Patents

Literature

35results about How to "Reduce the difficulty of temperature control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

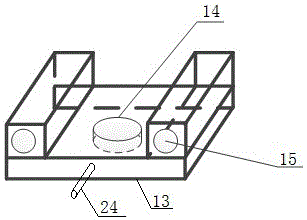

Wafer bonding clamping device, aligning machine, bonding machine and warping substrate adsorption method

InactiveCN106340485AUniform deliveryReduce the difficulty of temperature controlSolid-state devicesSemiconductor/solid-state device manufacturingTemperature controlEngineering

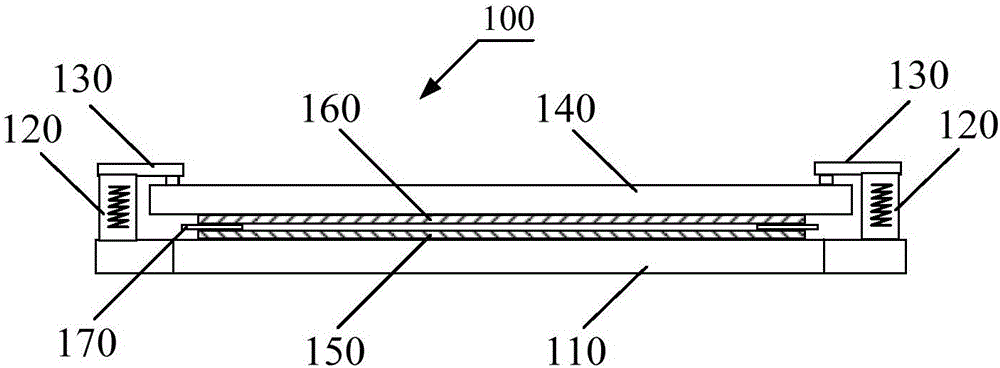

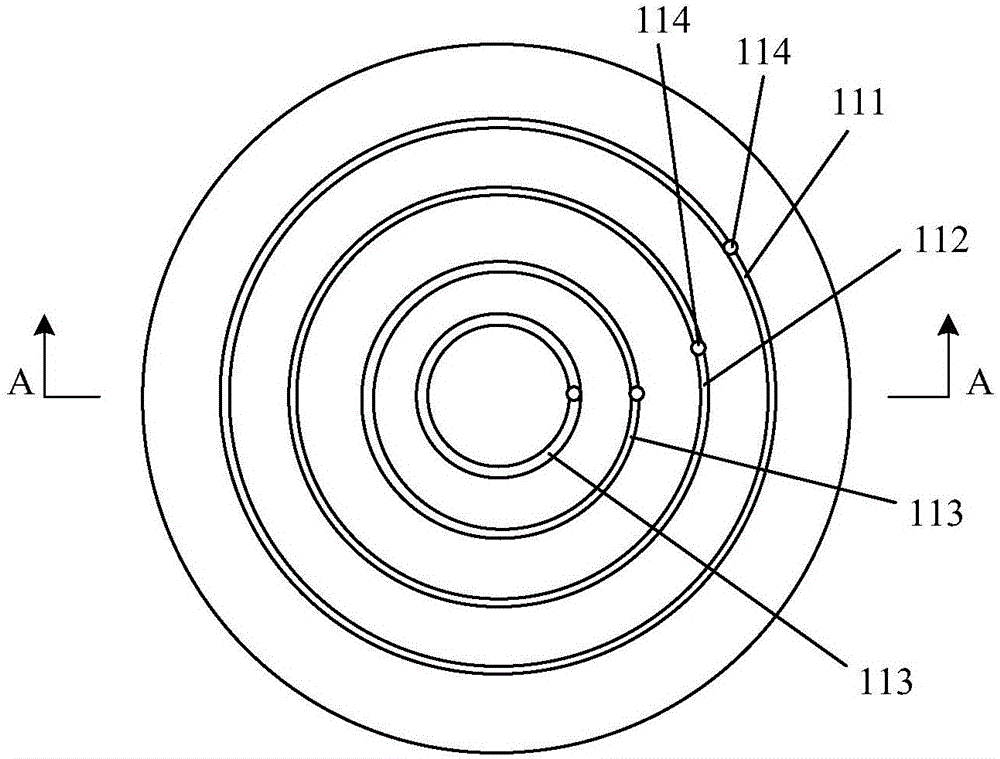

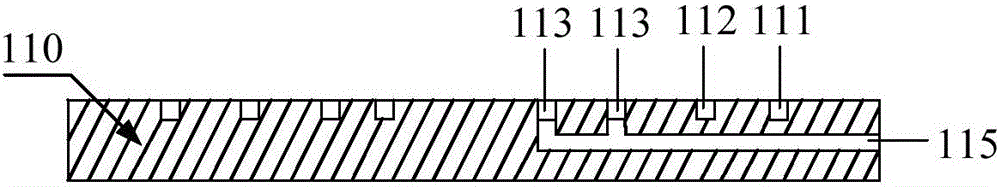

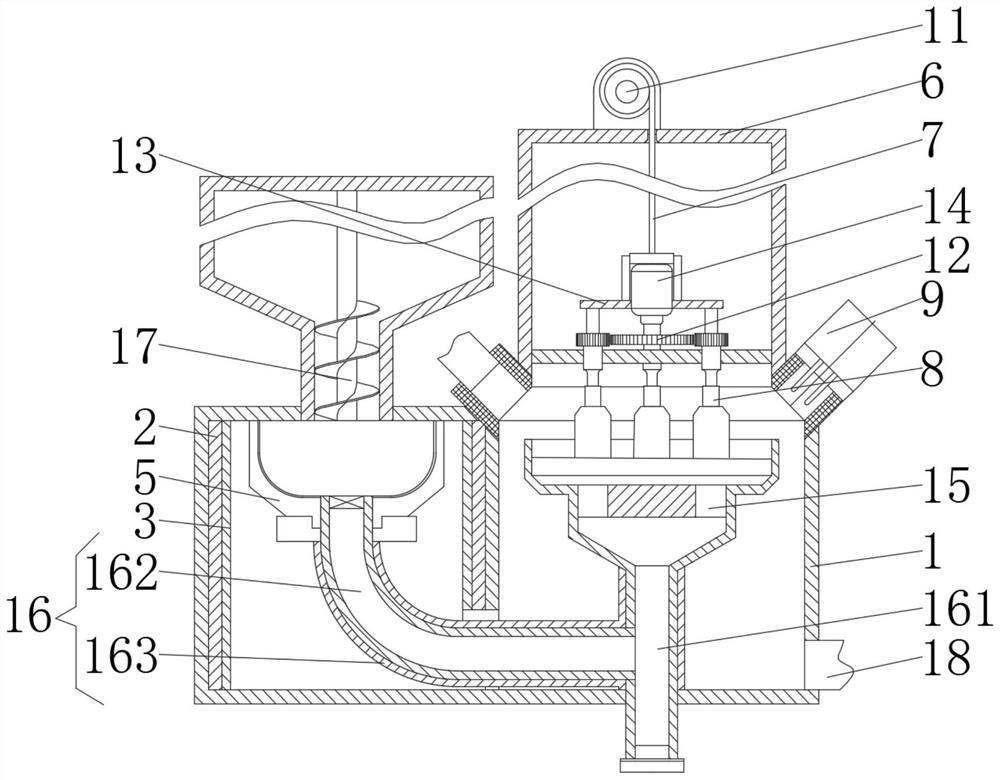

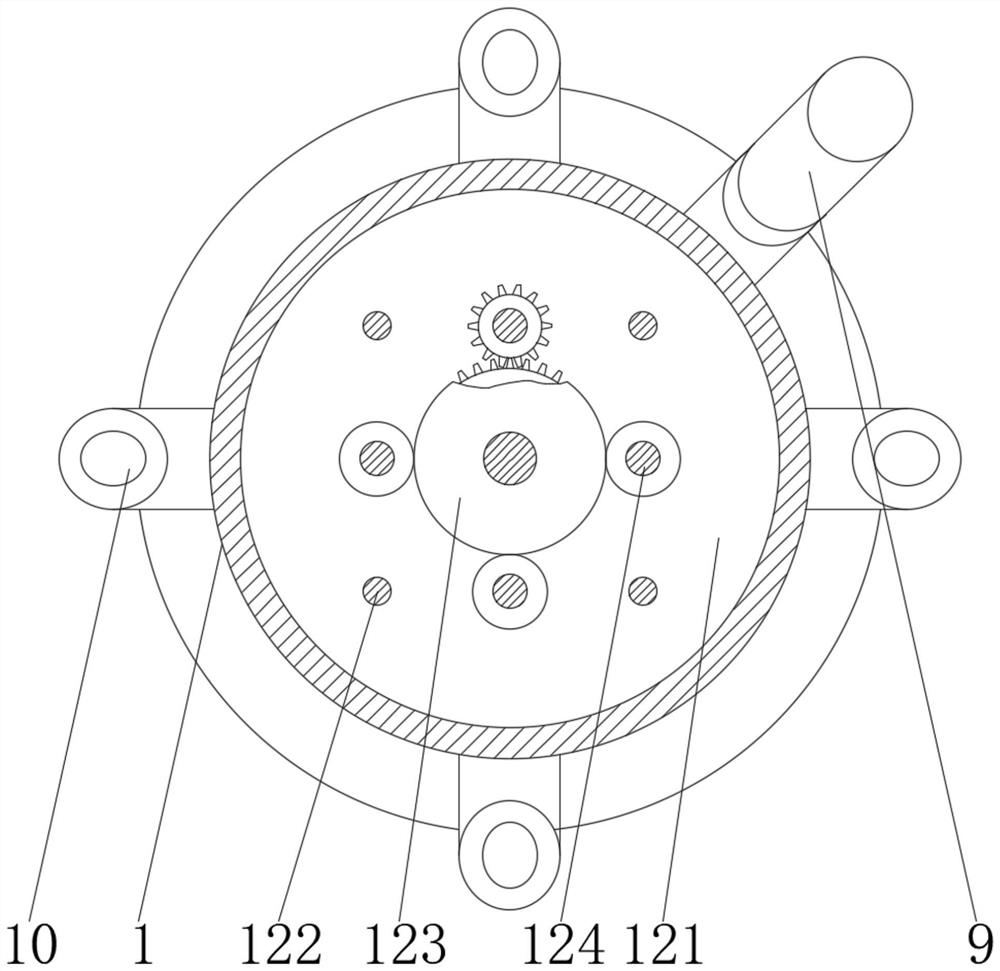

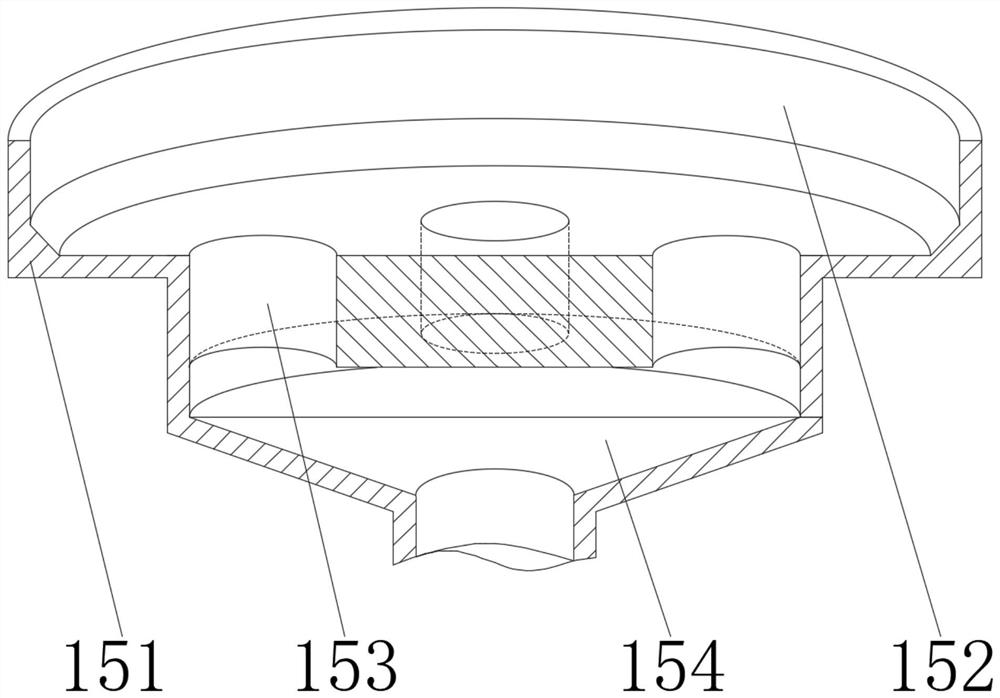

