Patents

Literature

439results about How to "Reduce internal temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

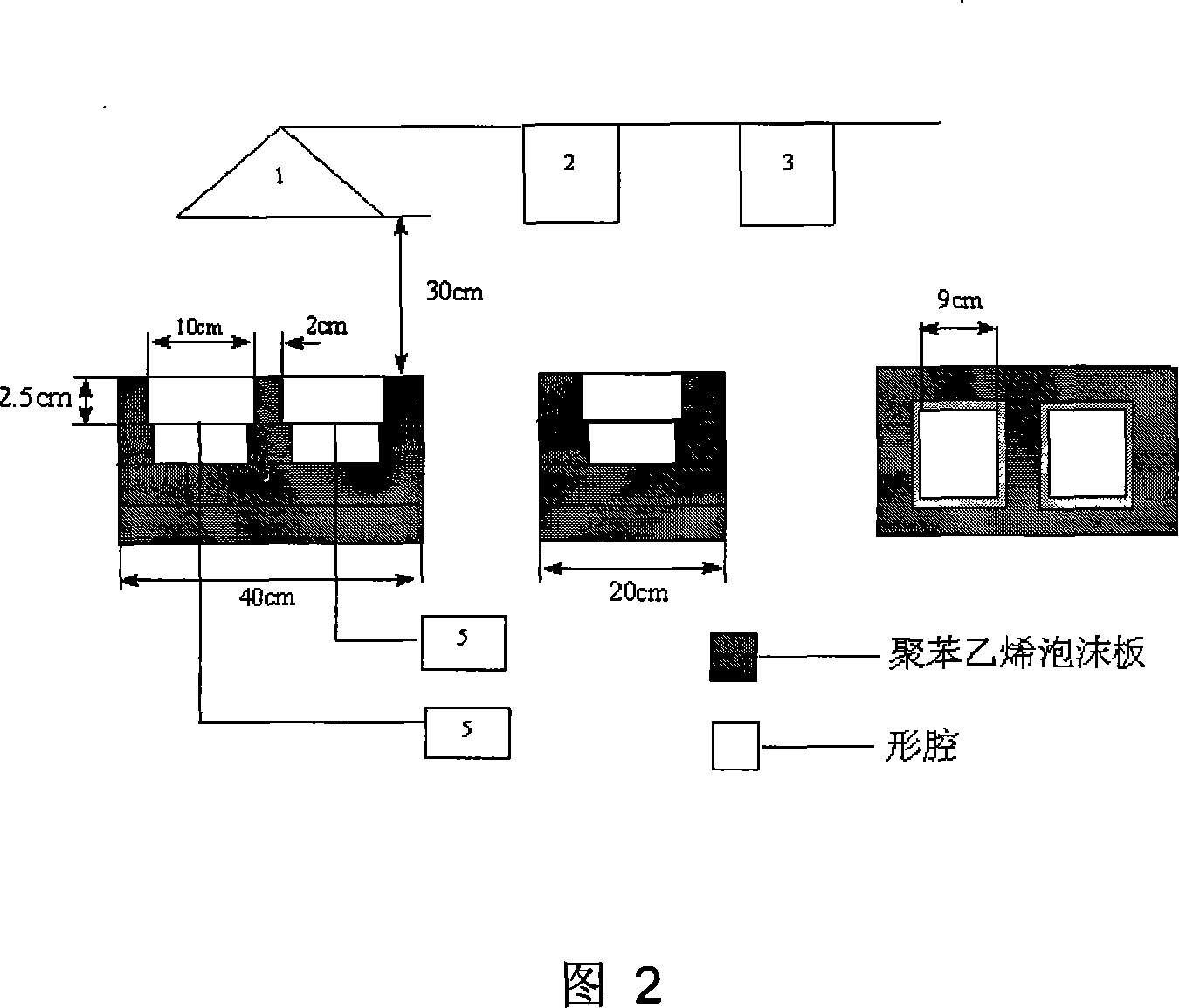

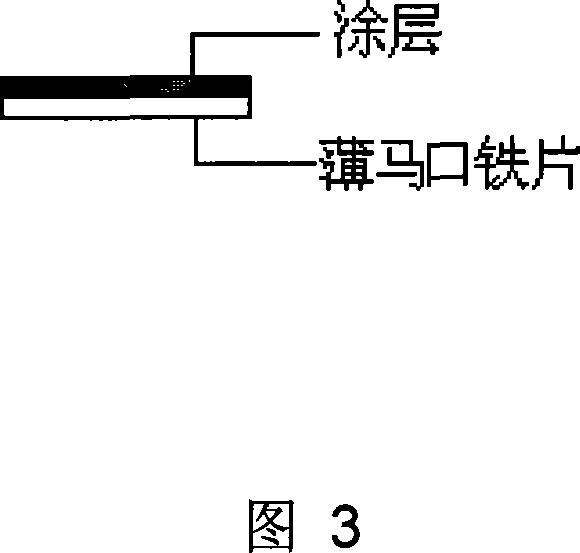

Thermal-insulating external-wall coating of nano-composite water and its production

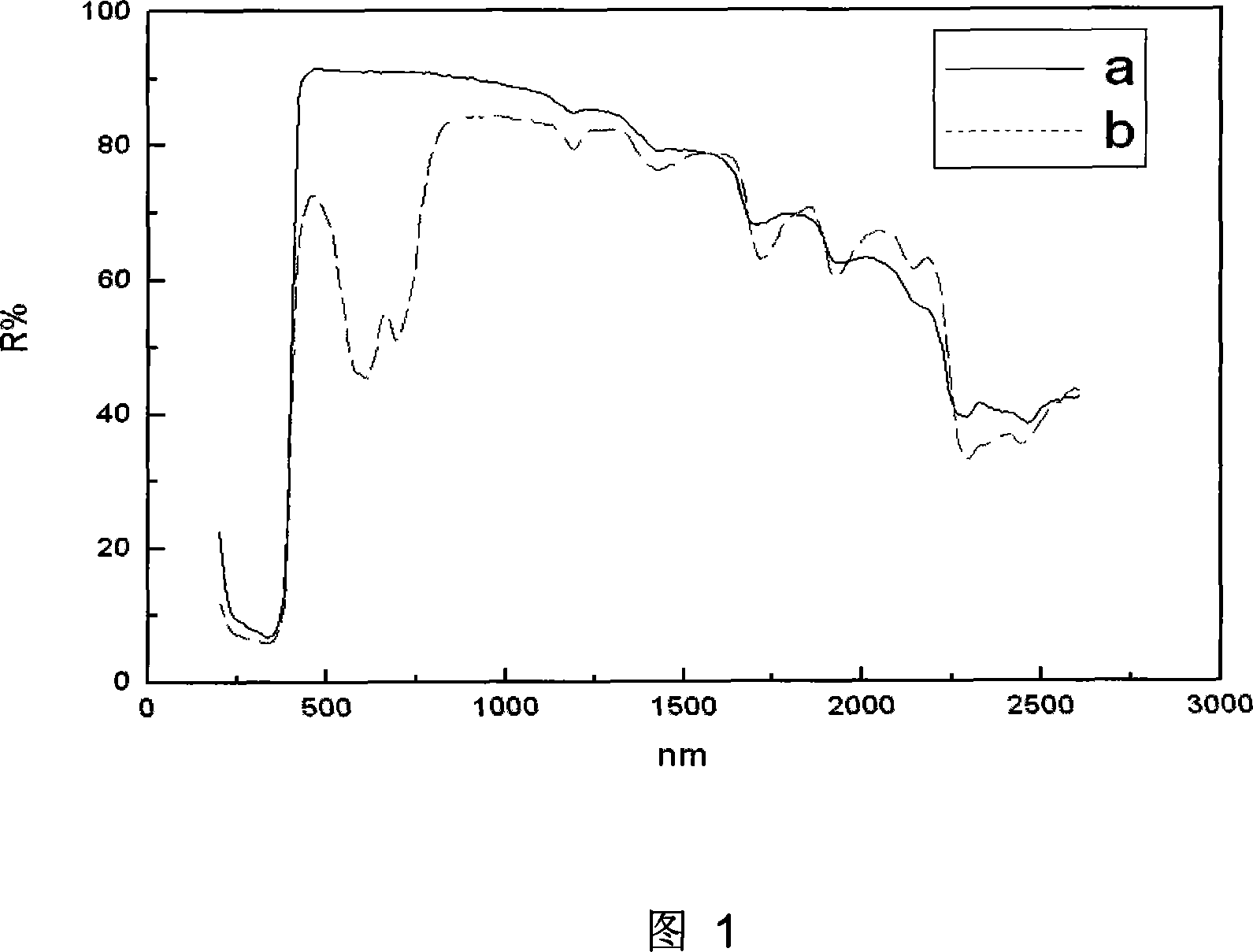

InactiveCN101029206AImprove insulation performanceGood weather resistanceFireproof paintsEmulsion paintsRefractive indexSlurry

A water nan-composite thermal-insulating coating for external wall and its production are disclosed. The coating consists of water, polymer emulsion, high-refractive index pigment, filler, nano-tin-antimony oxide slurry, nano-SiO2, wet dispersant, filming accessory, pH adjuster, thickener, de-foaming agent, anti-freezing agent and mildew-proof bactericide. It's cheap and simple, has excellent wash and weather resistances, better thermal-insulating performance, safe storage and no environmental pollution. It can be used for apparatus surface and architecture external wall.

