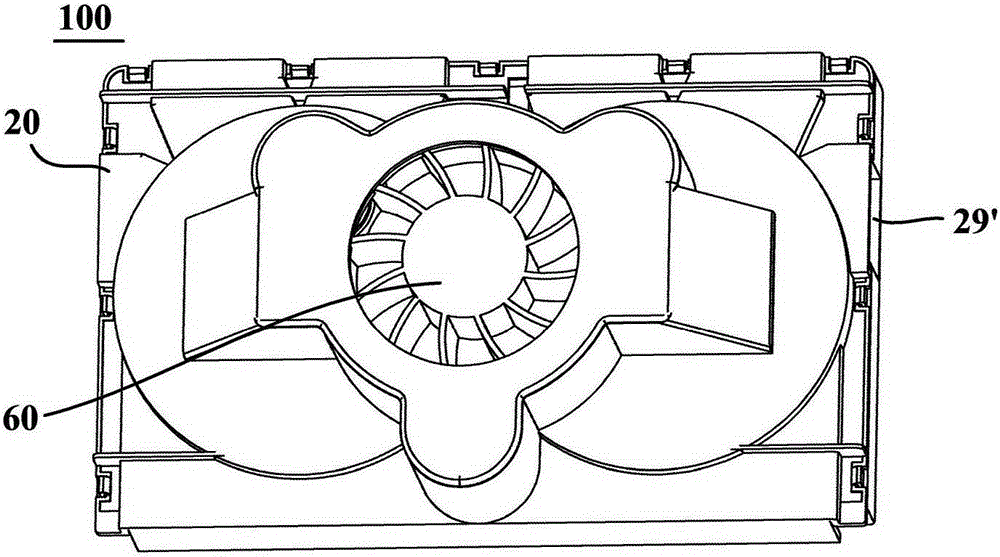

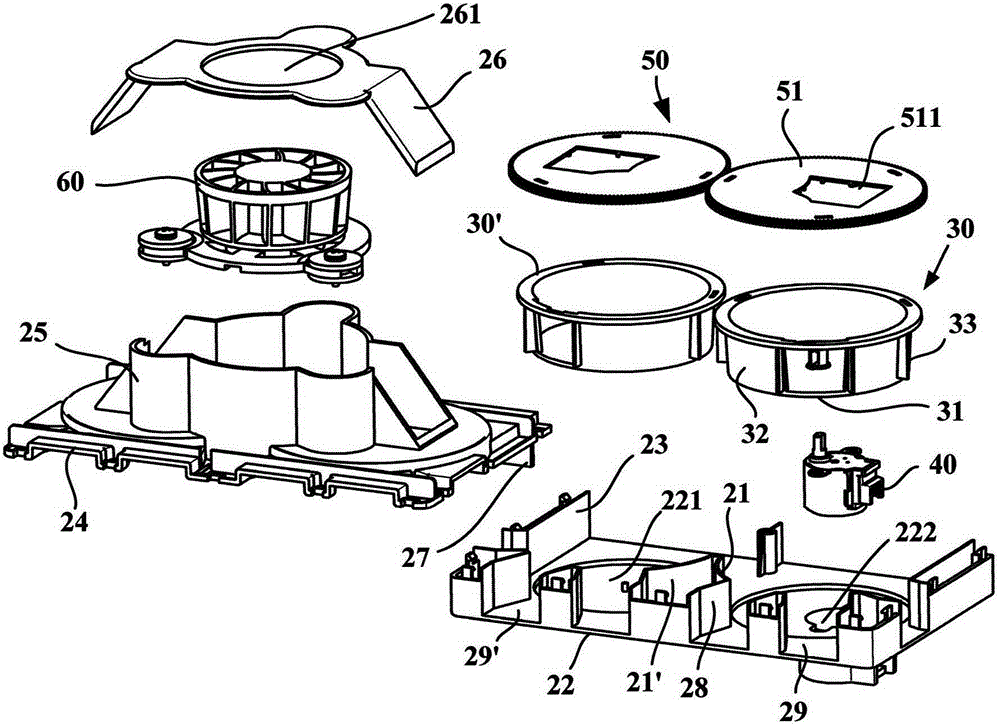

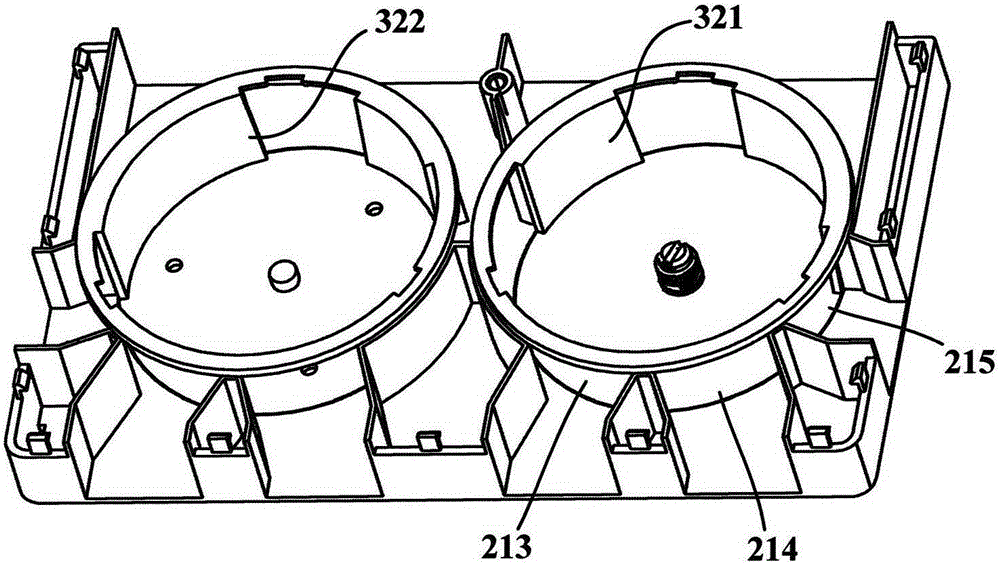

Shunt air supply device and refrigerator with shunt air supply device

ActiveCN106196841AImprove efficiencyImprove operational efficiencyLighting and heating apparatusCooling fluid circulationRefrigerated temperatureExhaust gas