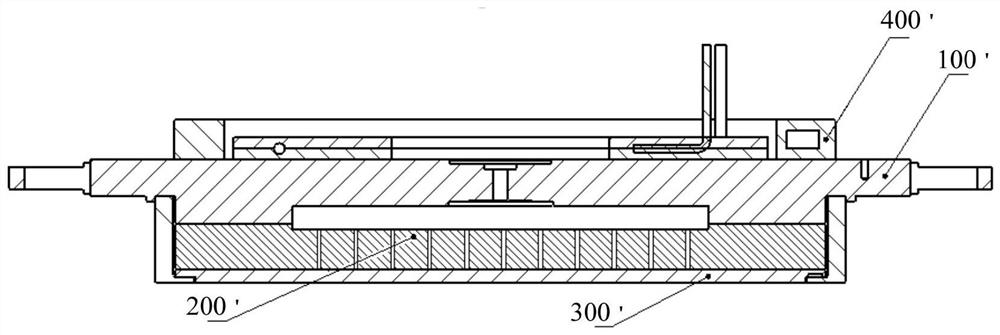

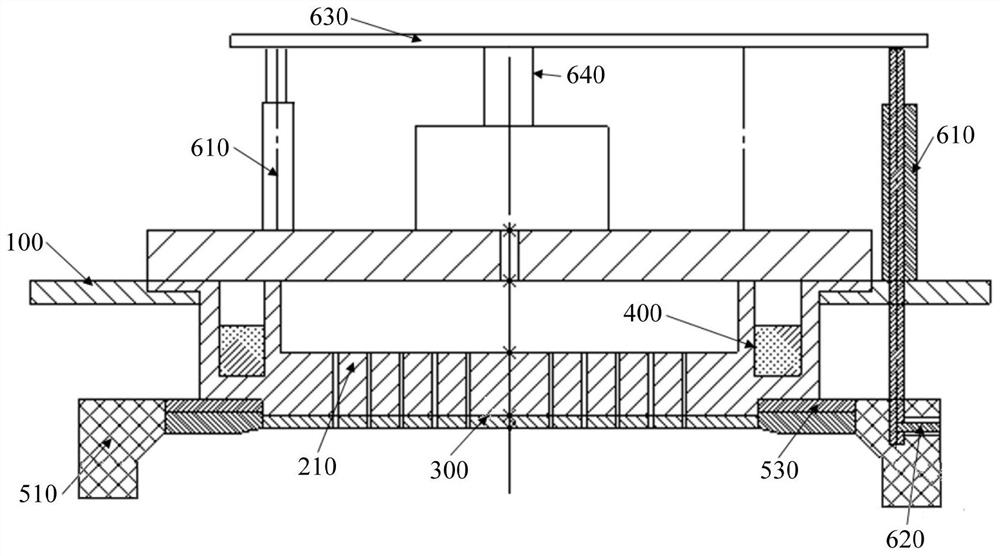

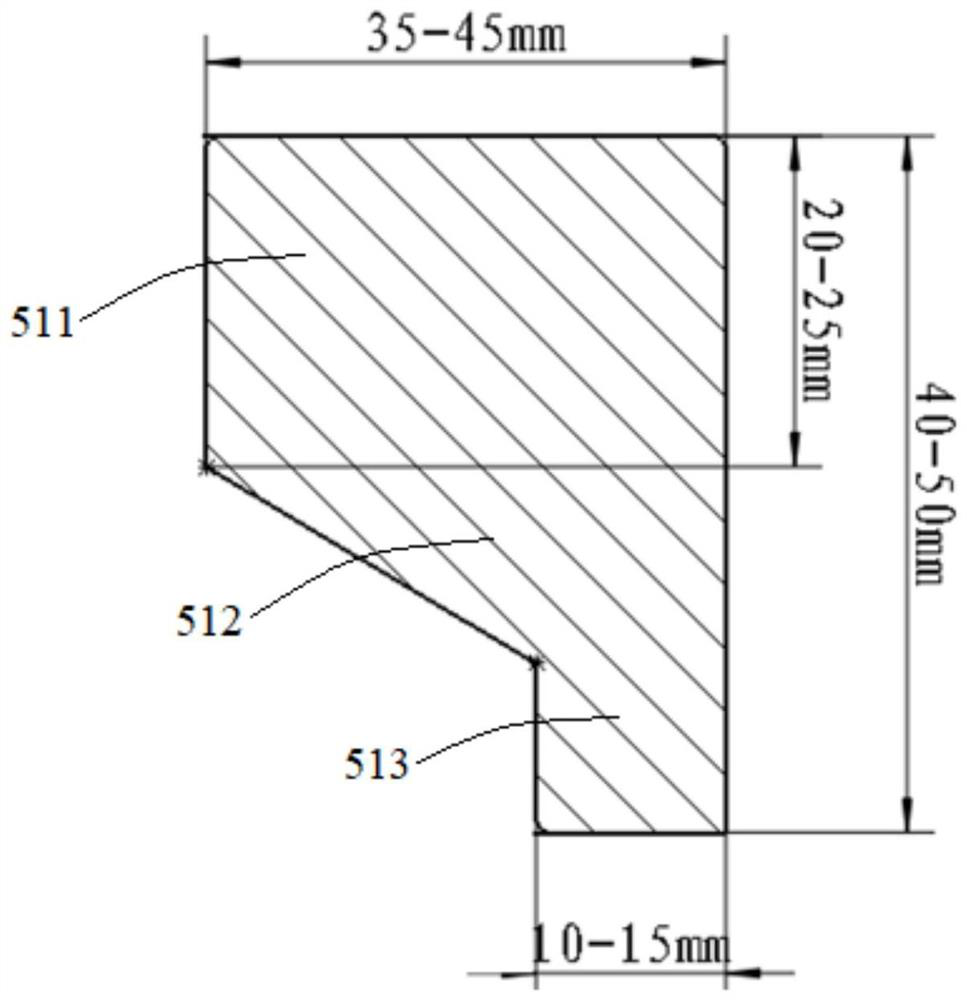

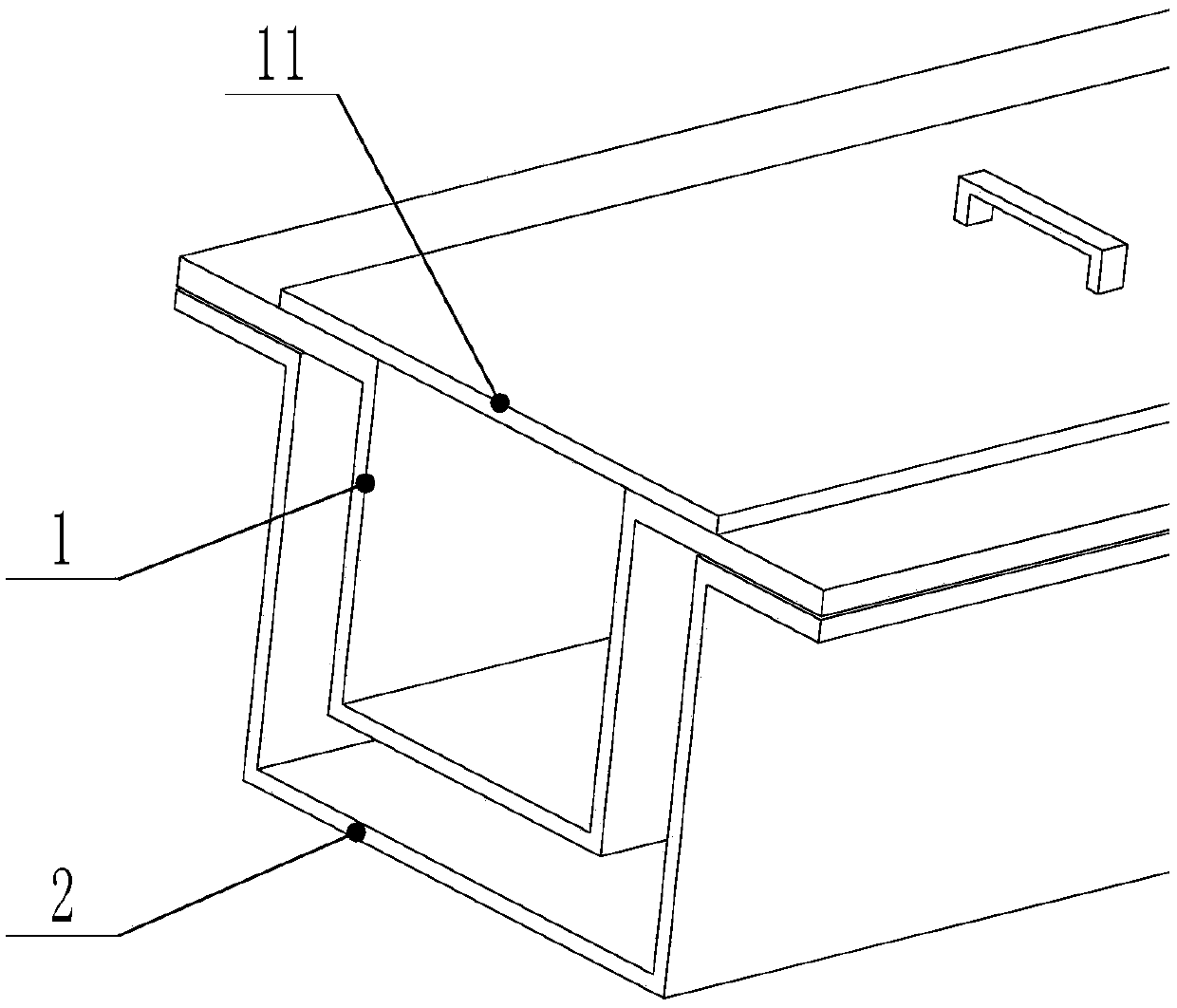

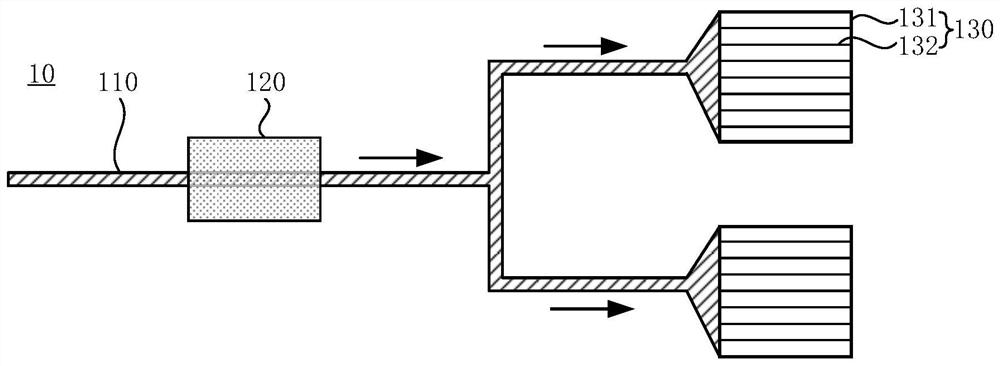

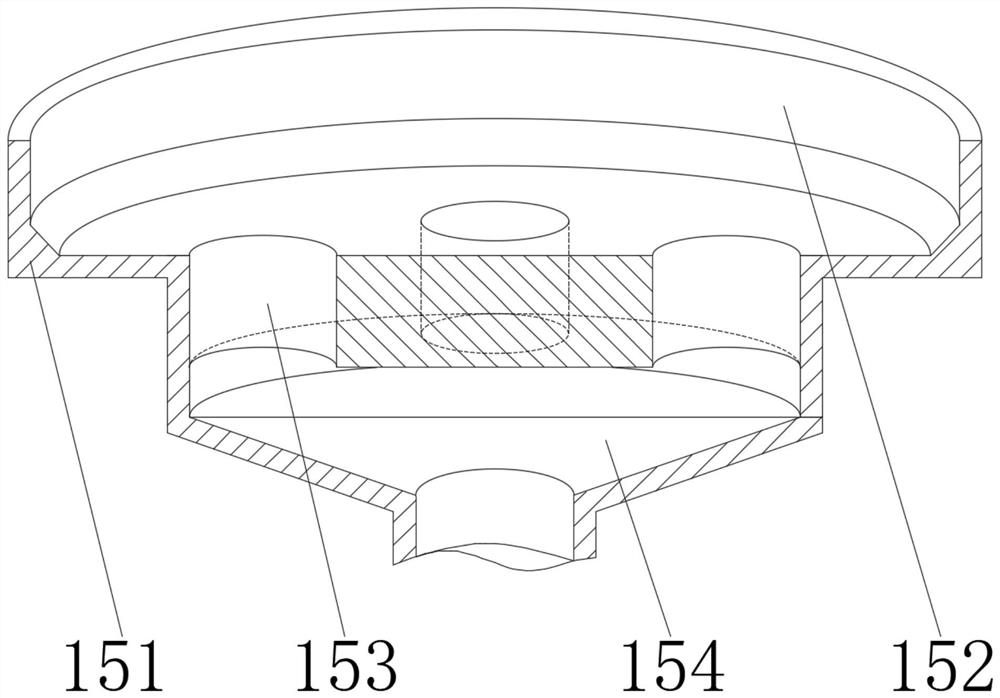

The invention discloses a wafer bonding clamping device which comprises a loading platform (110), a clamping mechanism (120), a pressing head (130) and a pressing plate (140). The pressing point of the pressing head (130) in the pressing plate (140) is arranged in an area other than the pressing plate (140) corresponding to a substrate. The pressing plate (140) and the loading platform (110) are made of the same material. The pressing plate (140) is compatible with substrates of all sizes. The invention further discloses an aligning machine and a bonding machine, wherein the aligning machine and the bonding machine use the wafer bonding clamping device. According to the invention, ineffective pressing surfaces can be reduced or eliminated, which facilitates temperature control; the production efficiency is improved; the wafer bonding clamping device has the advantages of uniform pressing performance and improves yield, and is compatible with wafers of all sizes and specifications. The invention further discloses a warping substrate adsorption method, so as to realize the adsorption of a warping substrate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