Owner:SOUTH CHINA UNIV OF TECH +1

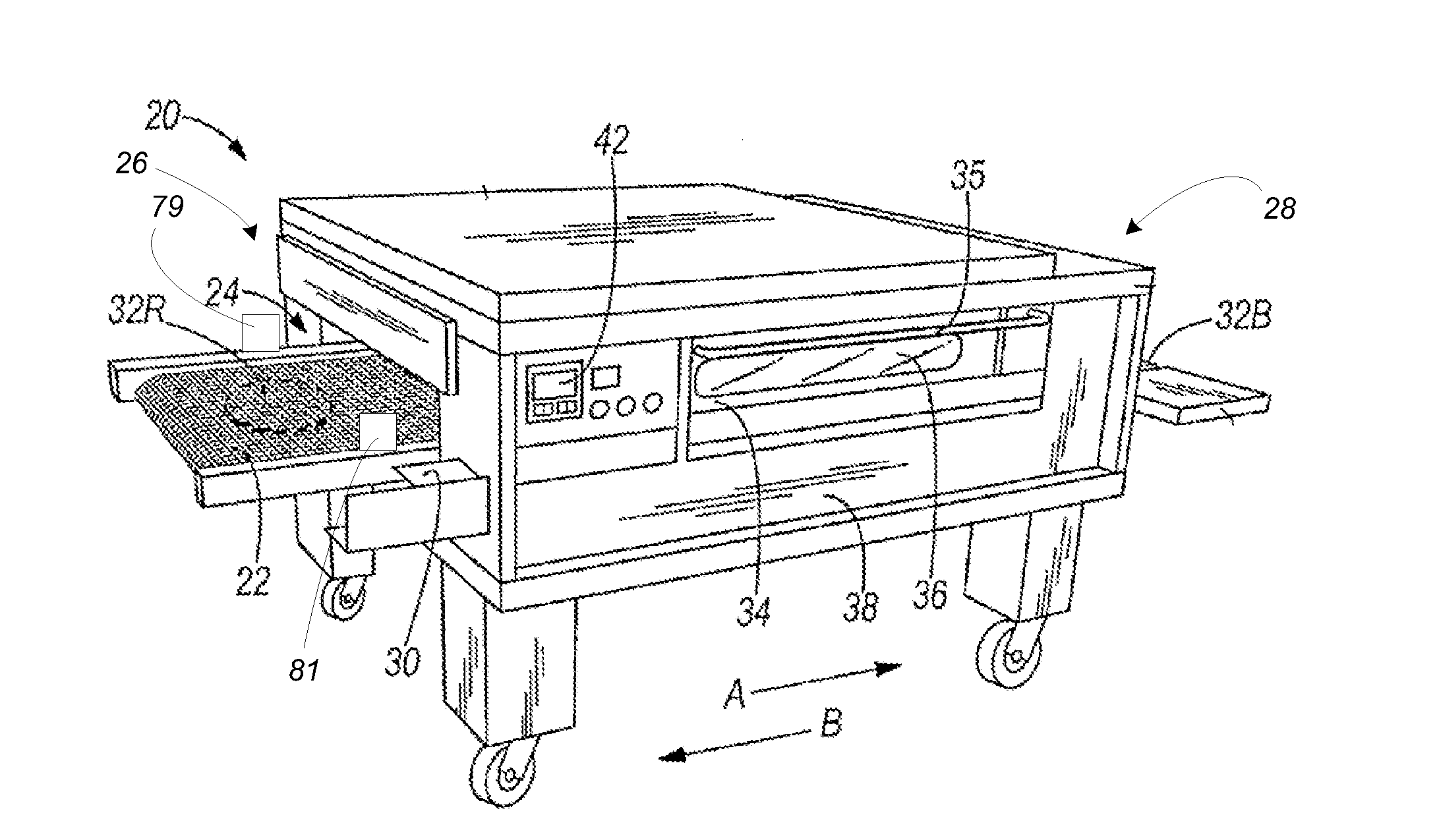

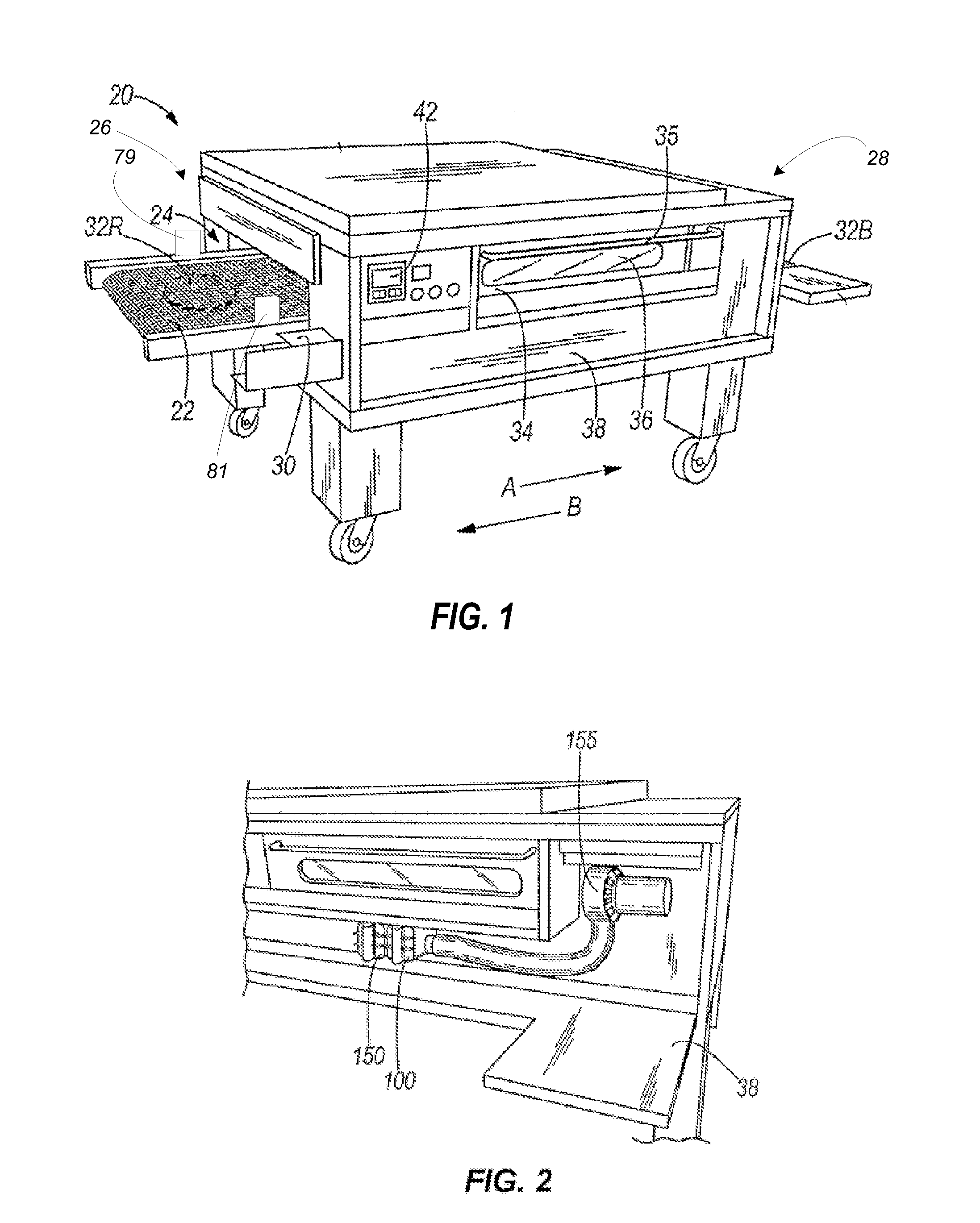

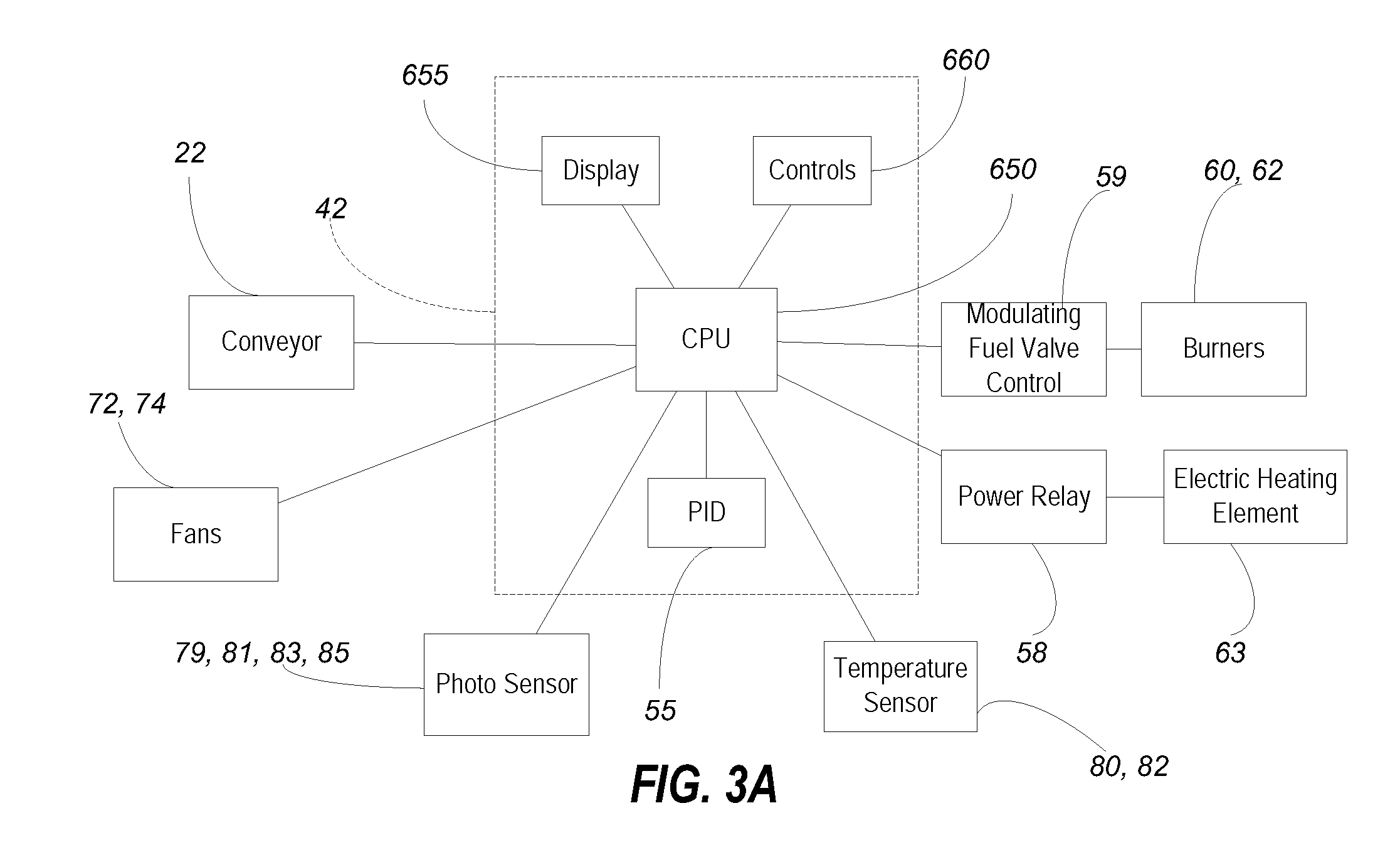

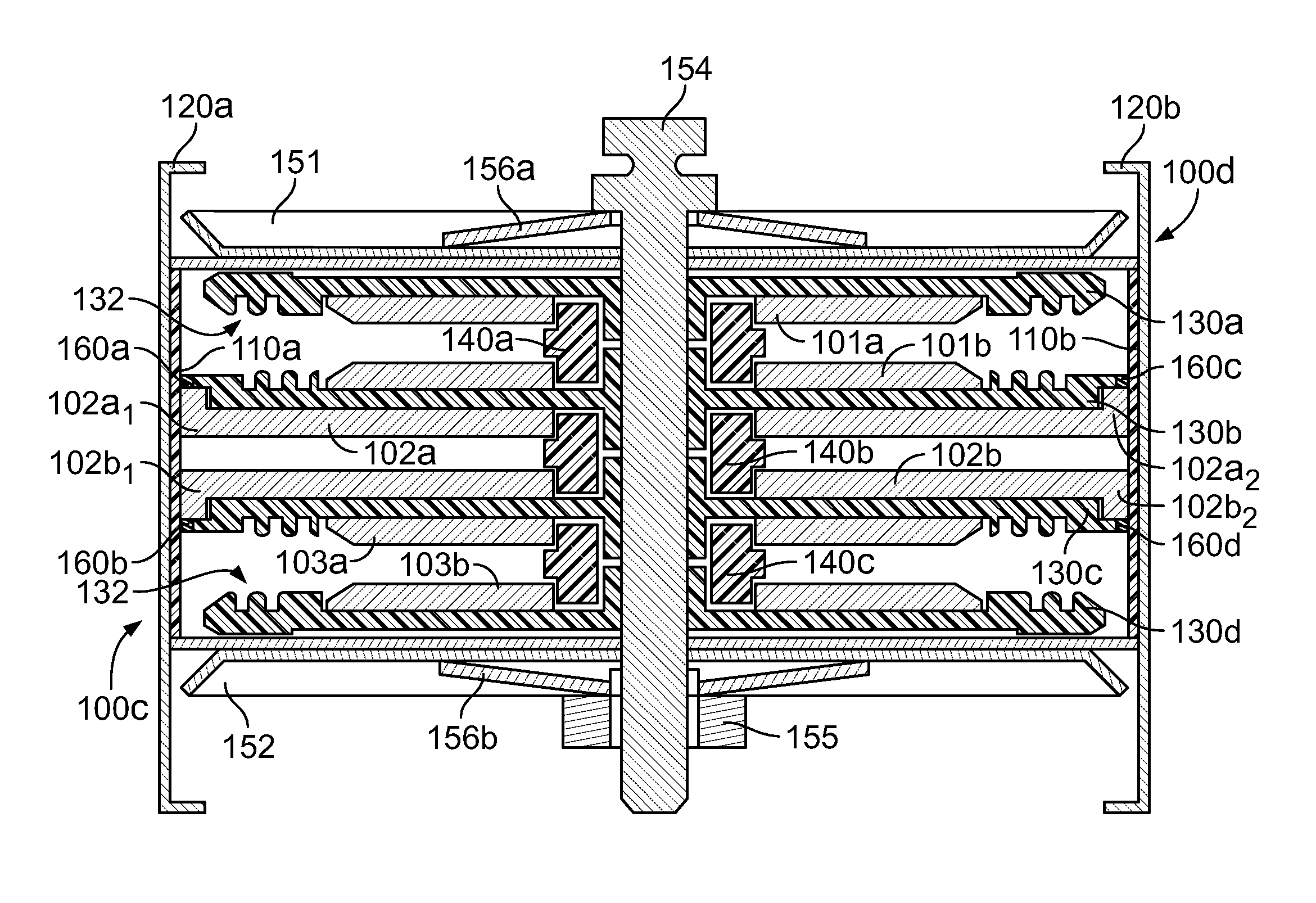

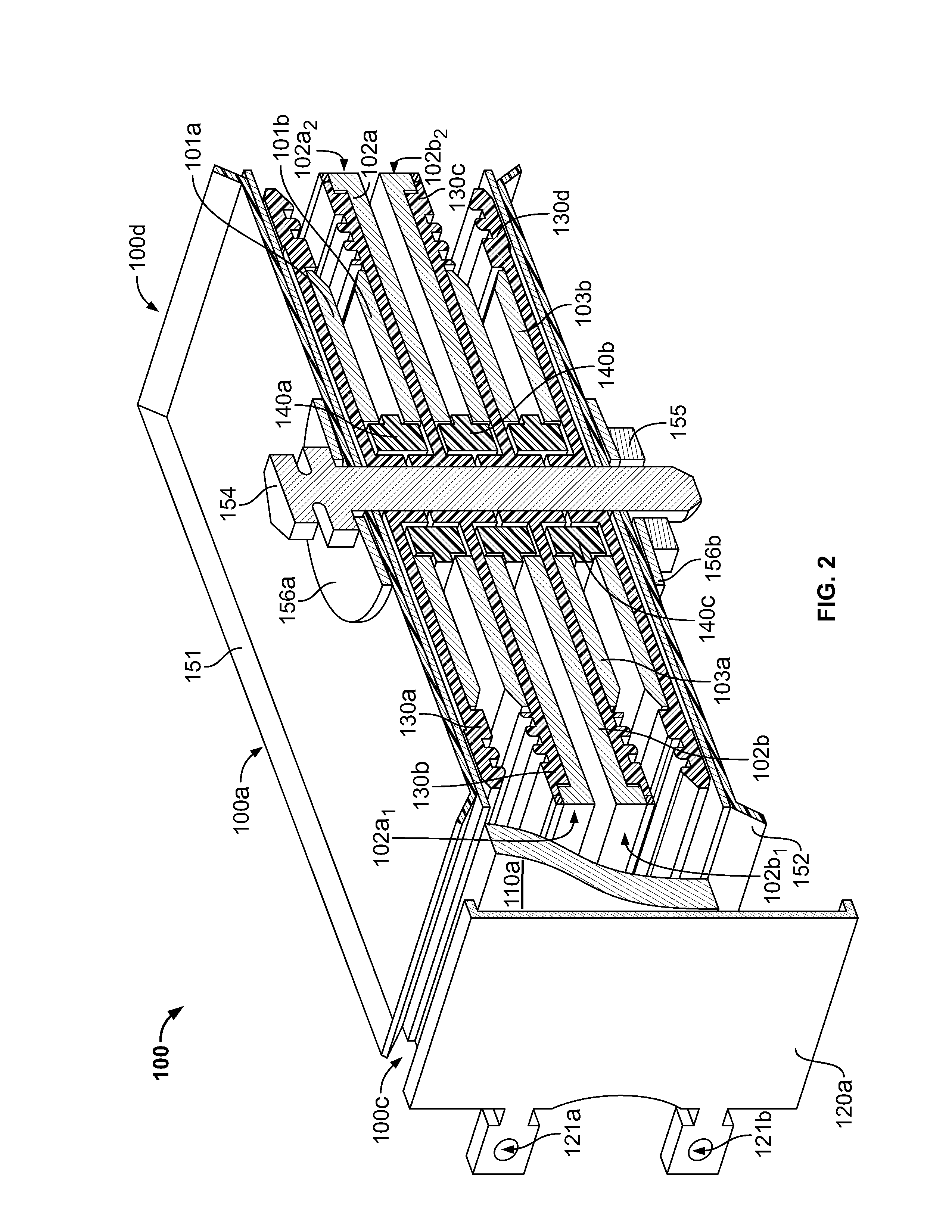

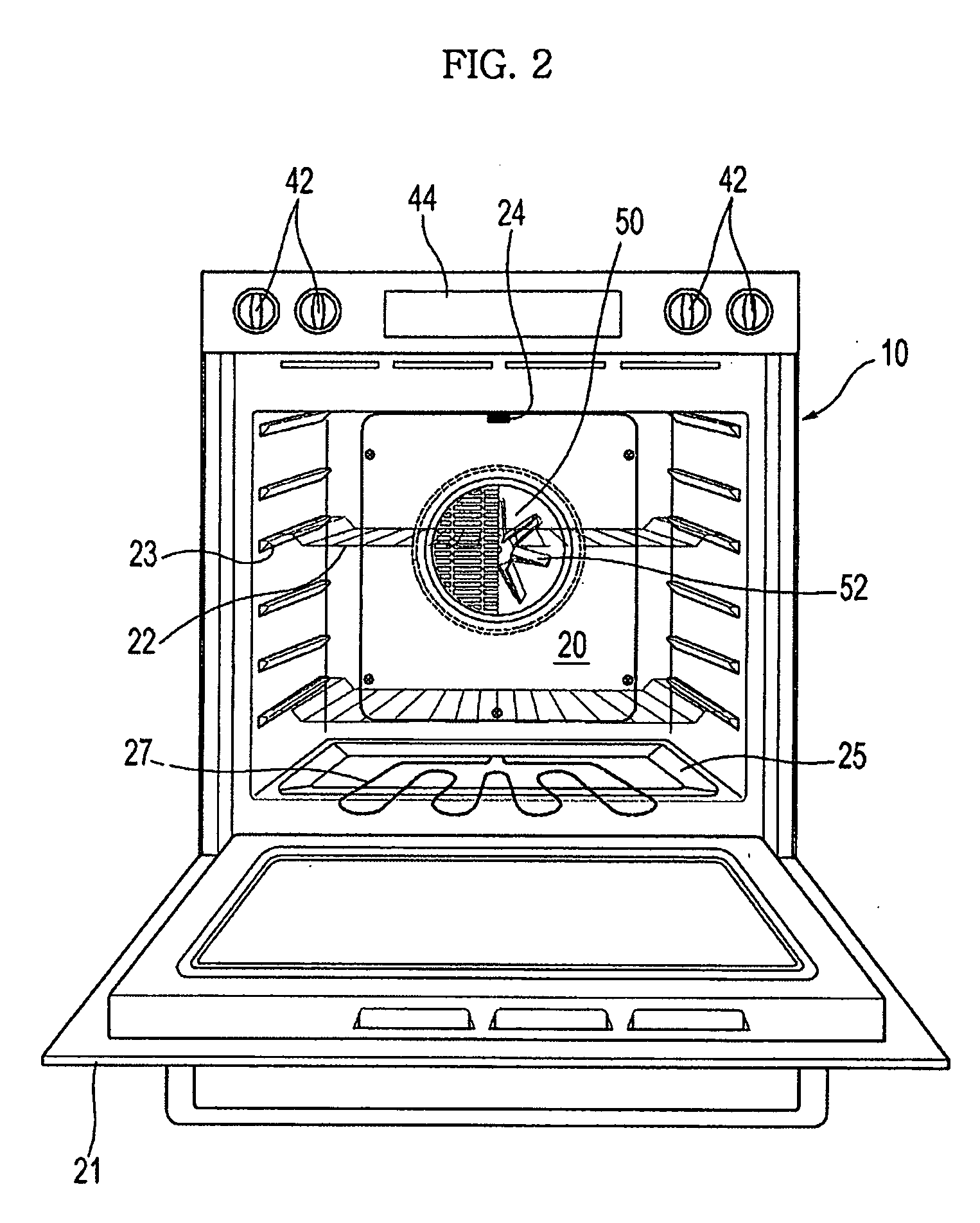

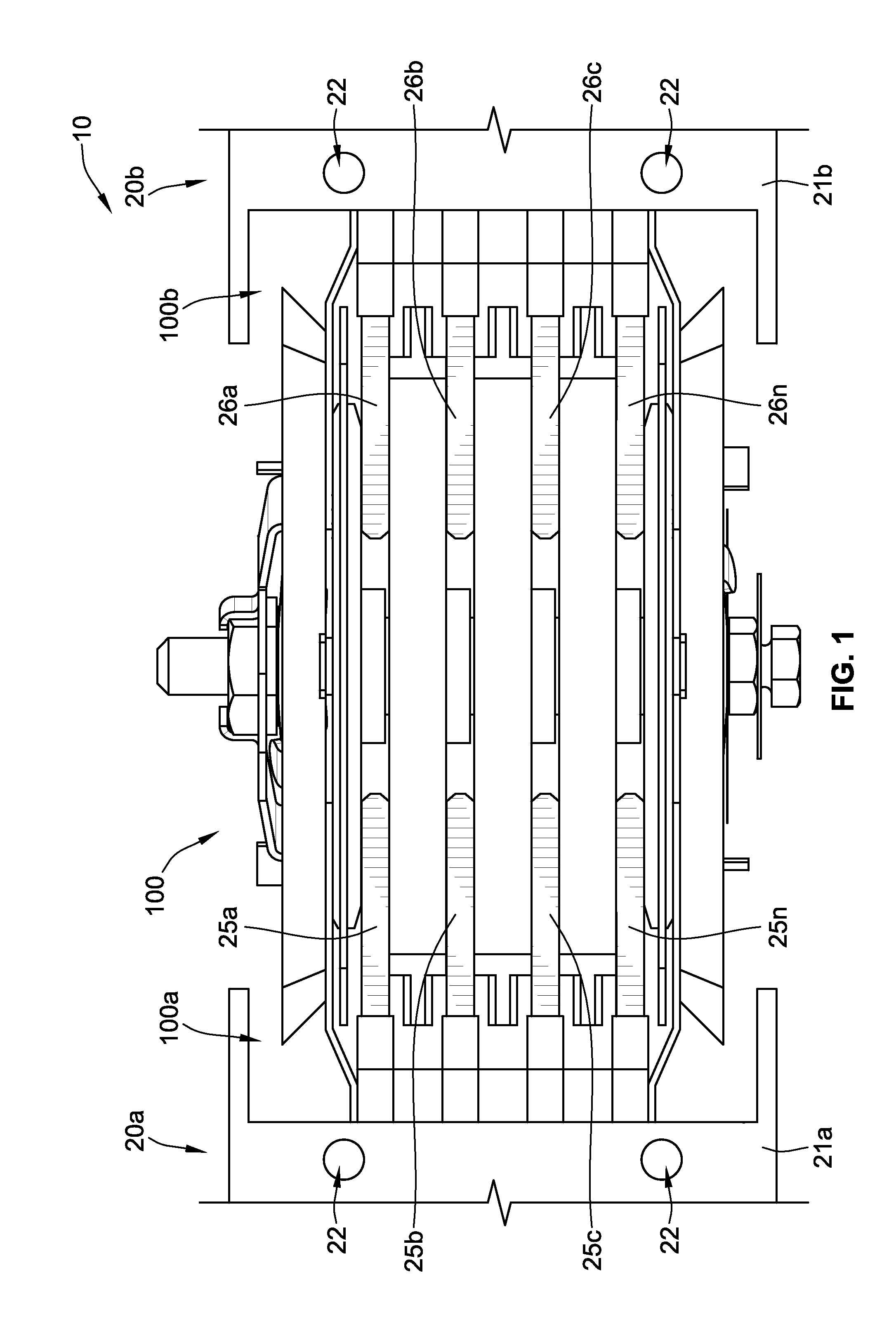

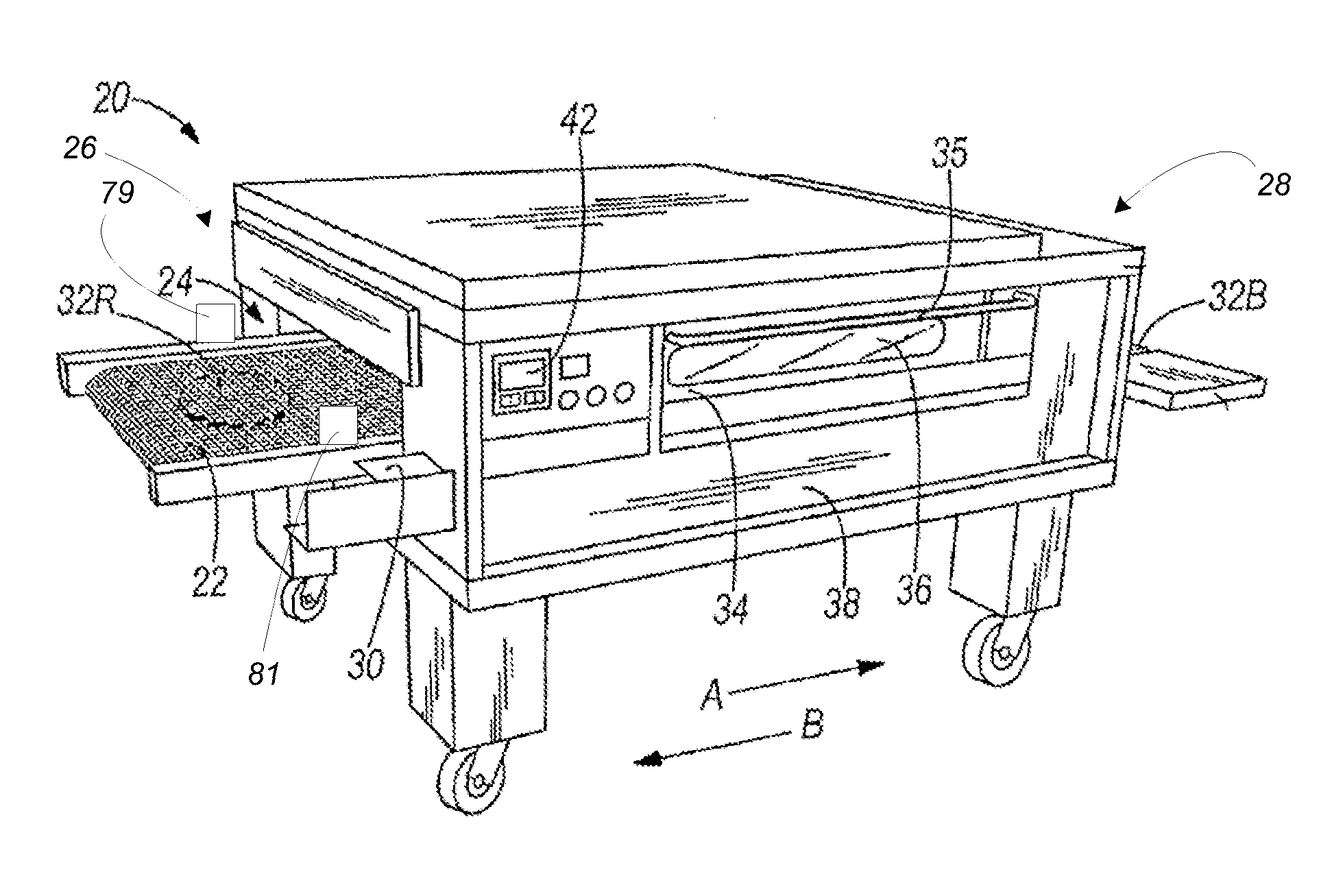

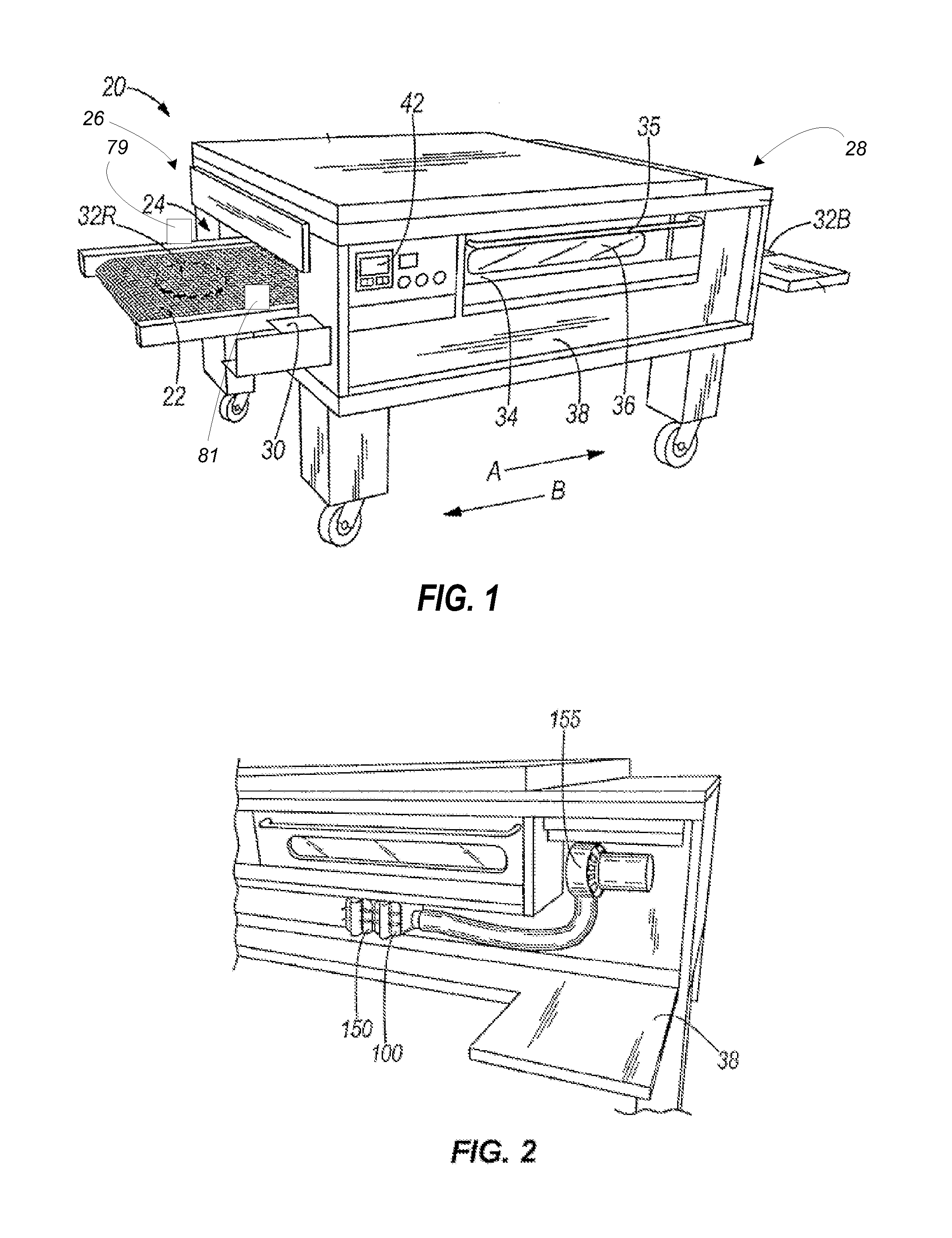

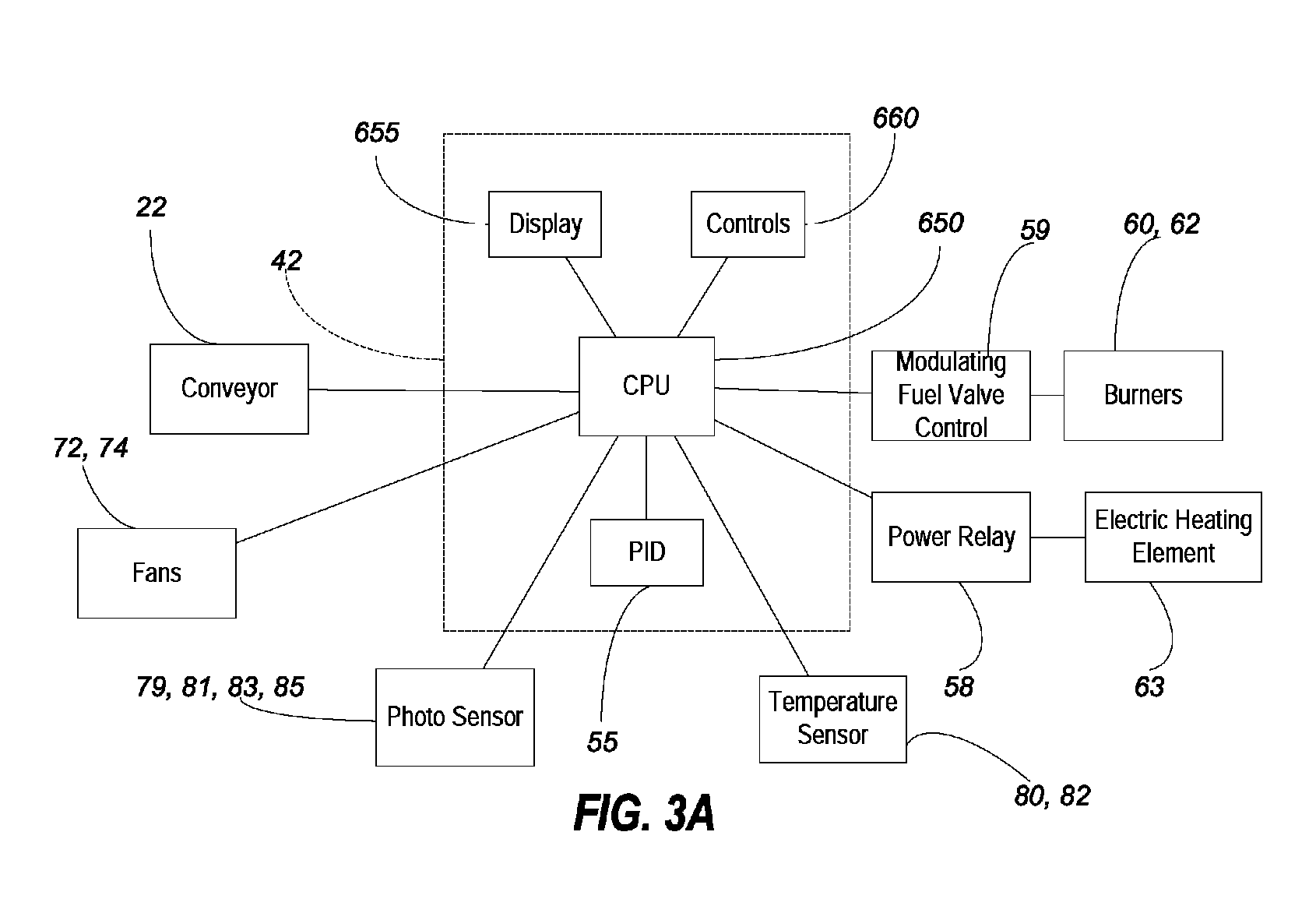

Conveyor oven apparatus and method

ActiveUS20110269085A1Increase productionReduce internal temperatureStoves/ranges foundationsDomestic stoves or rangesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

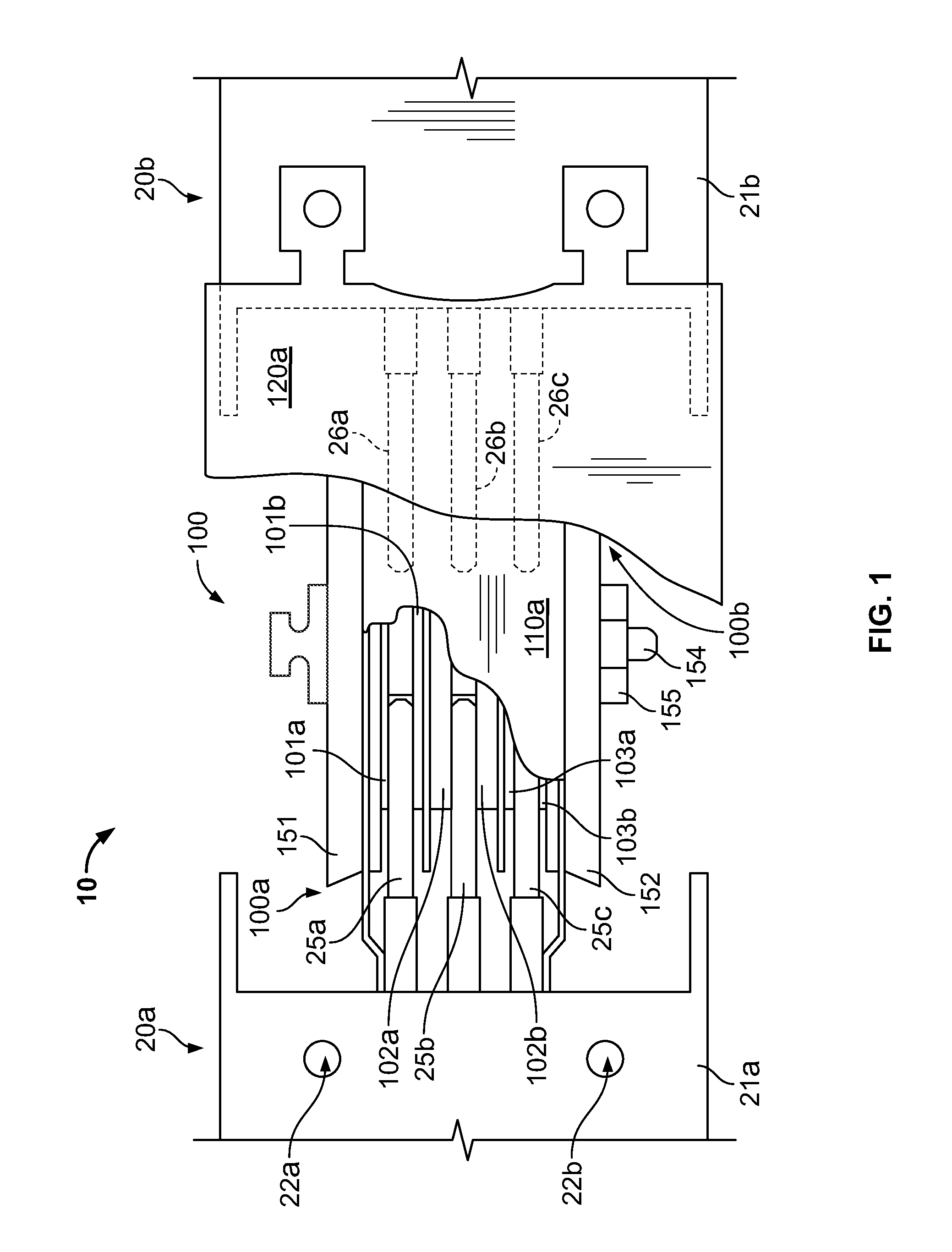

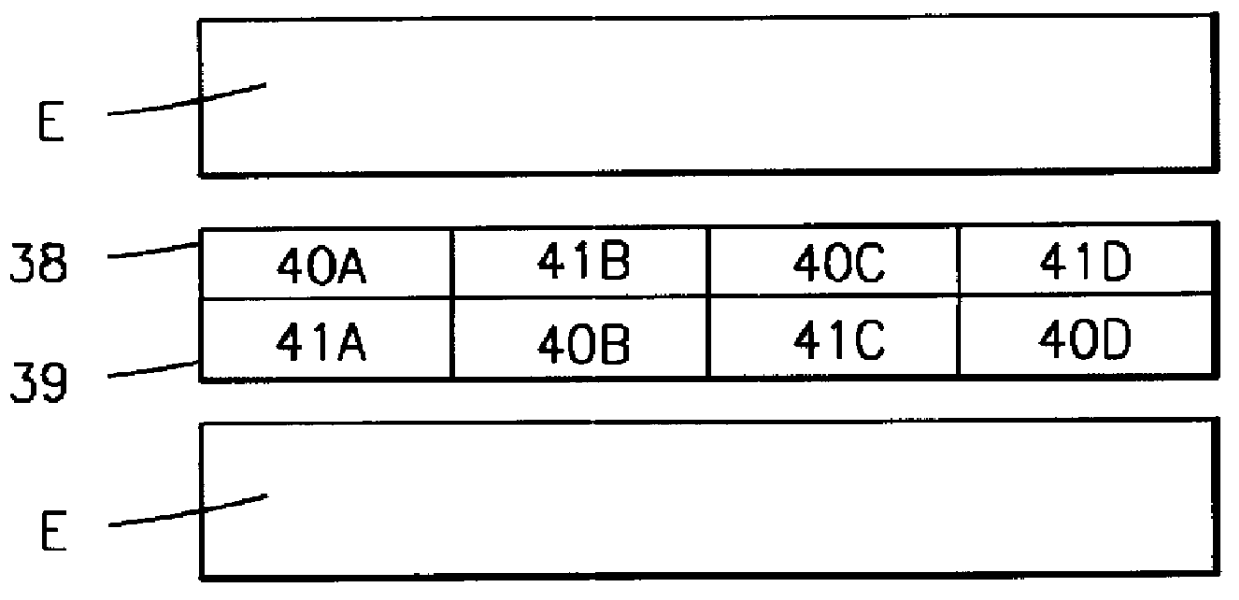

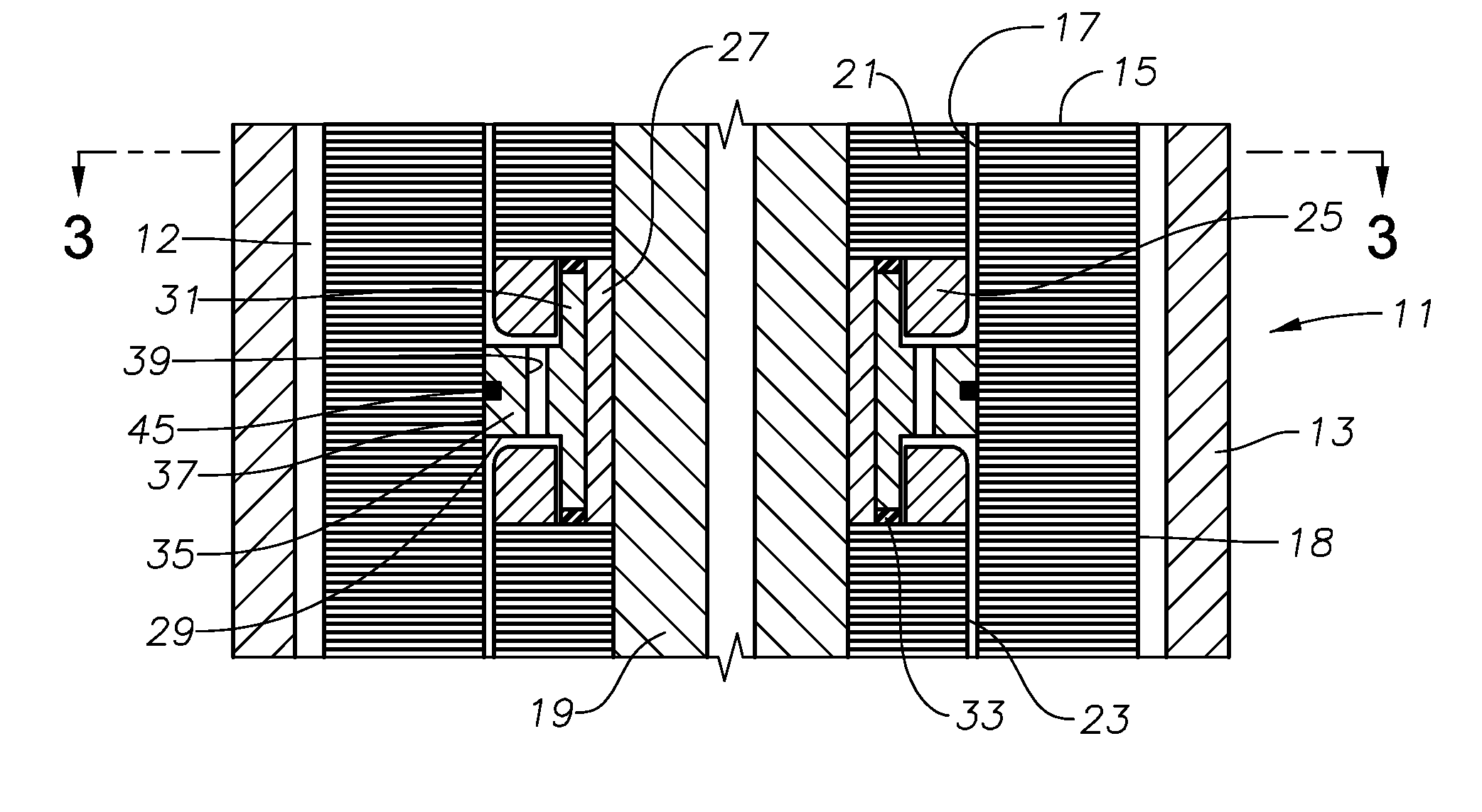

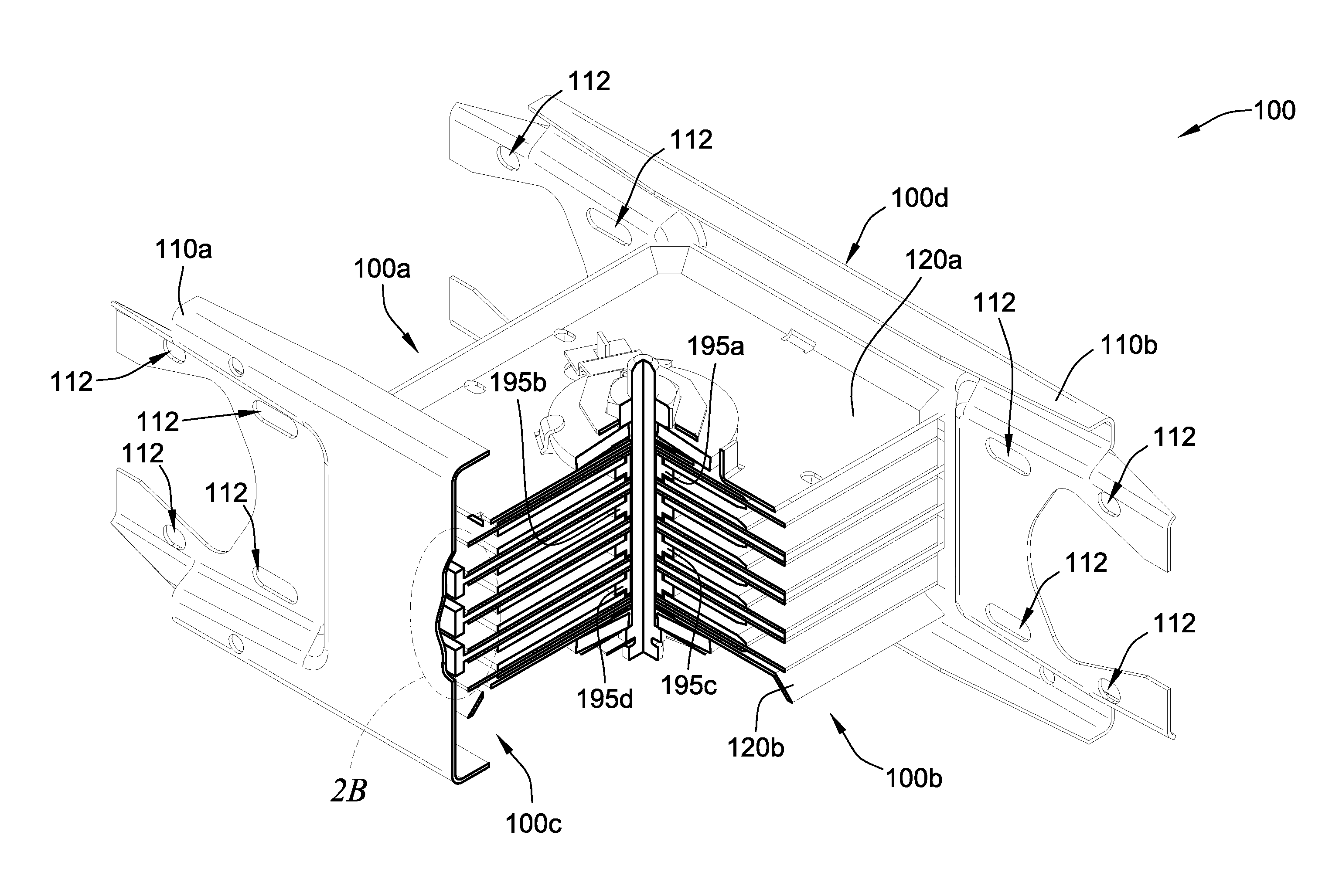

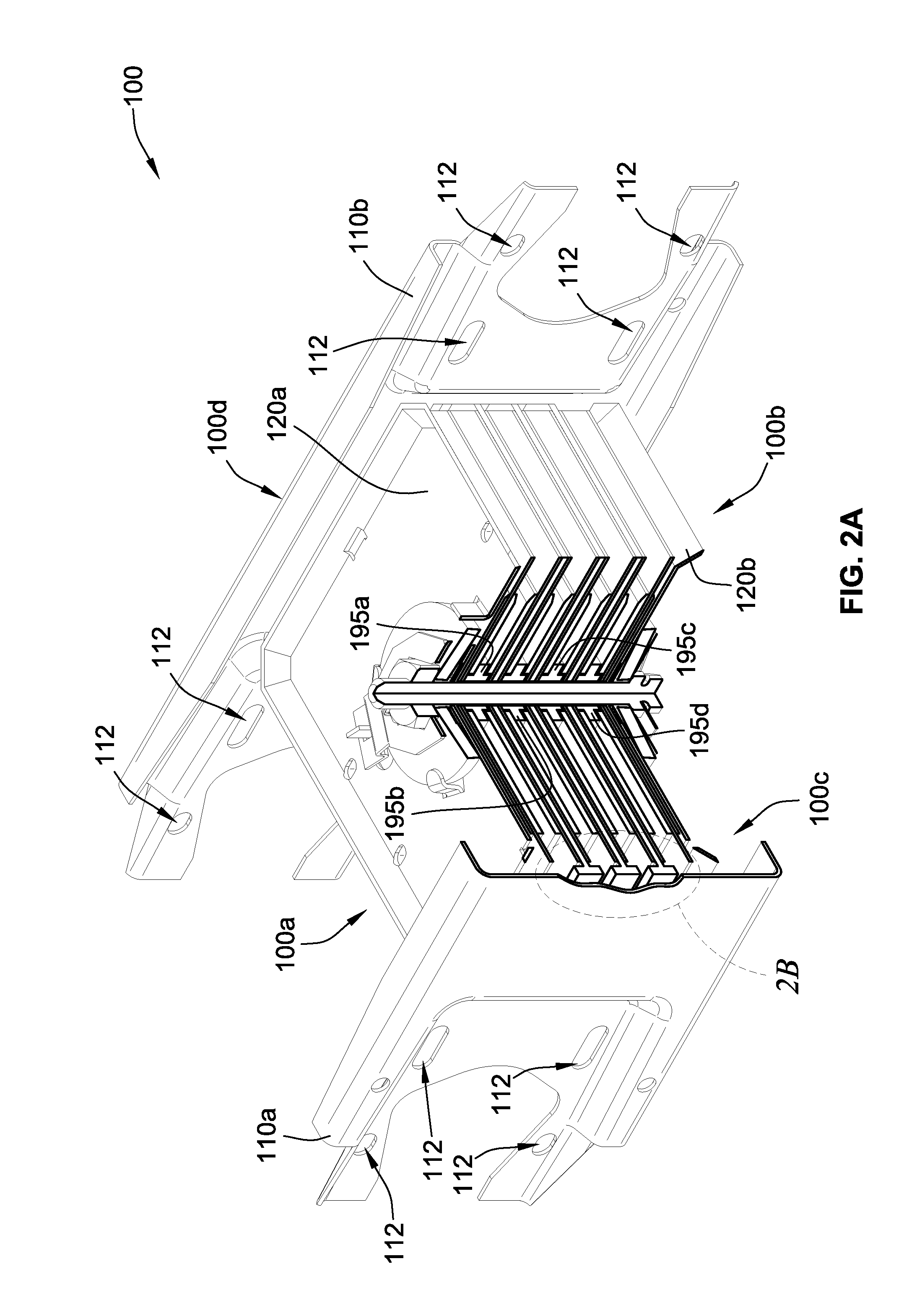

Thermally efficient busway joint pack

ActiveUS7819681B1Reduce internal temperatureCoupling device connectionsCooling bus-bar installationsThermal energyInternal temperature

A busway joint pack includes a pair of opposing phase connector plates, a first insulating sheet, a second insulating sheet, a first side panel, and a second side panel. The busway joint pack passively transfers thermal energy generated in its core to an exterior housing such that the thermal energy is dissipated or transferred to the surrounding environment, which reduces the internal temperature of the joint pack. The first and the second insulating sheets are positioned and selected with a particular thermal resistance and dimensions such that a portion of the thermal energy generated in the core of the busway joint pack is transferred from the pair of opposing phase connector plates to the external housing.