The invention relates to a shunt air supply device and a refrigerator with the shunt air supply device. In particular, the invention provides the shunt air supply device. The shunt air supply device comprises a shell and an air supply device, wherein the shell has two half parts symmetrical about a geometric symmetric surface; each half part has multiple exhaust ports; two adjusting pieces are symmetrically arranged about the geometric symmetric surface; each adjusting piece is controlled to totally shield, partially shield or totally expose each exhaust port of one half part, so that respective exhaust areas of multiple exhaust ports of the half part are adjusted; the air supply device is configured to accelerate air currents to flow into each half part; and the air currents pass through one or more of the multiple exhaust ports of each half part to flow out of the half part. In addition, the invention further provides a refrigerator with the shunt air supply device. The multiple exhaust ports in each half part of the shunt air supply device and the refrigerator can enable left and right sides of an exhaust area in each layer in a refrigerator storage chamber to exhaust air, so that each layer of space in the storage chamber is uniformly cooled, and the air supply efficiency is high.

Owner:HAIER SMART HOME CO LTD

Alcohol distillation device convenient for loading and unloading fermented grains

The invention belongs to the field of wine making equipment and particularly relates to an alcohol distillation device convenient for loading and unloading fermented grains. The alcohol distillation device comprises three distillation devices and a collection tank, wherein the three distillation devices are connected in series; an extrusion unit is used for extruding the fermented grains into thedistillation devices; a distillation cylinder is fixed on the inner surface of a side plate I through a mounting plate I; when the distillation devices are used for distilling the fermented grains, aninterlayer I is filled with steam, the humidity in the fermented grains in the distillation cylinder is increased, an upper base plate I and the side plate I are driven to move in the vertical direction through the stretching and shrinking of a pressure bar, and a first base plate I is driven to rotate by a motor through a rotating shaft and is cooperated with a baffling cover so as to convey thefermented grains back to a recycling box; and an air inlet is used for conveying air to a distillation unit, so as to discharge the fermented grains from the distillation unit. The alcohol distillation device is mainly used for automatically loading and unloading the fermented grains, the alcohol distillation efficiency can be improved, and the production cost can be lowered.