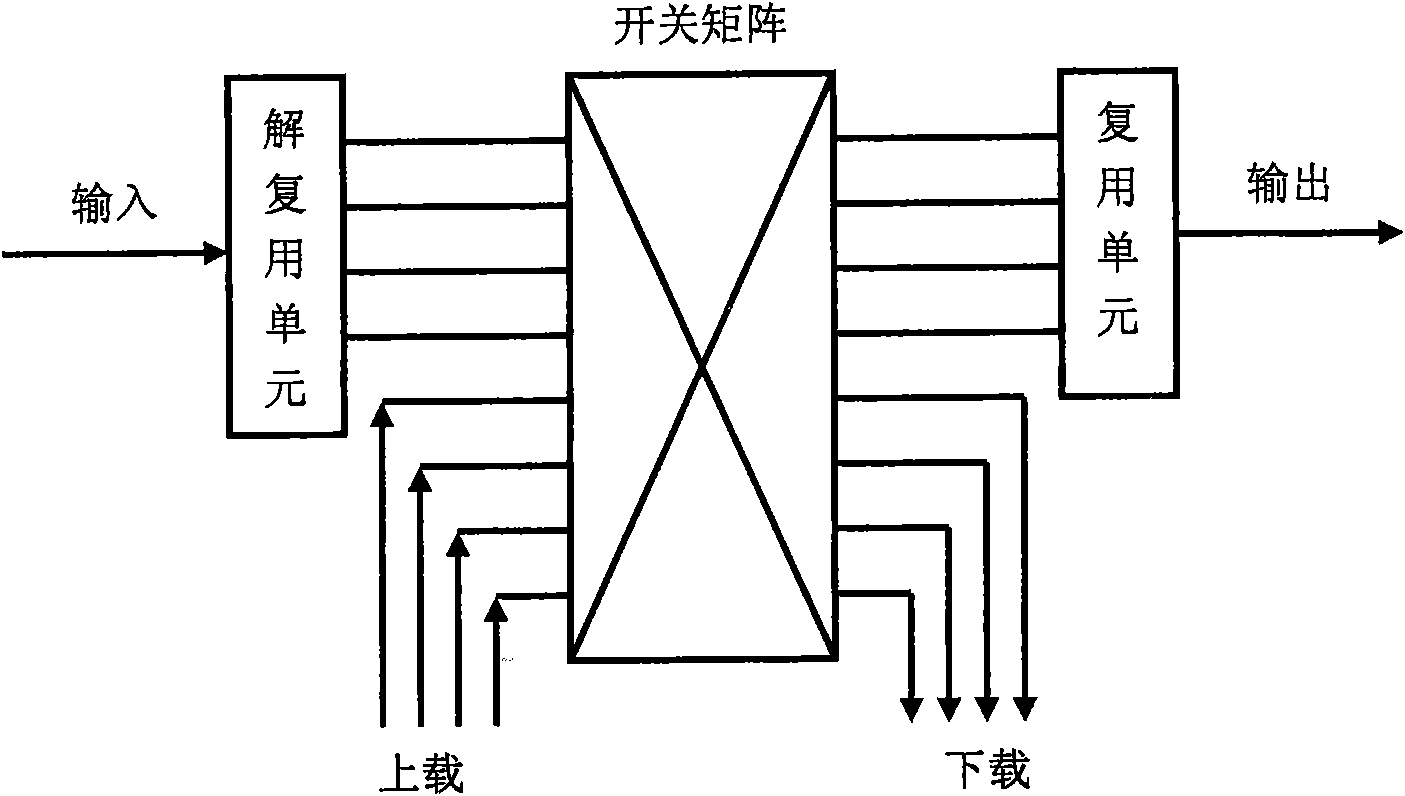

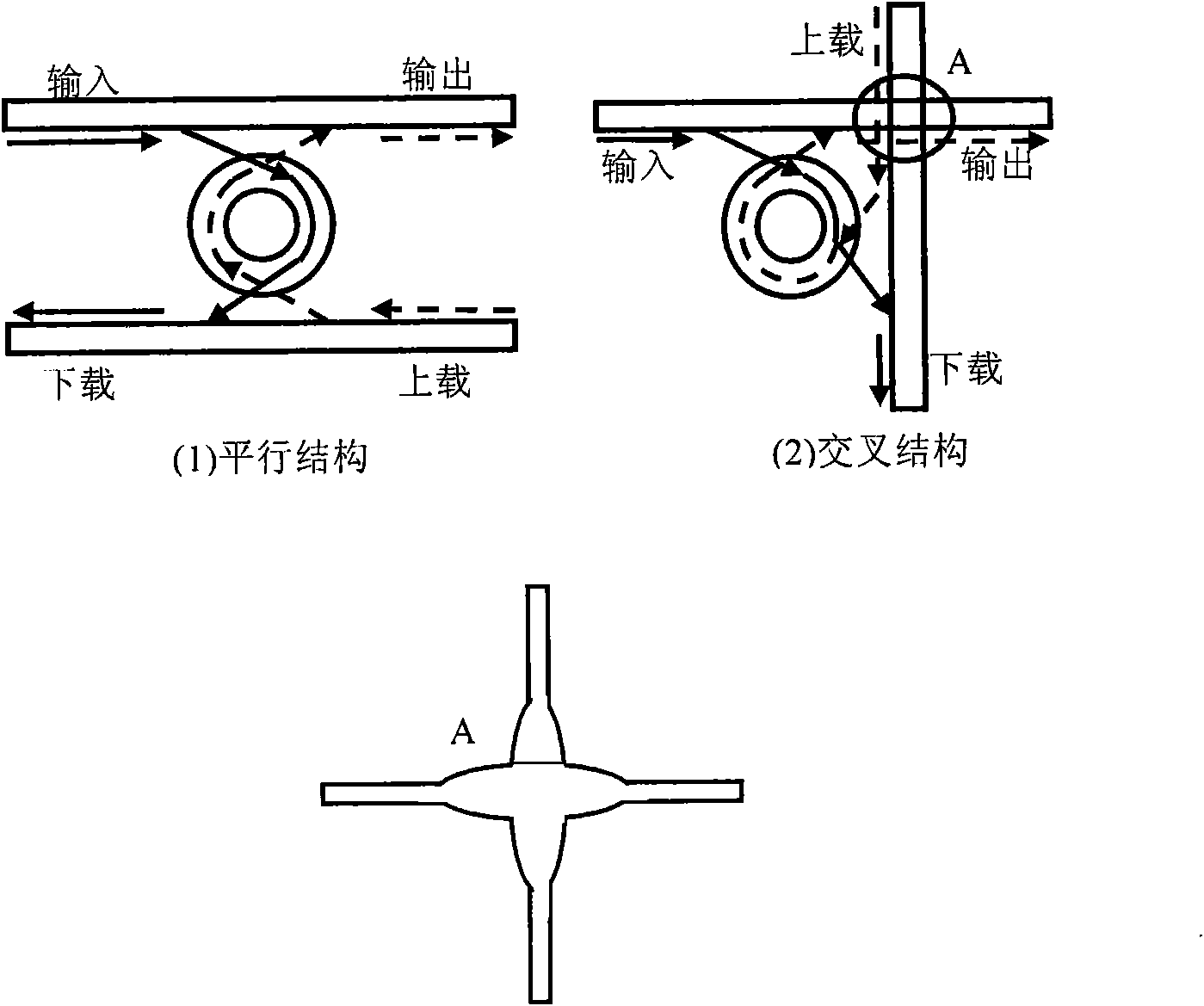

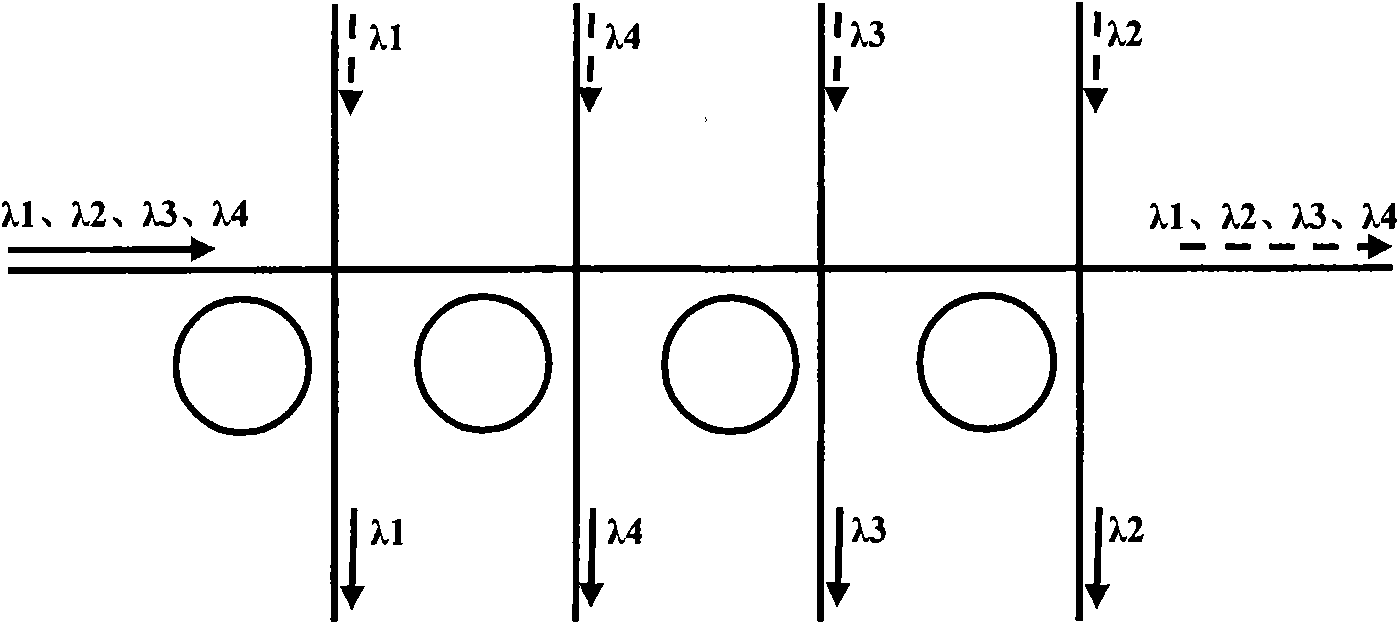

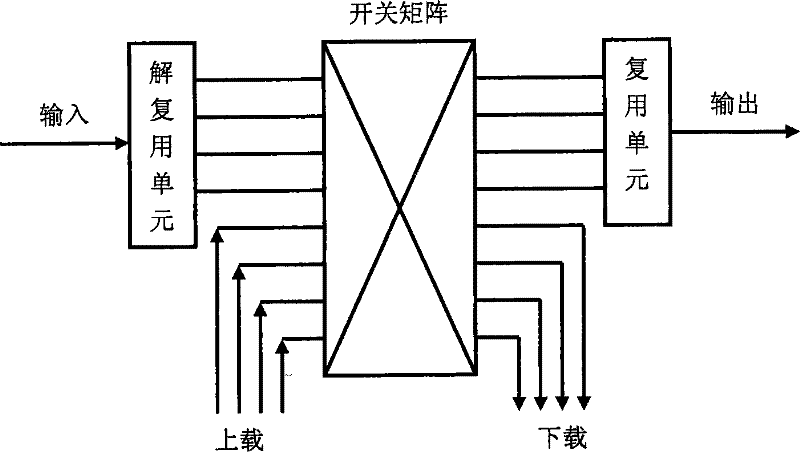

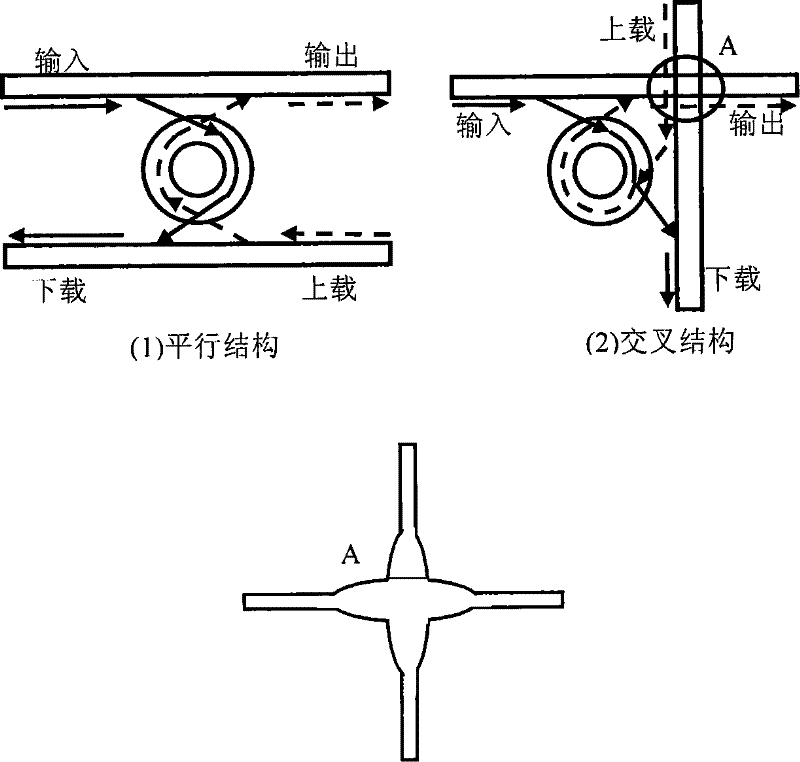

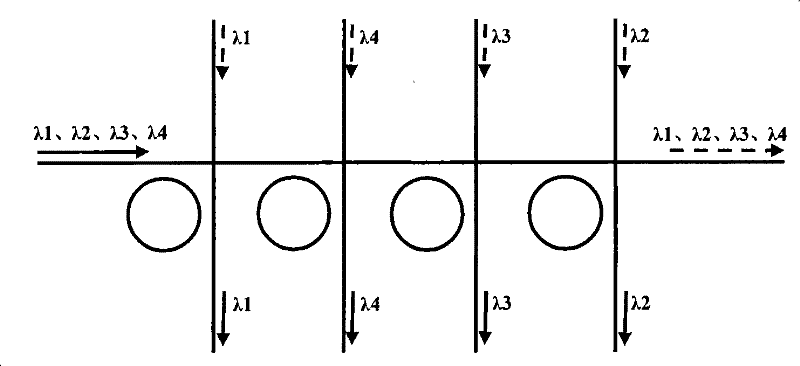

Reconfigurable optical add-drop multiplexer structure for realizing 16 channels with multiple orders

InactiveCN101552648AImprove response rateReduce the difficulty of temperature controlWavelength-division multiplex systemsTemperature controlFrequency spectrum