Owner:SQUARE D CO

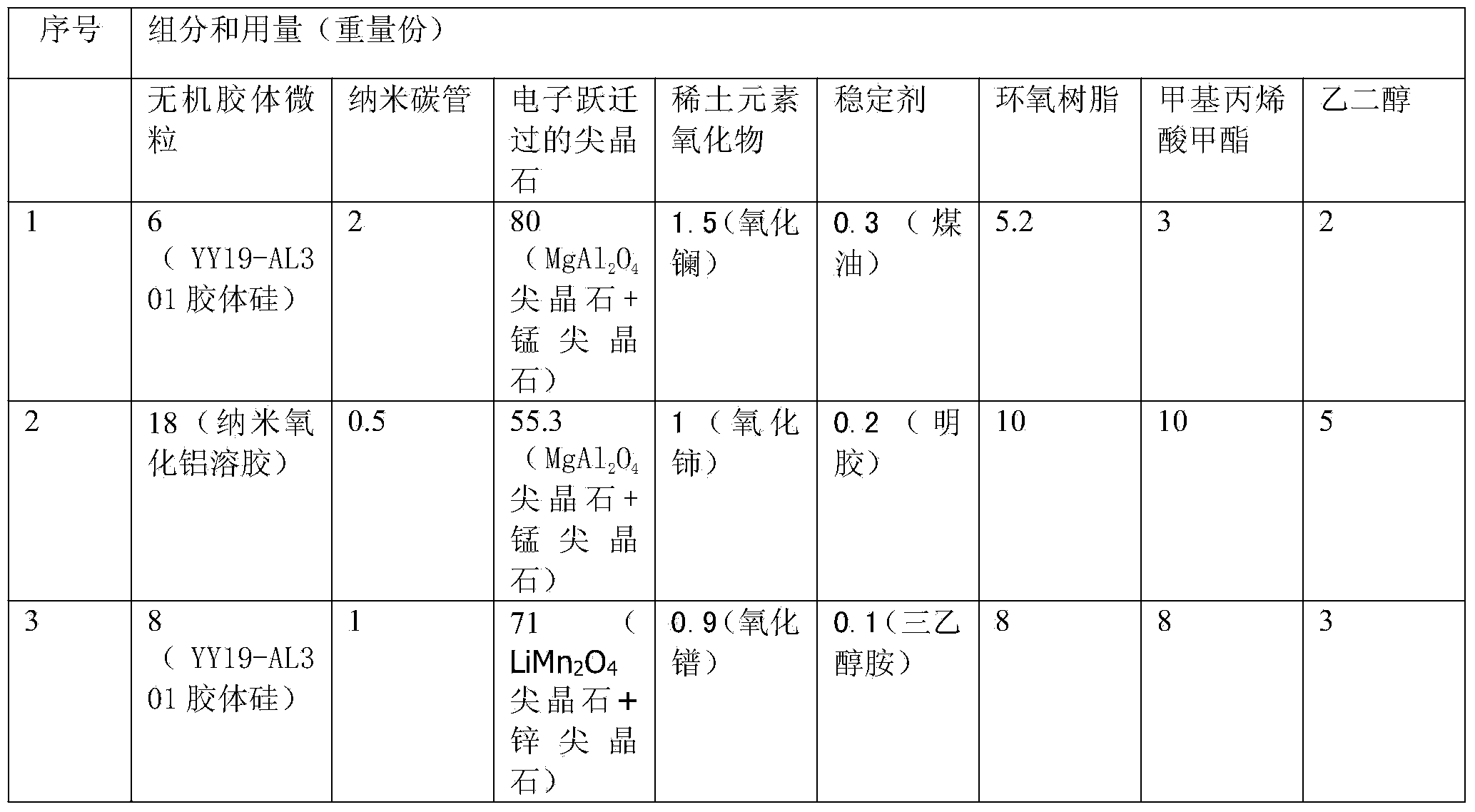

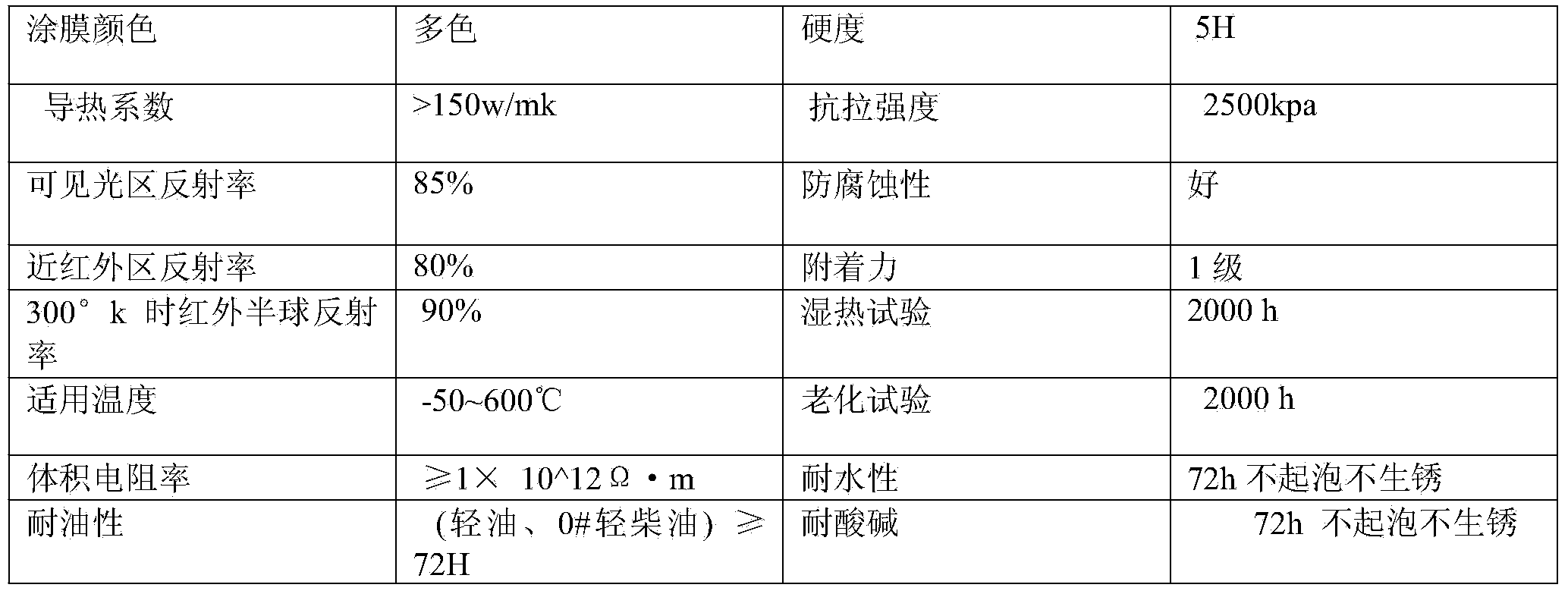

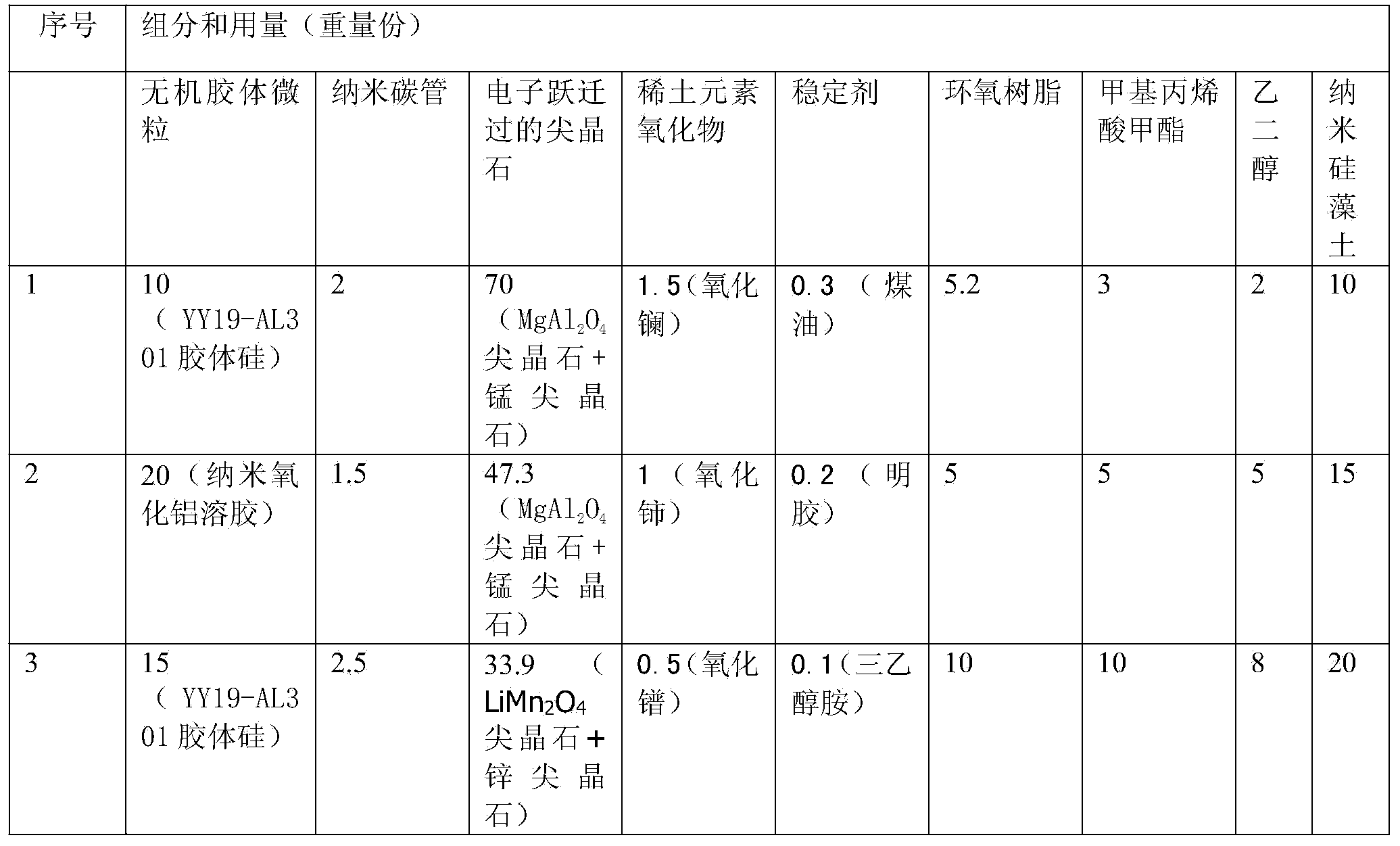

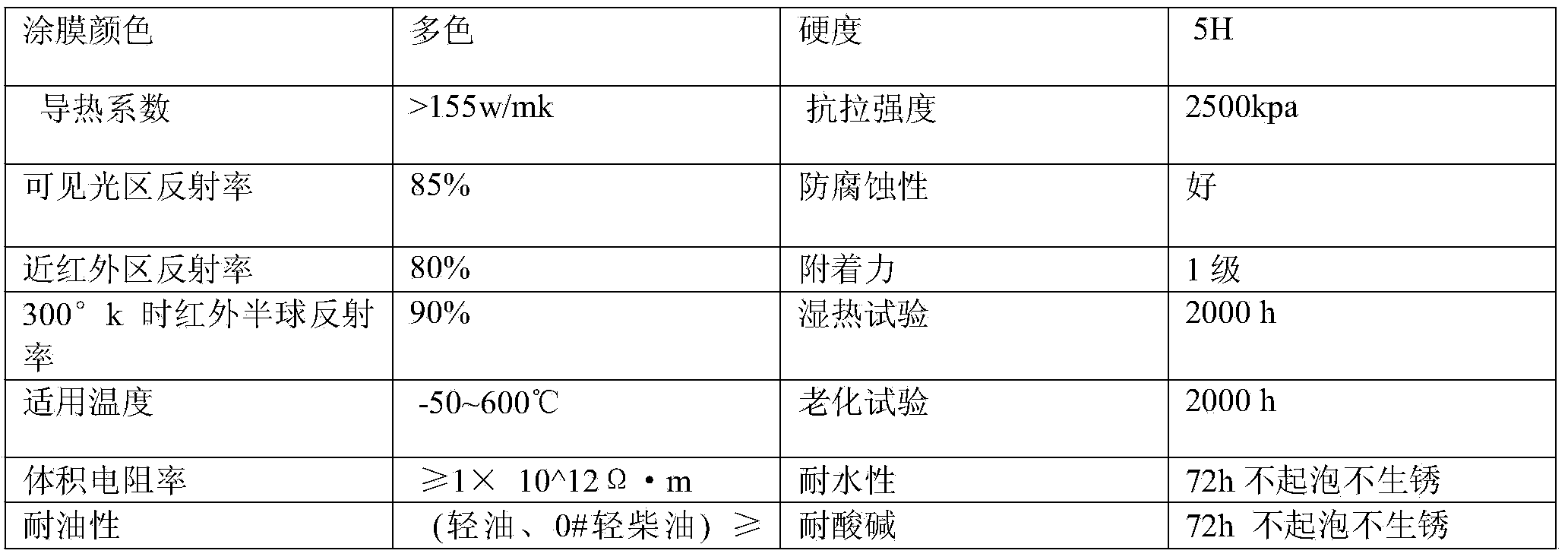

Coating for cooling surface of light-emitting diode (LED) radiator

ActiveCN103965671AGood self-cleaningEasy constructionReflecting/signal paintsRare-earth elementCorrosion

The invention discloses a coating for cooling the surface of a light-emitting diode (LED) radiator. The coating is characterized by being prepared from the following components in parts by weight: 6-20 parts of inorganic colloidal particle, 0.5-2 parts of carbon nano-tube, 15-80 parts of electron transition spinel, 0.05-2 parts of rare-earth element oxide, 0.1-0.3 parts of stabilizer, 3-10 parts of epoxy resin, 3-10 parts of methyl methacrylate and 2-5 parts of ethylene glycol. The coating has obvious heat dissipating and cooling effects, is not affected by surrounding medium when taking the cooling effect, can be used in a vacuum environment, also has the advantages of good self-cleaning property, corrosion resistance, waterproofness, fire retardancy, insulativity, and acid and alkali resistance, and convenient construction when taking a radiation cooling effect.

Owner:NINGBO AISHI ELECTRIC EQUIP

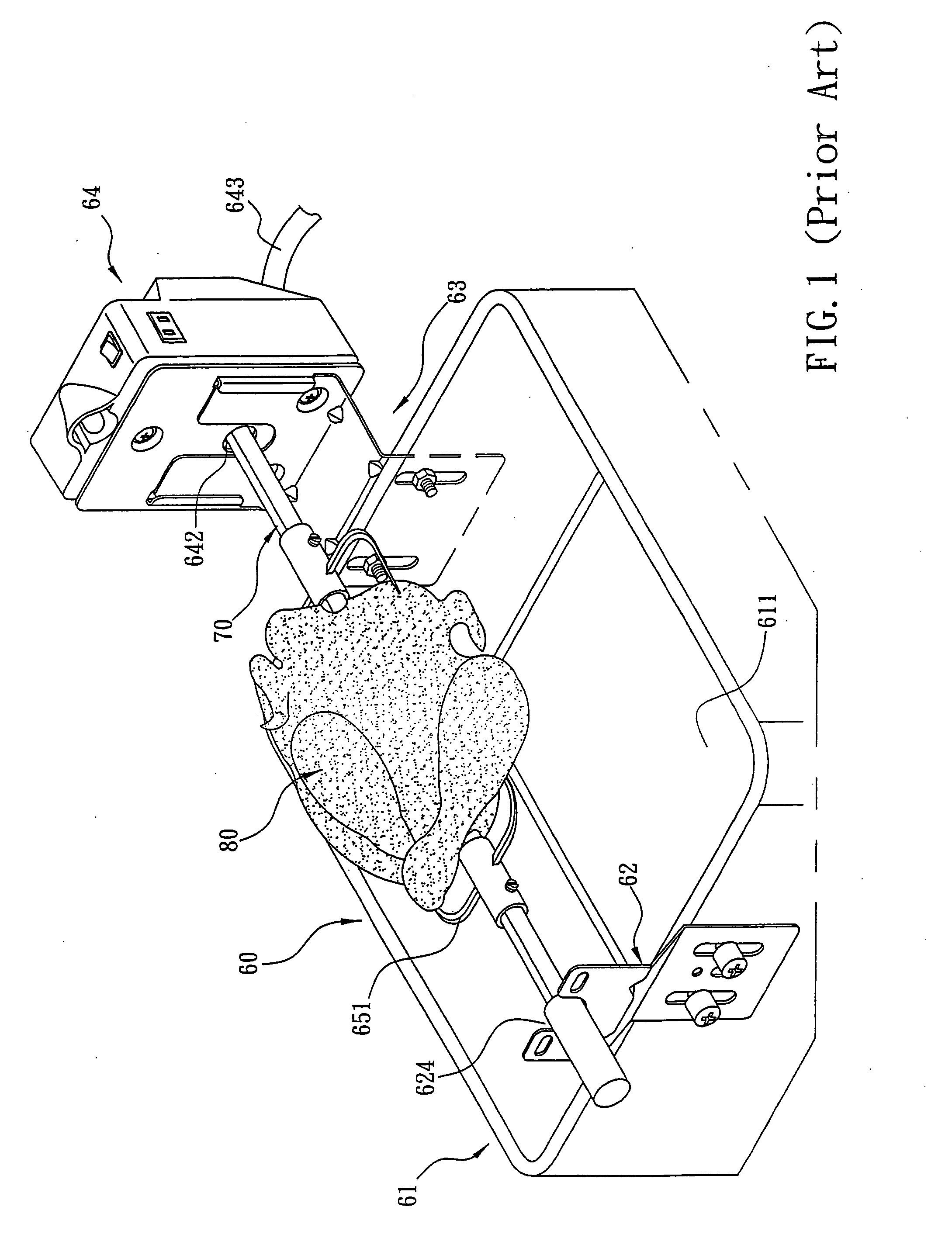

Water-repellent motor assembly for rotisserie and casing thereof

InactiveUS20080088192A1Useful life of motorIncrease heatRoasting apparatusRoasters/grillsEngineeringTroffer

The present invention is to provide a water-repellent motor assembly for rotisserie and casing thereof, which comprises an inner shroud, a motor provided in the inner shroud and an outer shroud mounted around the inner shroud. A plurality of parallel bent, elongated projecting plates are projected out of an outer surface of the outer shroud. A plurality of second openings are formed on the outer shroud, correspond to the projecting plate, and are partially concealed by the projecting plates for preventing fluid from entering the outer shroud. The inner shroud comprises one or more recesses on its outer surface. A plurality of raised members are formed on an outer surface of the inner shroud and correspond to the second openings. The raised members are protruded toward the second openings and each of the raised members comprises a first opening formed on its projecting portion.

Owner:HSU HUANG HSI

Nanometer acrylic acid microemulsion, water-thinned heat reflecting and isolating paint and their production process

InactiveCN1361186AWill not polluteImprove densification performanceFireproof paintsOrganic solventEmulsion

The present invention is one kind of nano acrylic acid microemulsion, water-thinned heart reflecting and isolating paint with the nano acrylic acid microemulsion and their prodcution process. The present invention aims at solving the technological problems of available paint, which contains great amount of organic solvent to pollute environment and has poor heat reflecting and isoalting performance. The water-thinned heat reflecting and isolating paint consists of nano acrlic acid microemulsion, conventional acrylic acid emulsion, pigment, filler, infrared ray reflector, assistant, pH regulator, densifier and softened water. The paint contains no organic solvent and has excellent heat reflecting and isolating performance.

Owner:耿世斋

Acrylic resin sun-heat reflecting coating

InactiveCN1405248AGood outdoor weather resistanceLow solar heat absorptionReflecting/signal paintsPolymer scienceAcrylic resin

The invention refers to a kind of crylic acid resin sun heat reflecting paint. It uses crylic acid resin as filmed material, it also includes following assistant dispersant, sum heat reflecting compound dye, solvent and plastic-strengthening agent. Thus, its life outdoor can reach to 8-10 years, and it has high sum heat reflecting rate.

