Bus with heat radiation function

A busbar and functional technology, applied in the field of high-current switchgear, can solve problems such as contact resistance increase, insulation aging, loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

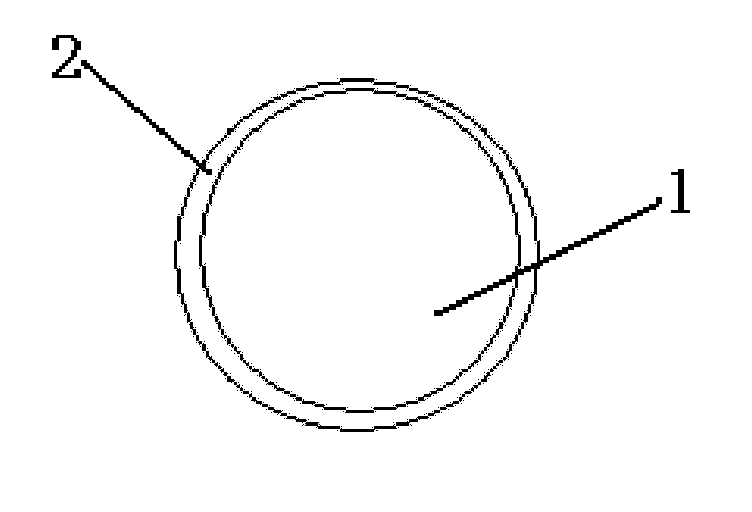

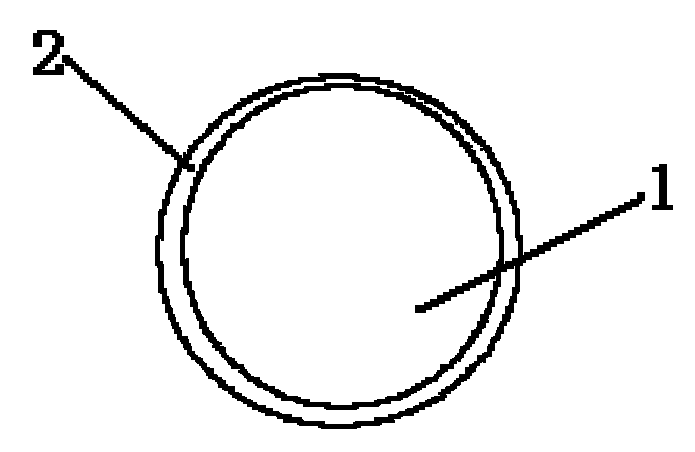

[0015] As shown in the drawings, a busbar with heat dissipation function includes a busbar conductor 1, and the outside of the busbar conductor 1 is coated with a radiation heat dissipation paint, and the radiation heat dissipation paint forms a heat dissipation layer 2 of the busbar.

[0016] The appropriate thickness of special heat-dissipating paint should be painted on the appropriate position of the bus conductor 1. The painting position should have a large heat-dissipating space, and it should not be the surface of the conductor near and opposite. Be even.

[0017] The radiation heat dissipation coating can form an effective heat insulation barrier, so as to achieve the effect of cooling and heat insulation. It emits the heat on the bus conductor in the form of 8-13.5μm wavelength.

[0018] The cooling range of the busbar is shown in the table below:

[0019] Bus base

[0020] The above embodiments do not limit the present invention in any way, and all technic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com