Nano-material freeze-drying preparation equipment

A drying equipment and drying technology, applied in lighting and heating equipment, household refrigeration devices, household appliances, etc., can solve the problems of uneven cooling distribution of nano-solutions, troublesome observation of freezer temperature, and delay in working time, etc. Accurate preparation results, improved sublimation efficiency, and smooth operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

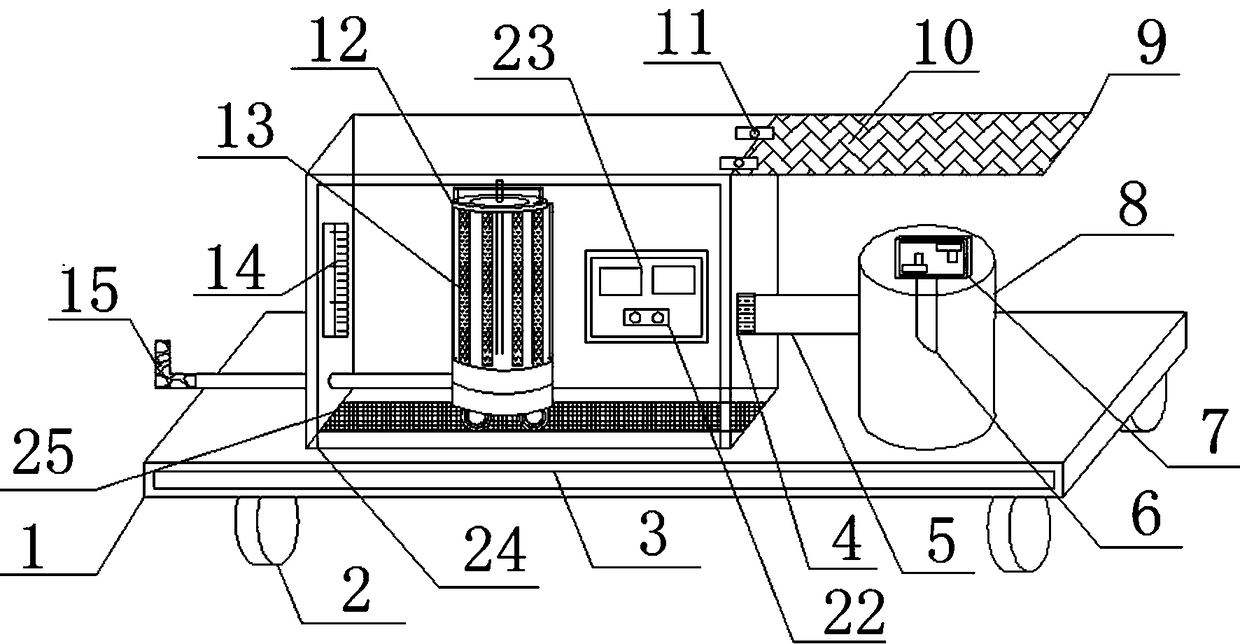

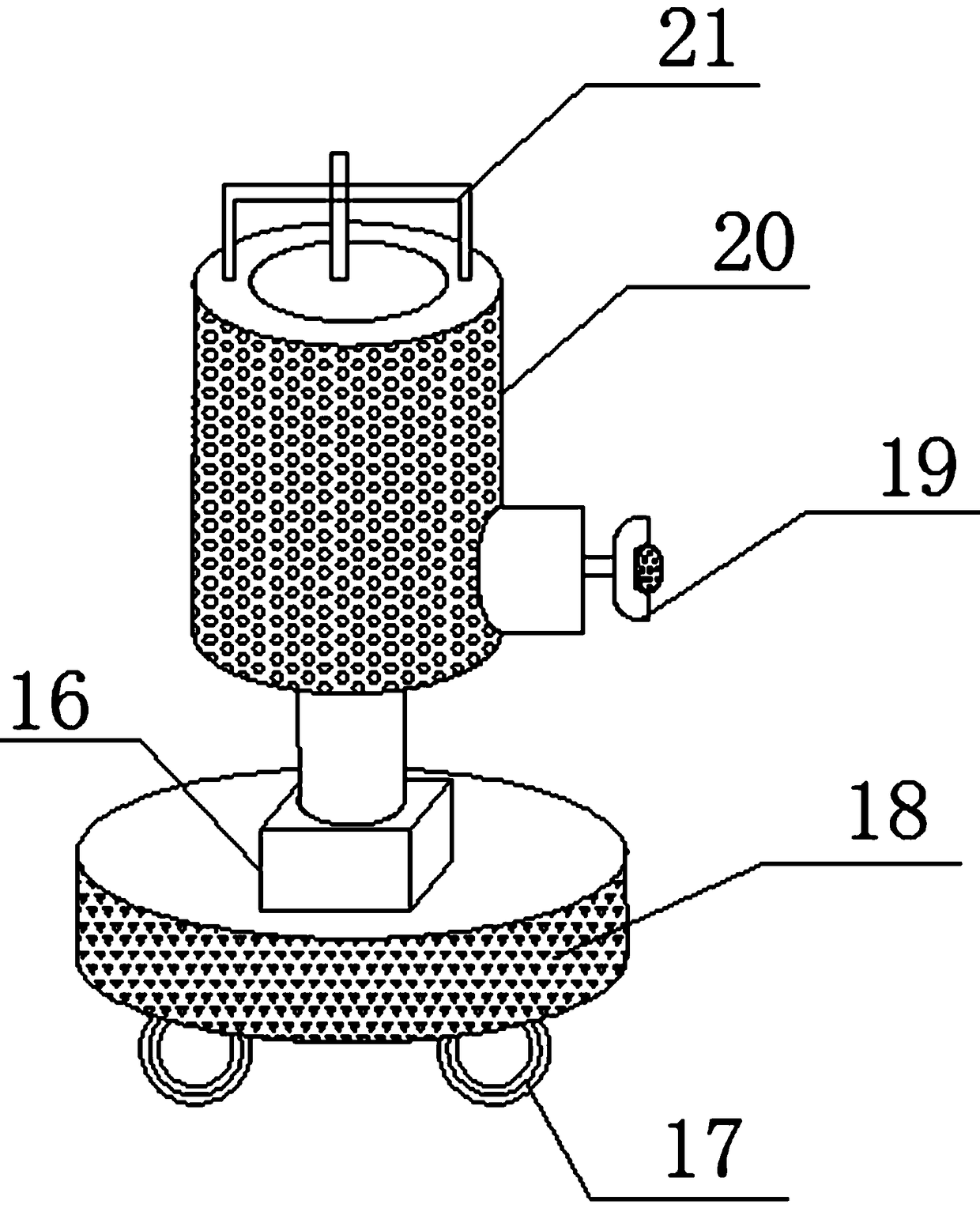

[0018] As a preferred embodiment of the present invention, a pulley 2 is provided at the bottom of the support plate 3 .

[0019] As a preferred embodiment of the present invention, one side of the refrigeration rotating device 12 is provided with a through hole and a push-pull rod 15, and the push-pull rod 15 is installed on the refrigeration rotating device 12 through the through hole.

[0020] As a preferred embodiment of the present invention, the top of the vacuum waste gas collection box 8 is also provided with a perforation, and the bottom of the vacuum pump 7 is provided with a suction pipe 6, and the suction pipe 6 is arranged in the vacuum waste gas collection box 8 through the perforation. .

[0021] As a preferred embodiment of the present invention, a valve 4 is provided at the connection between the pipeline 5 and the freezer 24 .

[0022] As a preferred embodiment of the present invention, the top of the freezer 24 is provided with a freezer top cover 9 and a h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com