Owner:杭州同福永酿酒有限公司

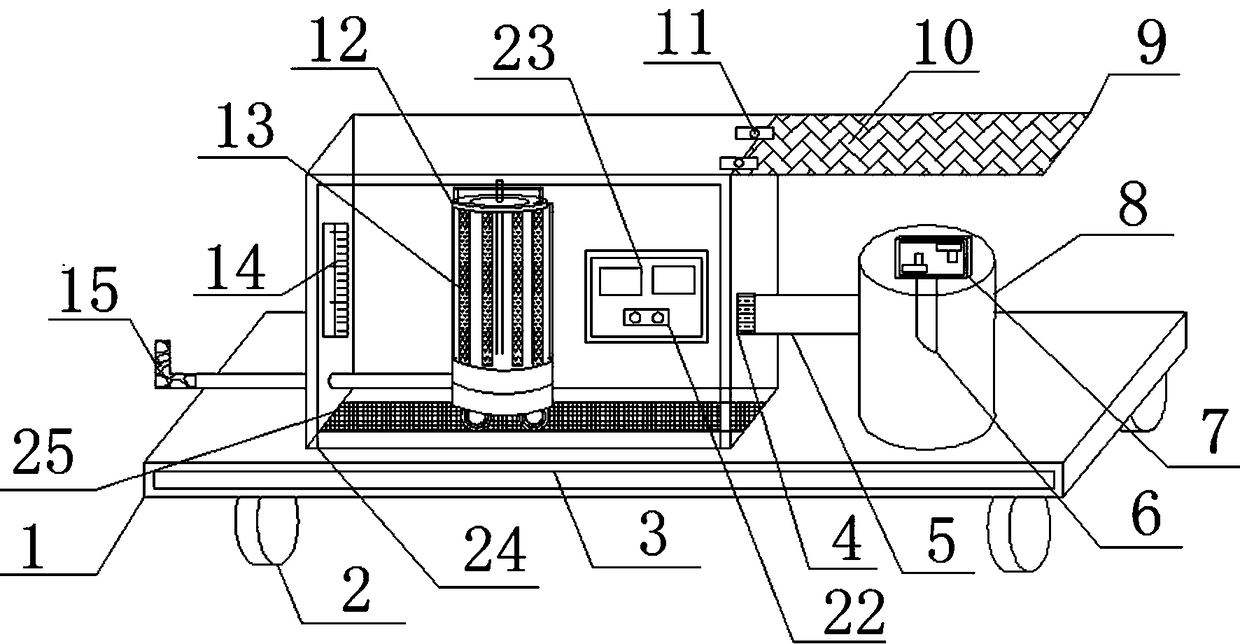

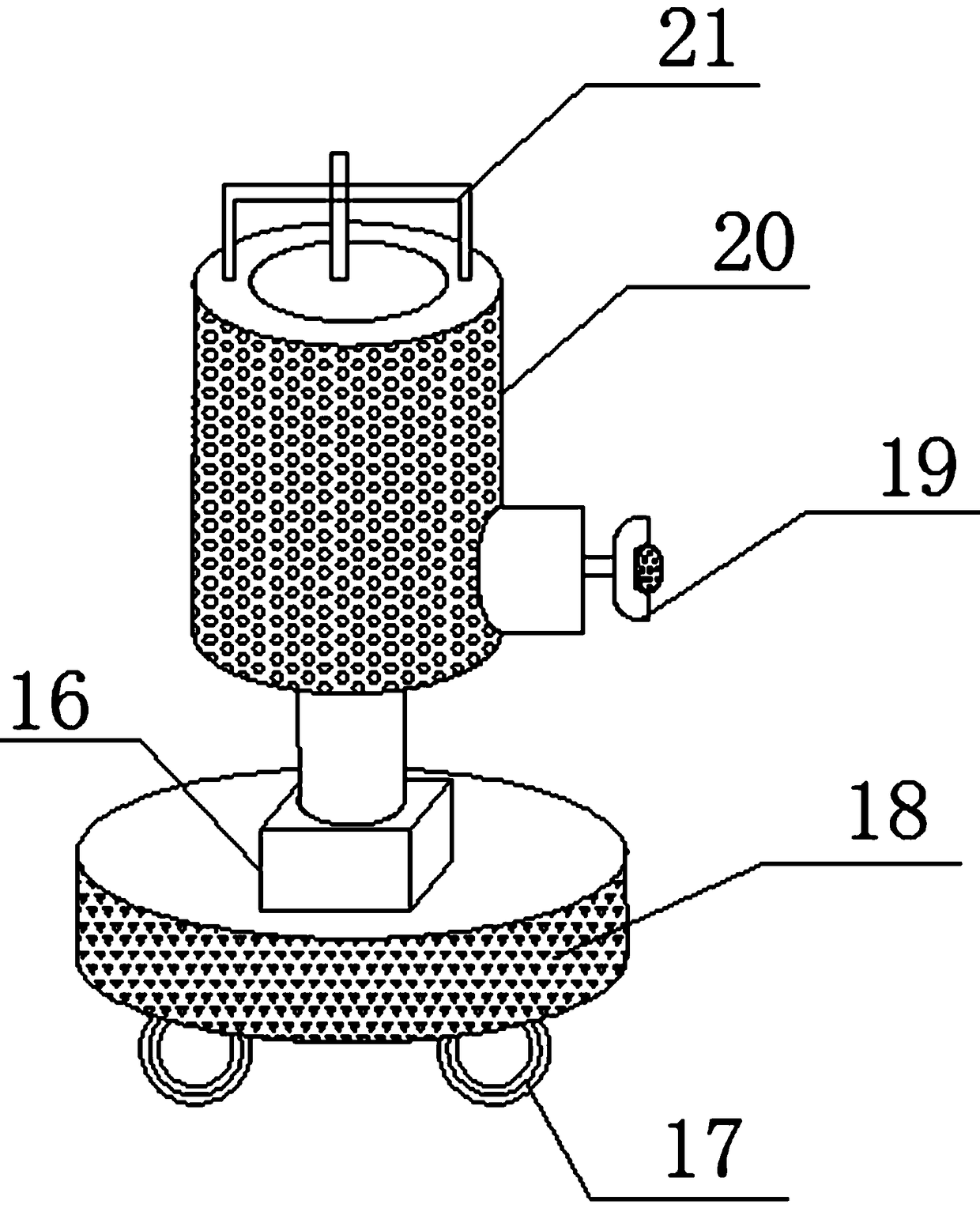

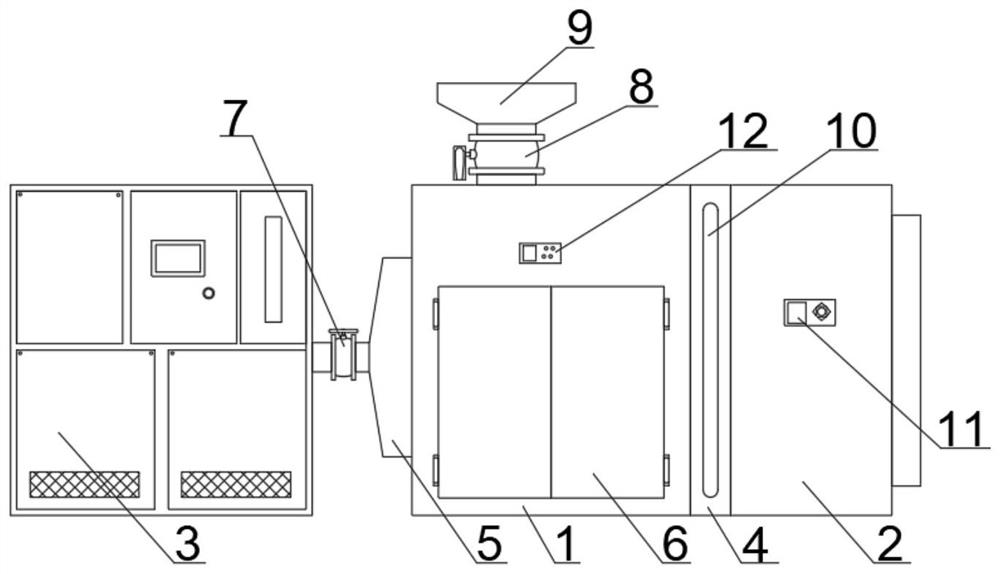

Nano-material freeze-drying preparation equipment

InactiveCN109464826AEvenly cooledImprove sublimation efficiencyDomestic cooling apparatusLighting and heating apparatusFreeze-dryingEngineering

The invention discloses nano-material freeze-drying preparation equipment. The nano-material freeze-drying preparation equipment comprises a freeze-drying equipment body; a supporting plate is arranged in the freeze-drying equipment body; a freezing box, a pipeline and a vacuum waste gas collecting box are arranged at the top of the supporting plate; the vacuum waste gas collecting box is connected with the freezing box through the pipeline; a refrigerating rotating device, a thermometer and a railway are arranged in the freezing box; the refrigerating rotating device comprises a refrigeratingrod, a supporting base, a motor, a liquid storage barrel, an atomizing spraying head, rollers and a liquid storage barrel top cover; the rollers are mounted at the bottom of the supporting base; therefrigerating rod is mounted on the side of the supporting base; the motor is mounted at the central position of the supporting base; the liquid storage barrel is mounted on an output shaft of the motor; the atomizing spraying head is mounted on the outer surface of the liquid storage barrel; a vacuum air sucking pump is arranged at the top of the vacuum waste gas collecting box; and the nano-material freeze-drying preparation equipment is novel in design, simple in structure, easy to implement and good in using effect.