Owner:北京京安固特化工有限责任公司

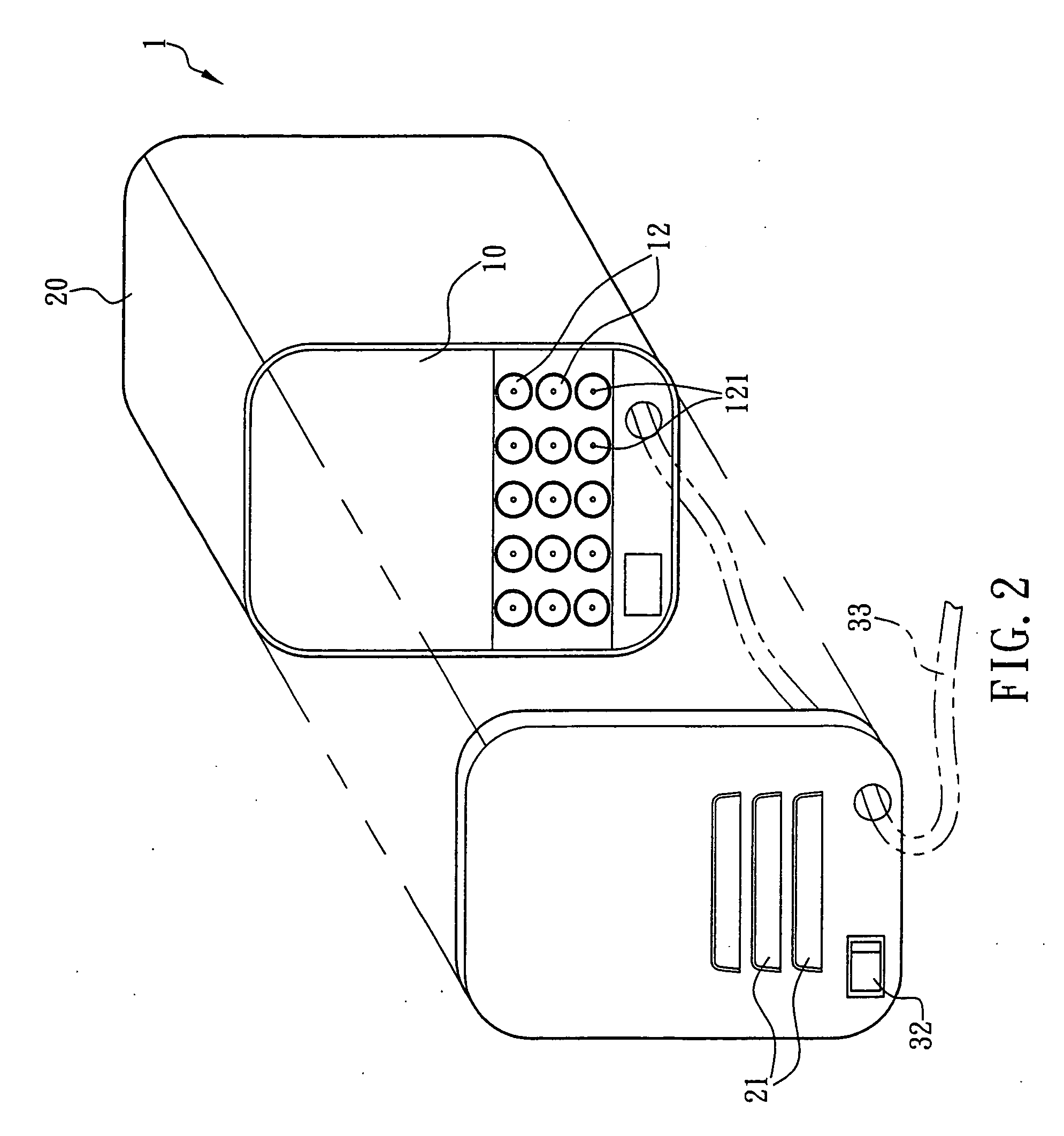

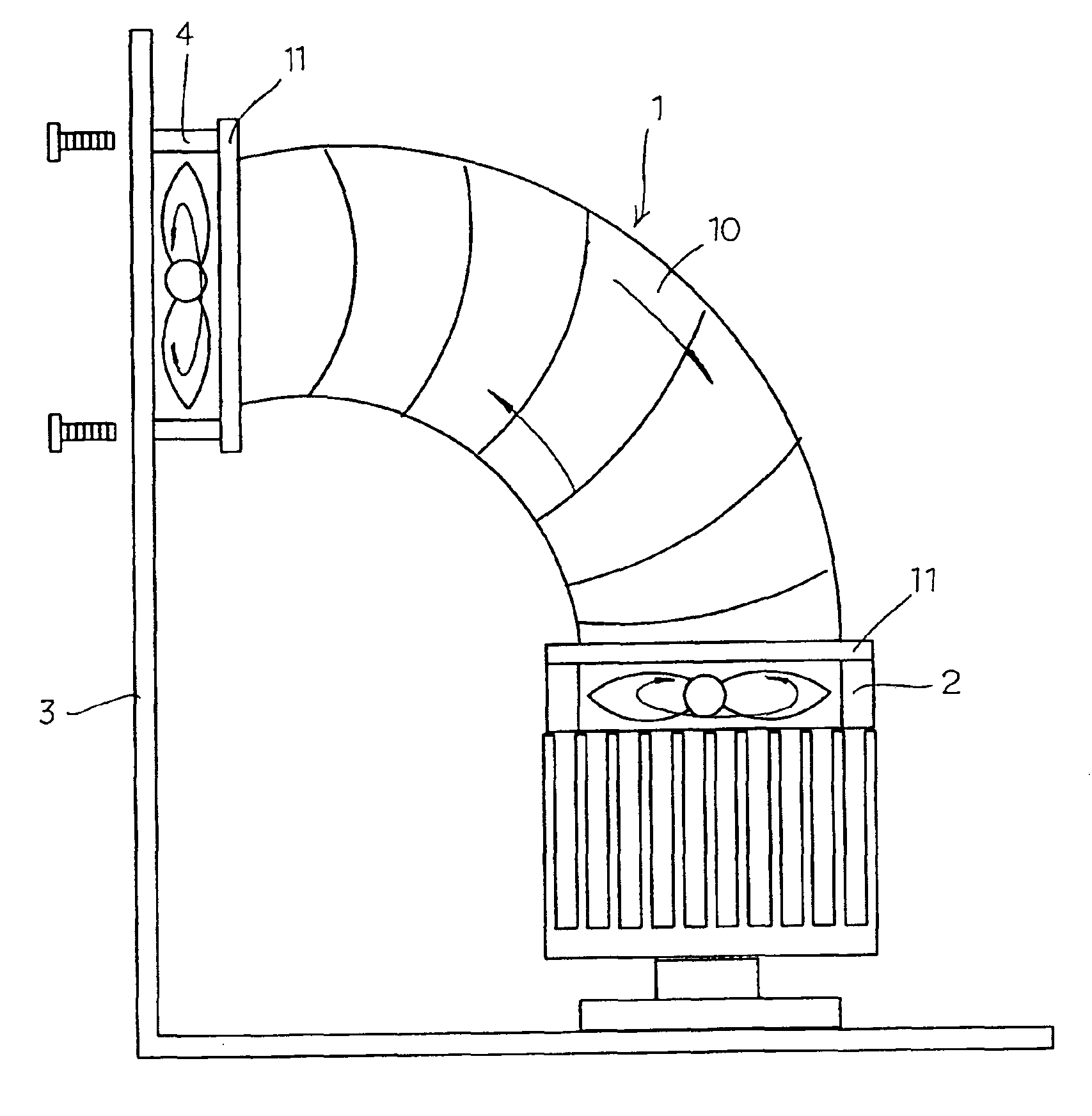

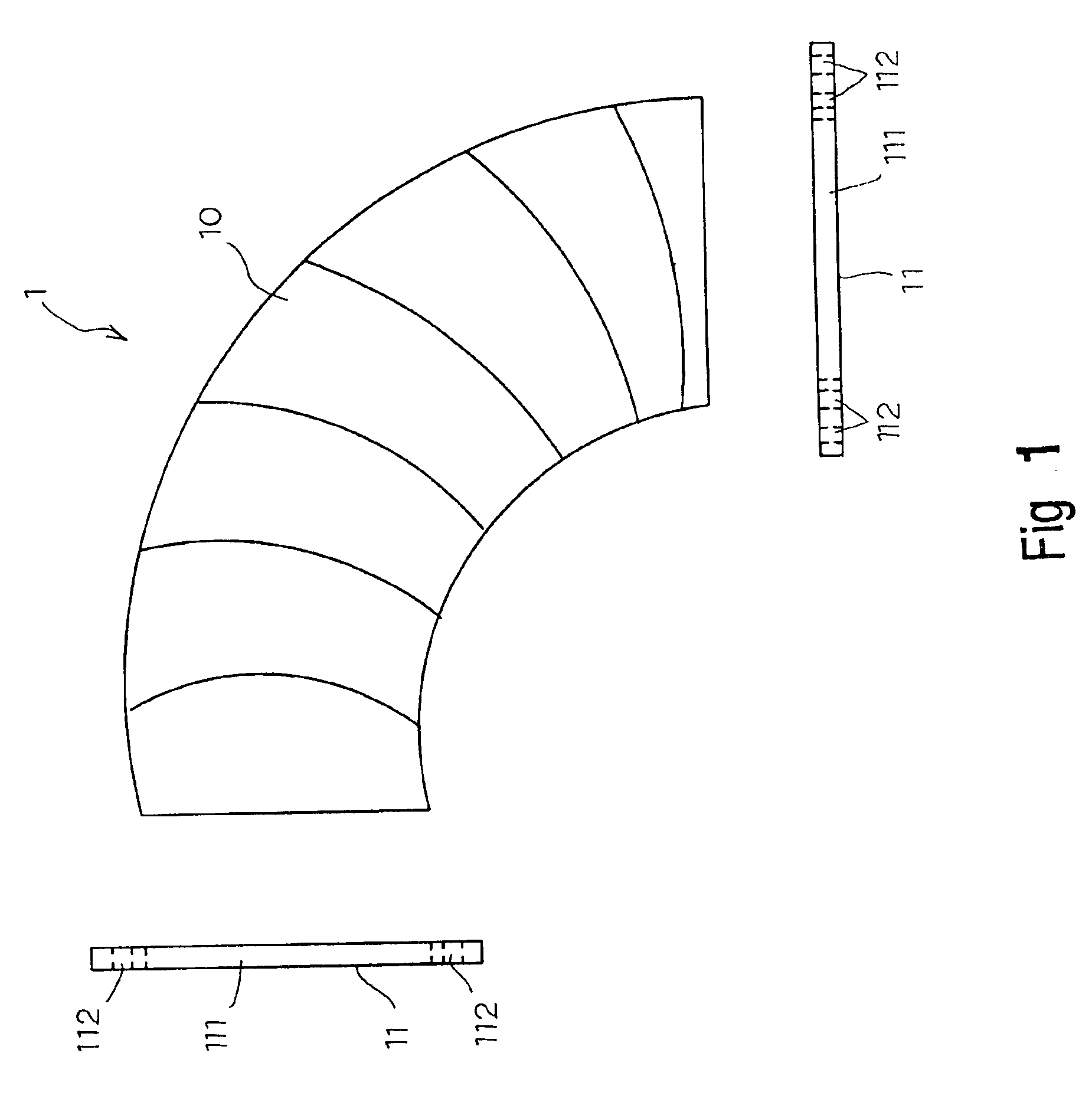

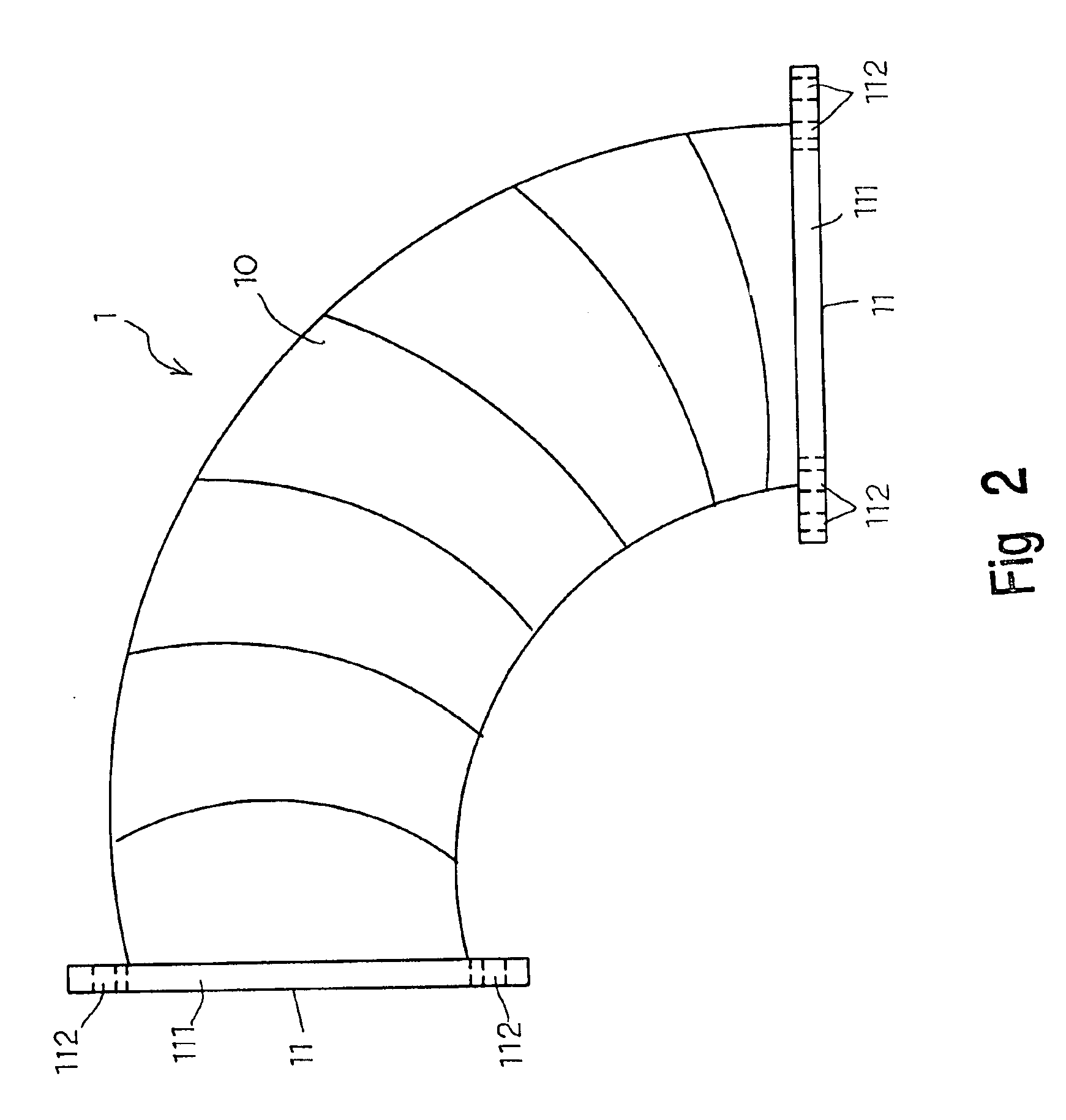

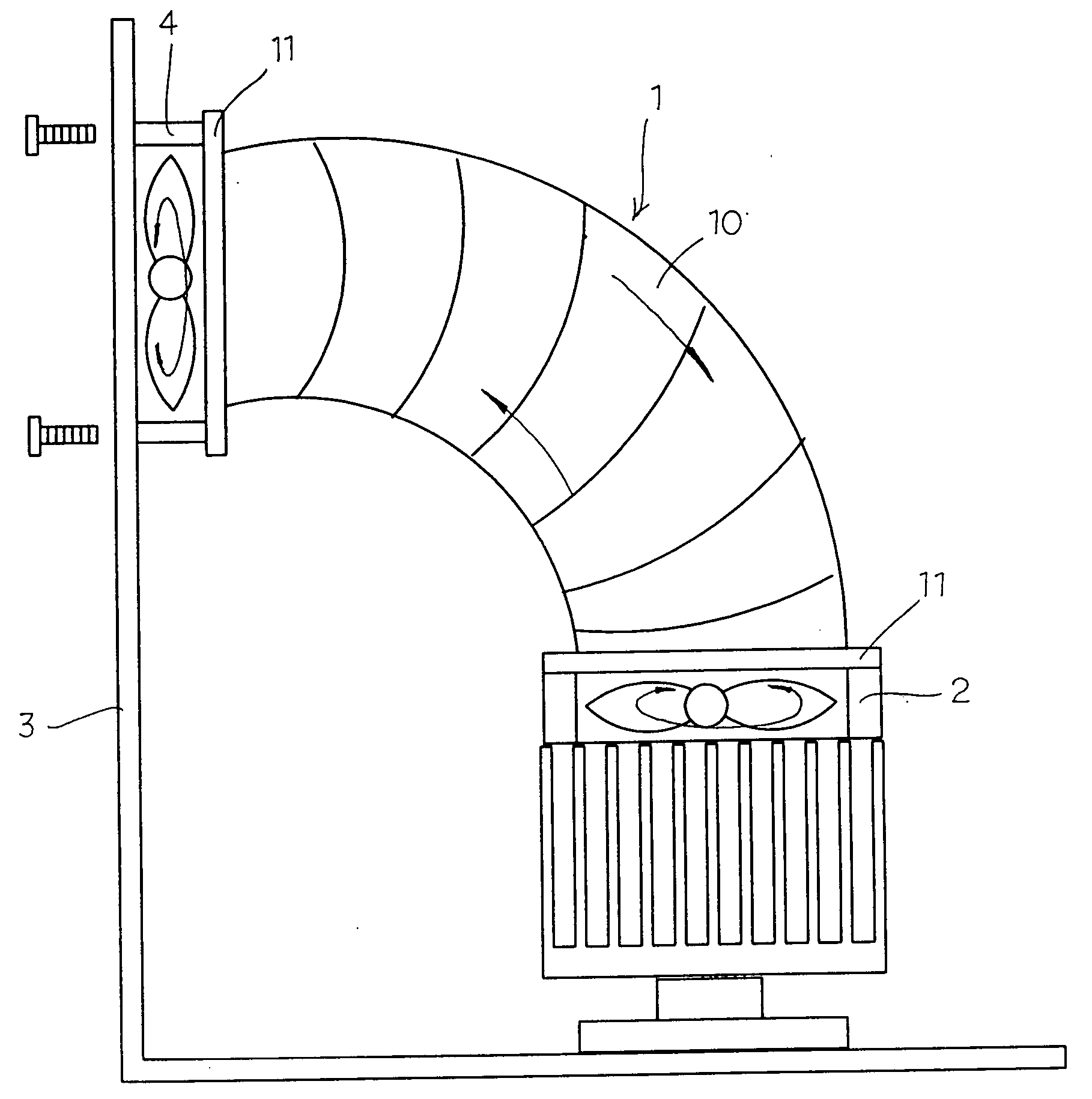

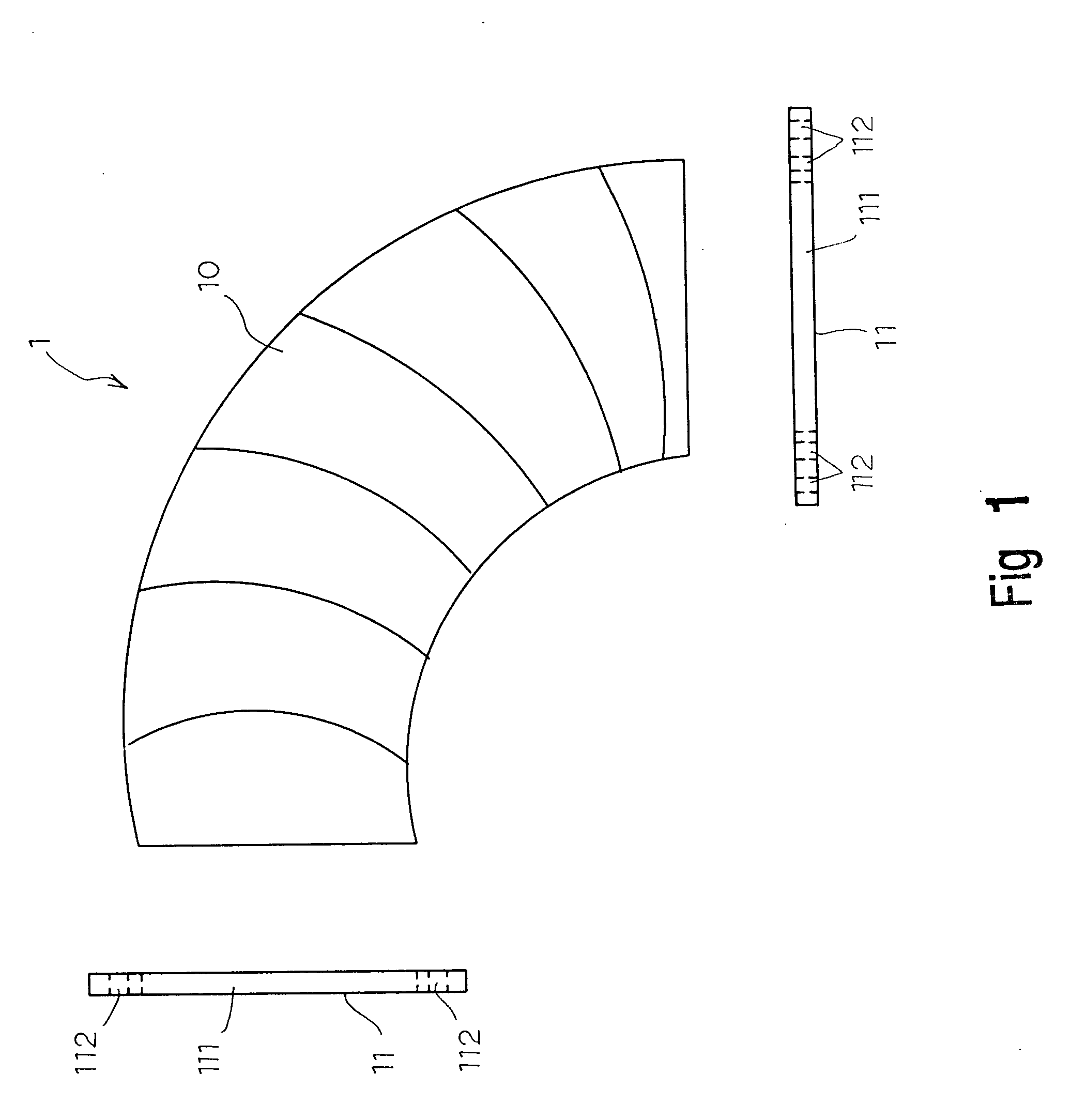

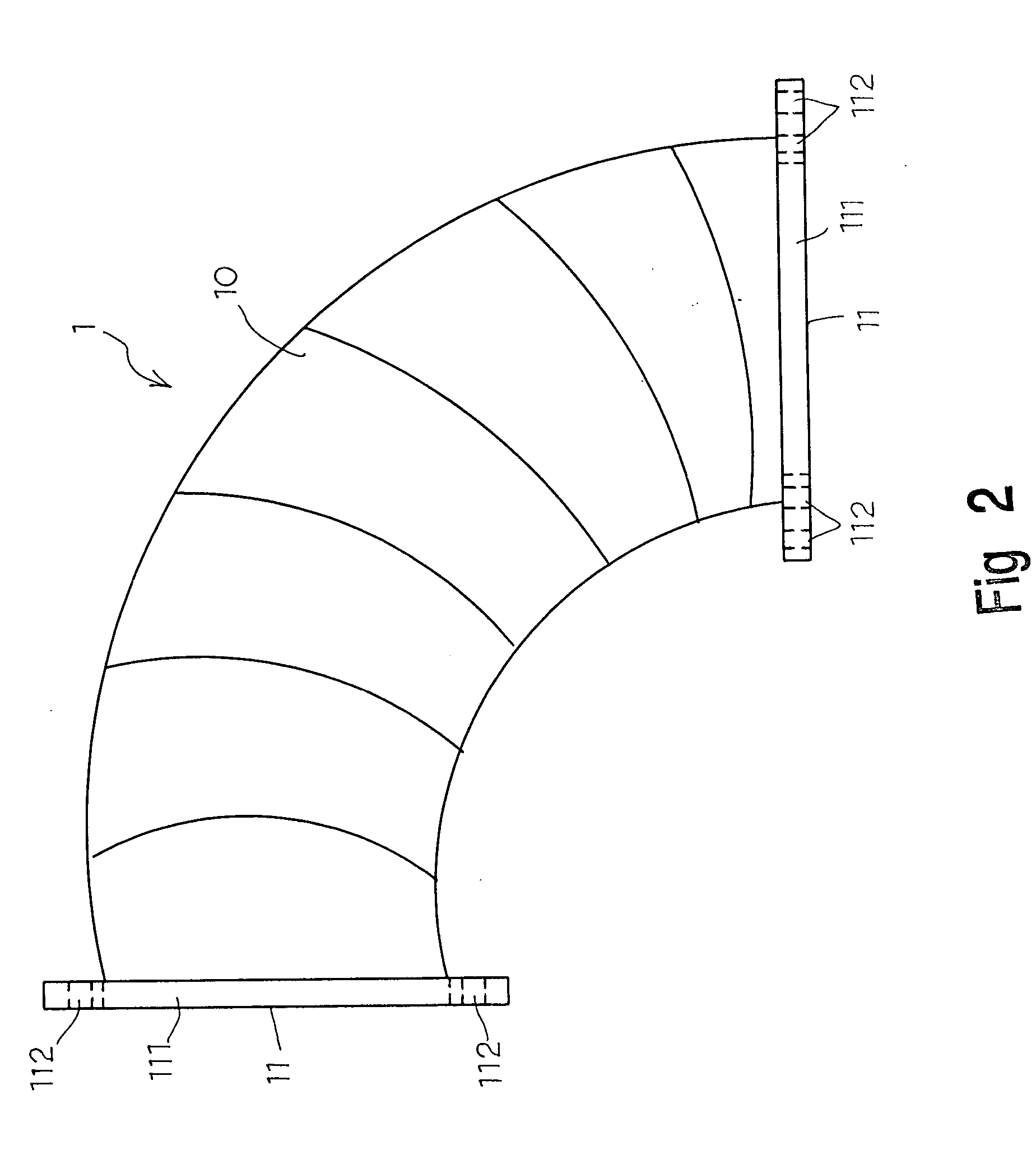

Extendible and flexible heat-dissipation air conduit base as computer heat dissipation device

InactiveUS6920044B2Reduce internal temperatureImprove cooling effectPump componentsDigital data processing detailsGuide tubeComputer engineering

The present invention is related to an extendible and flexible heat-dissipation air conduit base as computer heat dissipation device. The invention mainly comprises an air conduit and fixtures. The air conduit is hollow and flexible with fixtures at both ends. Each fixture is in rectangle shape and connects with the air conduit through a circular hole. The fixture also has several positioning holes and through holes for metal wire to pass through and secure the air conduit with the fixture. By this design, the fixture at one end of the air conduit connects to a heat dissipation fan for CPU. Thus, it provides an excellent heat dissipation channel for computer CPU and helps to achieve the desirable heat dissipation effect.

Owner:LIN CHUAN HUNG +1

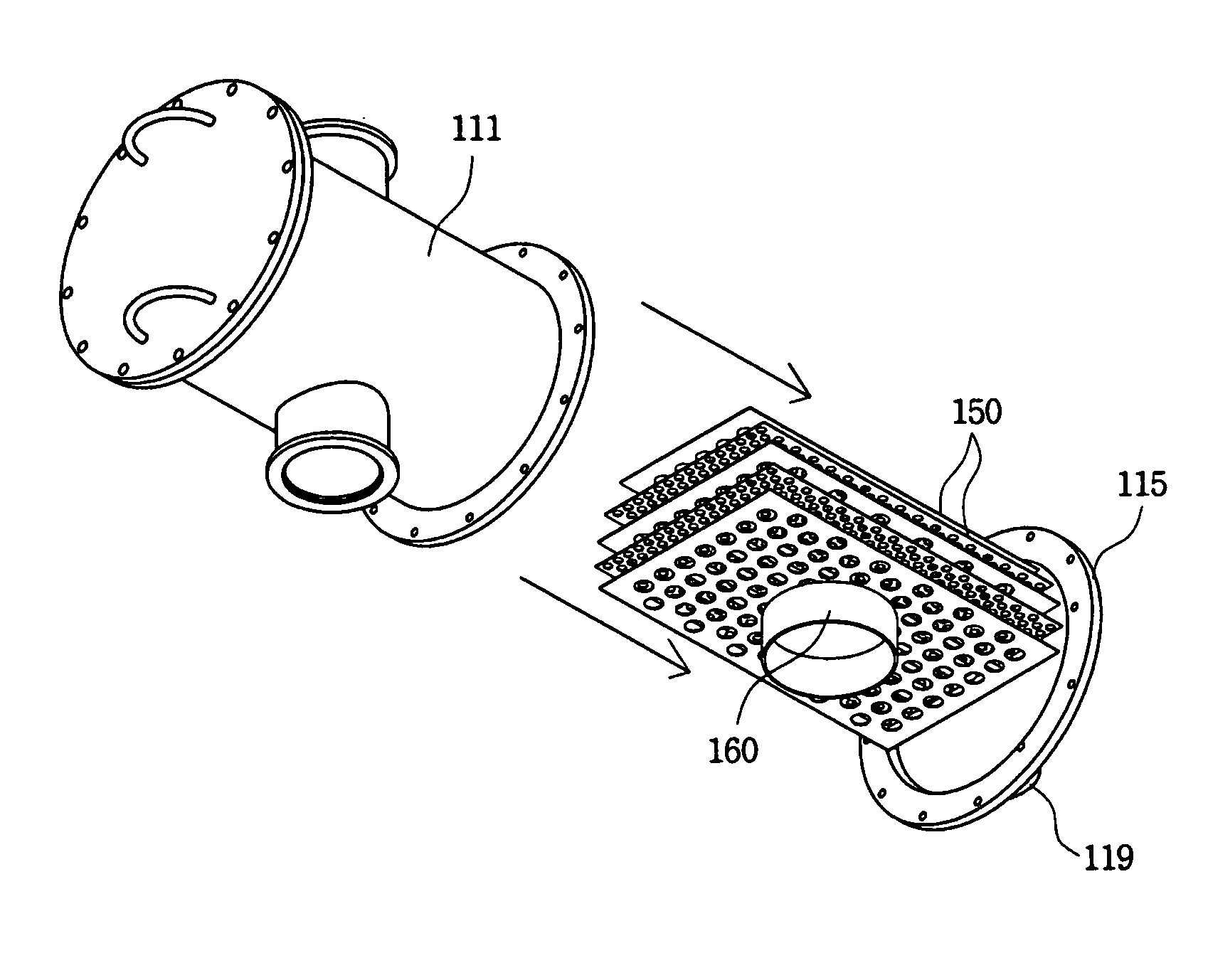

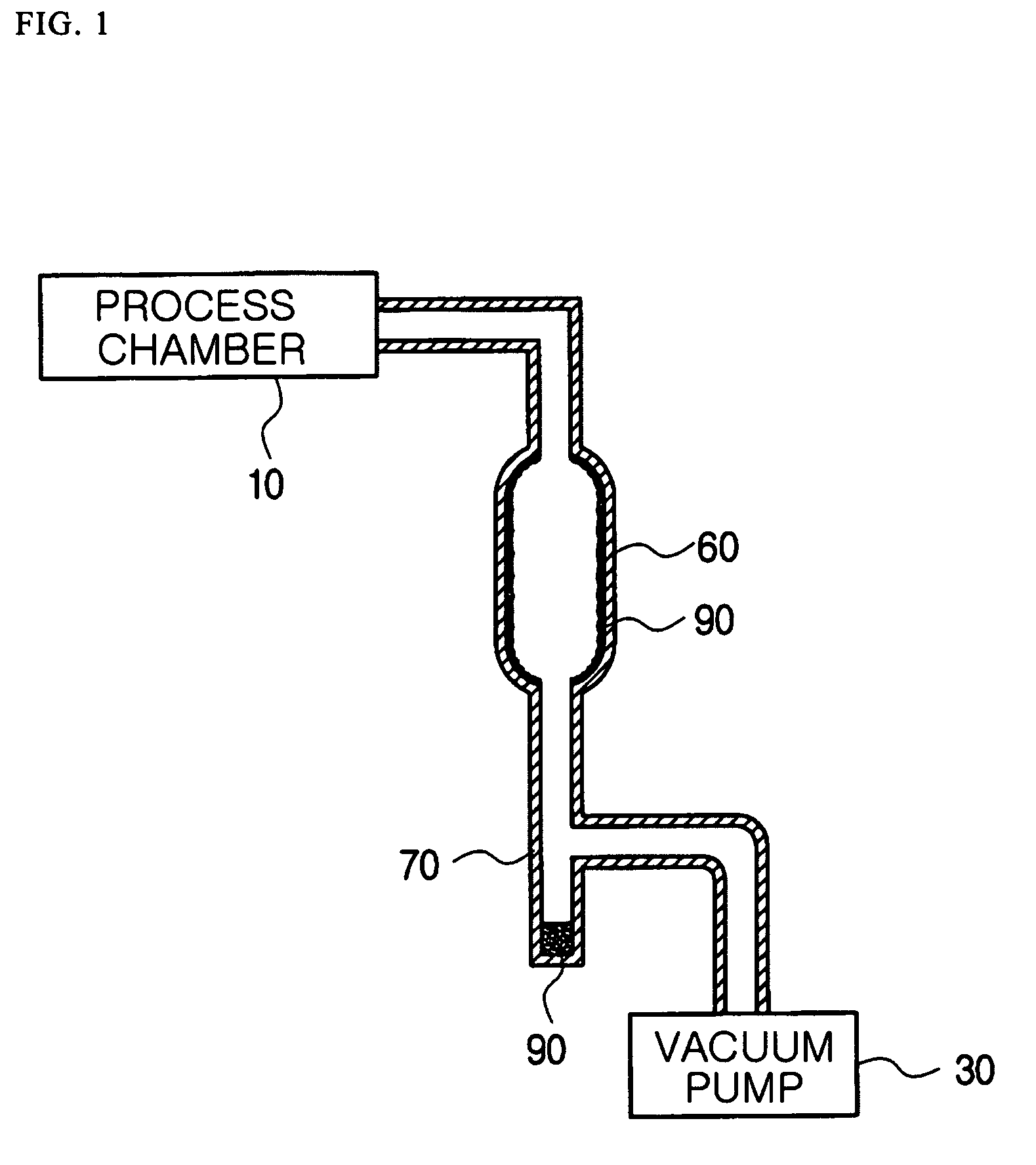

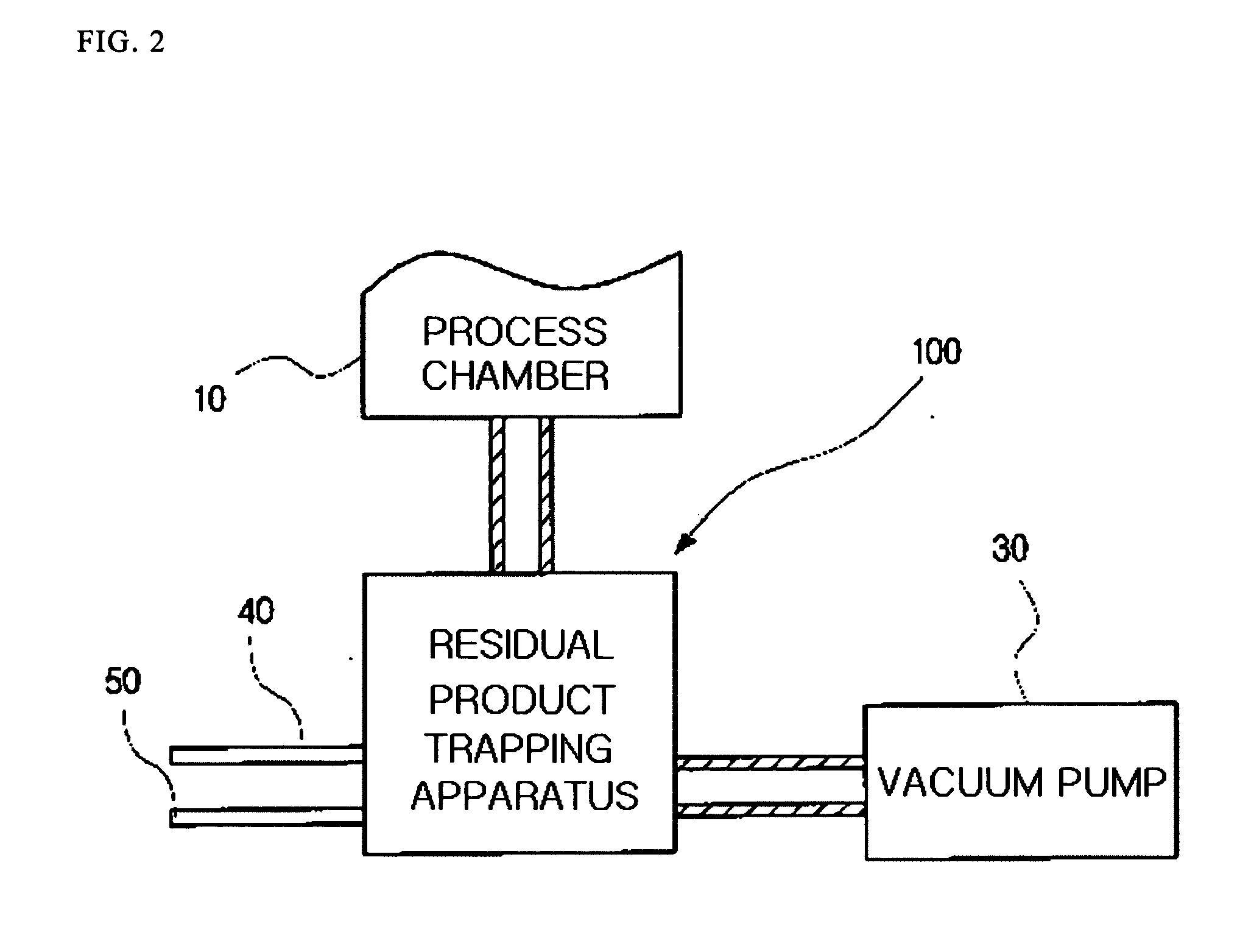

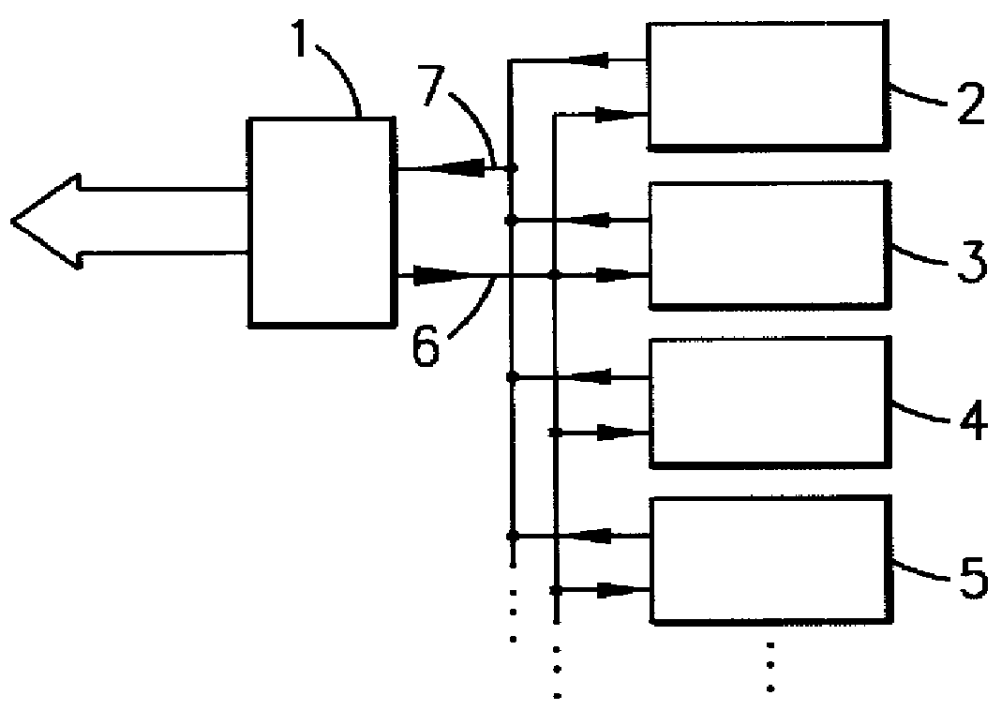

Apparatus For Trapping Residual Product Of Semiconductor Manufacturing Process

InactiveUS20090217634A1Reduce internal temperatureEfficient trappingCombination devicesSolidificationChemistrySemiconductor

An apparatus for trapping residual product of semiconductor manufacturing processes increases trapping effect and trapping capacity of residual product of reaction by maximizing an effective area for the residual product of reaction to be trapped while actively preventing the residual product of reaction generated in a process chamber during a thin film deposition and etching process from sucking into a vacuum pump, thereby easily removing the trapped residual product of reaction, including hollow housing having an inner containing space, first connection pipe connecting process chamber and housing, second connection pipe connecting vacuum pump and housing, and a protrusion extending inwardly and protruding from a housing base, cooling element disposed inside the housing for cooling the residual product of reaction flowing into the housing through the first connection pipe, and trap plates disposed inside the housing as multiple layers on which the residual product of reaction is laminated.

