Preparation of composite active polypeptide biological microlite freeze-dried powder

An active polypeptide, freeze-dried powder technology, applied in cosmetic preparations, cosmetic preparations, preparations for skin care, etc., can solve the problems of less novel and unique appearance, harsh storage conditions, unfavorable storage and transportation, etc. Appearance, anti-oxidant enhancement, UV protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Containing bFGF active peptide mixture formula:

[0030]

[0031] Preparation:

[0032] Weigh the material according to the formula, dissolve it in deionized water, swell overnight at 4°C, filter and sterilize through a 0.22um microporous membrane, dispense it into vials, and put it into a freeze dryer. Turn on the freeze dryer and keep it at 4°C±1°C for 2 hours; cool down to below -20°C, keep the temperature of the freeze-drying chamber at -20±2°C, and pre-freeze the product for 6 hours; start vacuuming, when the vacuum reaches 10Pa After that, heat up; adjust the temperature of the freeze-drying chamber to rise slowly to 0.0°C, the temperature rise should not exceed 1.0°C per hour, and keep it under vacuum for 28 hours; continue to adjust the temperature of the freeze-drying chamber, and raise the temperature to 35°C at a rate of 5°C / h , keep warm for 3 hours. Introduce nitrogen, helium or argon, adjust the freeze-drying chamber to normal pressure, press the inne...

Embodiment 2

[0037] Containing EGF active peptide mixture formula:

[0038]

[0039] Preparation:

[0040] Weigh the material according to the formula, dissolve it in deionized water, swell overnight at 4°C, filter and sterilize through a 0.22um microporous membrane, dispense it into vials, and put it into a freeze dryer. Turn on the freeze dryer and keep it at 4°C±1°C for 3 hours; cool down to below -20°C, keep the temperature of the freeze-drying chamber at -20±2°C, and pre-freeze the product for 7 hours; start vacuuming, when the vacuum reaches 10Pa After that, heat up; adjust the temperature of the freeze-drying chamber to rise slowly to 0.0°C, the temperature rise should not exceed 1.0°C per hour, and keep it under vacuum for 25 hours; continue to adjust the temperature of the freeze-drying chamber, and raise the temperature to 30°C at a rate of 3°C / h , keep warm for 5 hours. Introduce nitrogen, helium or argon, adjust the freeze-drying chamber to normal pressure, press the inner...

