Side-spraying cooling tank

A technology of cooling tank and tank body, applied in the field of cooling tank, can solve the problems of slow circulation speed and unsatisfactory cooling effect in the cooling process, and achieve the effect of uniform transmission and distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

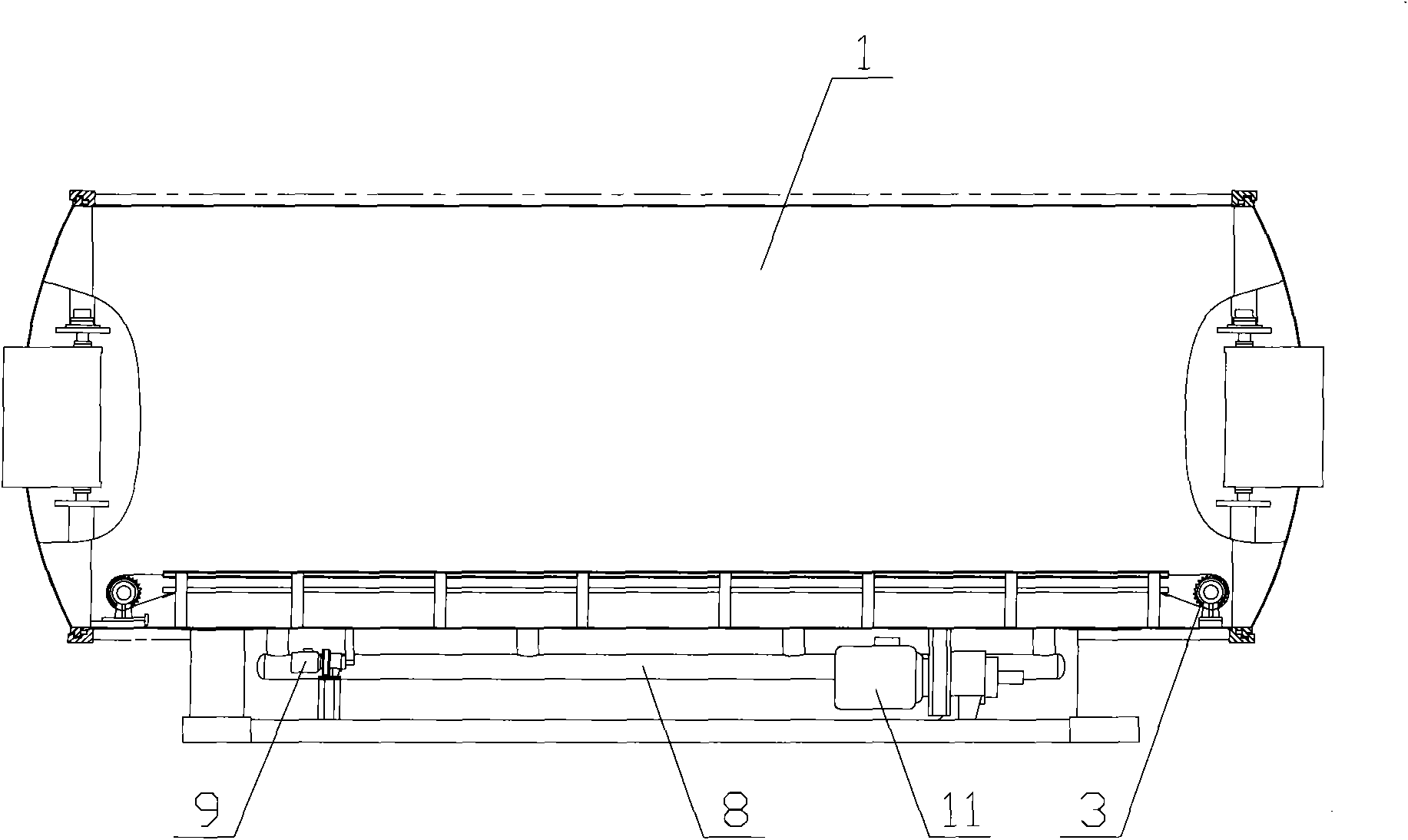

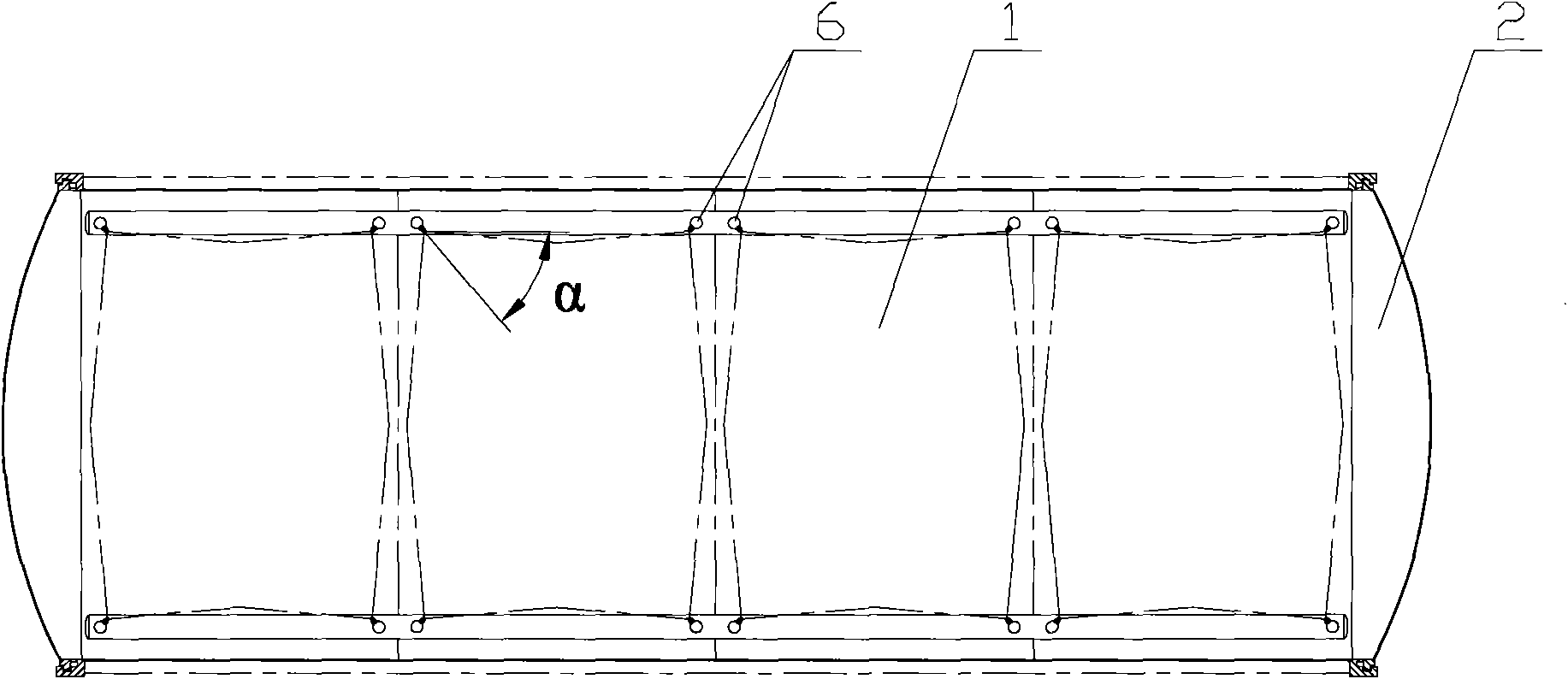

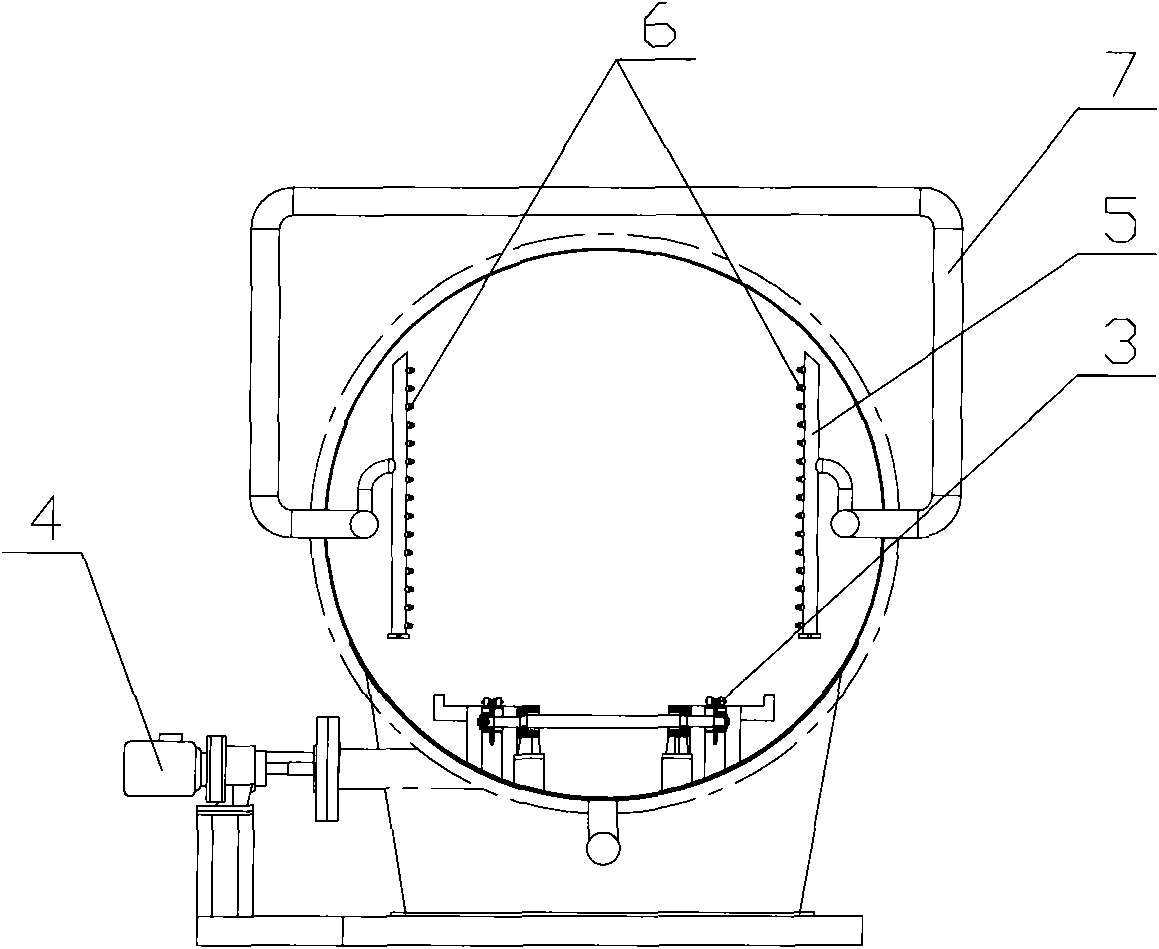

[0018] Such as Figure 1 to Figure 4 As shown, it is a side-spray cooling tank according to the present invention, which includes a tank body 1 and tank doors 2 at both ends of the tank body 1. The tank door 2 is sealed and connected to the tank body 1 through a door lock device 10. The inner bottom of the tank body 1 is provided with The shelf guide rail 3 is provided with a conveyor belt connected to the motor 4 on the shelf guide rail 3, and inner trays are placed on the conveyor belt, and several layers of inner trays are stacked. The bottom of each inner tray is a water-permeable mesh, so that the inner tray The trays can be cooled by water, and the materials are placed in the inner trays, and the motor 4 drives the conveyor belt to convey the materials at a constant speed. Two sides in tank body 1 are provided with connecting pipe 15, and connecting pipe 15 is vertically distributed, and connecting pipe 15 is provided with fan-shaped nozzle 6 facing to the water outlet, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com