Owner:柳州若思纳米材料科技有限公司

Side-spraying cooling tank

The invention discloses a side-spraying cooling tank, which comprises a tank body and tank doors at two ends of the tank body; the bottom of the tank body is provided with a goods shelf guide rail which is provide with a conveyor belt connected with a motor; the motor drives the conveyor belt to convey materials; connecting pipes I are arranged on two side in the tank body, and are provided with fan-shaped nozzles of which the water outlets are opposite; the connecting pipes I are connected with a circulating device for circulation; internal trays are arranged on the conveyor belt, provided with a plurality of layers and stacked; and the bottom of each internal tray is a water permeable mesh. The side-spraying cooling tank effectively improves circulating speed, makes cooling effect more ideal, ensures the even transfer and distribution of cold quantity, and makes the materials in each layer of internal tray evenly cooled; simultaneously, the temperature in the tank body always keeps stable according to a set value in all stages of the whole temperature reduction process; and a single-section or multi-section cooling mode can be adopted in the tank body so as to meet the temperature reduction requirements of different products.

Owner:老娘舅餐饮股份有限公司

Crucible heating and cooling system for manufacturing high borosilicate glass

InactiveCN113354255AImprove heating efficiencyImprove cooling efficiencyPot furnacesGlass furnace apparatusThermodynamicsCrucible

The invention discloses a crucible heating and cooling system for manufacturing high borosilicate glass, which comprises a temperature changing module, a power module, a watering module and a sealing module, the temperature changing module comprises a workbench, a solid-bottom cylinder installed on the top of the workbench, an arc-shaped plate fixedly connected with the solid-bottom cylinder, a ring body connected to the outer side of the arc-shaped plate in a sleeving mode, a sleeve plate arranged in the solid-bottom cylinder and an L-shaped ring body connected to the outer side of the ring body and the solid-bottom cylinder in the sleeving mode. According to the invention, after the crucible is mounted on the sleeve plate, a transmission pipe for refrigerating or heating is inserted into a gas inlet pipe, then a motor is started, the motor enables a first bevel gear and a third bevel gear to rotate through a second bevel gear, the rotating directions of the first bevel gear and the third bevel gear are opposite, and in the process, gas entering an annular box body is discharged through a plurality of second through holes; the gas is uniformly blown to the outer surface of the rotating crucible, and the outer surface of the crucible is uniformly heated or cooled, so that the heating or cooling efficiency of the crucible is improved, and the energy consumption is reduced.

Owner:江苏立晶工业科技有限公司

Stirrer for preventing raw material adhesion

InactiveCN106268430AInhibit sheddingAvoid stickingRotary stirring mixersMixer accessoriesEngineeringDrive motor

The invention belongs to the iron oxide pigment production technical field, discloses a stirrer for preventing raw material adhesion, and is used for solving the problem of easy adhesion of conventional stirrer pigments on the stirrer inner wall. The stirrer comprises a kettle body; a discharge port is formed in the lower part of the kettle body, and a feed port is formed in the upper part of the kettle body; the kettle body is provided with a stirring shaft driven to rotate by a drive motor; a lower section of the stirring shaft is connected with stirring blades; the kettle body comprises an inner shell; the inner shell is provided with a cavity; the periphery of the inner shell is sleeved with an outer shell; a vacuum cavity body is formed between the outer shell and the outer wall of the inner shell; the cavity body is internally provided with a work liquid, and the inner wall of the cavity body is provided with a liquid absorbing core; the shell body of the outer shell is sleeved with an electric heater; the electric heater is connected with an external power source; the inner shell is provided with a water filling port and a water outlet which communicate with the cavity.

Owner:ZHEJIANG UNITED PIGMENT

Ice cream production method and ice cream machine

The invention discloses an ice cream production method and an ice cream machine. After entering the ice cream machine from a feeding pipe, ice cream is congealed through a refrigerant; the ice cream is treated orthogonally by two different groups of ultrasonic waves, namely the ice cream starts to be nucleated for 3 minutes when the material temperature is negative 1 DEG C-negative 3 DEG C along with the ultrasonic action intensity being 0.8-1 W / cm<2> and the total power being 230 W; and the ice cream starts to perform phase transition when the material temperature is negative 3 DEG C-negative6 DEG C along with the ultrasonic action intensity being 1-1.2W / cm<2>, the total power being 250W and the ultrasonic treatment time being 12 minutes. Air is introduced into the freezing cavity through an air compressor and is mixed with raw materials of ice cream, orthogonal double-frequency ultrasonic wave can assist congelation, so that the cavitation effect is remarkable, the ice cream congelation efficiency is remarkably improved, the formed ice crystals and bubbles are smaller but distributed more uniform, a secondary sterilization effect is formed, and the taste and quality of the ice cream are better.