Owner:NEWPROTECH

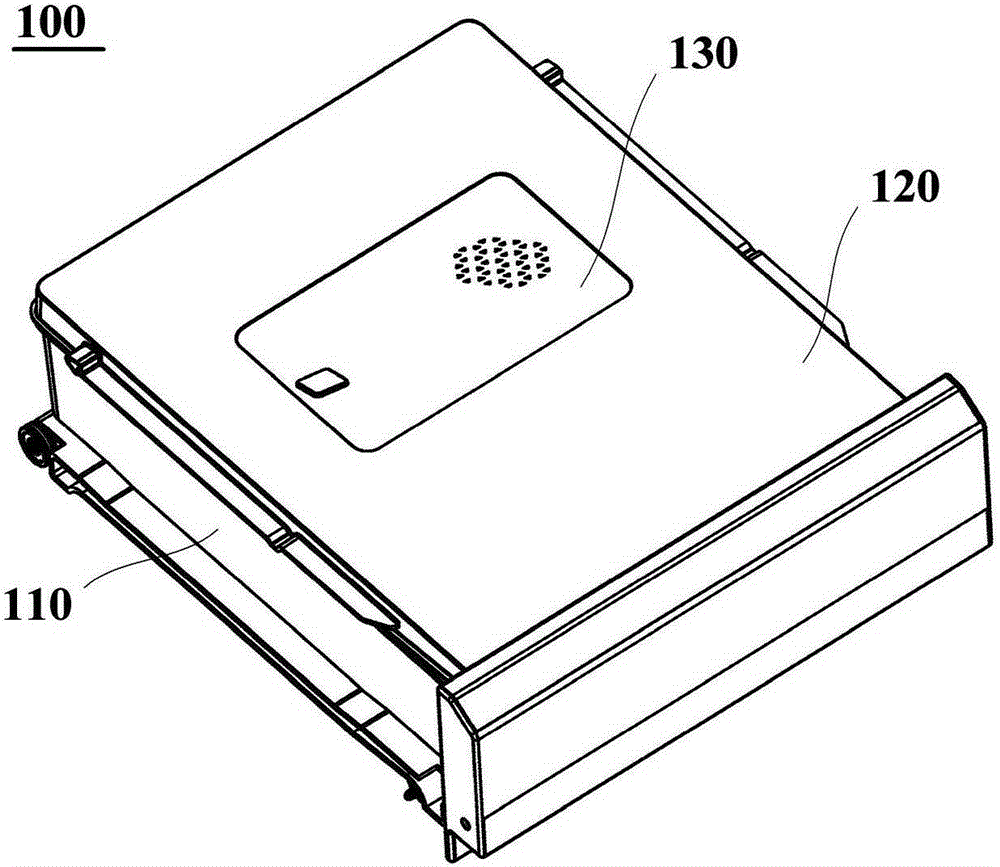

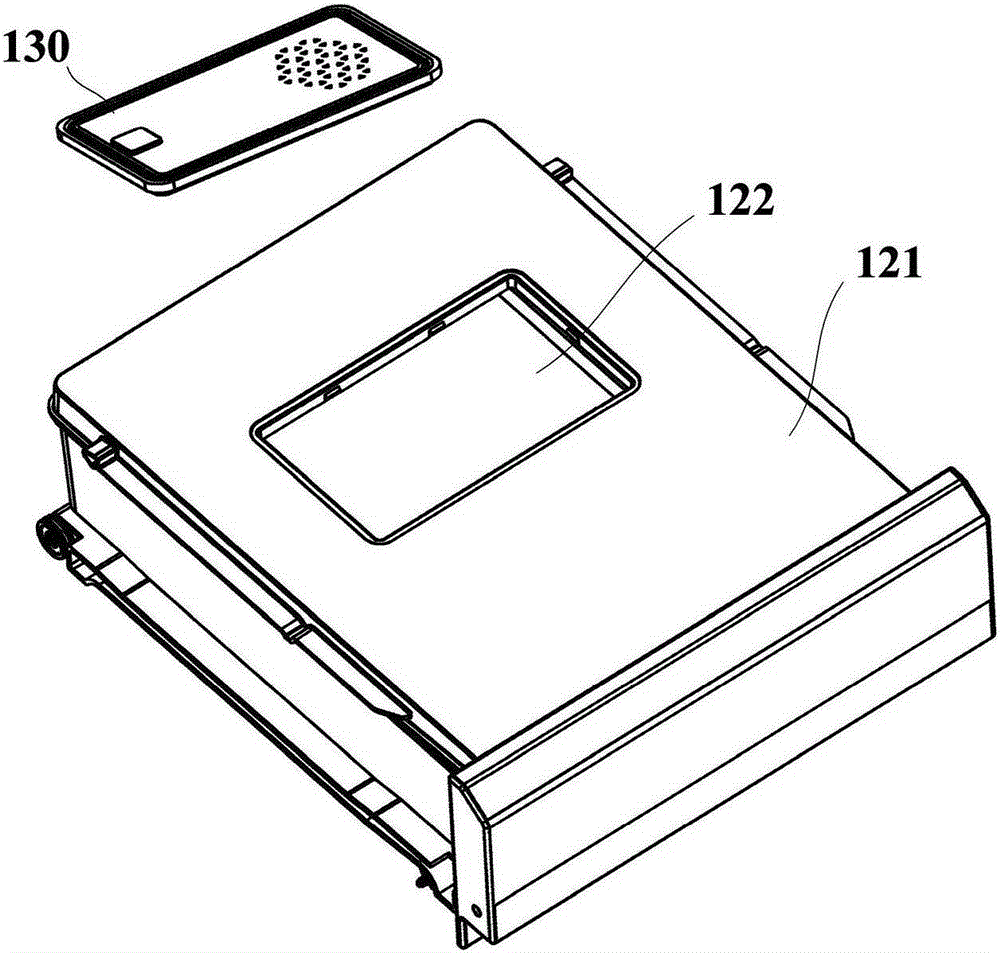

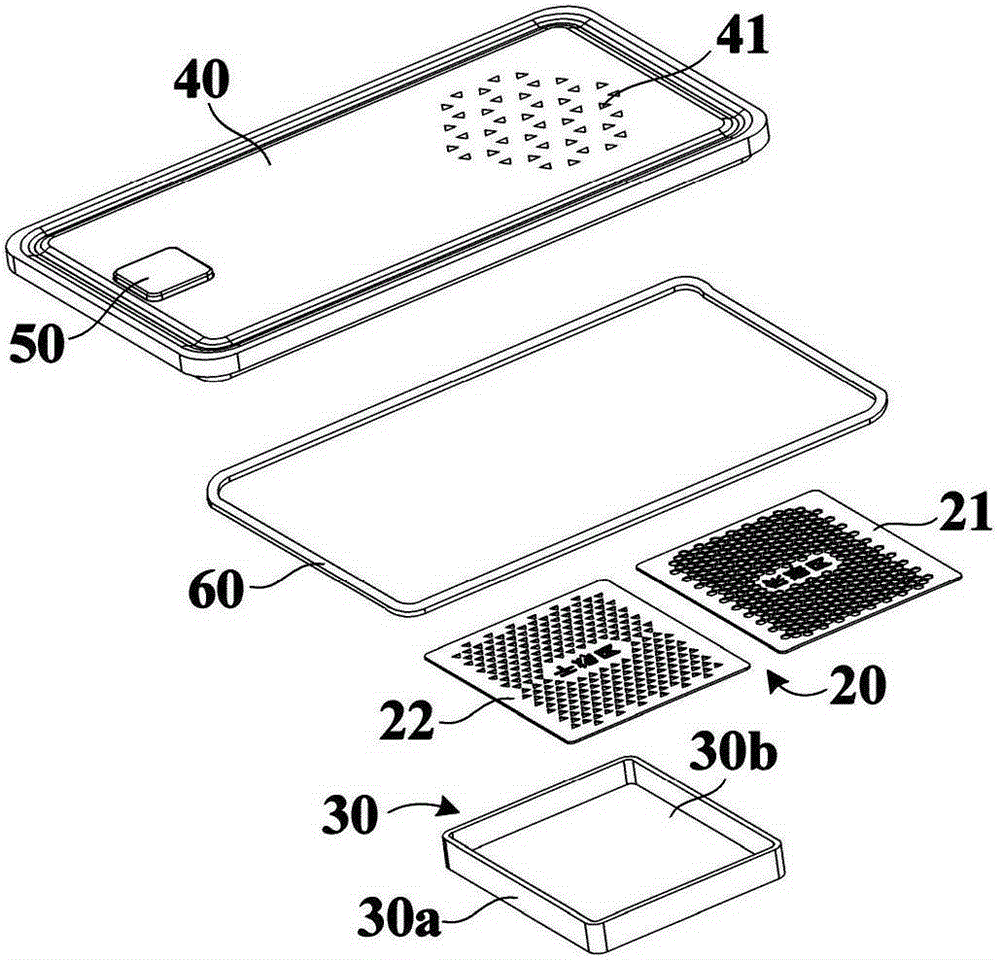

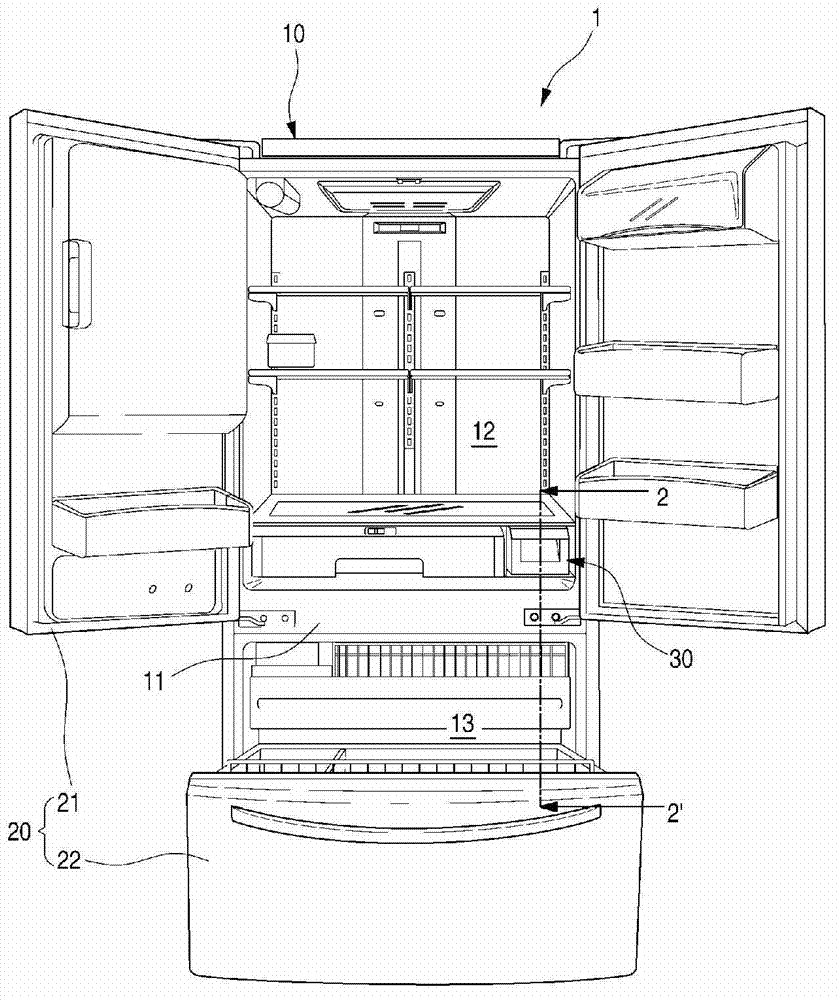

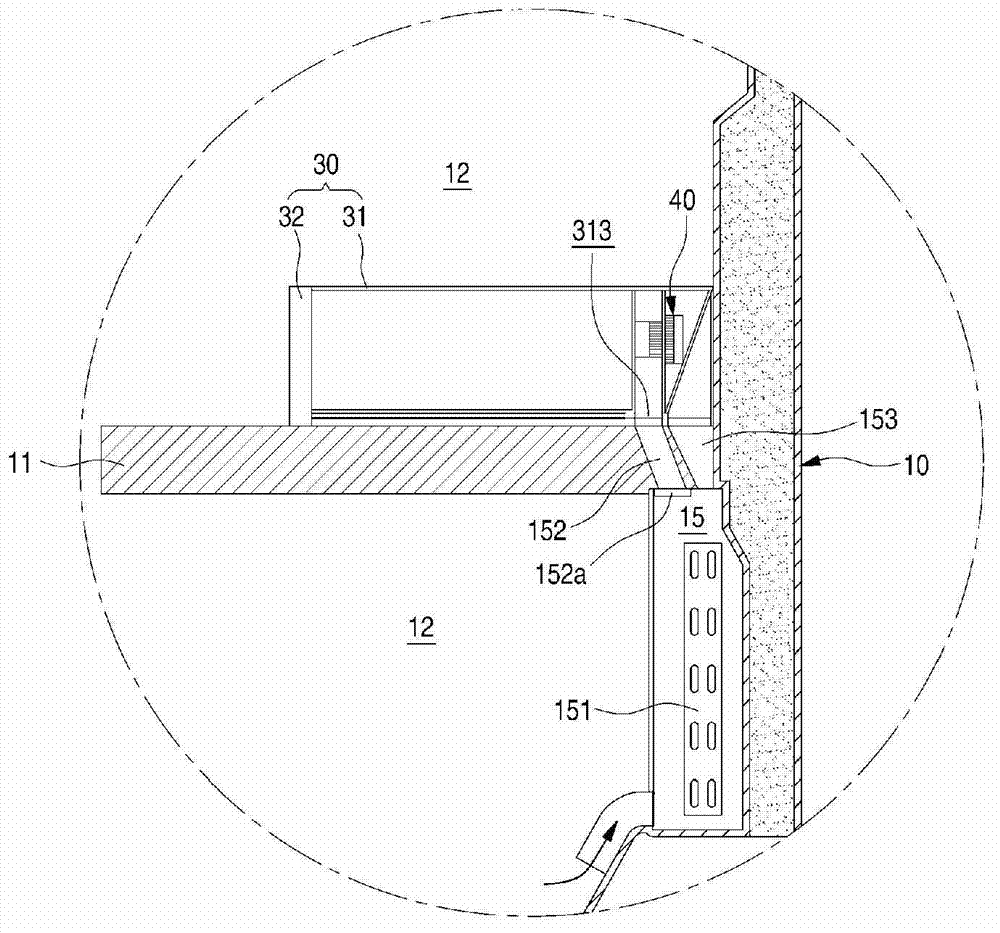

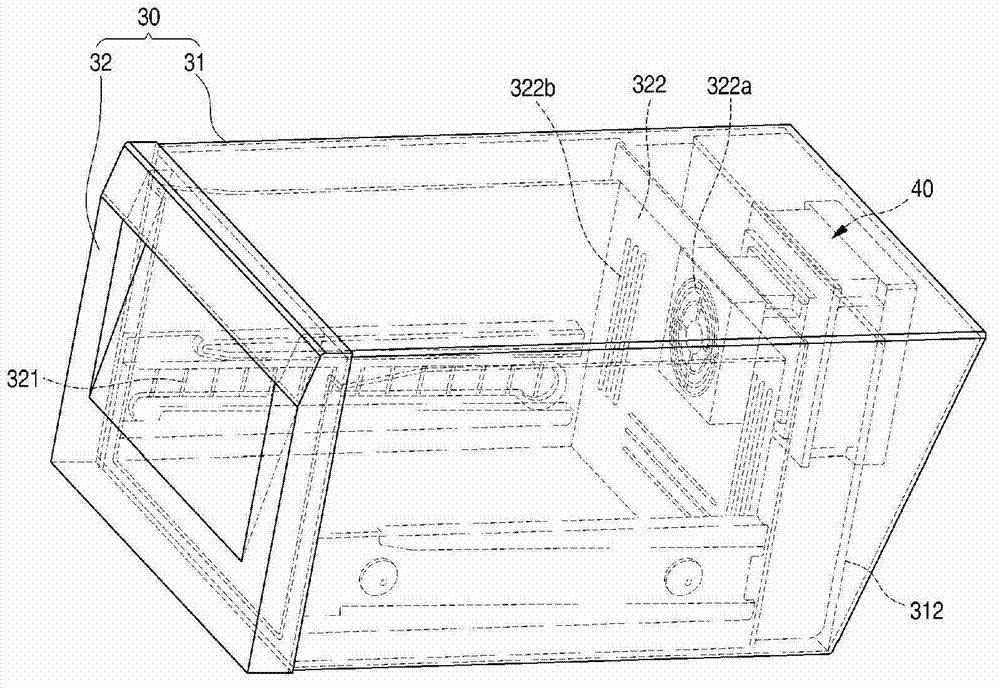

Object storage device and refrigerator with object storage device

ActiveCN105180581AReduce internal temperatureLow moisture absorptionLighting and heating apparatusSupportInterior spaceEngineering

The invention relates to an object storage device and a refrigerator with the object storage device. In particular, the object storage device comprises a drawer and a sealing device, and the sealing device is arranged to singly seal the drawer or arranged to be matched with an object storage room of the refrigerator to seal the drawer. Specially, the object storage device further comprises a humidity adjusting device which is installed in the sealing device and comprises an adjusting part and a switching part, wherein the adjusting part comprises a moisturizing module used for improving or keeping the humidity in the drawer and a drying module used for reducing the humidity in the drawer; and the switching part is arranged to enable at least a part of moisturizing module or at least a part of drying module to be exposed in the internal space of the drawer in an operationable manner, so that the drawer works in the moisturizing mode or the drying mode. In this way, the dry and wet multiplex aim of the internal space of the drawer can be achieved. In addition, the invention further provides the refrigerator with the object storage device, and the dry and wet multiplex drawer is provided for the refrigerator.

Owner:HAIER SMART HOME CO LTD

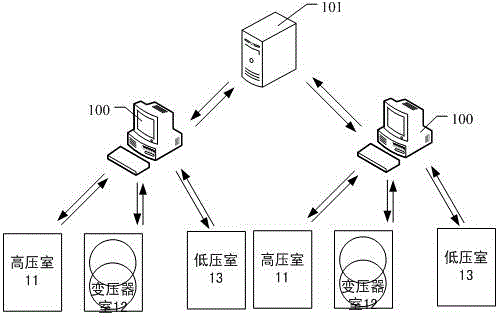

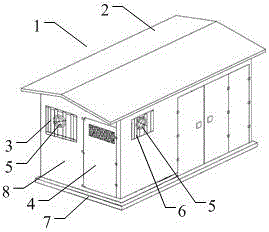

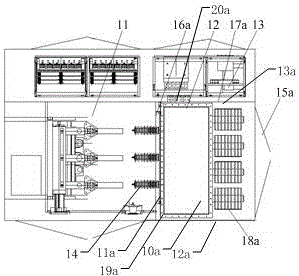

Comprehensive power supply system with remote monitoring function

ActiveCN106169708AEasy maintenance and repairReduce surface temperatureBoards/switchyards circuit arrangementsEarthing arrangementsNatural ventilationTransformer

The invention provides a comprehensive power supply system with a remote monitoring function. The comprehensive power supply system comprises a box, wherein the box comprises a base plate, wall bodies and a top cover, and a high-voltage room, a transformer room, a low-voltage room and an industrial personal computer are arranged in the box; in a box-type substation, the high-voltage room, the transformer room and the low-voltage room are provided with doors and windows, and exhaust fans are arranged on the windows, so that natural ventilation and mechanical ventilation are combined, and maintenance is convenient; the wall bodies and clapboards on the circumference of the substation are respectively provided with inner-layer steel plates and outer-layer steel plates, a cavity is formed between each inner-layer steel plate and outer-layer steel plate, and fireproof sound-insulation cotton is arranged in each cavity; and radiation heat-dissipation cooling coating coats the surface of each outer-layer steel plate. The radiation heat-dissipation cooling coating can radiate object heat and achieve heat-dissipation waterproof functions; and the radiation heat-dissipation cooling coating can automatic radiate the heat of the coated object to an atmospheric space, reduces surface and interior temperature of the box-type substation and also achieves a soundproof function.

Owner:SHANDONG JINREN ELECTRIC

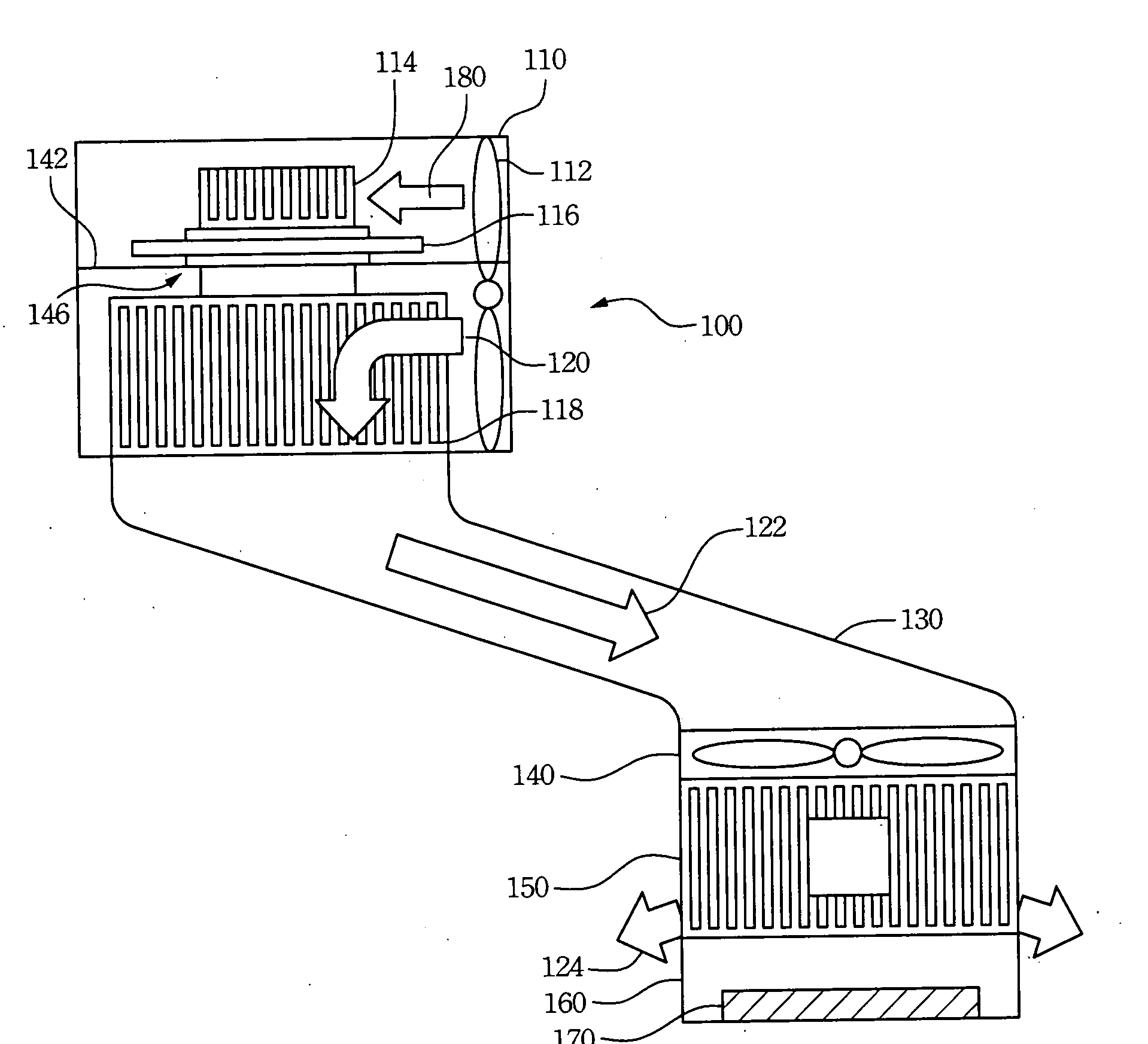

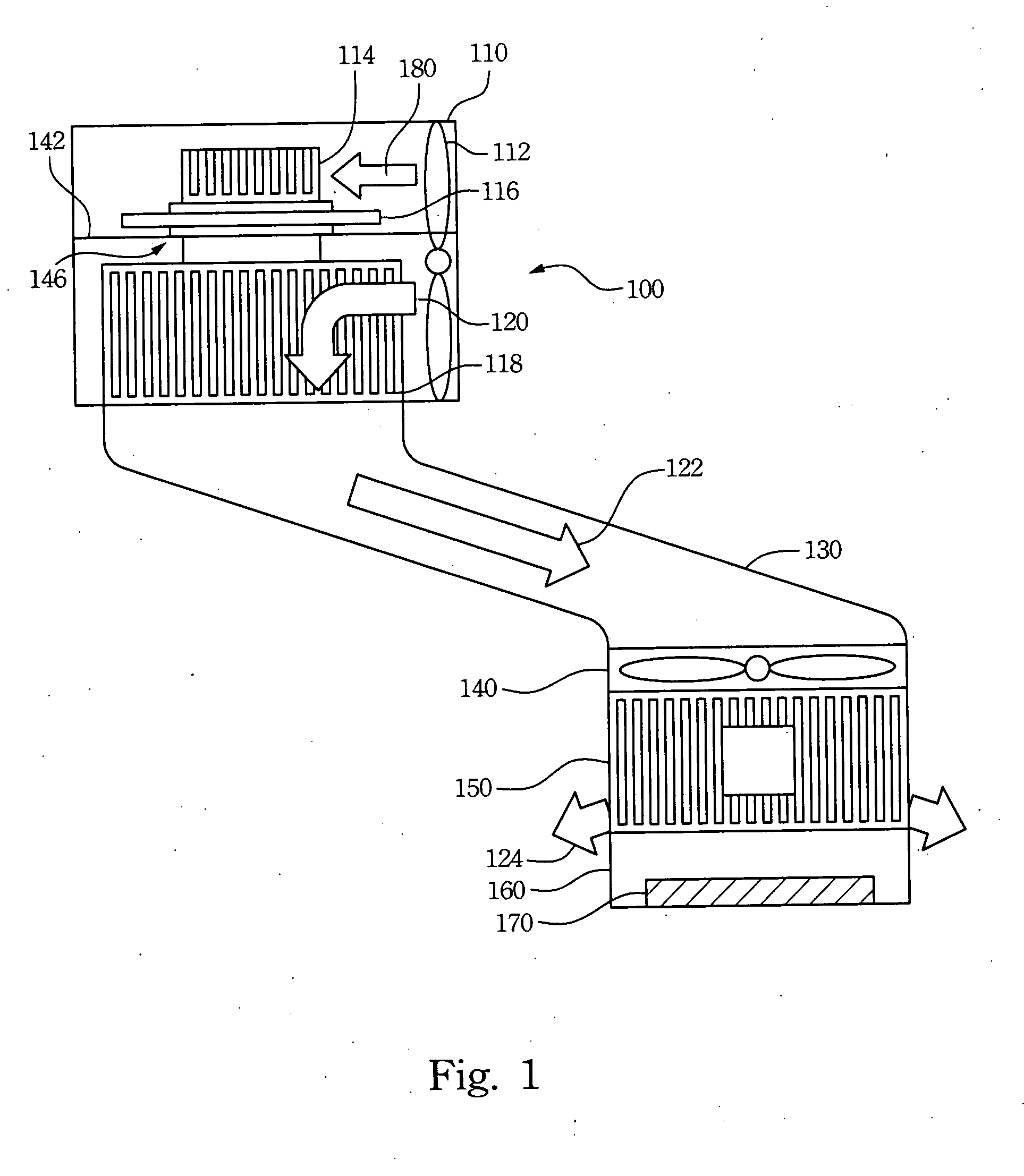

Double-effect thermoelectric cooling apparatus

InactiveUS20070204627A1Lower operating temperatureOperational stability can be improvedDomestic cooling apparatusSemiconductor/solid-state device detailsThermoelectric coolingGraphic card

A double-effect thermoelectric cooling apparatus is described. The double-effect thermoelectric cooling apparatus includes a heat-dissipating barrel, a wind guide, cooling fins, and a fan. The heat-dissipating barrel further includes a thermoelectric chip-cooling module and heat-dissipating fins disposed therein. The fan drives a part of air passing through the heat-dissipating fins to remove a heat exchanged by the thermoelectric chip-cooling module. One end of the wind guide is coupled to a heat source of an electronic device, for example, a CPU or a graphic card of a computer. Another end of the wind guide is coupled to the fan to guide another part of the air through the cooling fins reducing the temperature thereof to the heat source of the electronic device to reduce the operating temperature of the heat source.

Owner:CHANNEL WELL TECH

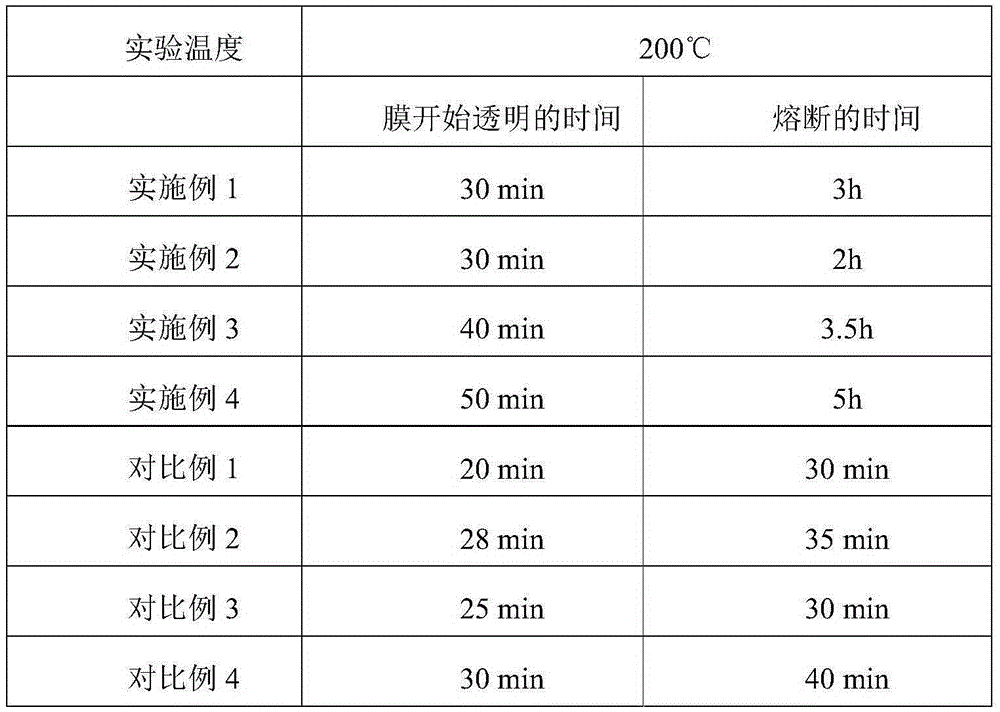

Power battery diaphragm and preparation method thereof as well as power battery comprising power battery diaphragm

ActiveCN105355824AImprove securityAvoid failureCell seperators/membranes/diaphragms/spacersPower batteryElectrical battery

The invention provides a power battery diaphragm and a preparation method thereof as well as a power battery comprising the power battery diaphragm. The power battery diaphragm comprises a diaphragm body provided with a first surface and a second surface opposite to the first surface; a first modified layer located on the first surface, and / or a second modified layer located on the second surface; the first modified layer and the second modified layer respectively comprise a base material and phase change capsules dispersed in the base material, wherein each phase change capsule is provided with a core-shell structure, a shell of the phase change capsule comprises a polymer and ceramic particles dispersed in the polymer, and comprises a phase change material. The thermal performance of the power battery diaphragm is high, the failure probability of the diaphragm under high temperature or thermal runaway is small, and the security of the power battery is remarkably improved by using the diaphragm.

Owner:BEIJING ELECTRIC VEHICLE

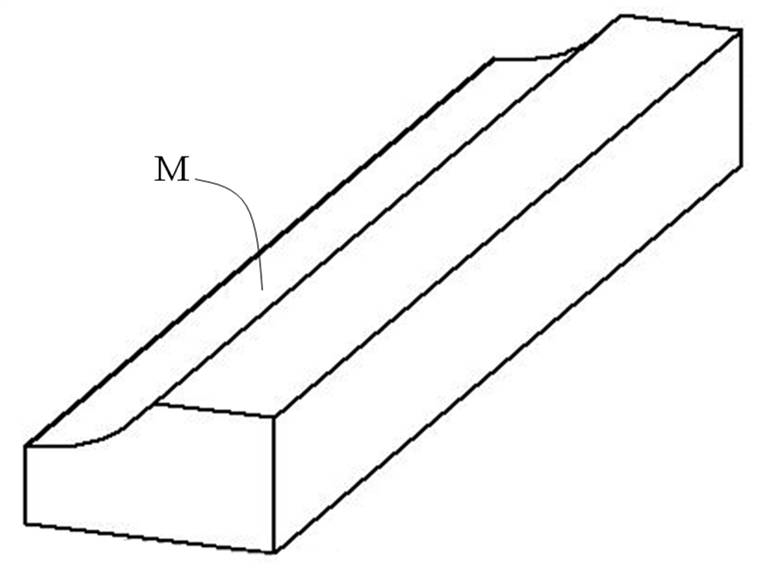

Method for manufacturing high-hardness and high-abrasion-resistant pre-bending machine lower die

ActiveCN102581145ALarge heat treatment deformationHigh hardnessShaping toolsManufactured materialEngineering

The invention discloses a method for manufacturing a high-hardness and high-abrasion-resistant pre-bending machine lower die, which belongs to the technical field of machining methods for pre-bending machine lower dies. The method includes steps of (1), preparing raw materials of the pre-bending machine lower die; (2), annealing a forged blank; (3), primarily machining the forged blank; (4), conditioning the pre-bending machine lower die, quenching the pre-bending machine lower die by water or oil after the pre-bending machine lower die is kept at the temperature ranging from 830 DEG C to 850 DEG C for 3 hours, and then tempering the pre-bending machine lower die under the condition of the temperature ranging from 680 DEG C to 700 DEG C; (5), realizing deep processing of the pre-bending machine lower die; and (6), realizing heat treatment of the pre-bending machine lower die, dipping an arc surface R of the pre-bending machine lower die into quenching media for cooling at first during quenching, and then dipping the complete pre-bending machine lower die into the quenching media after the arc surface R is cooled in the quenching media for 4 minutes to 6 minutes. The raw materials of the forged blank include from 1.70 to 2.2% of Cr. The pre-bending machine lower die is low in final deformation, high in hardness and fine in abrasion resistance, and does not crack during the heat treatment, and the surface cannot sink even if the pre-bending machine lower die bears extremely high pressure during usage.

Owner:马鞍山博新高科产业服务有限公司

Extendible and flexible heat-dissipation air conduit base as computer heat dissipation device

InactiveUS20050073812A1Reduce internal temperatureImprove cooling effectPump componentsDigital data processing detailsEngineeringComputer engineering

The present invention is related to an extendible and flexible heat-dissipation air conduit base as computer heat dissipation device. The invention mainly comprises an air conduit and fixtures. The air conduit is hollow and flexible with fixtures at both ends. Each fixture is in rectangle shape and connects with the air conduit through a circular hole. The fixture also has several positioning holes and through holes for metal wire to pass through and secure the air conduit with the fixture. By this design, the fixture at one end of the air conduit connects to a heat dissipation fan for CPU. Thus, it provides an excellent heat dissipation channel for computer CPU and helps to achieve the desirable heat dissipation effect.

Owner:LIN CHUAN HUNG +1

Cooling system and method for distributing cooled air

InactiveUS6161612AGreat and great efficiencyImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesProcess engineeringHeat exchanger

A cooling system employing redundant system components is disclosed. The system includes multiple sets of heat: exchanger units, with each set being in fluid communication with a separate, independently operated fluid pump unit. The heat exchanger units are arranged in at least one row of heat exchanger units. The two sets of heat exchanger units are evenly interspersed with each other along the row of heat exchanger units so that a substantially uniform distribution of cooled air is provided in the event one fluid pump unit fails.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO +1