The invention discloses a reconfigurable optical add-drop multiplexer (an ROADM structure) for realizing 16 channels with multiple orders. The ROADM structure comprises an input part, a first-order filtration area, a second-order filtration area, a local download area, a combiner and an output part which are connected through nanometer wire waveguides. The ROADM structure has a certain width by utilizing the free spectral width of a micro-ring resonator and filters a plurality of paths of incident wavelengths with respective orders so as to ensure that the wavelength number in each download waveguide is reduced progressively and finally realize the single wavelength download in each output port, thereby reducing the temperature control difficulty and improving the response speed of devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

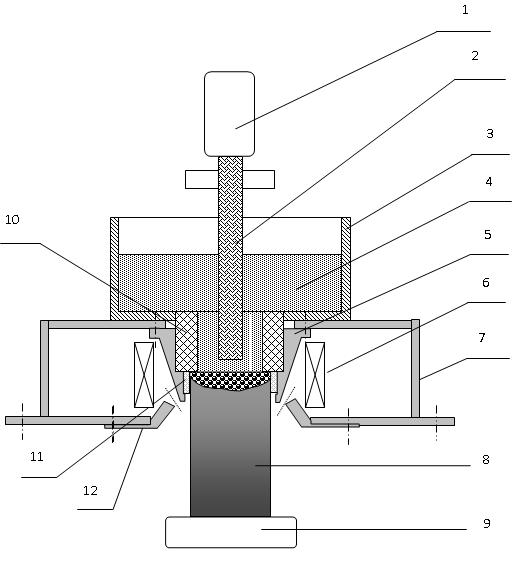

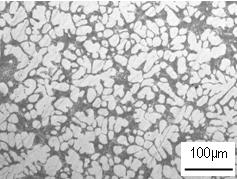

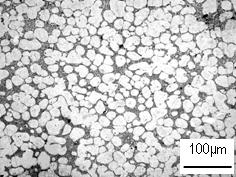

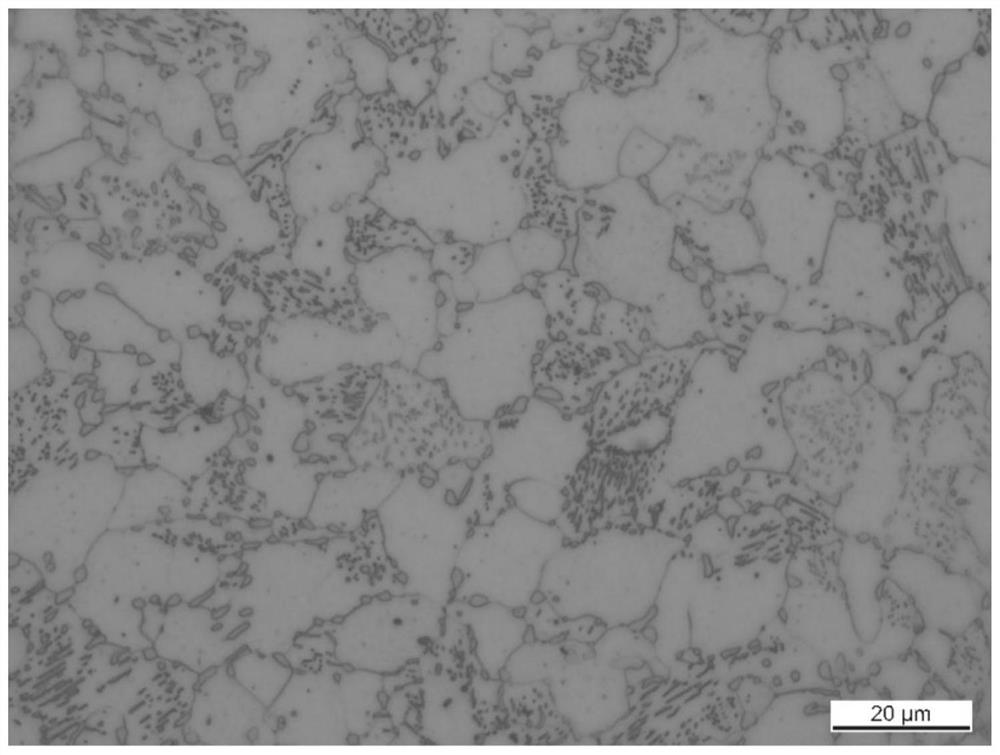

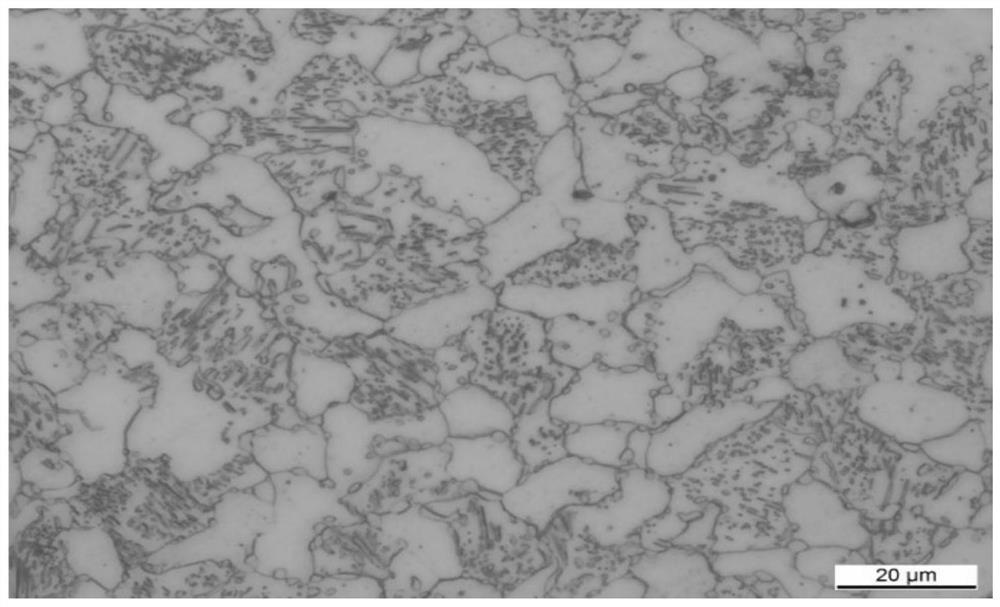

Continuous casting method for producing aluminium alloy semisolid casting ingot

The invention belongs to the technical field of metal semisolid processing and relates to a continuous casting method for producing an aluminium alloy semisolid casting ingot. The continuous casting method is characterized by comprising the following steps: firstly, a flow splitting disc, a flow guiding pipe and a stirring rod of a mechanical stirrer positioned at the central part of the flow guiding pipe are preheated at the temperature of 50-80 DEG C; then overheat aluminium liquid with qualified smelting is casted into the flow splitting disc continuously at the temperature of 100-200 DEG C higher than the temperature of a liquid phase line; when the level of the aluminium liquid in the flow splitting disc reaches the range from 50 to150mm, a dummy ingot base starts to act, the continuous casting process is started, and the level of aluminium liquid in the flow splitting disc needs to be maintained in the range from 50 to 150mm; and finally, while the process of continuous casting is started, simultaneously an electromagnetic stirrer positioned at the outer part of the flow guiding pipe and the mechanical stirrer positioned at the central part of the flow guiding pipe are started and aluminium liquid flowing through the flow guiding pipe is stirred. The continuous casting method has the advantages that the aluminium alloy semisolid casting ingot can be produced in a low-cost and large-batch manner, and the continuous casting method is especially suitable for batch production of large-diameter aluminium alloy semisolid casting ingots.