Owner:SOUTH CHINA UNIV OF TECH

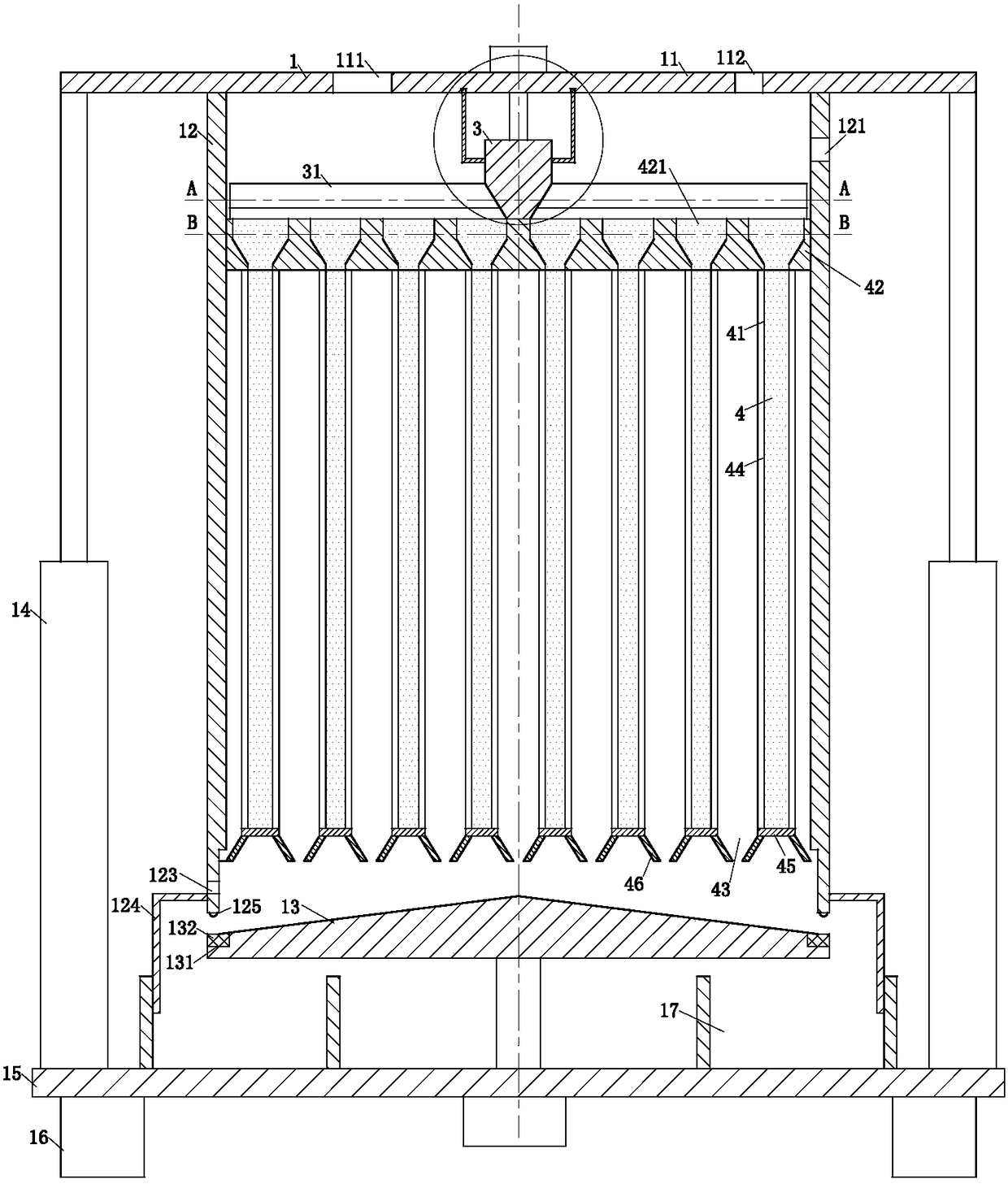

Internal structure of furnace body

InactiveCN109425221AIncrease temperatureEvenly heatedPump componentsMaintainance of heating chambersEngineeringHigh pressure

The invention provides an internal structure of a furnace body. The internal structure comprises a liner; chamber bodies of the liner are connected with a partition plate; the partition plate is usedfor dividing the liner into at least two chamber bodies; one chamber body is a working chamber; an internal rolling wheel mechanism is arranged inside the working chamber; a workpiece is placed on theinternal rolling wheel mechanism; and a fan is arranged at one side of the liner. On one hand, the internal structure provided by the invention can realize uniform heating or cooling of the workpiece; and on the other hand, the inside of the liner is made from a high temperature resisting material and can resist a temperature larger than or equal to 450 DEG C, so the internal structure is especially applicable to places which can bear strong burning and high pressure.

Owner:张跃

Engine cold and hot impact equipment

The invention discloses engine cold and hot impact equipment, which comprises a heat preservation box body, a heating box body and an industrial refrigerating machine, wherein a stand column is installed at the bottom in the heat preservation box body through a bearing, a containing plate is fixed to the top of the stand column through bolts, and a driving motor is installed on one side of the stand column through an installation frame; an air inlet groove is formed in one end of the inner top of the heat preservation box body, a small suction fan is installed in the air inlet groove through the installation frame, an air outlet groove is formed in the other end of the inner top of the heat preservation box body, and a small air outlet fan is installed in the air outlet groove through theinstallation frame. Cold air is provided for the interior of the heat preservation box body through the industrial refrigerating machine, the temperature heated by the electric heating pipe is blown into the heat preservation box body through the fan, the cold air or hot air can circulate in the heat preservation box body, the engine can rotate during testing, the temperature rising and falling speed is high, the engine is heated and cooled evenly, and the equipment is suitable for being widely used and popularized.

Owner:SUZHOU YINGTEMO AUTOMOBILE TECH CO LTD

Partial freezingmachine for live seafood

InactiveCN103960744AEvenly cooledRapid coolingFood freezingFood processingWater storage tankElectric machinery

Apartial freezingmachine for live seafood comprises a case, a freezing machine, a refrigerating pipeline and a controller, wherein a water storage tank is arranged in the case, and a grid conveying belt is arranged in the water storage tank. Compared with a traditional partial freezingmachine for the live seafood, the partial freezingmachine has the advantages that the case is also provided with a cover, the cover is matched with the case in size, a stirring motor is arranged on the cover, a fan is fixedly arranged at the lower end of a stirring machine, and the fan sinks into a freezing fluid. According to the partial freezingmachine, the stirring motor and the cover are added, and the stirring motor controls the fan to stir the freezing fluid when the refrigerating pipeline performs refrigeration, so that the freezing fluid flows circularly and is refrigerated more evenly, and the temperature is reduced faster; meanwhile, the cover covers other surfaces of the freezing fluid except an upward inclined section part, so that the heat transfer between the freezing fluid and the air is reduced to the maximum extent, effects caused by jumping of the live seafood in the water storage tank on usage can be prevented, the working efficiency of the partial freezingmachine for the live seafood is improved, and the electric power is greatly saved.