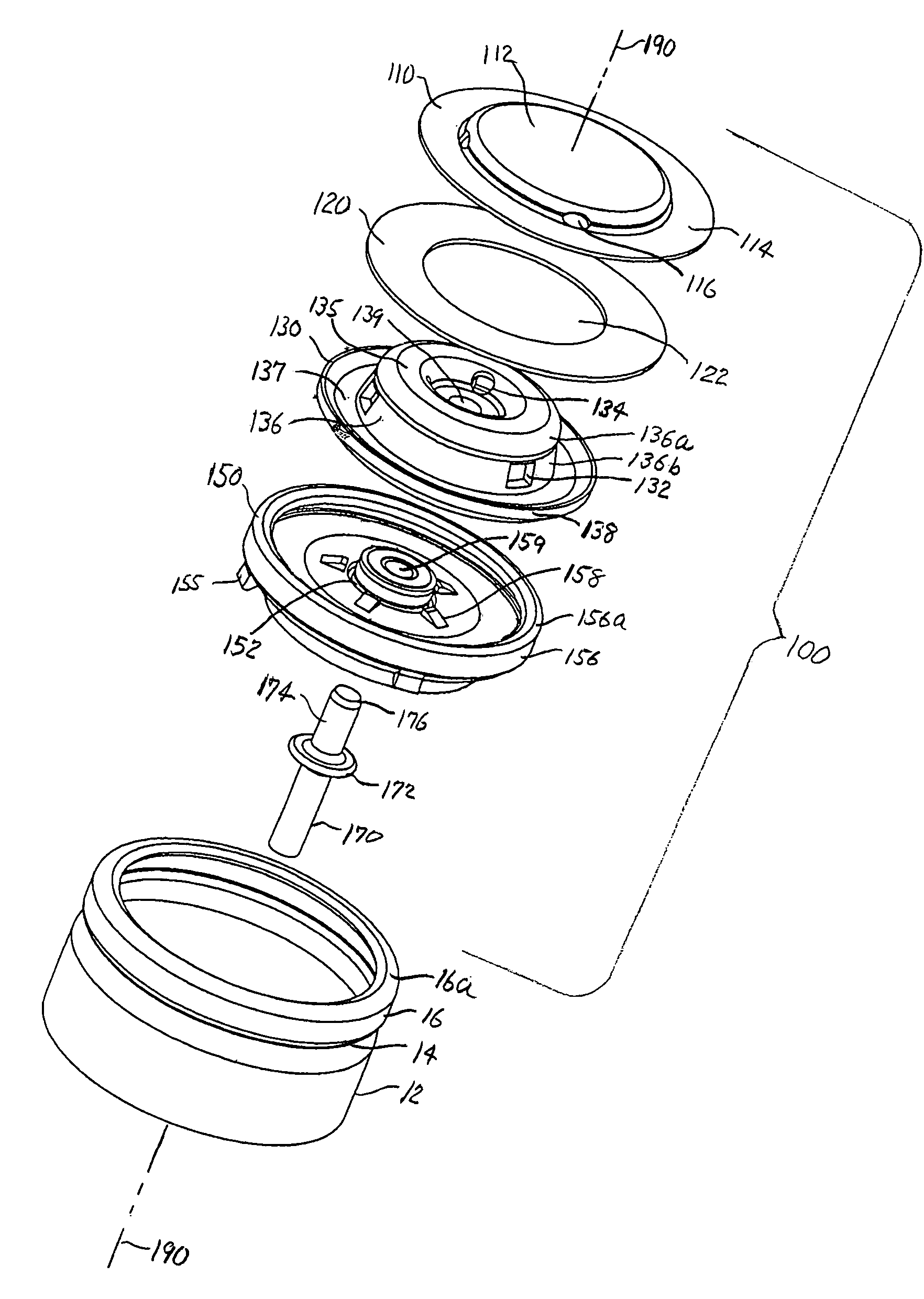

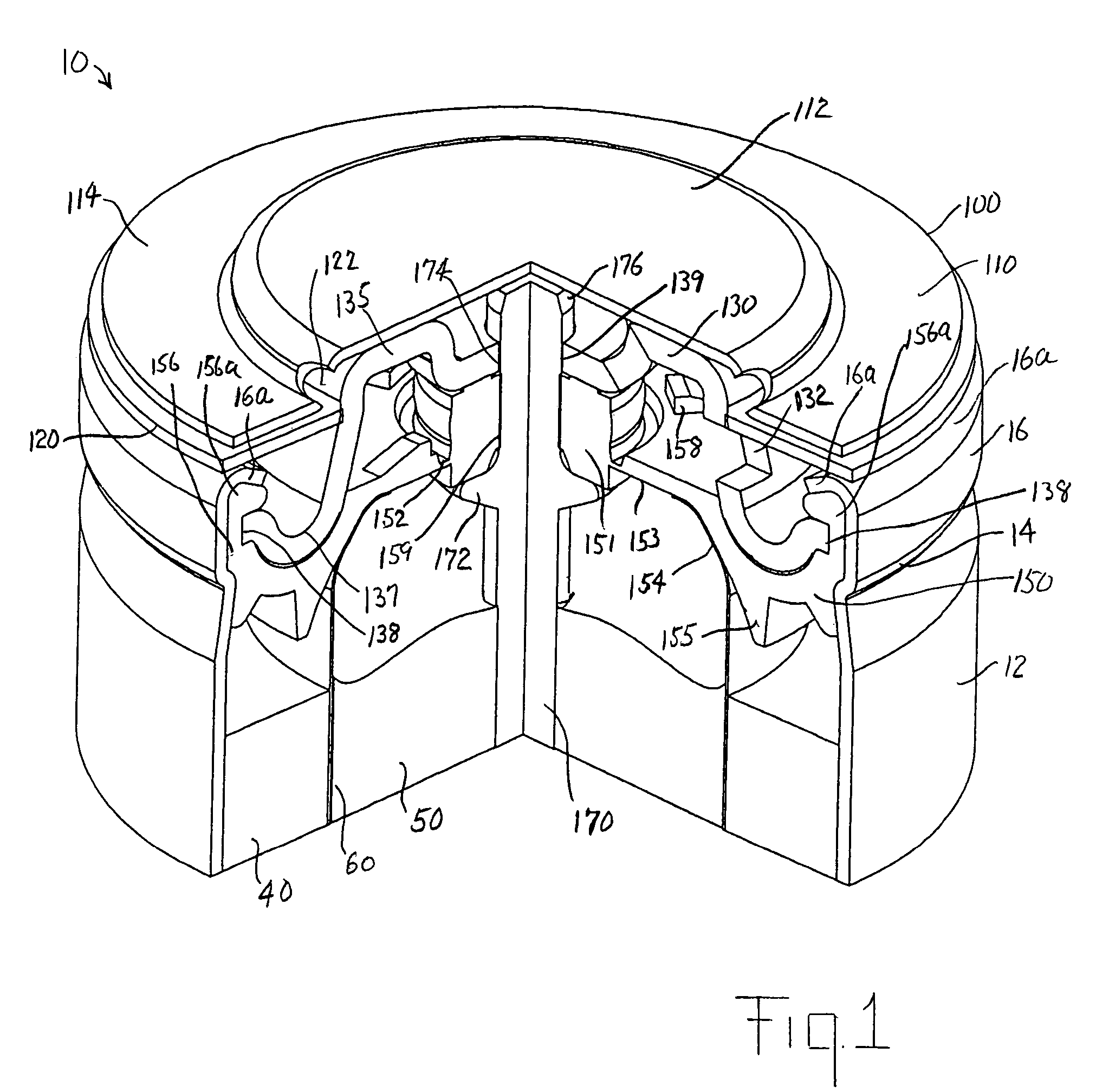

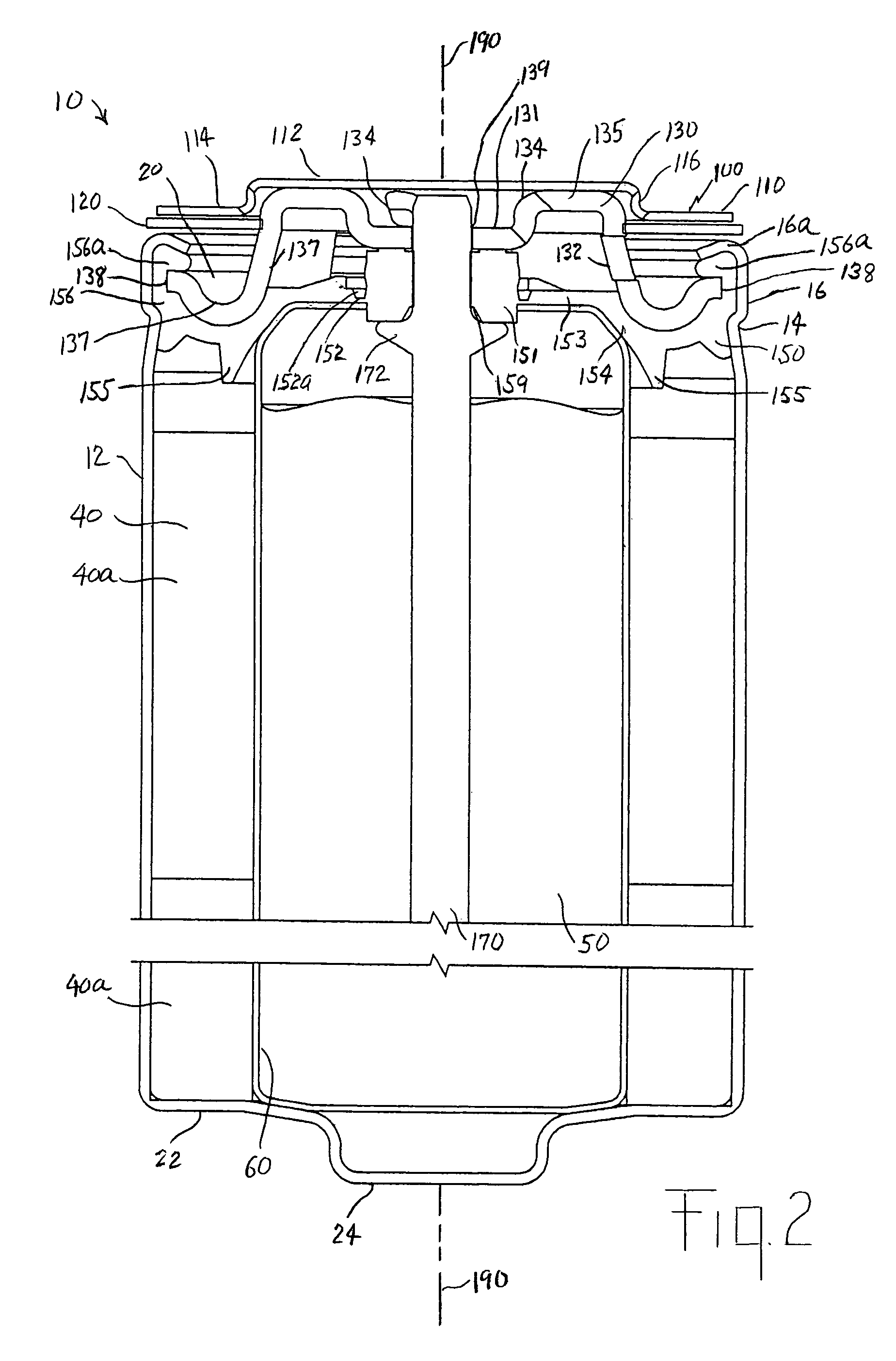

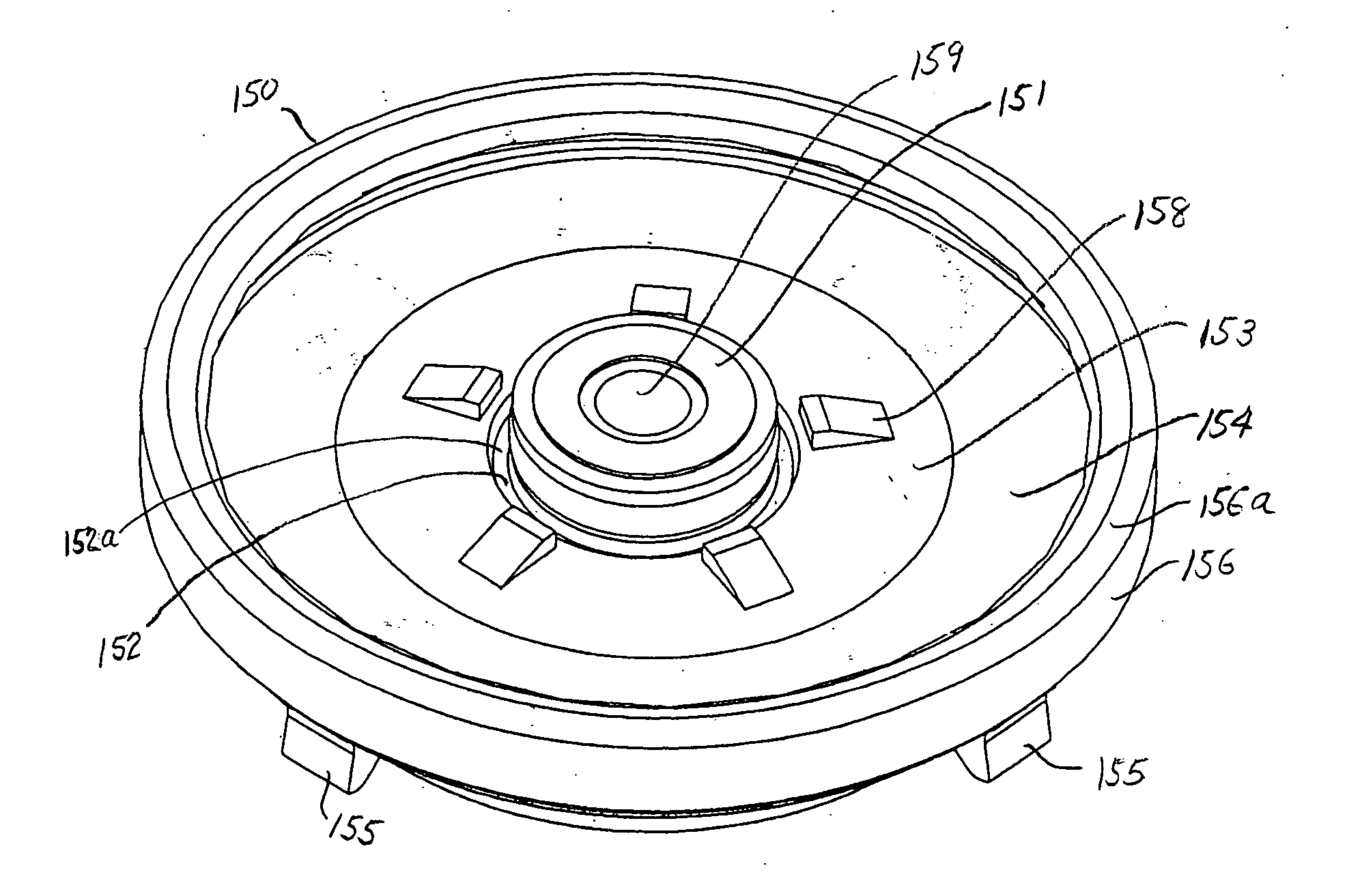

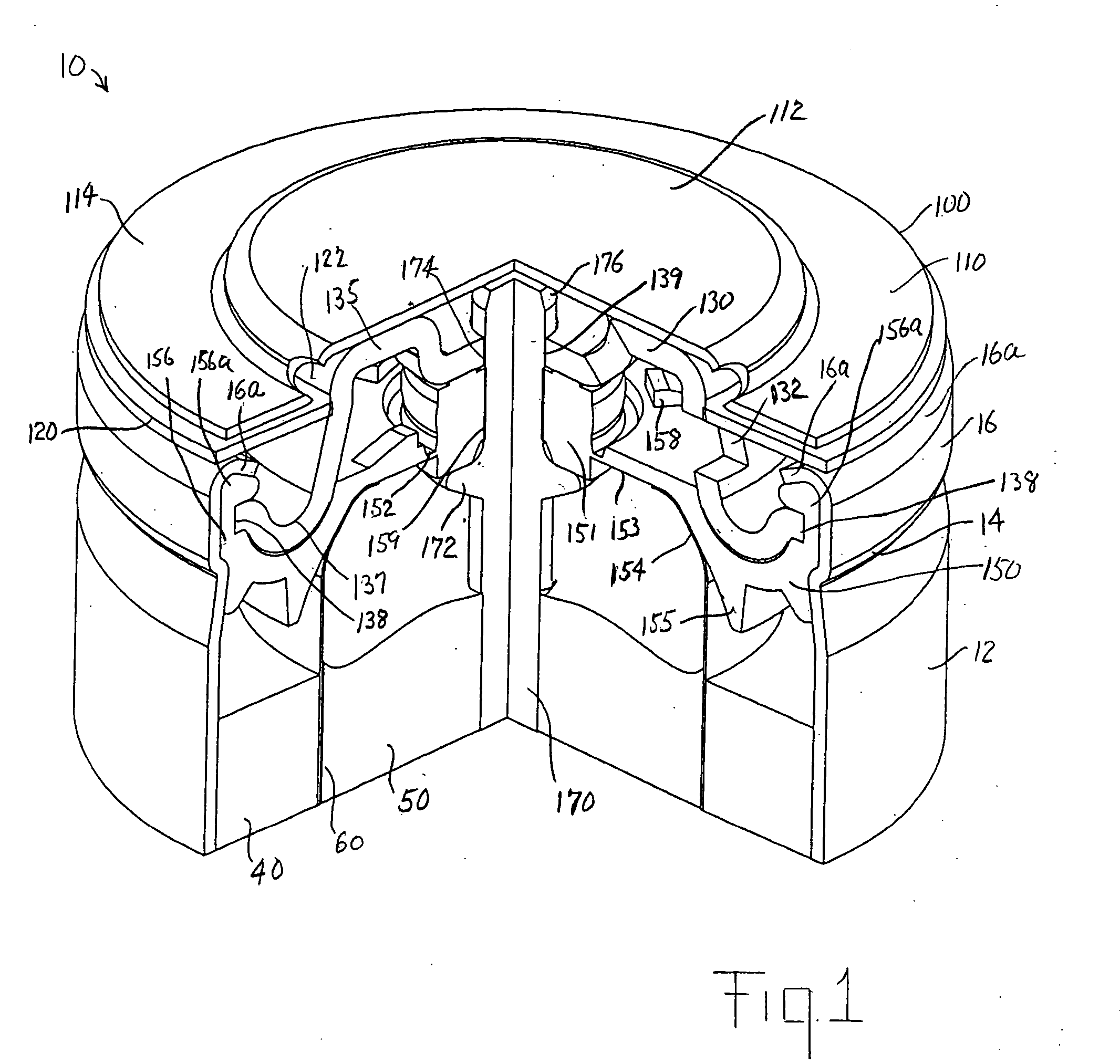

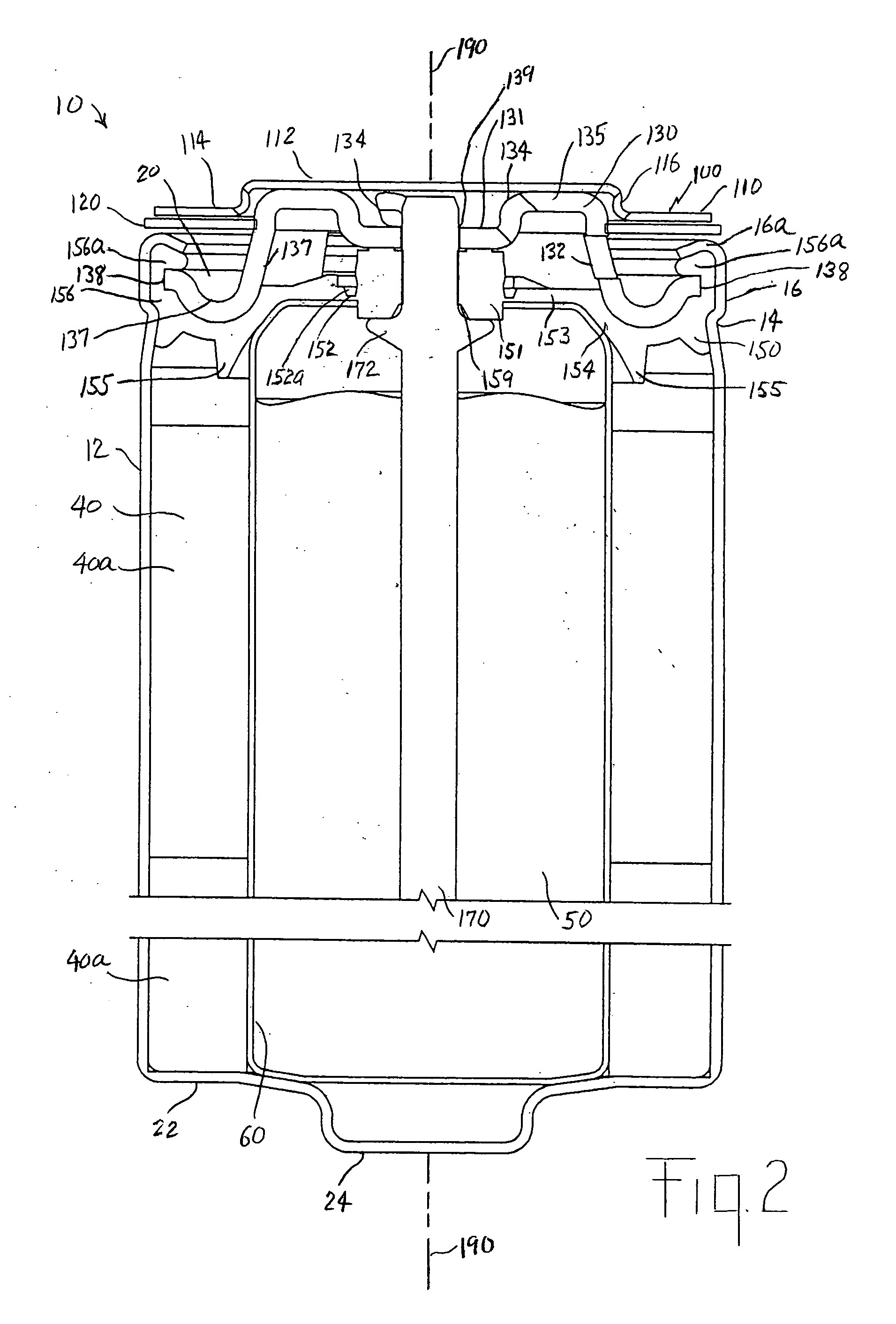

End cap assembly and vent for high power cells

ActiveUS7579105B2Preventing a catastrophic ruptureQuick releaseSmall-sized cells cases/jacketsAqueous electrolyte cellsMechanical engineeringMembrane configuration

And end cap assembly and venting system therein for closing and sealing the open end of a cell housing. The end cap assembly comprises a sealing disk underlying an end cap, and a metal support disk between the end cap and the sealing disk. The metal support disk has a plurality of primary vent apertures and a plurality of secondary vent apertures through its surface. The primary vent apertures are spaced apart along a path located at a greater distance from the central longitudinal axis of the metal support disk than the secondary vent apertures. The insulating sealing disk may have a thinned portion therein forming an rupturable membrane circumventing the central hub of the sealing disk. The insulating sealing disk may have protrusions emanating from its top surface to deflect the membrane during rupture. The venting system releases internal gases rapidly from the cell in the event of an abusive or short circuit discharge.

Owner:DURACELL U S OPERATIONS

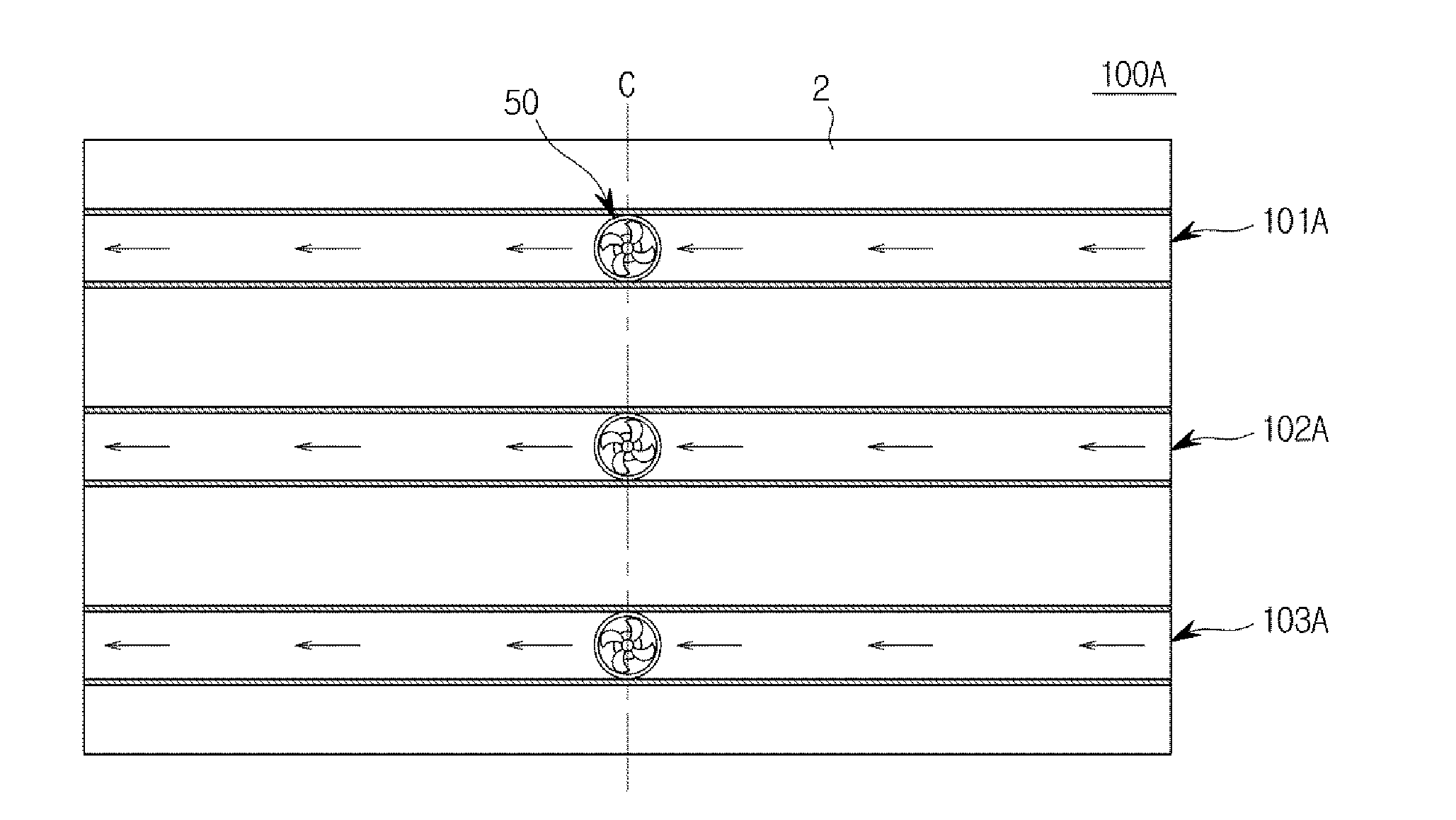

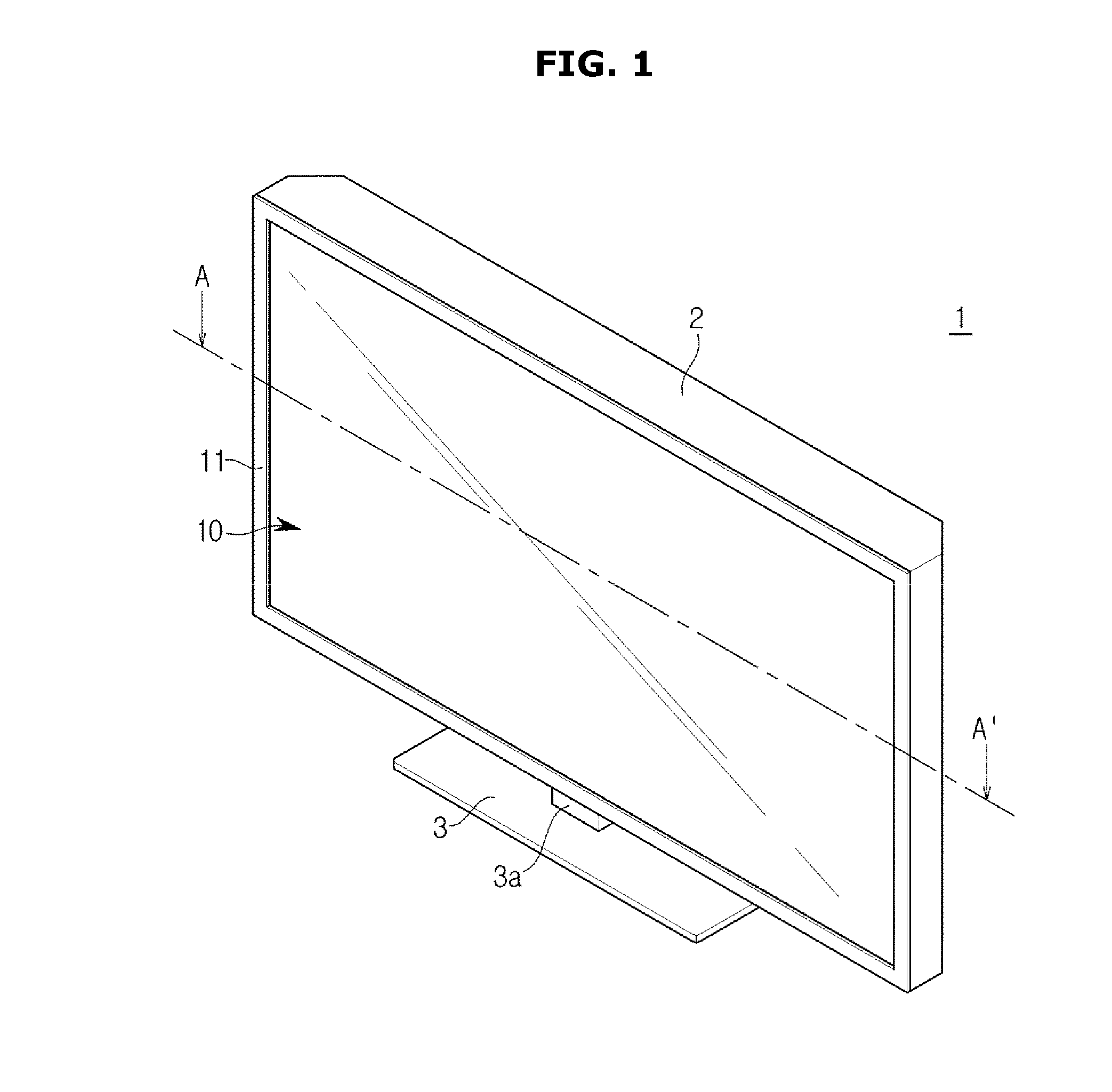

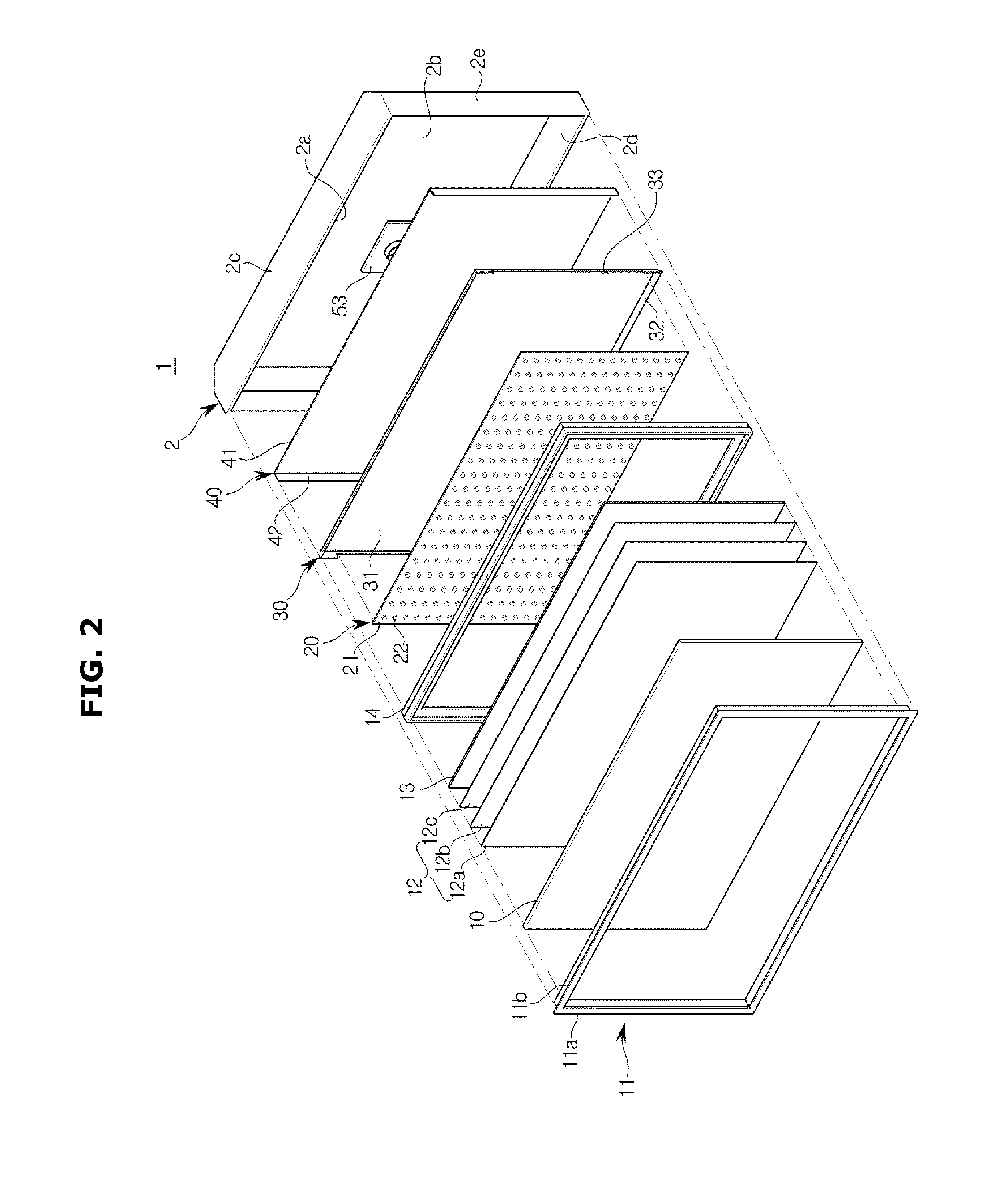

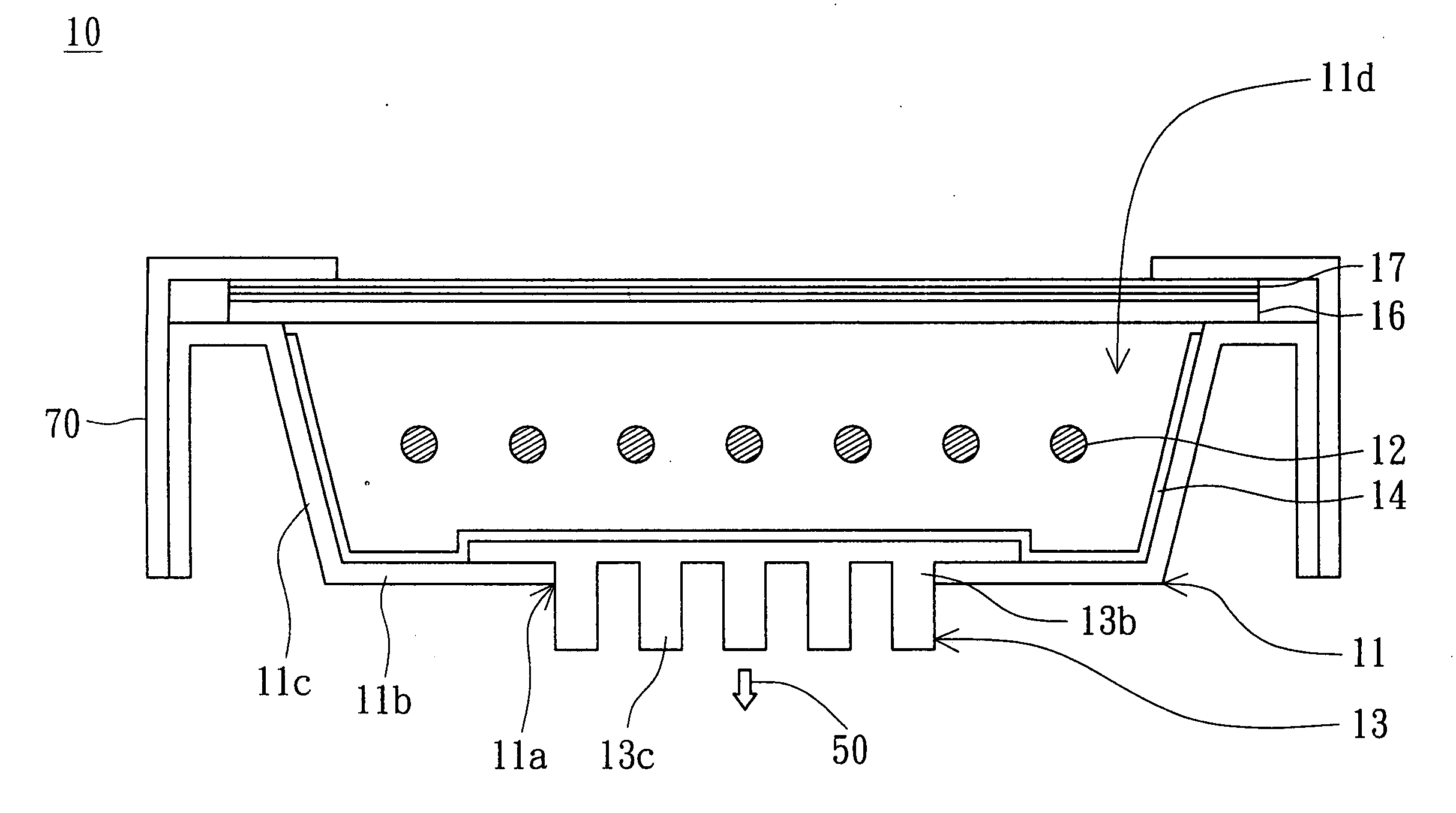

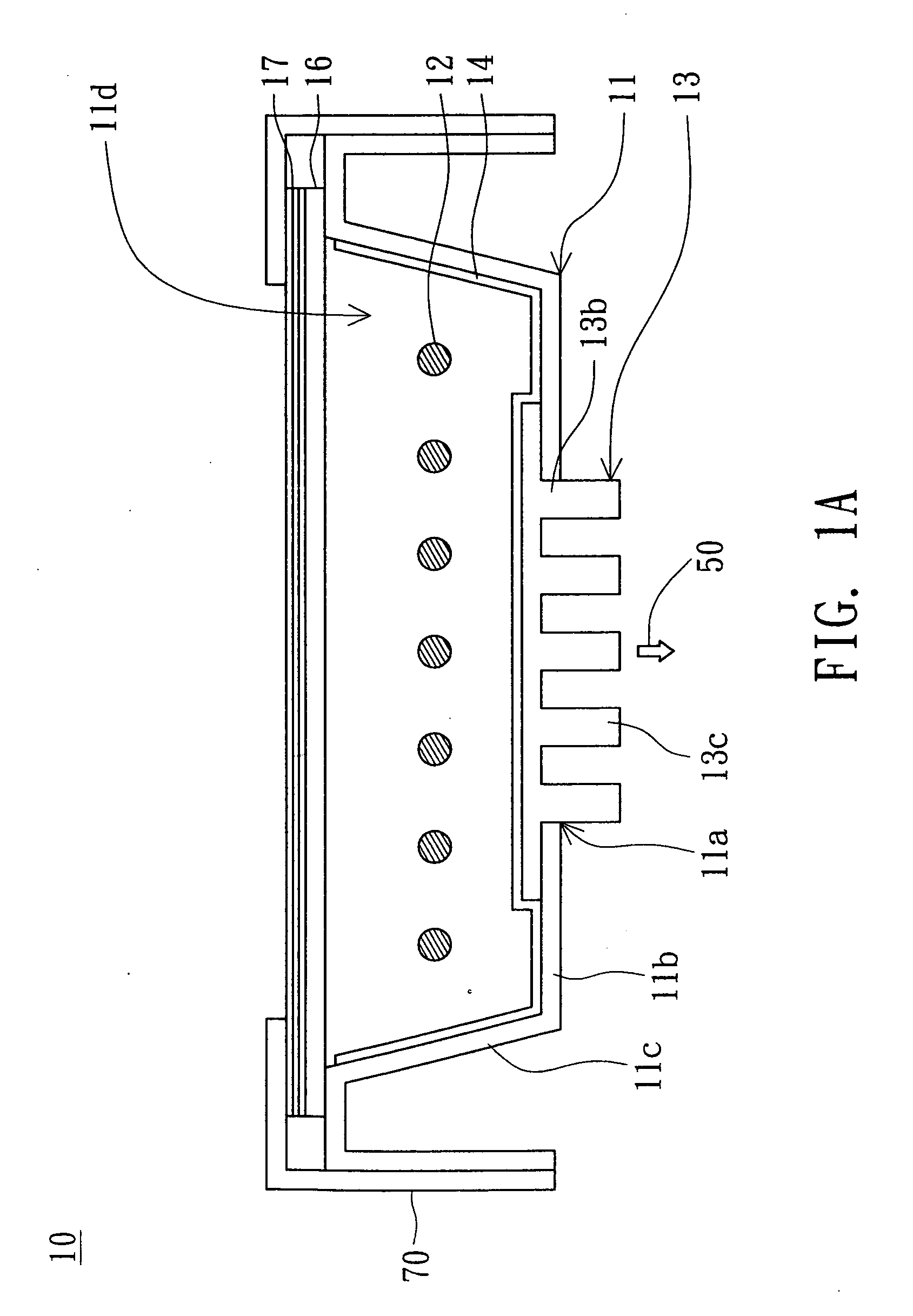

Display apparatus

ActiveUS20160265759A1Improve cooling efficiencyIncreased durabilityLighting heating/cooling arrangementsNon-linear opticsAir cycleEngineering

Disclosed herein is a display apparatus having a cooling path provided to enhance cooling efficiency. The display apparatus includes a display panel configured to display images; a light source configured to radiate light toward the display panel; a bottom chassis disposed in rear of the light source; a case provided in rear of the bottom chassis; a circulative cooling path provided as to have air circulated surroundings of the bottom chassis.

