Paint with strong adhesion for cooling surface for LED (light emitting diode) radiator

A technology with strong adhesion and heat dissipation body, applied in the direction of reflection/signal paint, coating, etc., can solve the problems of high-power LED light source, large heat generation, influence of LED light source life, poor heat dissipation effect, etc., and achieve good coating technology. , The effect of protecting the goodness of the equipment and the convenience of construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

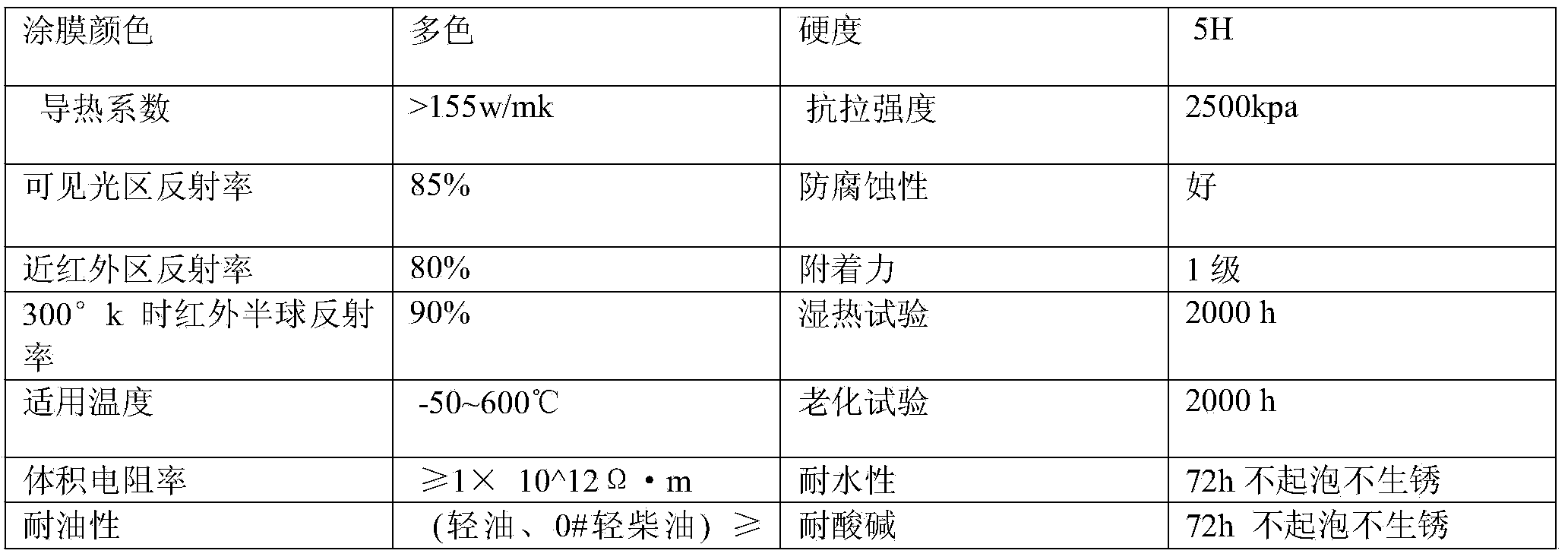

Examples

Embodiment Construction

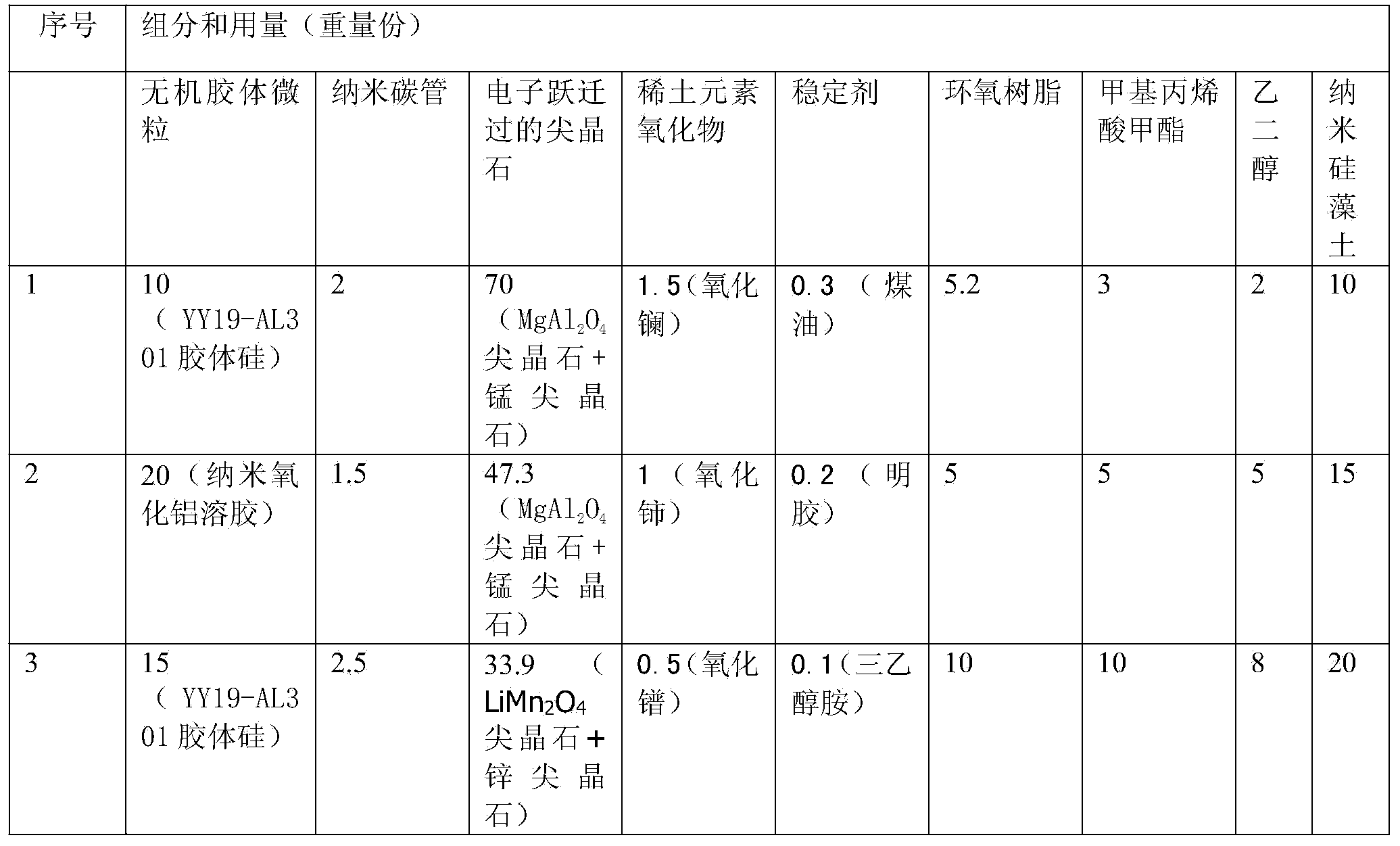

[0024] Describe the present invention in further detail below by specific embodiment, but the present invention is only limited to following embodiment. Example

[0025] All raw materials of the present invention, unless otherwise specified, are commercially available products, such as the diatomite of MGZ-800 produced by Shenzhen Yoshida Chemical Co., Ltd.

[0026] The preparation method is as follows:

[0027] (1) Weighing each component of the formula ratio, then adding the carbon nanotubes into ethanol at a temperature of 50-80°C, and stirring evenly;

[0028] (2) Then the inorganic colloidal particles are added to the mixed system of epoxy resin and methyl methacrylate and stirred evenly;

[0029] (3) Mix the solutions of step (1) and step (2), then add spinel after electronic transition, rare earth element oxide, nano-diatomite and stabilizer and stir evenly to obtain the surface heat dissipation of LED heat sink with paint.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com