Owner:温州吴昊农业生物科技有限公司

Stretching and shaping mould for producing automobile steel plate transmission wheel

The invention discloses a stretching and shaping mold for producing an automobile steel plate transmission wheel. The stretching and shaping mold comprises a mold working table for producing the automobile steel plate transmission wheel, a mold machining body and a multi-stage adjustable stretching device are arranged above the mold working table, and the multi-stage adjustable stretching device is disposed inside the mold machining body. The mold machining body is further internally provided with a cooling forming device and a pre-lubricating device, the function of multi-stage stretching adjustment in the process of machining the automobile steel plate transmission wheel is realized, so that the mold can produce automobile steel plate transmission wheels with different structures, and the practicability of the mold is enhanced. A water-cooled cooling molding method can directly cool the surface of a product in a machining forming cavity, and the surface of the product is uniformly cooled, so that the problem that the damage caused to the product during extrusion of the product due to the inconsistent up and down molding speed of the product is avoided. The speed of cooling and forming of the product is improved, and therefore the production efficiency of the steel plate transmission wheel is improved.

Owner:安徽扬子职业技术学院

Moisture absorbing and cooling capacity balancing refrigerator

PendingCN107144071AExtended service lifeExternal pressure balancePump componentsLighting and heating apparatusRefrigerator carStore food

The invention relates to a moisture absorbing and cooling capacity balancing refrigerator and discloses the refrigerator which can balance the cooling capacity inside the refrigerator to rapidly balance the up and down temperature difference in a refrigerator body, can also balance inner pressure and outer pressure so that opening can be facilitated and can also absorb moisture in time after the refrigerator is closed so that frosting and freezing can be avoided. The moisture absorbing and cooling capacity balancing refrigerator is mainly composed of a refrigerator door body inner plate, a cooling capacity balancing and dehumidifying device, a connection pipe and a bi-directional valve. The cooling capacity balancing and dehumidifying device is arranged on the center portion of the refrigerator door body inner plate and connected with the connection pipe pre-arranged in a refrigerator door body interlayer, and the other end of the connection pipe is connected with the bi-directional valve arranged on the side of the refrigerator door body. The moisture absorbing and cooling capacity balancing refrigerator has the beneficial effects that the structure is simple, and installing and replacing are convenient; by means of the arrangement of the bi-directional valve, the air pressure inside the refrigerator and the air pressure outside the refrigerator are balanced, opening is facilitated, and wet and hot air can be exhausted in time; and the low-temperature air in the refrigerator body is pumped and blown to the lower portions of the two sides, the temperature on the periphery inside the refrigerator is rapidly balanced, the load of a compressor is reduced, the service life of the refrigerator is prolonged, up-down circulation of cold air flow in the refrigerator body enables stored food to be cooled evenly, and therefore the energy consumption is reduced.