Owner:SAMSUNG ELECTRONICS CO LTD

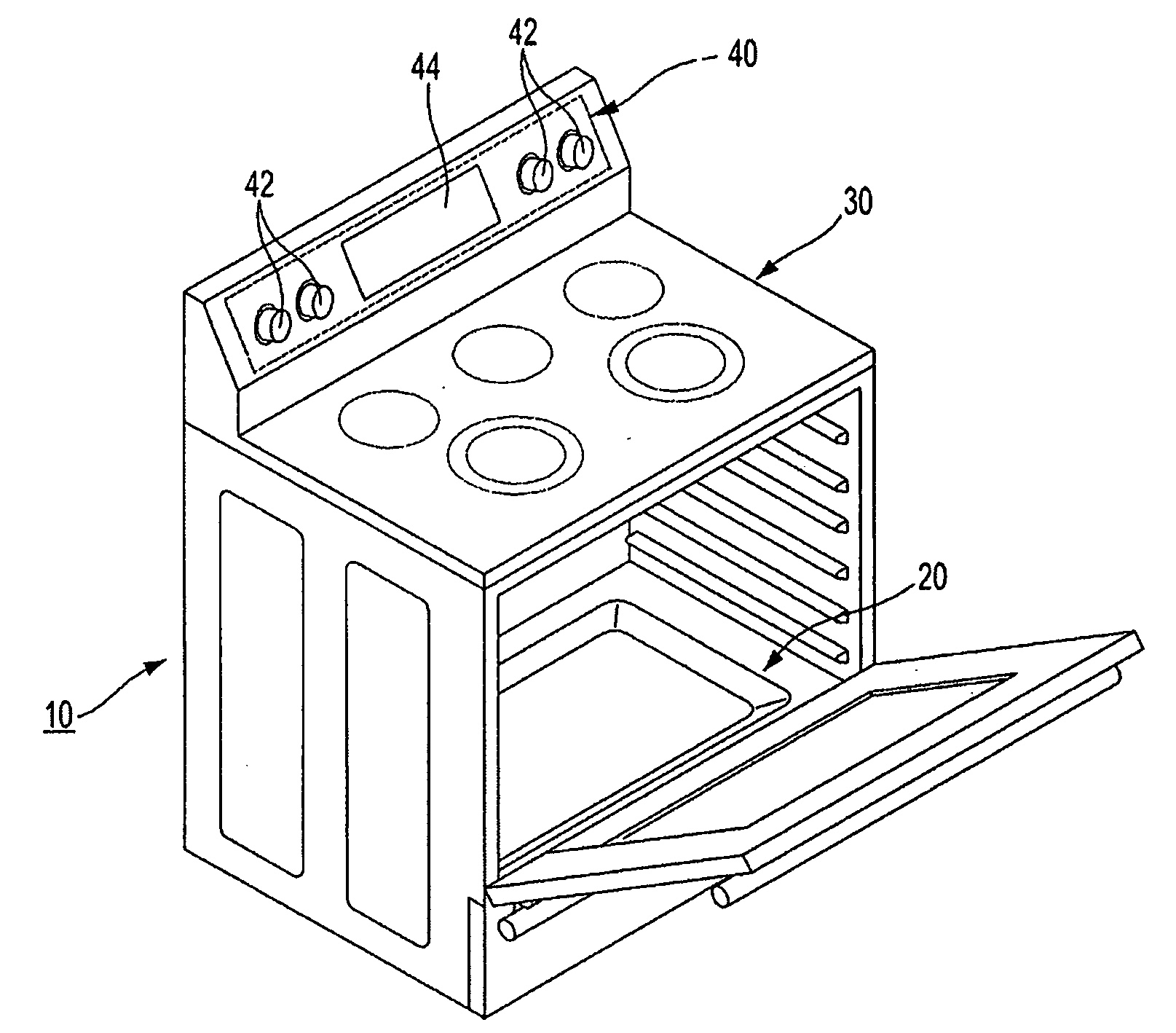

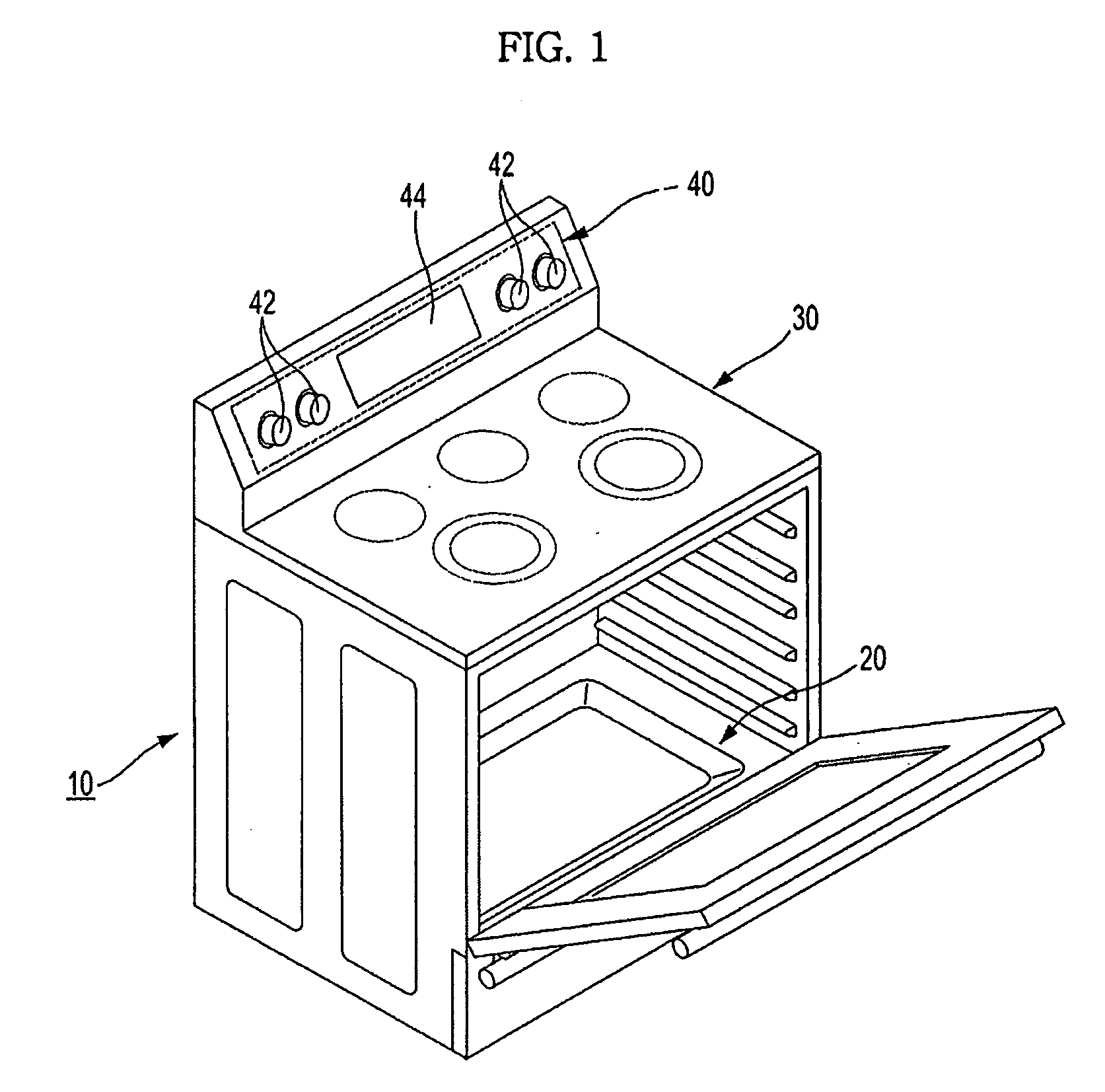

Cooking apparatus and method of controlling steam cleaning thereof

InactiveUS20090078291A1Improve cleaning performanceMaximizing amountSelf-cleaning stoves/rangesOven air-treatment devicesProcess engineeringSteam condensation

A cooking apparatus and a method of controlling steam cleaning thereof realize optimal cleaning performance by maintaining an internal temperature of a cooking chamber at a temperature suitable for steam condensation at the time of cleaning the inside of the cooking chamber using steam. The cooking apparatus includes a cooking chamber, a steam supplying unit to supply steam into the cooking chamber, a temperature sensing unit to sense an internal temperature of the cooking chamber, and a control unit to compare the sensed internal temperature with a reference temperature and operate the steam supplying unit if the internal temperature of the cooking chamber is less than the reference temperature.

Owner:SAMSUNG ELECTRONICS CO LTD

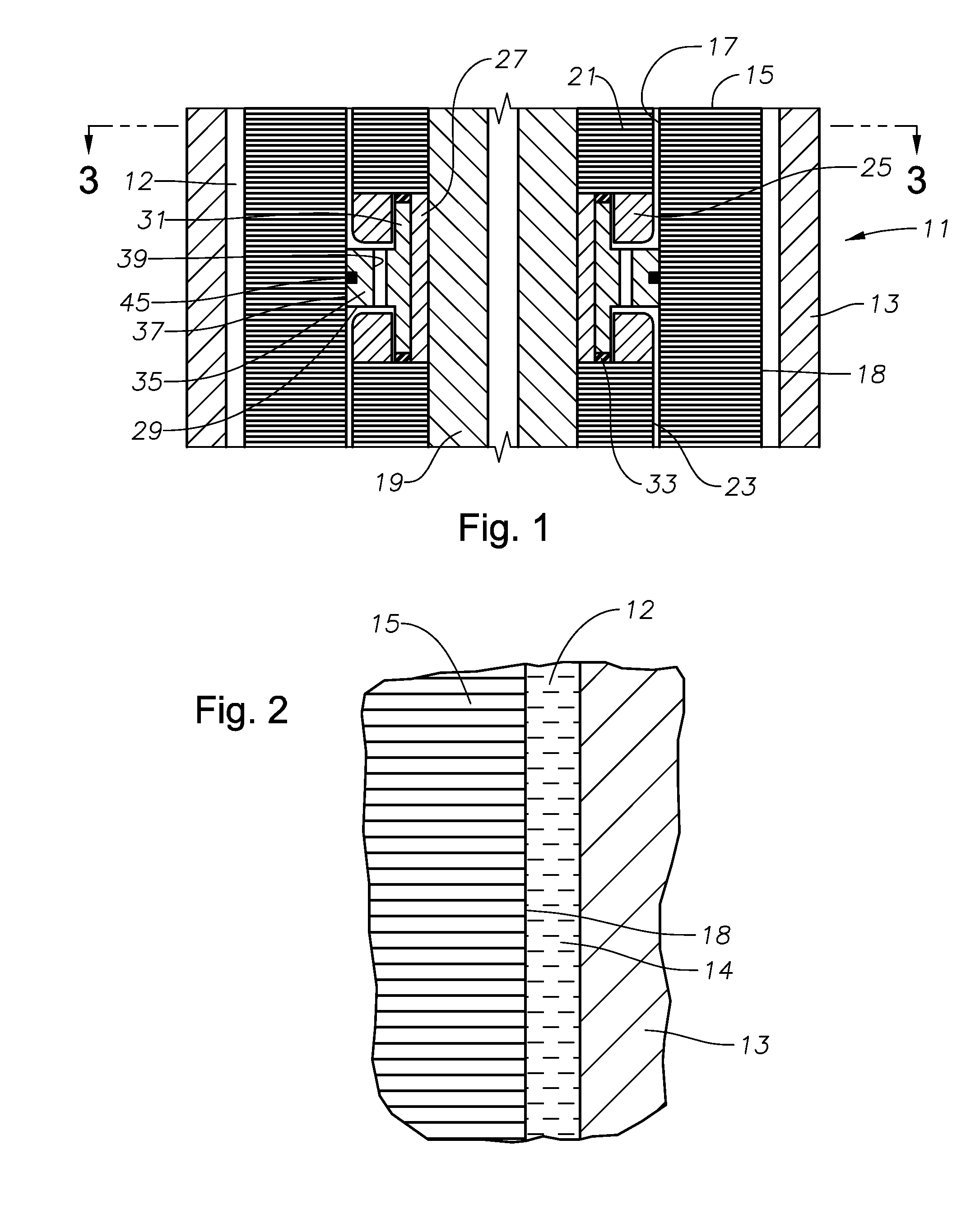

Enhanced thermal conductivity material in annular gap between electrical motor stator and housing

InactiveUS20100102648A1Improve heat transfer performanceMaintain reliabilityMagnetic circuit rotating partsFluid removalEngineeringLubricant

A submersible electric motor has feature to enhance thermal conductivity from the motor interior to the exterior. The motor has a cylindrical housing and a stator rigidly mounted within housing. A rotatable rotor is located within the stator. A gap formed between the stator's outer diameter and the inner wall of the housing is filled with a high thermal conductivity material to improve heat transfer from the motor. The remaining portion of the housing may be filled with a dielectric lubricant that has lesser thermal conductivity than the high thermal conductivity material.

Owner:BAKER HUGHES INC

End cap assembly and vent for high power cells

ActiveUS20060188779A1Preventing a catastrophic ruptureQuick releaseSmall-sized cells cases/jacketsAqueous electrolyte cellsEngineeringMechanical engineering

And end cap assembly and venting system therein for closing and sealng the open end of a cell housing. The end cap assembly comprises a sealing disk underlying an end cap, and a metal support disk between the end cap and the sealing disk. The metal support disk has a plurality of primary vent apertures and a plurality of secondary vent apertures through its surface. The primary vent apertures are spaced apart along a path located at a greater distance from the central longitudinal axis of the metal support disk than the secondary vent apertures. The insulating sealing disk may have a thinned portion therein forming an rupturable membrane circumventing the central hub of the sealing disk. The insulating sealing disk may have protrusions emanating from its top surface to deflect the membrane during rupture. The venting system releases internal gases rapidly from the cell in the event of an abusive or short circuit discharge.

Owner:DURACELL U S OPERATIONS

Busway joint pack with heat sink insert

ActiveUS20140141636A1Reduce internal temperatureCoupling device connectionsButt joining bus-barsHeat spreader

A busway joint pack includes a first connector plate and a second connector plate that is spaced from the first connector plate such that the connector plates are configured to engage a pair of phase-conductors of a pair of busway sections. The busway joint pack further includes a first insulator assembly and a second insulator assembly. Each of the insulator assemblies includes a heat sink and two electrically insulating sheets on either major side surface of the heat sinks. The insulator assemblies are positioned adjacent to the connector plates such that the insulating sheets electrically insulate the heat sinks from the connector plates. Side panels are positioned adjacent to the heat sinks and abut end surfaces thereof to aid in transferring heat generated in the busway joint pack to the surrounding environment via the heat sinks and side panels.

Owner:SCHNEIDER ELECTRIC USA INC

Paint with strong adhesion for cooling surface for LED (light emitting diode) radiator

ActiveCN103965672AImprove self-cleaningImprove anti-corrosion performanceReflecting/signal paintsRare-earth elementEpoxy

The invention discloses paint with strong adhesion for cooling the surface for an LED (light emitting diode) radiator. The paint is characterized by being prepared from the following components in parts by weight: 10-25 parts of inorganic colloidal particles, 1-3 parts of carbon nano-tube, 25-90 parts of electron transited spinel, 0.05-1.5 parts of rare earth oxide, 0.1-0.5 part of a stabilizing agent, 3-15 parts of epoxy resin, 2-10 parts of methyl methacrylate, 10-25 parts of nano- diatomite and 2-10 parts of ethylene glycol. The paint has remarkable heat dissipating and cooling effects, is not influenced by peripheral media, can be used in a vacuum environment, plays a role in radiating and cooling, and has the advantages of good self-cleaning performance, corrosion resistance, water resistance, flame retardance, insulating performance and acid-alkali resistance, and is convenient to construct.

Owner:NINGBO AISHI ELECTRIC EQUIP

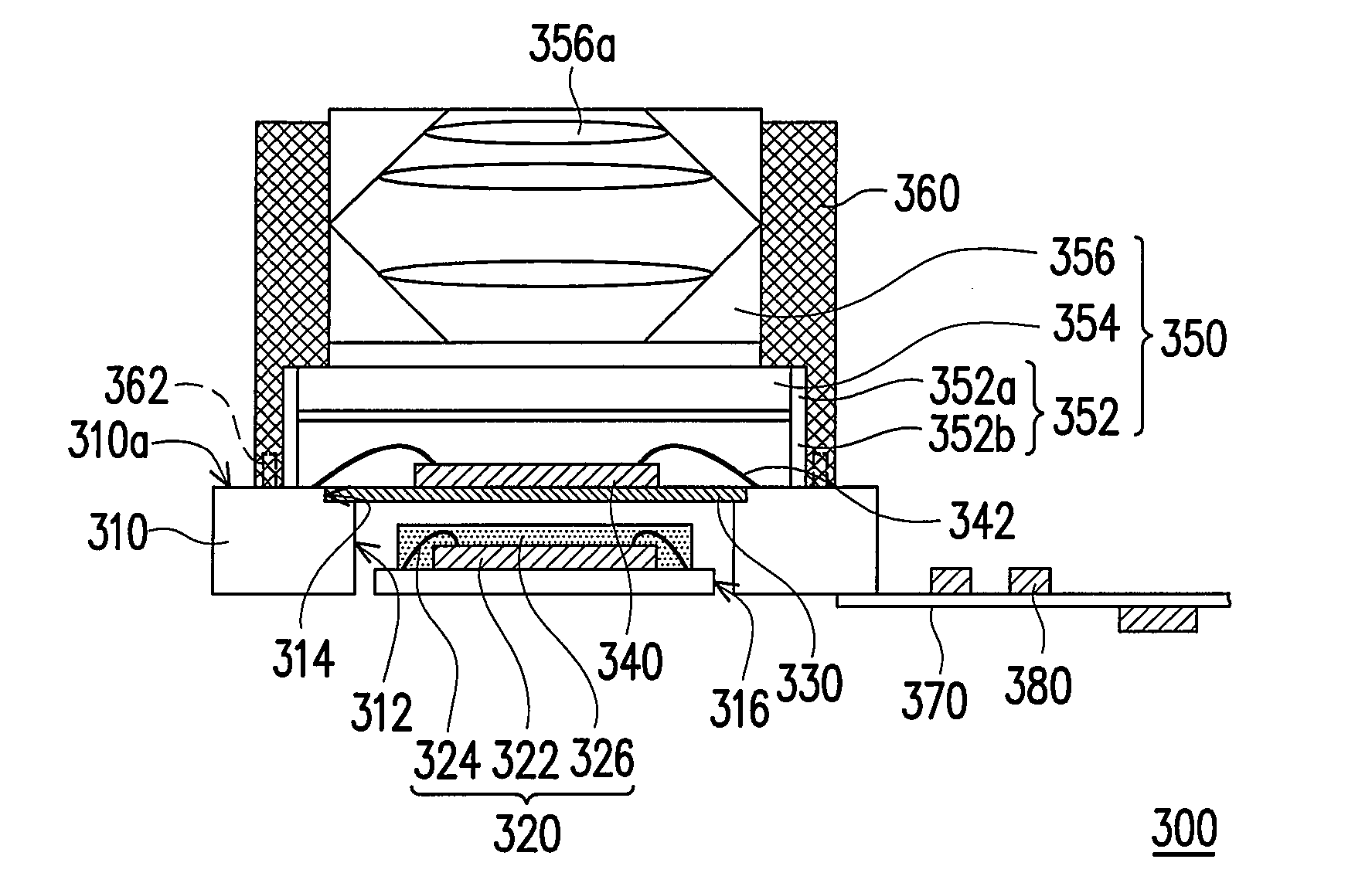

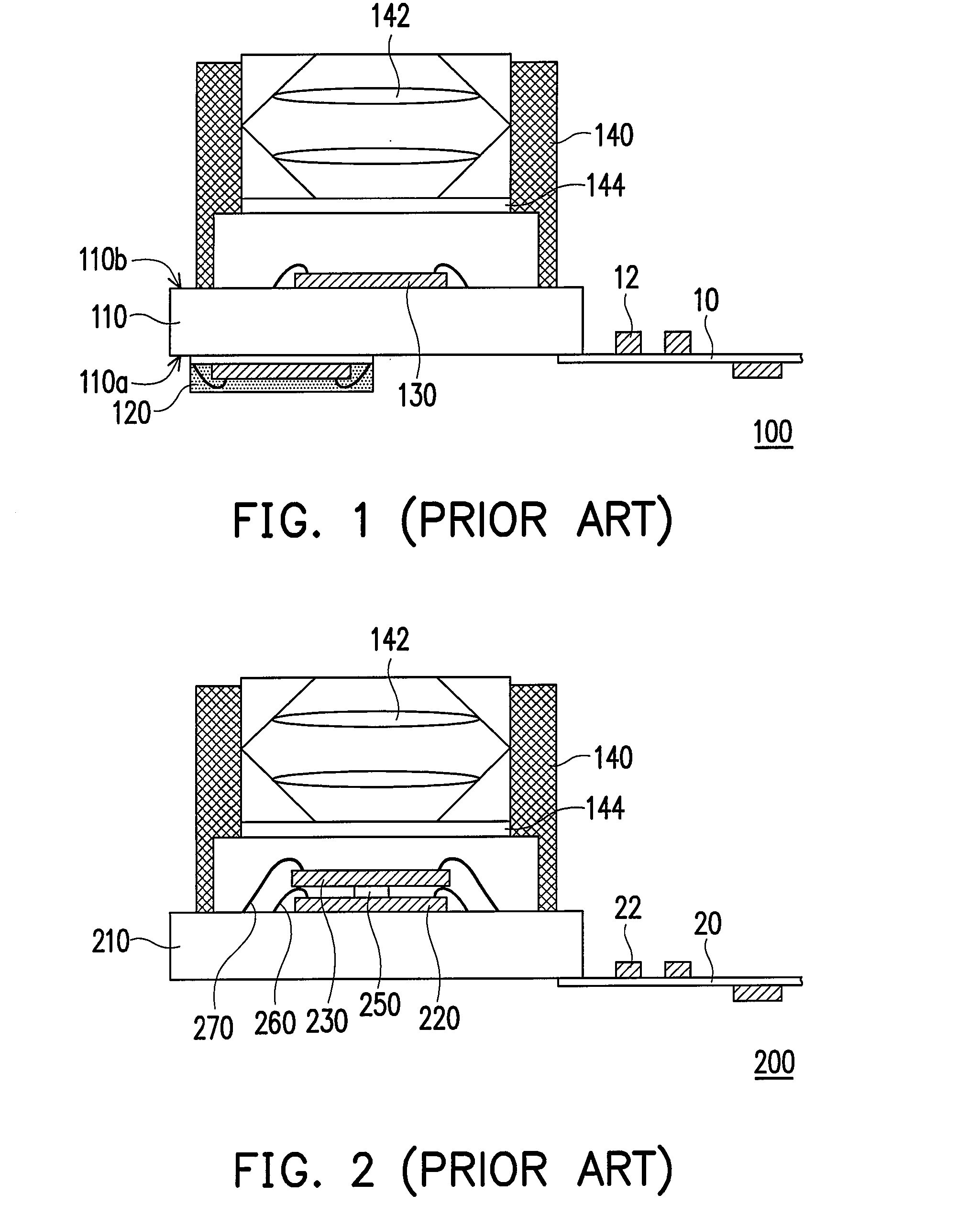

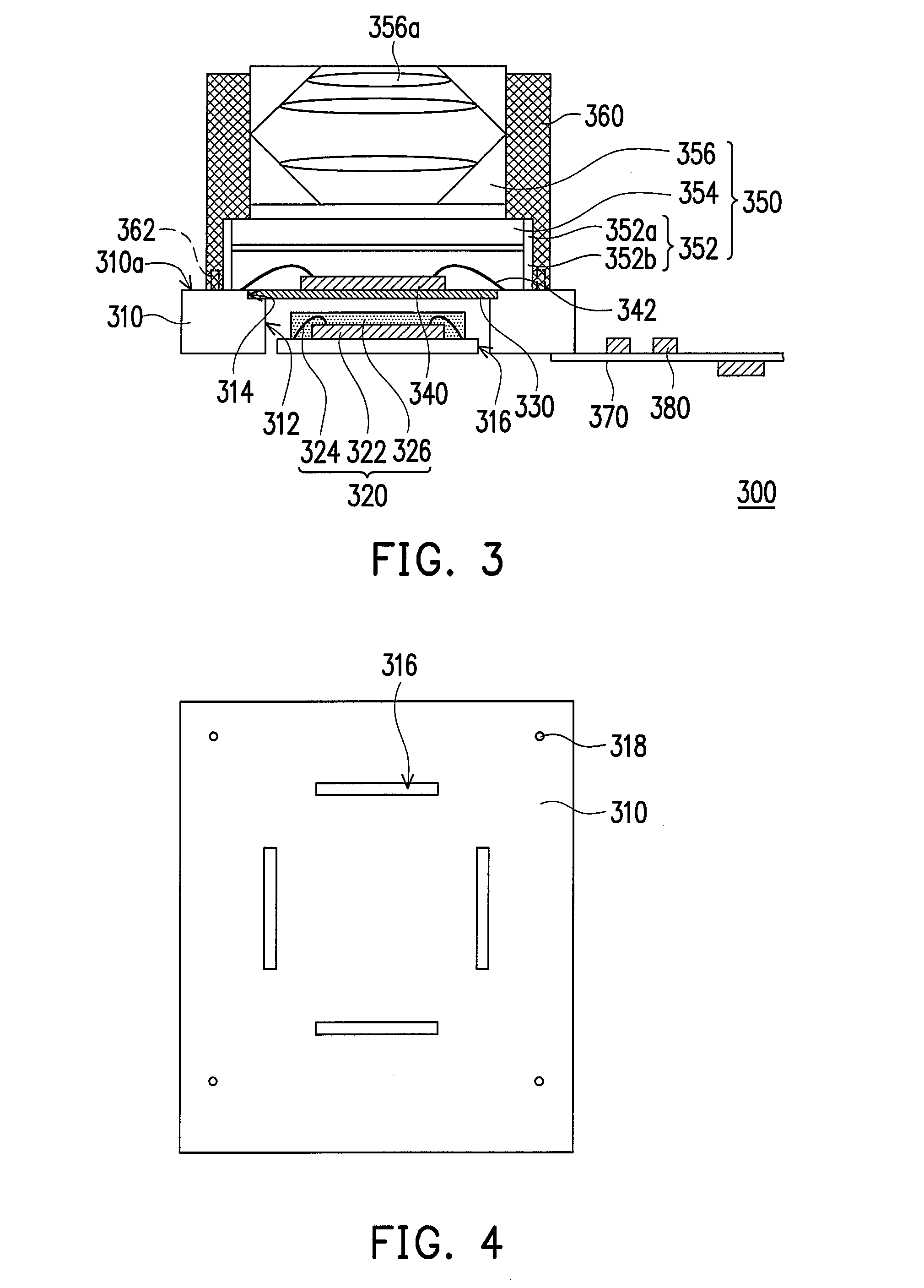

Image sensor module

ActiveUS20080048097A1Solve the real problemReduce the overall heightTelevision system detailsSolid-state devicesComputer scienceImage signal

An image sensor module including a substrate, an image signal processor, a supporting board, an image sensor chip and a cover is provided. A concave is located on a surface of the substrate. The image signal processor is disposed in the concave, and is electrically connected to the substrate. The supporting board is disposed on the surface of the substrate and covers the concave. The image sensor chip is disposed on the supporting board and electrically connected to the substrate. The cover is disposed on the substrate, and covers the image sensor chip.

Owner:ADVANCED SEMICON ENG INC

Conveyor oven apparatus and method

ActiveUS9585400B2Increase productionReduce internal temperatureDomestic stoves or rangesOven air-treatment devicesEngineeringInternal temperature

An oven with a sensor positioned to detect an event that will cause a decrease in the internal temperature of a tunnel. The oven includes a controller configured to increase the thermal output of a heating element in anticipation of the upcoming decrease in the internal temperature. In some embodiments, the oven is a conveyor over and the sensor is positioned to detect a food item approach the tunnel on a conveyor. In some embodiments, the amount of current provided to an electric heating element is increased by increasing the target temperature. In some embodiments, the amount of current provided to the electric heating element is increased by a predetermined offset.