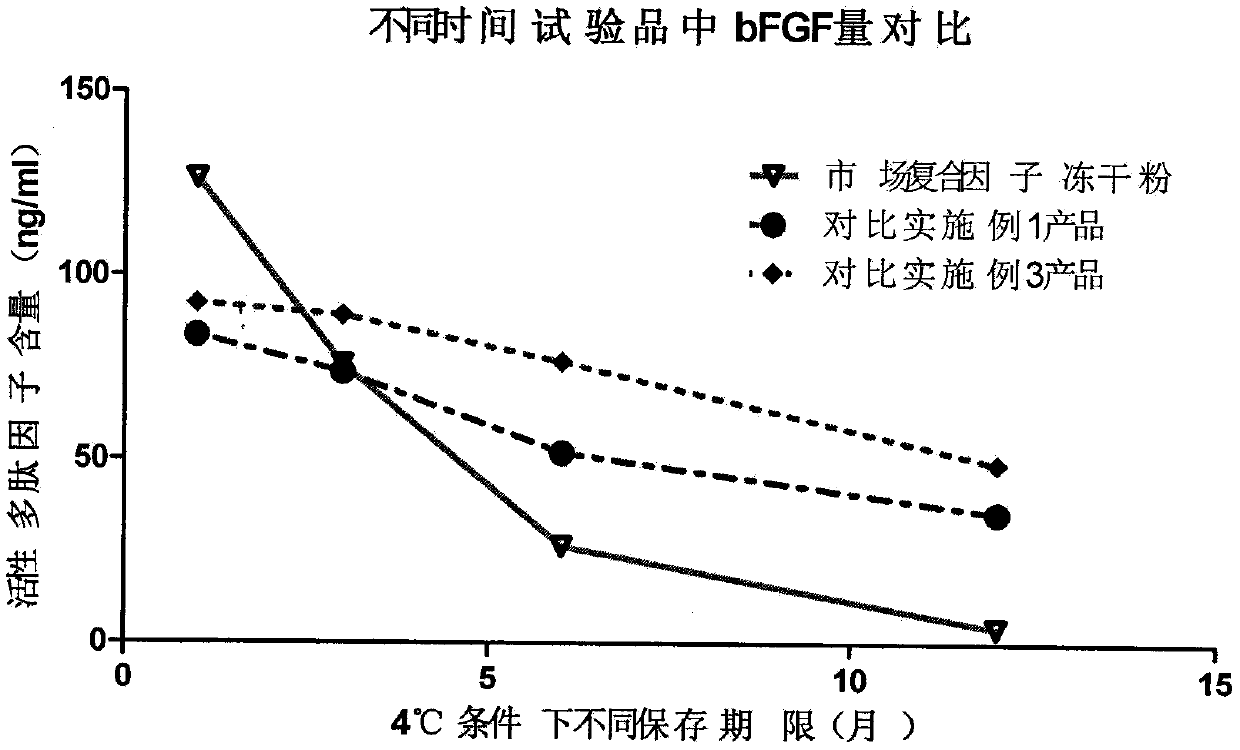

Embodiment 3

[0045] Formula containing complex active peptide mixture:

[0046]

[0047] Preparation:

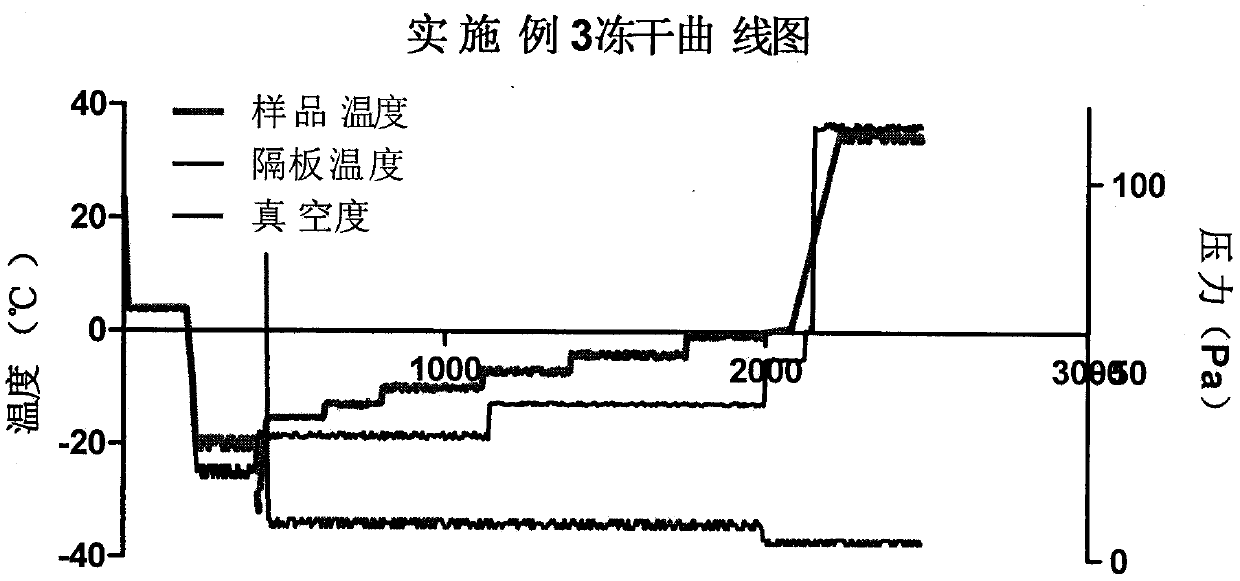

[0048] Weigh the material according to the formula, dissolve it in deionized water, swell overnight at 4°C, filter and sterilize through a 0.22um microporous membrane, dispense it into vials, and put it into a freeze dryer. Turn on the freeze dryer and keep it at 4°C±1°C for 3 hours; cool down to below -20°C, keep the temperature of the freeze-drying chamber at -20±2°C, and pre-freeze the product for 7 hours; start vacuuming, when the vacuum reaches 10Pa After that, heat up; adjust the temperature of the freeze-drying chamber to rise slowly to 0.0°C, and the temperature rise does not exceed 1.0°C per hour, and keep it under vacuum for 25 hours; continue to adjust the temperature of the freeze-drying chamber, and raise the temperature to 35°C at a rate of 10°C / h , keep warm for 3 hours. Feed nitrogen, helium or argon, adjust the freeze-drying chamber to normal pressure, press the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com