Owner:JIANGSU STAR COLD CHAIN TECH CO LTD

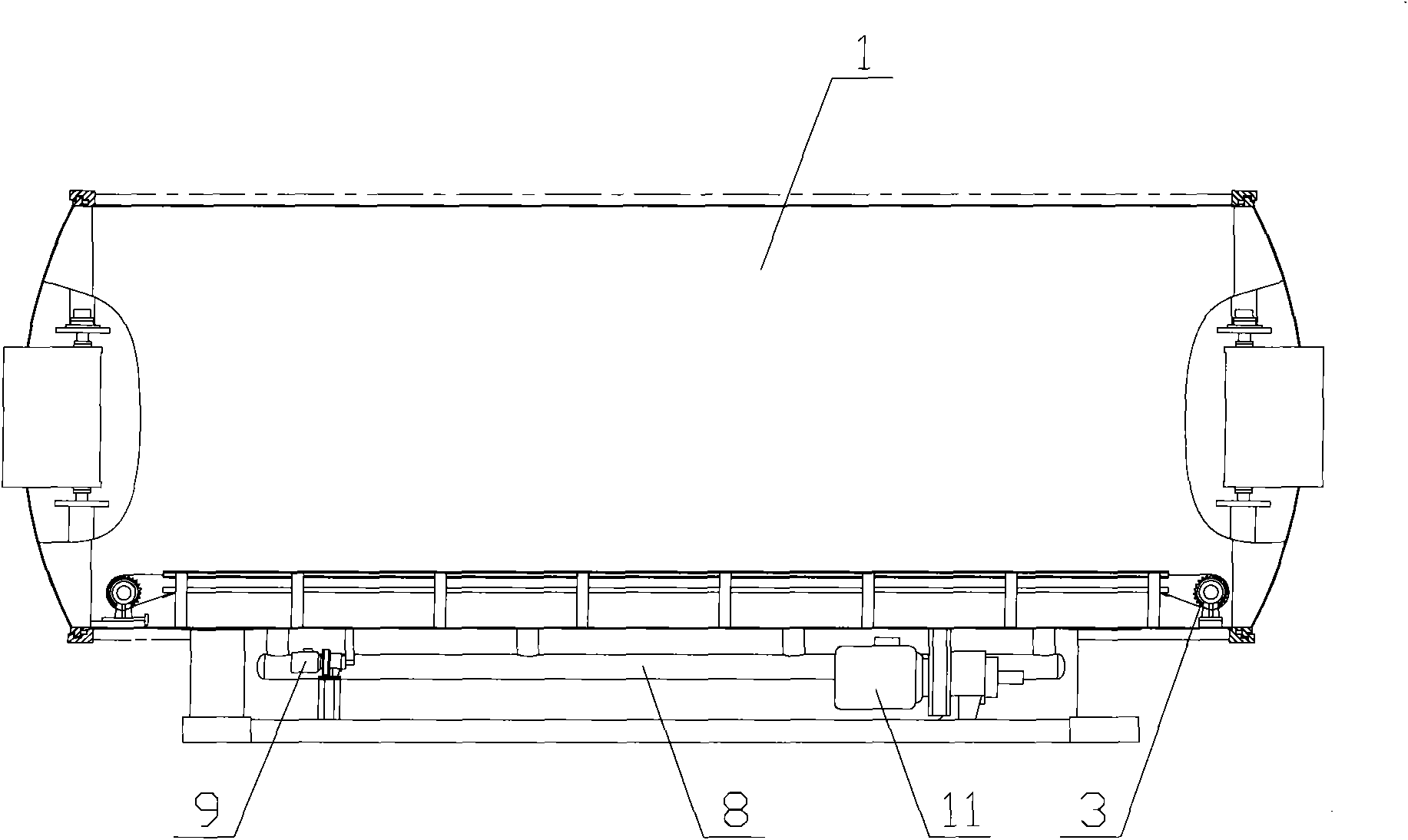

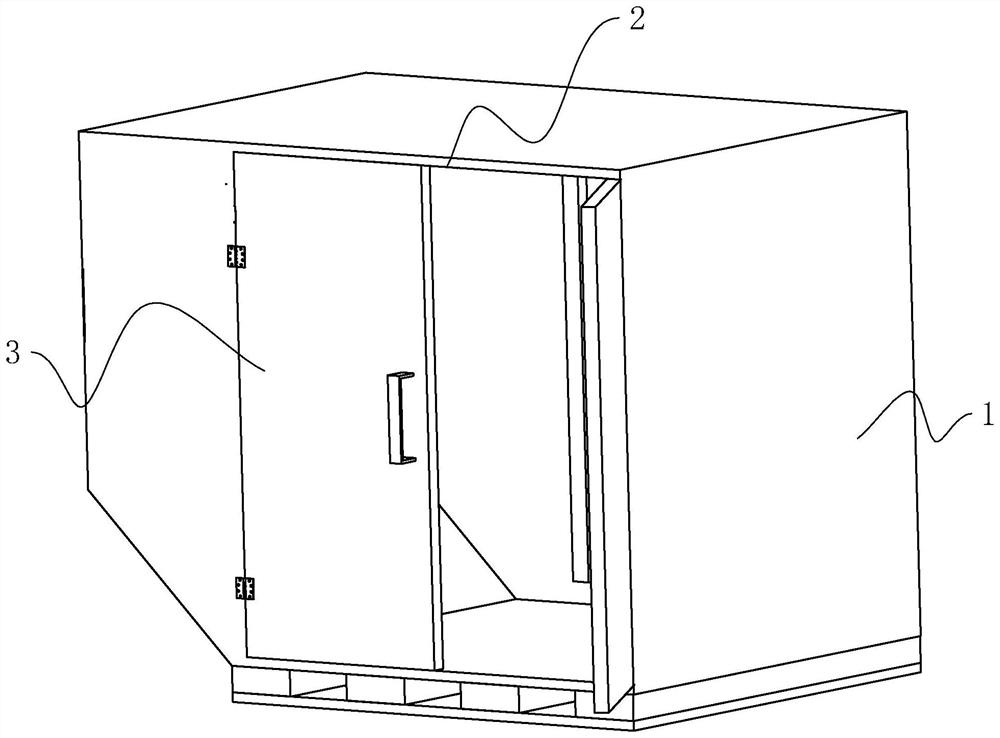

Air container with refrigeration function

ActiveCN112407635BReduce the temperatureImprove deteriorationLarge containersTank wagonsAviationRefrigeration

The present application relates to the field of air containers, in particular to an air container with refrigeration function, which includes a box body, and a partition is arranged in the box body, and the partition plate divides the box body into an installation chamber and a cargo storage chamber. A refrigeration device for reducing the temperature of the cargo storage chamber is provided in the compartment. The application has the effect of improving the lack of refrigeration or cooling function in the existing air container and helping to reduce the deterioration or failure of items during transportation.

Owner:无锡市航空地面设备有限公司

Air conditioner and air outlet control method thereof

InactiveCN111853939AFast Cooling or HeatingHeating or cooling evenlyMechanical apparatusSpace heating and ventilation safety systemsPhysicsAir volume

The invention provides an air conditioner and an air outlet control method thereof. The air conditioner comprises a machine shell (4), an upper air opening (10) and a lower air opening (11) are formedin the machine shell (4), the upper air opening (10) is in communication with the lower air opening (11) through an air duct, an air supply fan (6) capable of achieving bidirectional air supply is arranged in the air duct, an auxiliary air opening (12) is further formed in the machine shell (4), and the auxiliary air opening (12) is located below the lower air opening (11) and communicates with the air duct. According to the air conditioner, the ventilation area of the position of the air opening can be adjusted, then the air inlet amount or the air outlet amount is increased, and rapid adjustment of the indoor temperature is achieved.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

Branching air-supplying device and refrigerator containing same

ActiveCN106225385AImprove efficiencyImprove operational efficiencyLighting and heating apparatusDomestic refrigeratorsElectric machineEngineering

The invention relates to a branching air-supplying device and a refrigerator containing the same. Concretely, the invention provides a branching air-supplying device comprising two half parts symmetric to a geometrical symmetric plane, two adjusting members, a motor, a transmission mechanism and an air supplying device, wherein each half part is provided with a plurality of air outlets; in different rotating positions, each air outlet of the two half parts is fully, partially covered or fully exposed by the two adjusting members; a rotating disc part of one adjusting member is installed on an output shaft of the motor; the transmission mechanism is configured to enable rotational movements of one adjusting member to be reversely transmitted to the other adjusting member in a synchronizing way; the air supplying device is configured to enable air flows to flow into each half part and flow out of each half part through one or a plurality of air outlets of each half part. Besides, the invention further provides a refrigerator containing the branching air-supplying device. The branching air-supplying device has compact structure, small size, few components and high air supplying efficiency.