Owner:TIANJIN FLEMINGS ALUMINUM

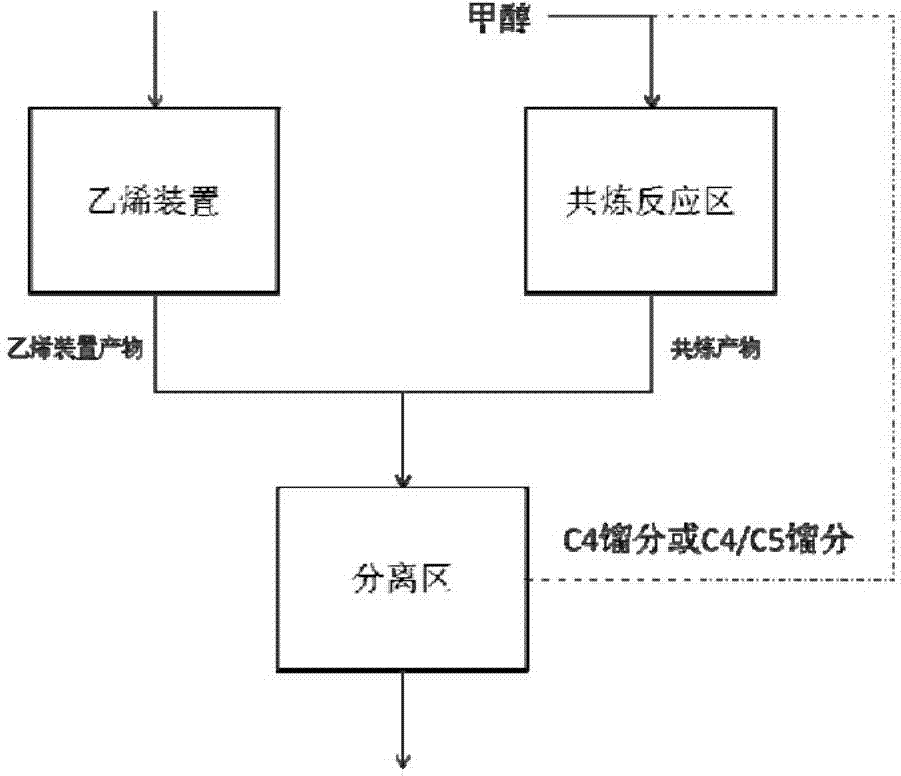

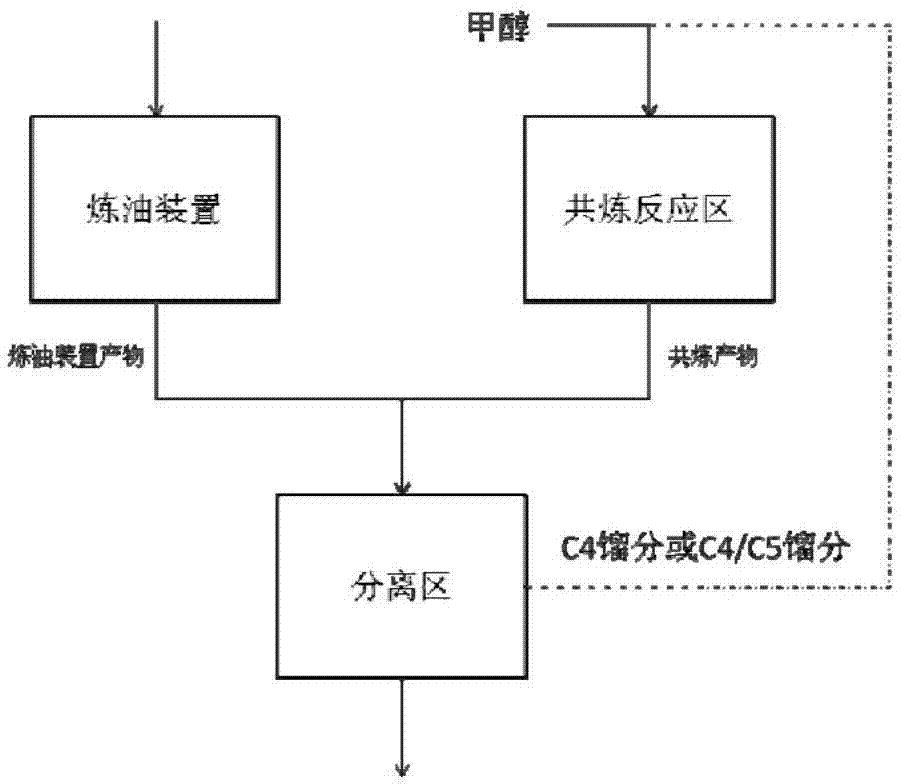

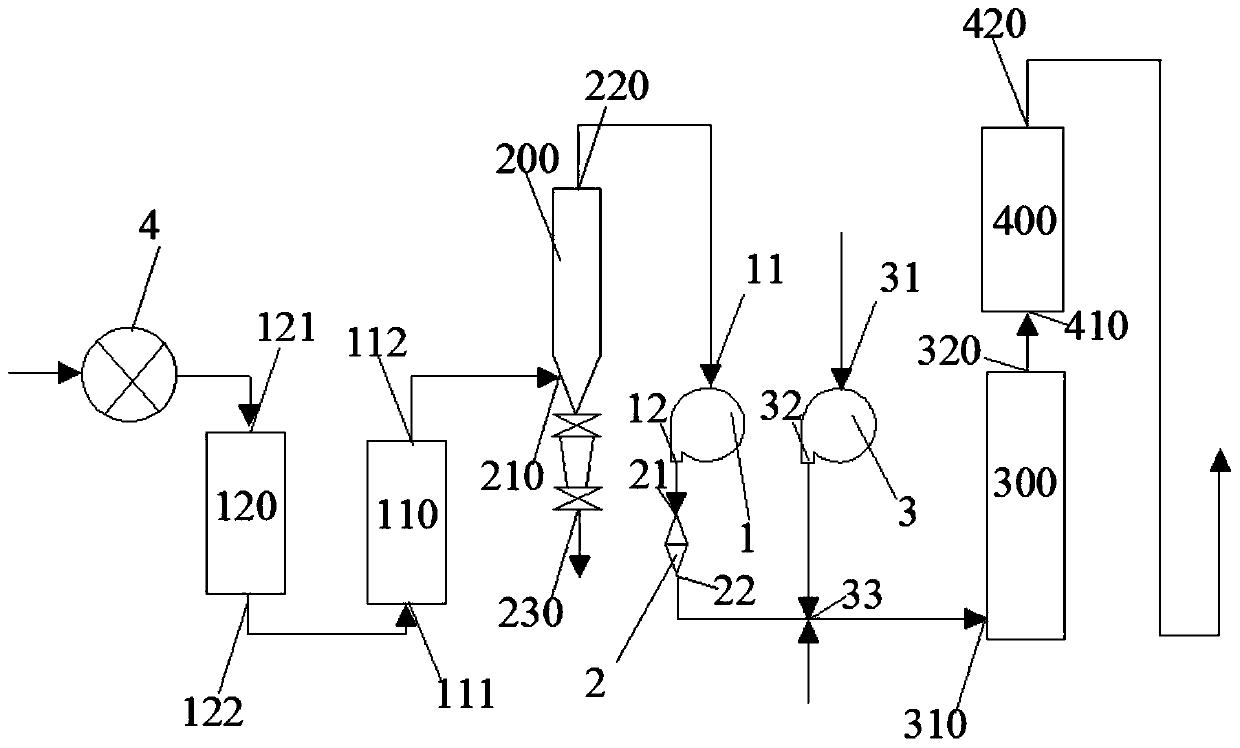

Process for producing propylene by using alcohol-hydrocarbon co-refining technology

InactiveCN103755510AReduce heat exchange difficultyReduce the difficulty of temperature controlHydrocarbon from oxygen organic compoundsEthylene productionOxideDimethyl ether

The invention discloses a process for producing propylene by using an alcohol-hydrocarbon co-refining technology. The process comprises the steps of (1) introducing a raw gas consisting of methanol and / or dimethyl ether, and C4 or C4 / C5 cut fractions and diluent gas into a co-refining reaction zone to have a co-refining reaction in contact with a catalyst, thereby obtaining a co-refining reaction product; and (2) putting the co-refining reaction product obtained in the step (1) and a product of an oil refining device or ethylene unit into a separation zone, performing dehydration and oxide removal, and then separating to obtain a product namely propylene and other hydrocarbon byproducts, wherein the C4 and C5 cut fractions in the hydrocarbon byproducts are returned to the co-refining reaction zone after crude separation. According to the process disclosed by the invention, methanol and / or dimethyl ether and C4 or C4 / C5 cut fractions are subjected to co-refining, so that a strong thermal effect existing in separate reactions of the two components is effectively neutralized, and the heat exchange difficulty is reduced; the separation zone is shared by the process and the oil refining device or ethylene unit, so that integrated production is realized, the added values of the C4 or C4 / C5 cut fractions of the oil refining device or ethylene unit are improved.

