Crucible heating and cooling system for manufacturing high borosilicate glass

A high borosilicate glass and cooling system technology, applied in glass manufacturing equipment, manufacturing tools, glass furnace equipment, etc., can solve problems such as increasing energy consumption, increasing time, reducing temperature rise, cooling efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

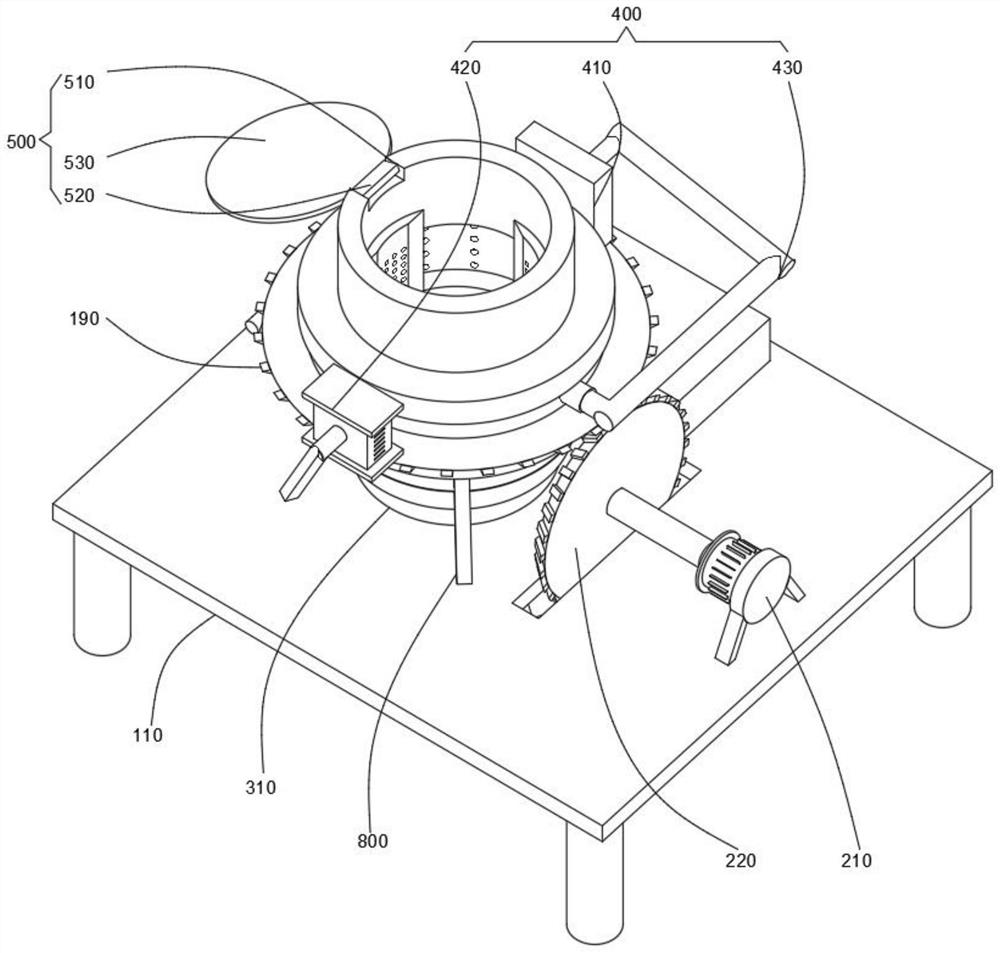

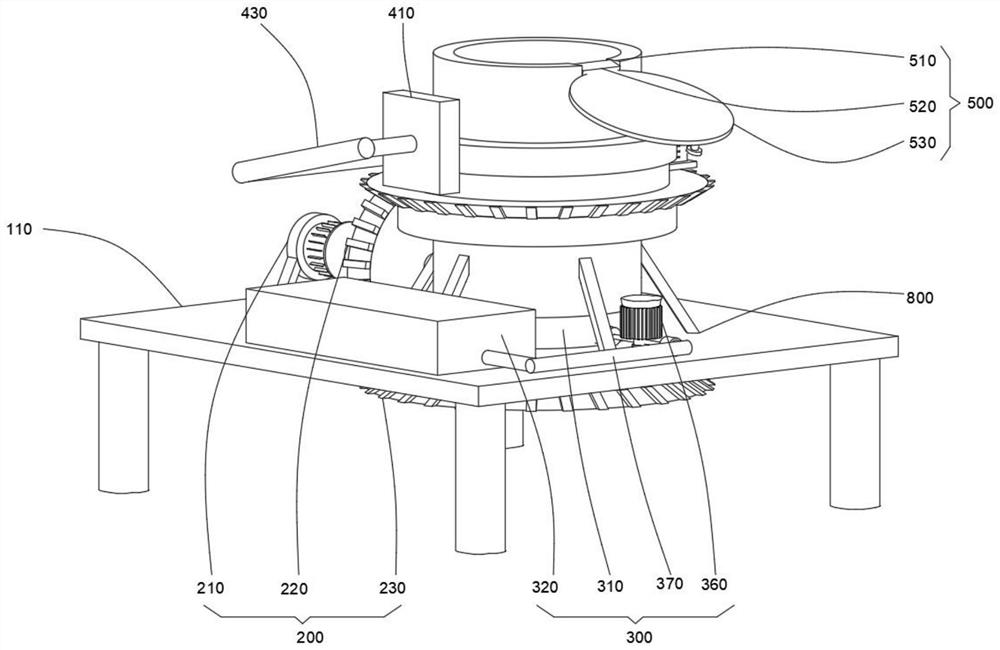

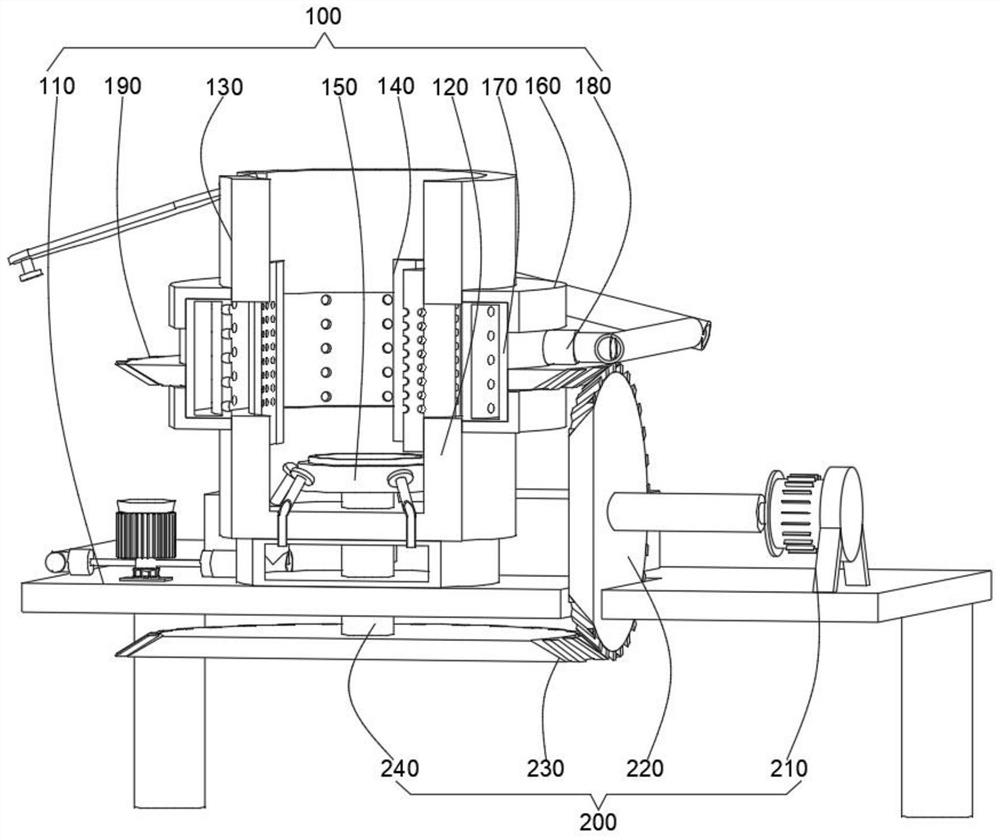

[0050] combine Figure 1-8 shown, combined with Figure 1-8 As shown, the crucible heating and cooling system for borosilicate glass manufacturing provided by the present invention includes a temperature variable module 100, a power module 200, a sprinkler module 300, and a sealing module 500. The temperature variable module 100 includes a workbench 110 and is installed on the working The solid-bottom cylinder 120 on the top of the table 110, the arc-shaped plate 140 affixed to the solid-bottom cylinder 120, and the ring body 130 sleeved on the outside of the arc-shaped plate 140, the arc-shaped plate 140 is used to complete the ring body 130 and the solid bottom cylinder 120, and the sleeve plate 150 built into the solid bottom cylinder 120, in this embodiment, the sleeve plate 150 is used to fix the crucible, sleeved on the ring body 130 and the solid bottom The L-shaped ring 160 outside the cylinder 120 is used to limit the annular box 170, so that the annular box 170 can ...

Embodiment 2

[0061] combine Figure 1-4 and Figure 7 As shown, on the basis of Embodiment 1, the radius of the cover body 530 is equal to the inner diameter of the ring body 130, and the cover body 530 is made of rubber material. With this structural design, the cover body 530 can hold the ring body 130 The inner diameter is just sealed, which reduces the discharge speed of the air in the solid-bottomed cylinder 120 and improves the efficiency of heating or cooling the crucible.

Embodiment 3

[0063] combine figure 1 and Figure 3-6 As shown, in the above-mentioned embodiment, the heating and cooling system for the crucible for high borosilicate glass manufacturing further includes a gas outlet assembly 600, the gas outlet assembly 600 is composed of a plurality of first through holes 610 and a plurality of second through holes 620, and a plurality of The first through-holes 610 are respectively opened on a plurality of arc-shaped plates 140, and the plurality of second through-holes 620 are respectively opened on the inside of the annular box 170, and a plurality of first through-holes 610 are opened on the arc-shaped plates 140 The resistance of the arc-shaped plate 140 to the gas flowing out of the annular box 170 can be reduced, and then the multiple second through holes 620 make the gas in the annular box 170 flow out more uniformly.

[0064] The working principle and application process of the present invention: in the initial state, the crucible is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com