Owner:HAIER SMART HOME CO LTD

Preparation of composite active polypeptide biological microlite freeze-dried powder

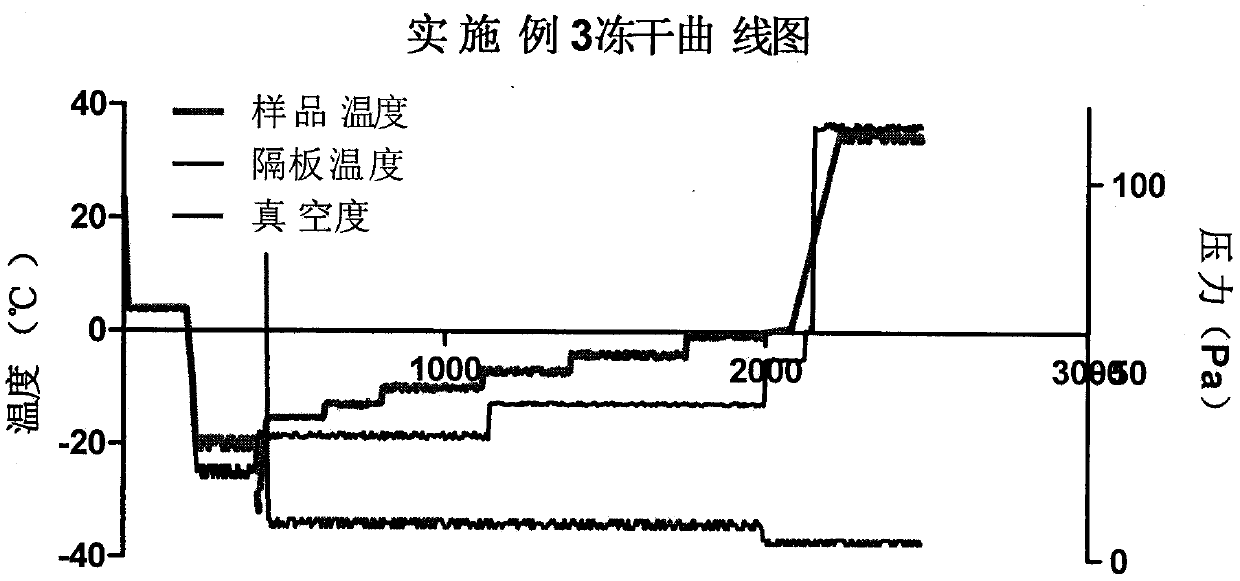

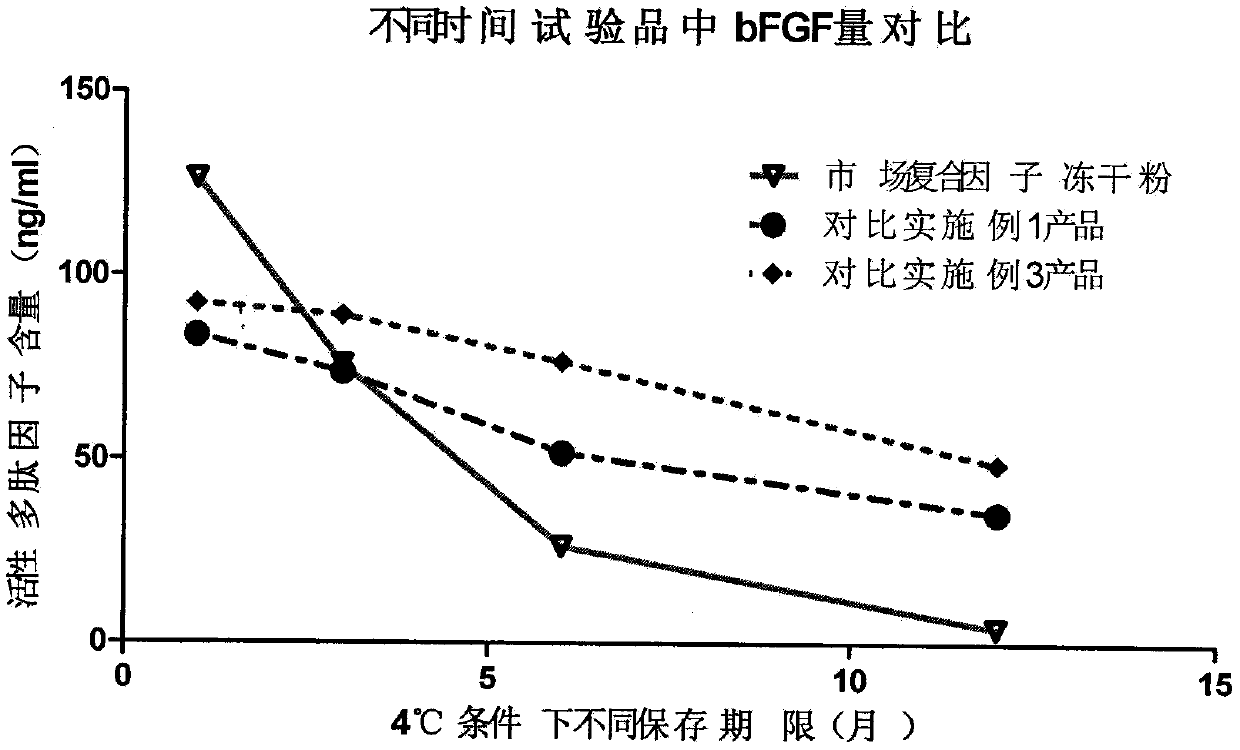

InactiveCN110269813AImprove biological activityImprove biostabilityCosmetic preparationsToilet preparationsActive componentFreeze-drying

The invention provides preparation of composite active polypeptide biological microlite freeze-dried powder, and is applied to the field of feature-beautifying anti-aging cosmetics. Composite active polypeptide is treated by a biological technique and freeze-dried powder is technically treated, so that effective feature-beautifying anti-aging active components are exerted. Composite active polypeptide containing mixed liquid is pretreated, and a freeze-drying technology is researched in details and improved, through the processes of solution prefreezing, primary drying and secondary drying, the prepared freeze-dried powder has scattering microlite surfaces. On one hand, the bioactivity and the stability of the composite bioactive polypeptide freeze-dried powder are improved, the obtained composite active polypeptide biological microlite freeze-dried powder can be stored for a long time under the condition of refrigeration or normal temperature, and on the other hand, the appearance of the freeze-dried powder can be improved. The surface of the active polypeptide biological microlite freeze-dried powder is different from the loose block or powder appearance surface of conventional freeze-dried powder. The technology is simple and easy to operate, and is suitable for industrial production.

Owner:广州暨大美塑生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com