Owner:ZHEJIANG UNIV

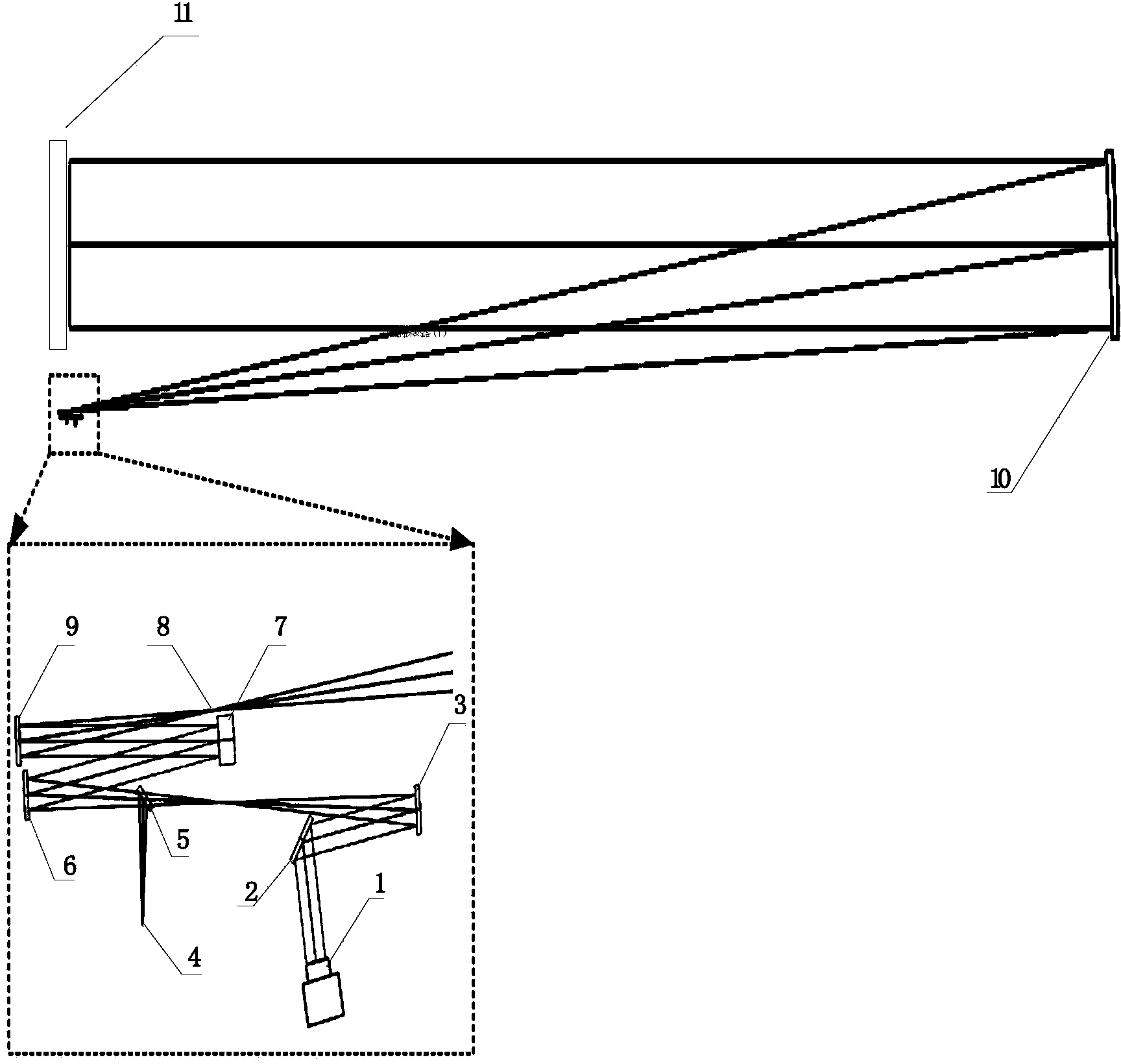

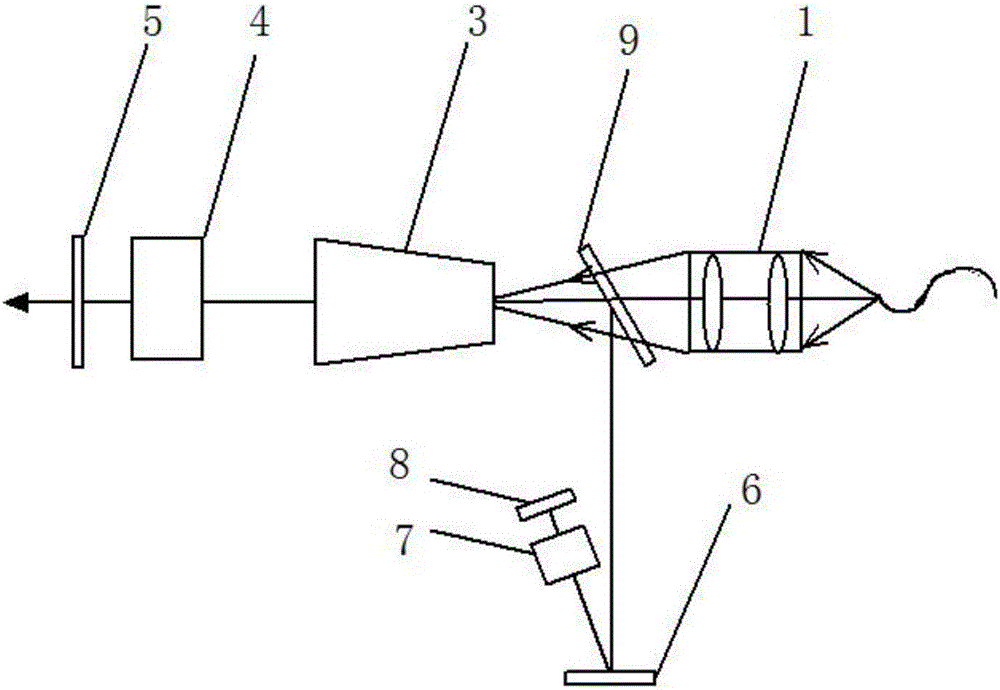

Parallel light tube wave-front aberration pre-compensation device based on adaptive optics

ActiveCN104238110AImprove calibration accuracyEliminate non-common optical path aberrationsOptical elementsBeam splittingOptoelectronics

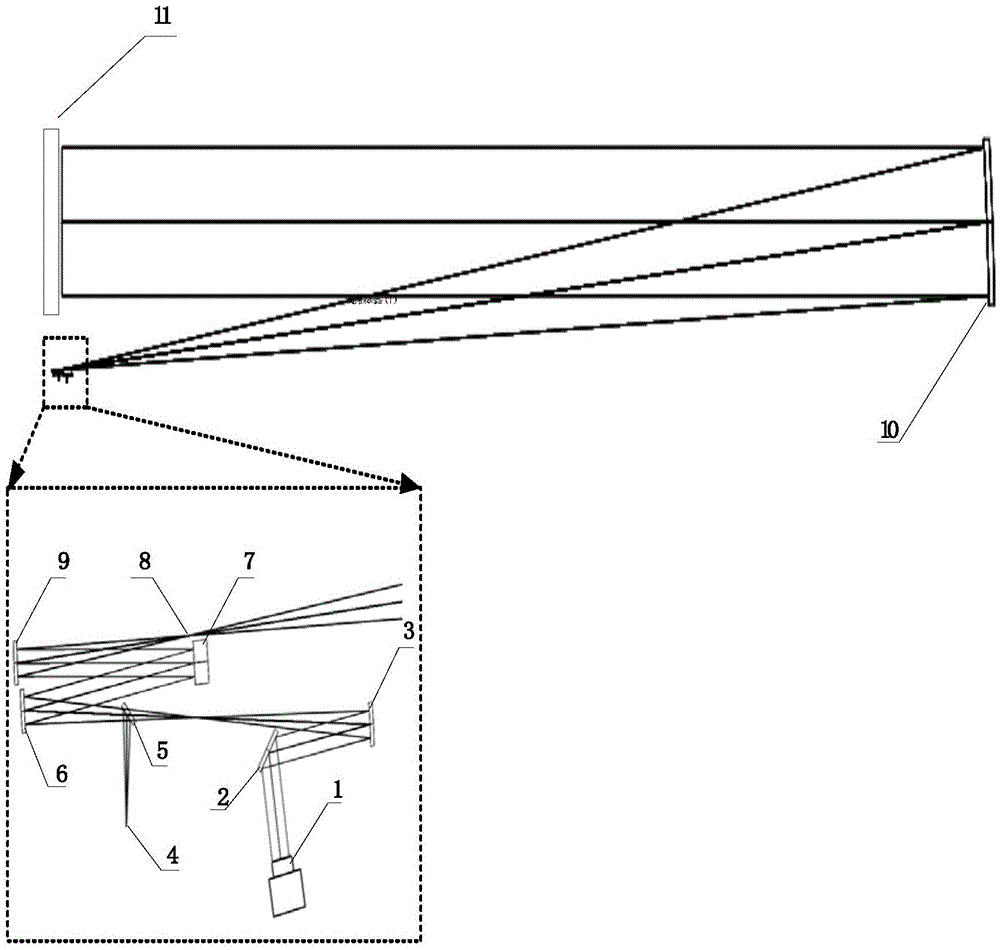

A parallel light tube wave-front aberration pre-compensation device comprises a large-caliber long-focal-distance parallel light tube and an adaptive optical system. The large-caliber long-focal-distance parallel light tube comprises a reflection mirror assembly and window glass. The adaptive optical system comprises an optical source assembly, a beam splitting piece, a first off-axis reflection mirror, a second off-axis reflection mirror, a third off-axis reflection mirror, a wave-front detector, a wave-front corrector and a turn-back reflection mirror. The parallel light tube wave-front aberration pre-compensation device can detect wave-front aberrations, introduced into the large-caliber long-focal-distance parallel light tube, caused by processing, installation, adjustment, temperature changes, temperature gradients, airflow disturbance, platform vibration and other factors in real time and can eliminate the wave-front aberrations through correcting in a high-accuracy mode in real time. In this way, the correction accuracy and the correction efficiency of the large-caliber long-focal-distance parallel light tube are greatly improved, the development difficulty of the large-caliber long-focal-distance parallel light tube is substantially lowered, a lot of test time is saved, and a lot of test cost is reduced.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

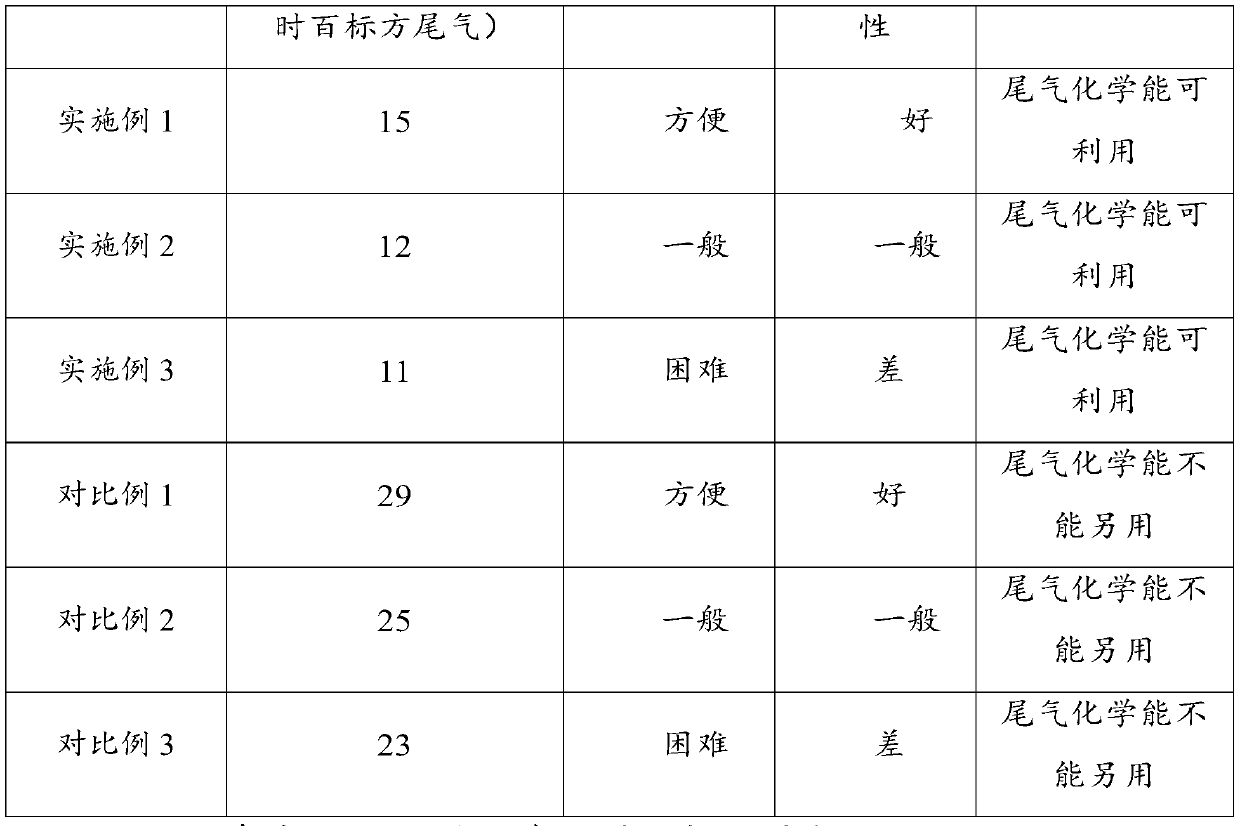

Engine exhaust temperature control method and device and engine exhaust temperature control system

