Moisture absorbing and cooling capacity balancing refrigerator

A cold ice and freezer door technology, applied in the field of freezers, can solve the problems of reducing the service life of the compressor, being unable to replace it, increasing loss, etc., achieving the effects of reducing the compressor load, convenient installation and replacement, and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

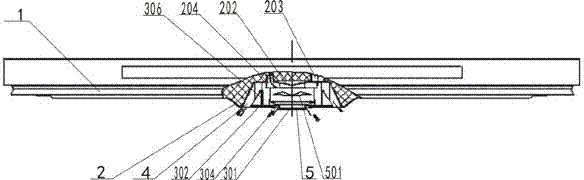

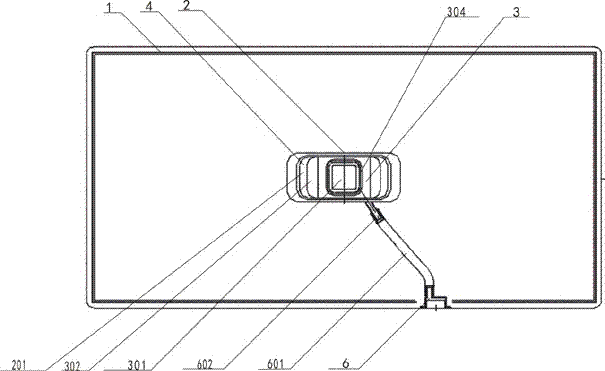

[0015] Embodiment 1, when the door of the freezer is opened, the touch switch placed on the door is turned off, and the frequency conversion fan (5) stops working; when the door is closed, the touch switch is closed, the circuit is connected, and the frequency conversion fan (5) ) starts, and within 2-5 seconds, the fan rotates at the maximum speed, and the hot and humid gas floating in the upper space of the cabinet is forcibly inhaled through the air inlet (304), and the wind force generated by the variable frequency fan is divided by the wind slope (202). Part of it flows back into the cabinet through the diversion slope (201) and the air outlet (4), and part of it flows into the two-way valve (6) through the dehumidification air inlet (203) along the connecting pipe (601). This part of the air flow contains a large amount of water vapor , press the piston (7) and overcome the elastic force of the push spring (704), push the piston (7) outward, and when the piston (7) moves ...

Embodiment 2

[0016] Embodiment 2: After the frequency conversion fan (5) works for 2-5 seconds, the speed of the frequency conversion fan (5) decreases under the control of the electronic control system, and it is in a normal working state, the wind force decreases, and the pressure on the piston (7) decreases , under the action of the push spring (704), the piston (7) resets, and the dehumidification groove (608) is in a closed state. At this time, the push spring (704) and the return spring (703) are in a balanced state. ) to ensure that the outlet of the air intake chamber (606) and the inlet of the air passage (705) are still in a dislocation state, and the outer wall of the outlet of the air inlet chamber (606) and the inner wall of the air passage inlet (705) are misaligned within 1 -2mm, that is, the two-way valve (6) is closed, and the variable frequency fan (5) is still working. At this time, the cold air in the cabinet is sucked by the air inlet The diversion slope (202), the div...

Embodiment 3

[0017] Embodiment 3, when opening the freezer, since the frequency conversion fan (5) is still in working condition, the temperature inside the cabinet is lower than the ambient temperature, and under the action of atmospheric pressure, the door of the freezer is not easy to open. function, breaking the balance between the push spring (704) and the return spring (703), causing the piston (7) to push into the two-way valve (6), so that the outlet of the air inlet chamber (606) coincides with the inlet of the air passage (705) Or partially staggered, the external air enters the air intake chamber (604) from the air intake chamber inlet (605) and enters the air passage inlet (705) through the air intake chamber outlet (606), and the air passage (706) enters the connecting pipe (601), Then it enters the freezer through the dehumidification air inlet (203), which balances the pressure inside and outside the freezer and facilitates the opening of the freezer door.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com