Owner:MIDDLEBY CORPORATION

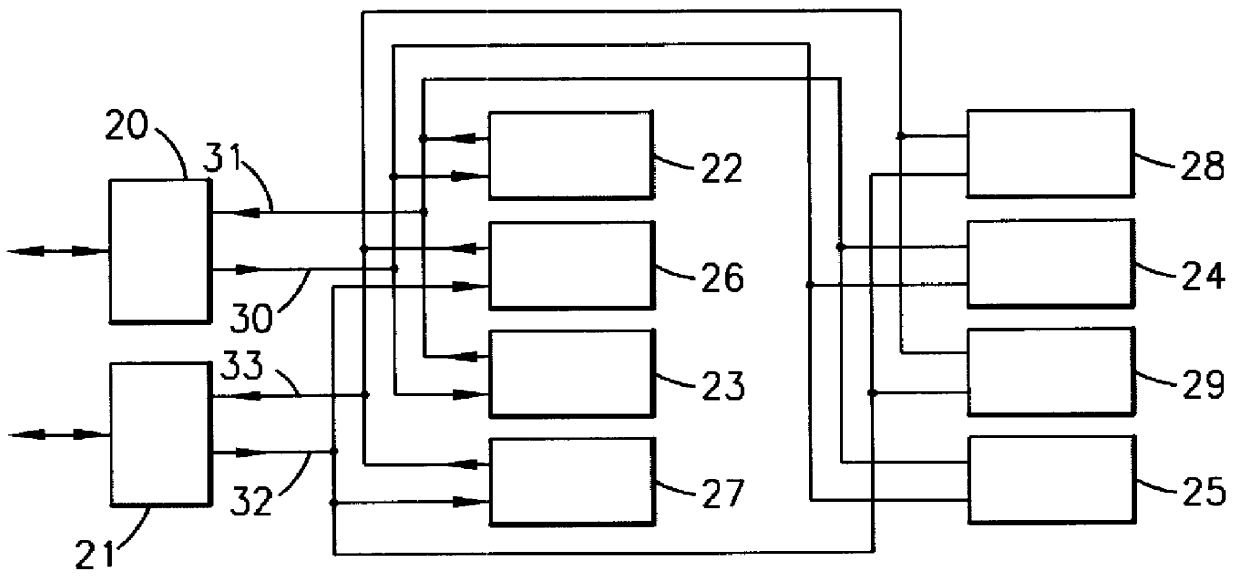

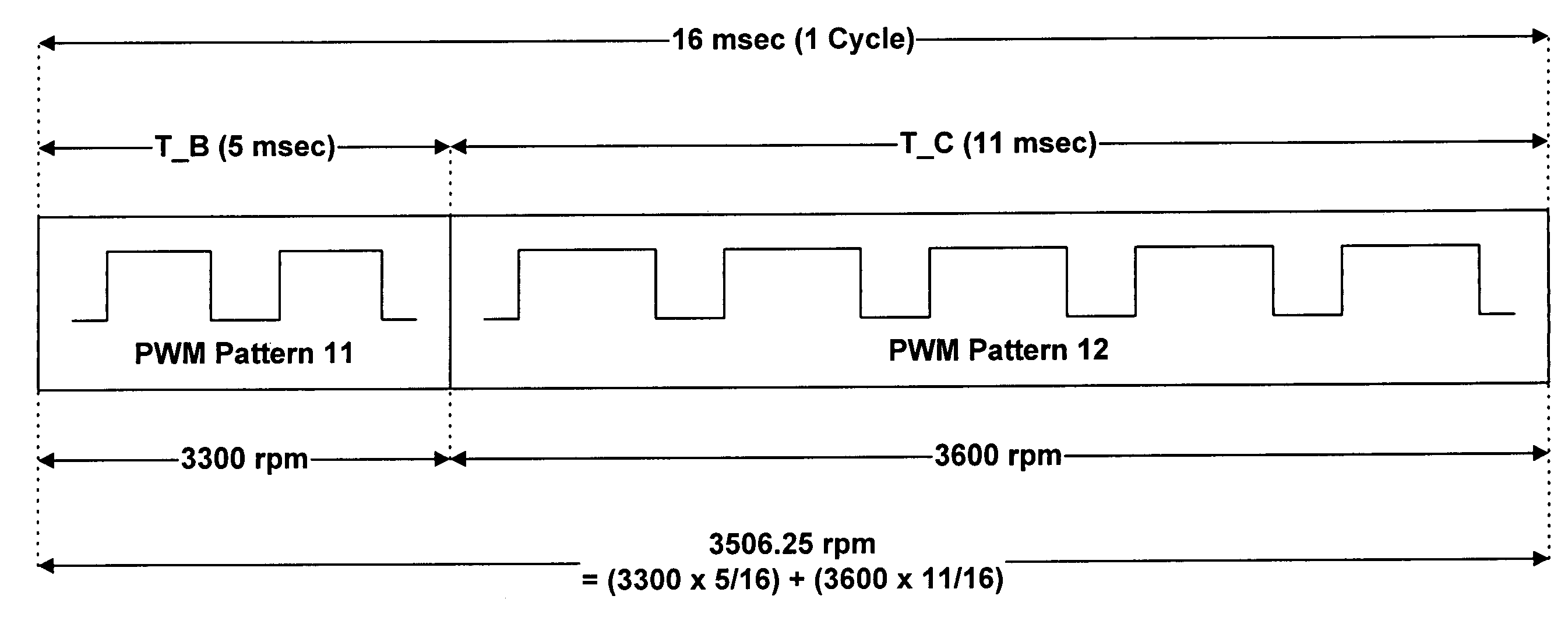

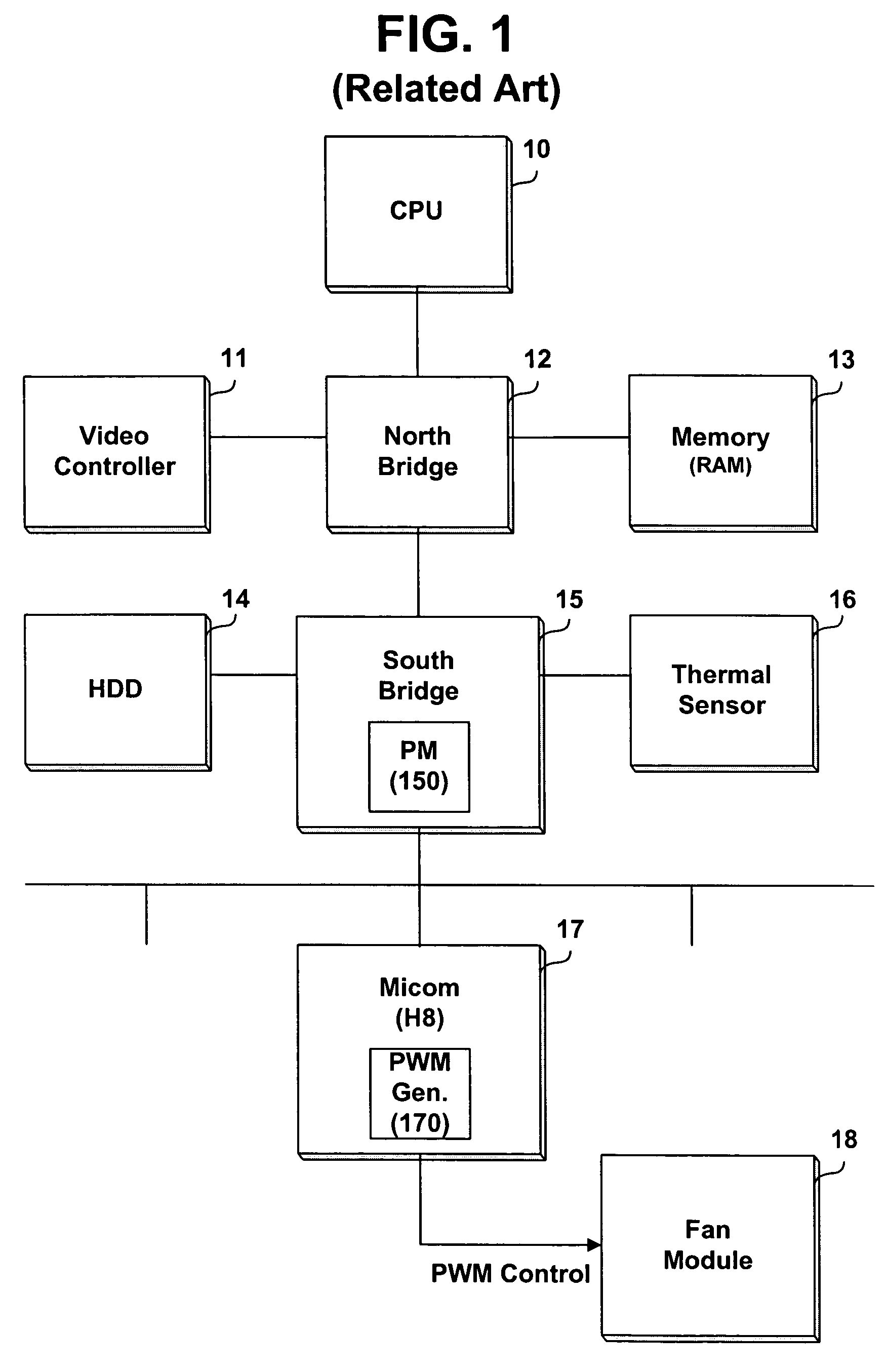

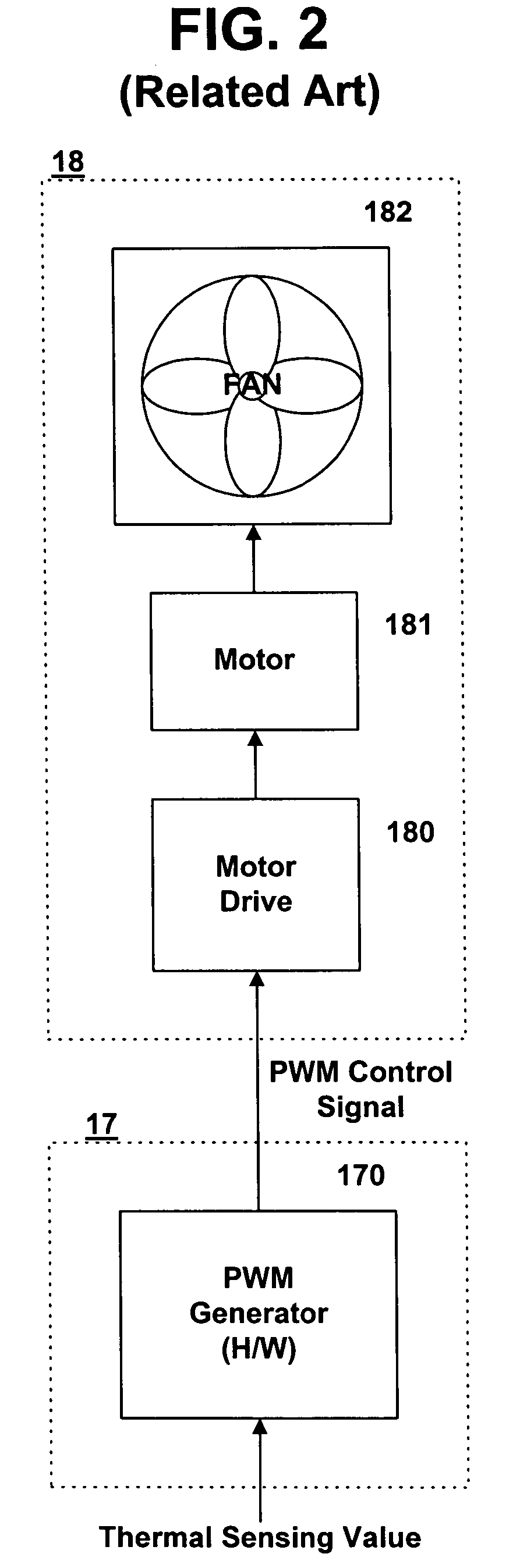

Apparatus and method for controlling fan drive in computer system

InactiveUS7190142B2Reduce internal temperatureReduce power consumptionEnergy efficient ICTDC motor speed/torque controlControl signalImage resolution

Embodiments of an apparatus and method can control a fan drive in a computer system. Such embodiments of apparatus and methods can alternately output a plurality of pulse width modulation (PWM) control signals at a predetermined time ratio and variably control a rotation speed of a cooling fan. The embodiments can use simple hardware based upon N-bit resolution in a PWM control signal generator included in the computer system for controlling the rotation speed of the cooling fan decreasing an internal temperature, such that the rotation speed of the cooling fan can be precisely and variably controlled, equally with the effect of an operation for controlling the fan drive using hardware based upon resolution of more than the N bits. Further, a physical configuration can be effectively simplified, and unnecessary power consumption can be reduced or prevented.

Owner:LG ELECTRONICS INC

Refrigerator

ActiveCN103250015AEfficient storageEasy to storeDomestic refrigeratorsInsulation for cooling apparatusEngineeringFood storage

A refrigerator is provided. In the refrigerator, cool air within the heat exchange chamber is supplied into a drawer assembly disposed inside a storage space, and also the inside of the drawer assembly is cooled using a thermoelectric module to quickly cooling the inside of the drawer assembly. Thus, food storage performance may be improved.

Owner:LG ELECTRONICS INC

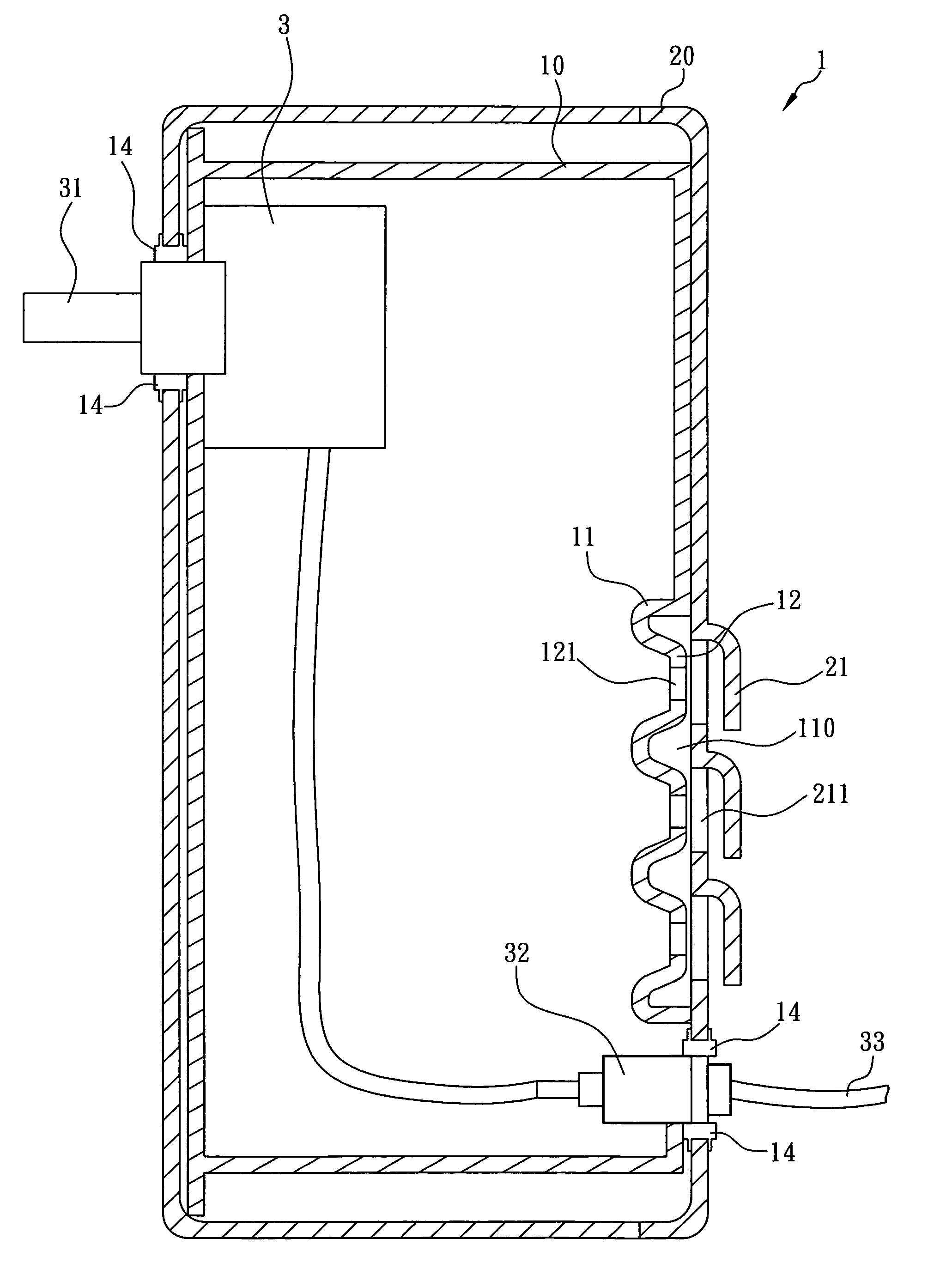

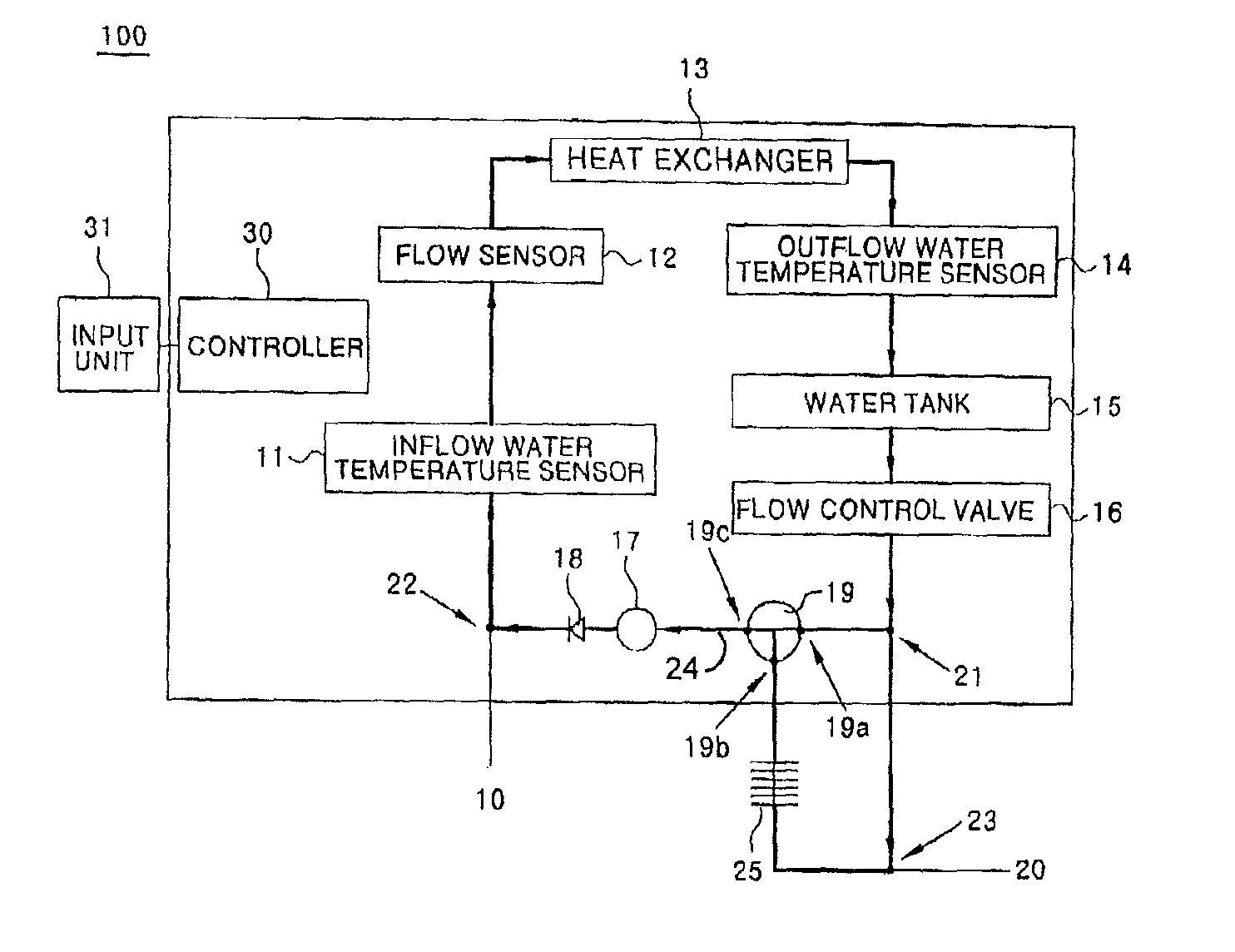

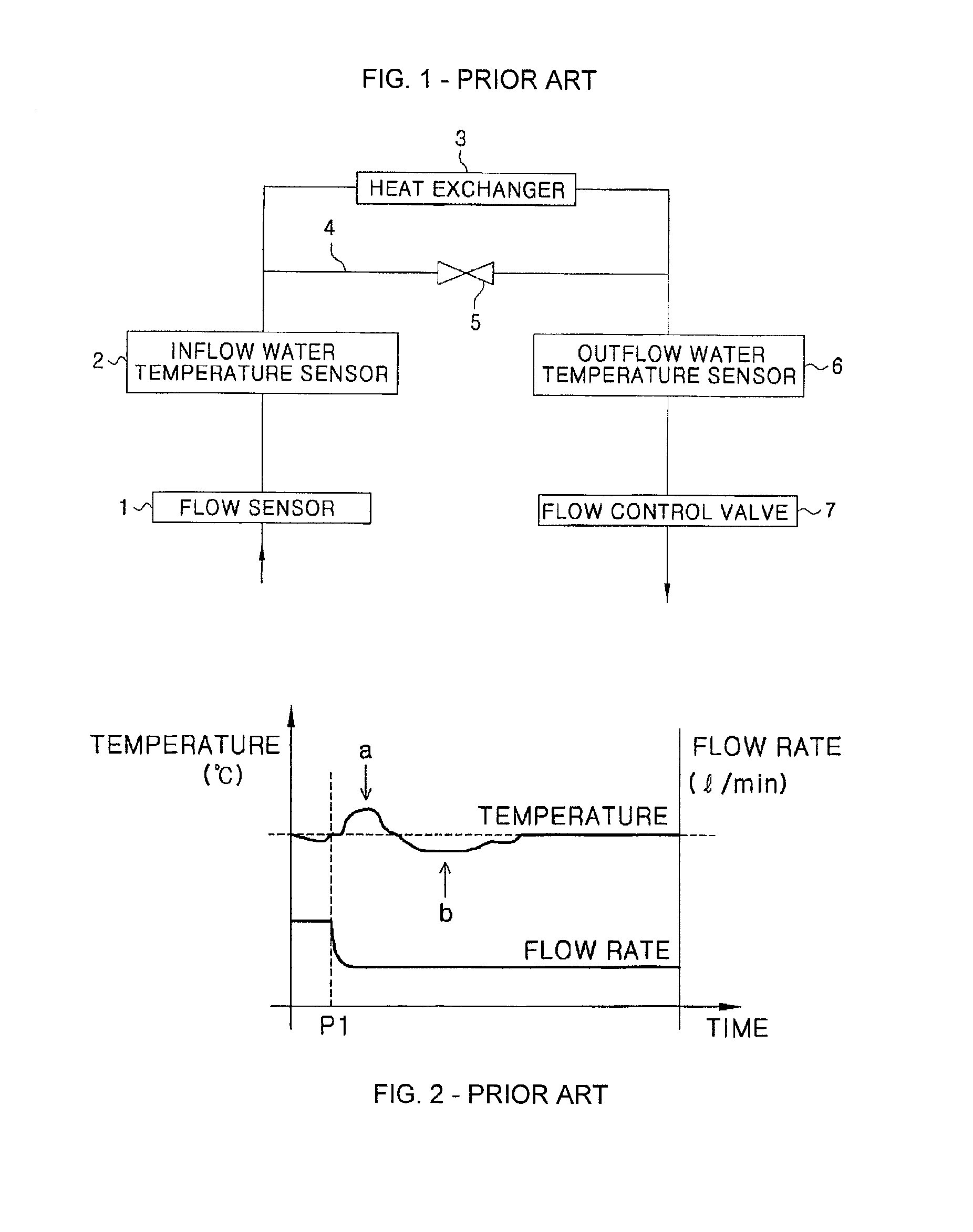

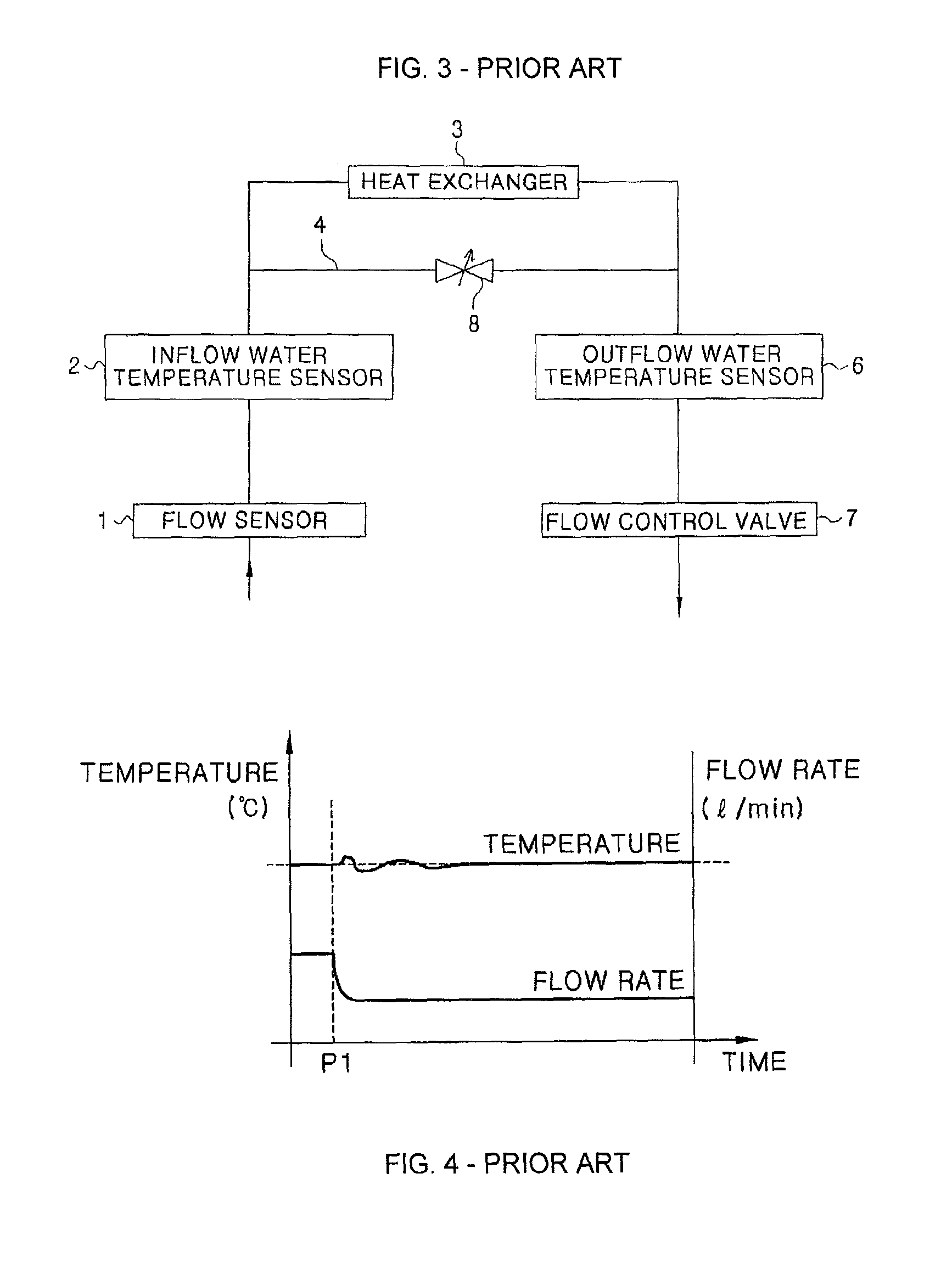

Hot water supply system for constantly maintaining temperature of hot water

ActiveUS8285129B2Enhances overshoot and undershootEffective maintenanceElectric heatingTemperatue controlWater dischargeWater flow

In a hot water supply system, a heat exchanger transfers heat from a heating device to inflow water to supply the inflow water at a user-set temperature. A flow sensor measures a flow rate of inflow water. A water tank stores outflow water discharged from the heat exchanger. A first temperature sensor, installed on an inlet pipe through which the inflow water flows, measures a temperature of the inflow water. A second temperature sensor, installed on an outlet pipe through which the outflow water flows, measures a temperature of the outflow water discharged from the heat exchanger. A controller includes an input unit to receive input from a user, wherein the controller controls an operation of the heating device based on at least one of: (1) comparison between the user-set temperature and the temperature of the outflow water; (2) variation in the flow rate; or (3) any combination thereof.

Owner:KYUNGDONG NAVIEN

Rubber anti-recovery agent and preparation thereof

The invention discloses a rubber anti-sulfuration recovery agent, which comprises the following components according to the percentage by weight: 50-55% of zinc fatty acid, 23-28% of aromatic acid zinc, 17-22% of poly zinc carbonate with branched chains. The invention also discloses a preparation method for poly zinc carbonate. The invention discloses a preparation method for the rubber anti-sulfuration recovery agent. The rubber anti-sulfuration recovery agent not only has anti-sulfuration recovery function on vulcanized rubber, but also can reduce the Mooney viscosity of gross rubber, improves the sizing processing performance and can reduce dynamic heat build-up of tread rubber of tyre. The preparation method of the rubber anti-sulfuration recovery agent is different from other simple mixed methods adopted for preparing general multicomponent mixtures. The rubber anti-sulfuration recovery agent is prepared by using the method that organic acid and zinc oxide directly reacts; and the reaction process has no pollution.

Owner:JIANGSU KAOU CHEM

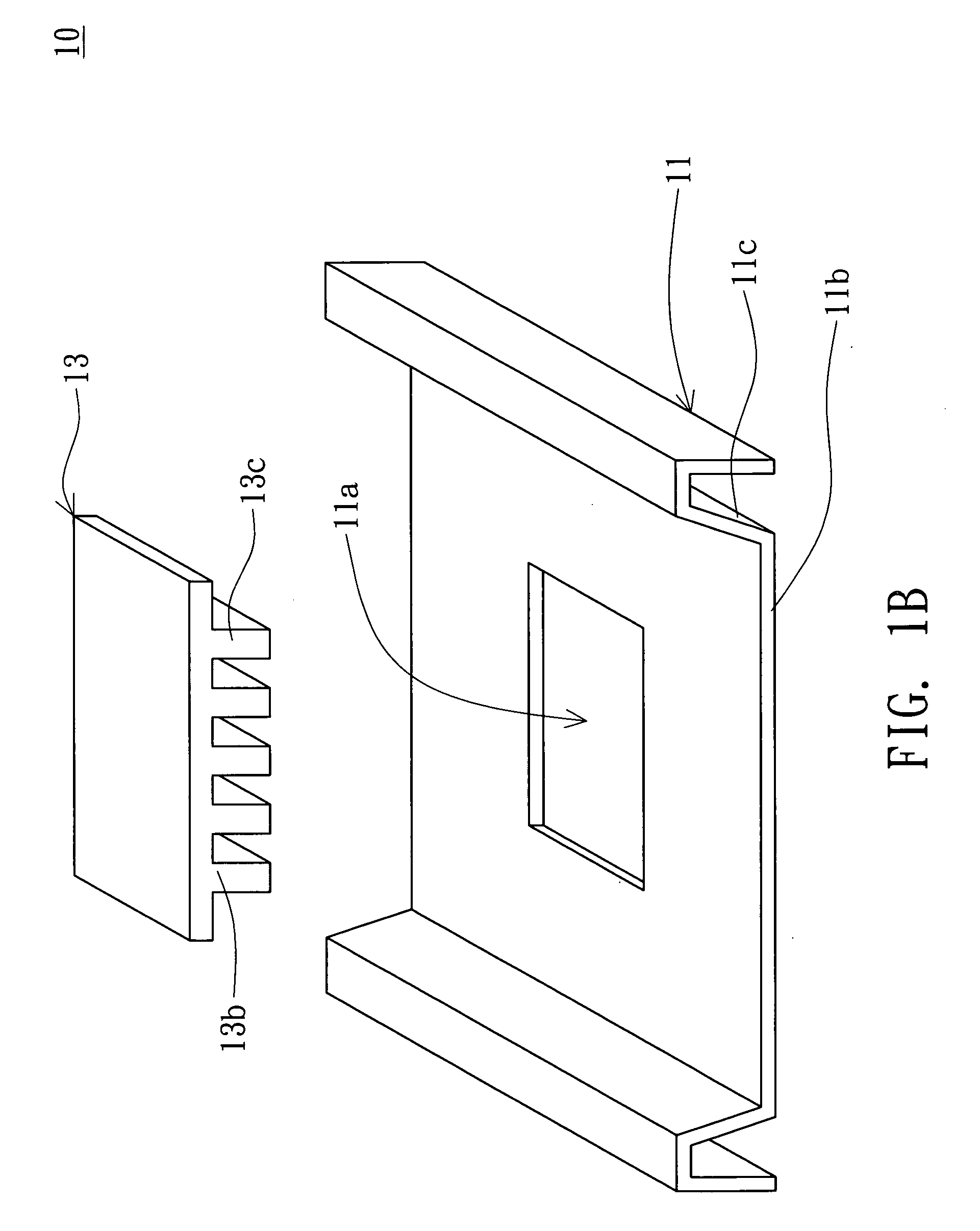

Backlight module and liquid crystal display device incorporating the same

InactiveUS20070182884A1Effective coolingReduce internal temperatureNon-linear opticsLiquid-crystal displayEngineering

A backlight module and a liquid crystal display device incorporating the same are provided. The backlight module includes a bezel, a light source and a heat dissipation element. The bezel has an opening. The light source is disposed on the bezel. The heat generation portion of the light source corresponds to the opening. One end of the heat dissipation element is positioned between the bezel and the light source. The other end of the heat dissipation element has a protrusion portion which is inserted into the opening and projected outside the bezel. The lateral surface of the protrusion portion is abutted against the inner wall of the opening.

Owner:AU OPTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com