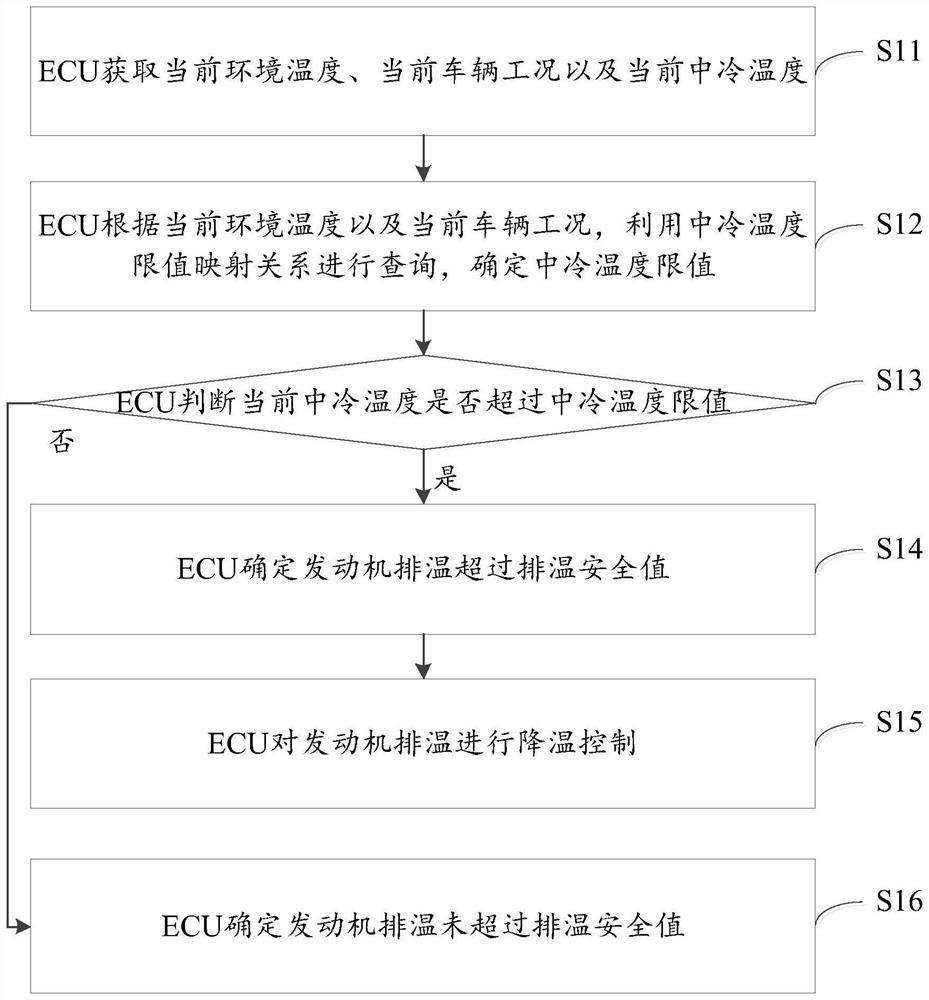

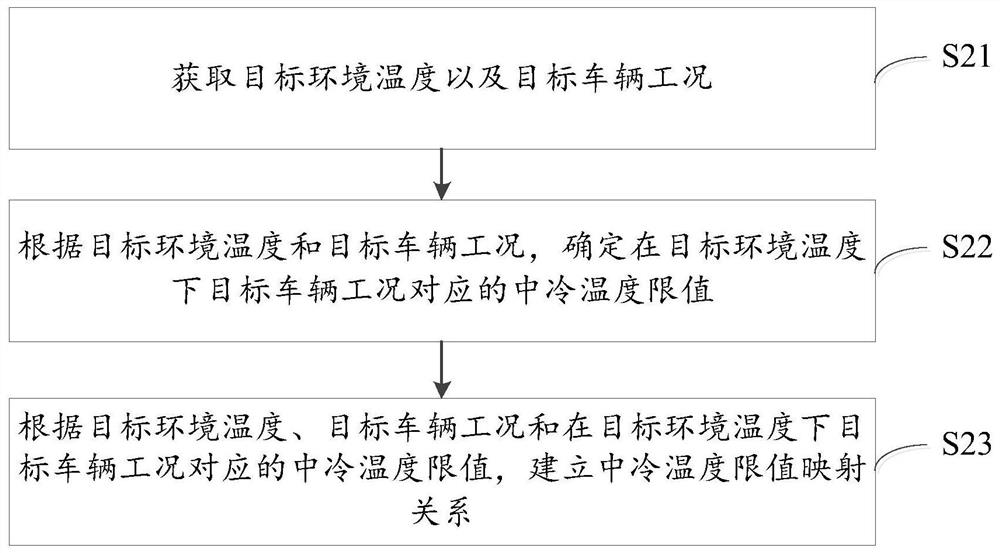

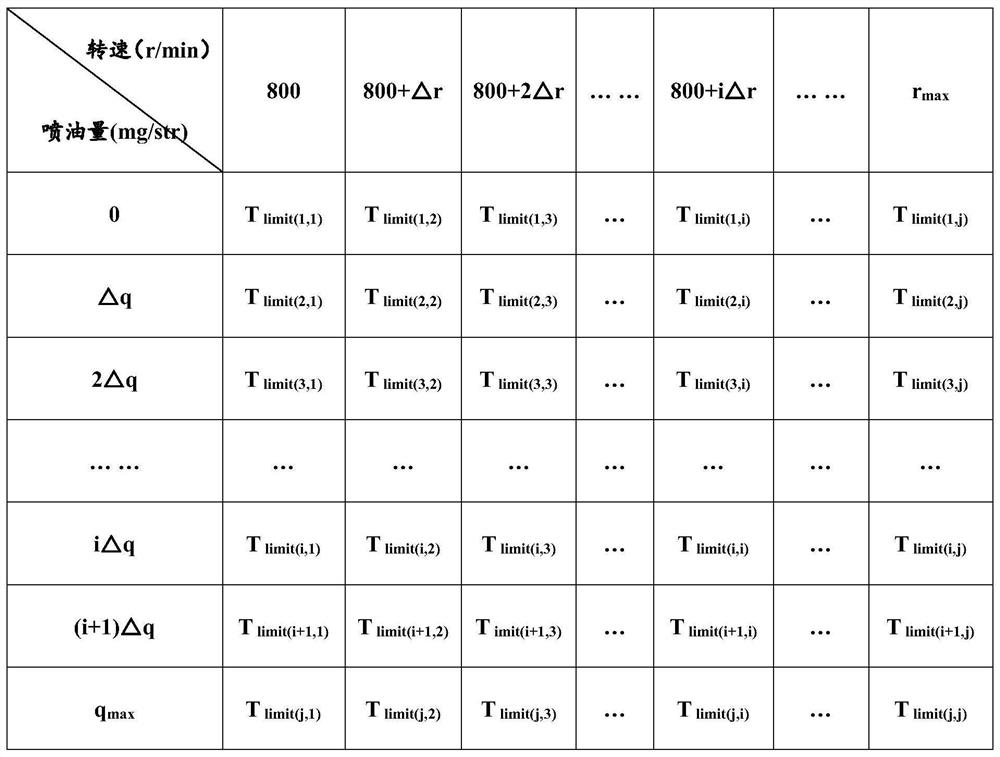

ActiveCN112628003AAvoid damageReduce the difficulty of temperature controlElectrical controlInternal combustion piston enginesTemperature controlCombustion chamber

The invention discloses an engine exhaust temperature control method and device and an engine exhaust temperature control system. An ECU obtains the current environment temperature, the current vehicle working condition and the current intercooling temperature; and the ECU inquires and determines an intercooling temperature limit value by utilizing an intercooling temperature limit value mapping relation according to the current environment temperature and the current vehicle working condition, determines that the engine exhaust temperature exceeds an exhaust temperature safety value when determining that the current intercooling temperature exceeds the intercooling temperature limit value, and performs cooling control on the engine exhaust temperature, and damage to components such as a combustion chamber and an exhaust pipe of an engine and environmental pollution due to the over-high exhaust temperature of the engine are avoided. Due to the fact that the above control process is executed by the ECU of the existing equipment, other additional equipment does not need to be added, the engine exhaust temperature can be accurately controlled on the premise that the additional equipment is not added, and the temperature control difficulty of the engine exhaust temperature control system and the production cost of the engine exhaust temperature control system are reduced.

Owner:SAIC MOTOR

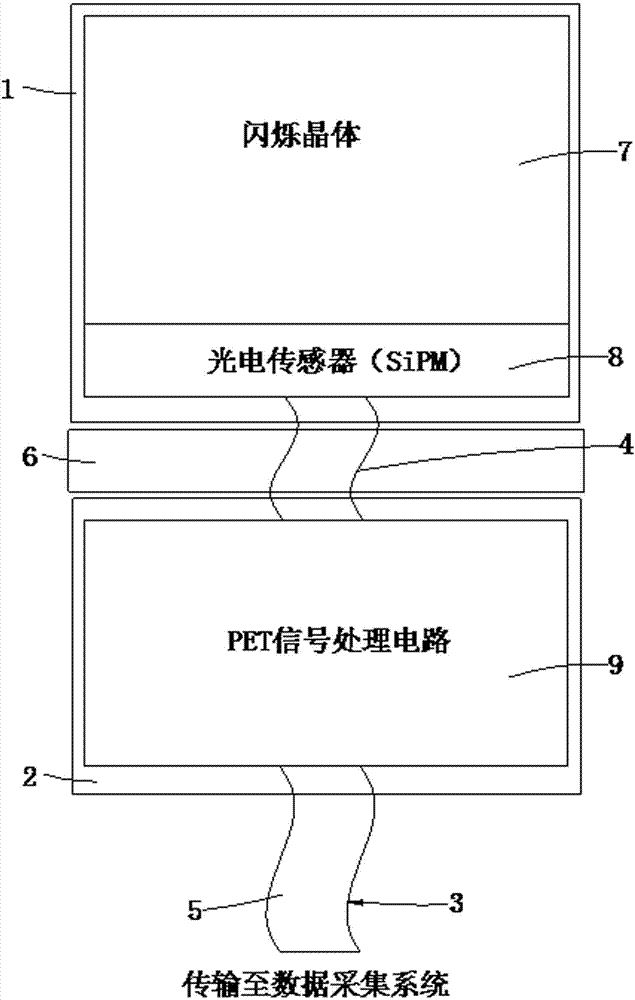

Novel PET detector framework based on SiPM

InactiveCN104720842AReduce control difficulty and maintenance costAvoid transmissionComputerised tomographsTomographyThermal insulationVoltage

The invention relates to a novel PET detector framework based on a SiPM. The novel PET detector framework comprises a detector box, an electronics box and a connecting cable, the connecting cable comprises an upper cable and a lower cable, the upper cable is arranged between the detector box and the electronics box and used for transmitting voltage needed for work of the detector box and output analog signals, the lower cable is arranged on the electronics box and used for transmitting digital and analog signals generated by the electronics box to a data acquisition system, a thermal insulation material is further arranged between the detector box and the electronics box, and the upper cable penetrates through the thermal insulation material. According to the novel PET detector framework, the performance and stability of a PET detector are improved, and the bulk temperature control difficulty and maintenance cost of the PET detector are also effectively reduced.

Owner:FMI MEDICAL SYST CO LTD

Czochralski monocrystalline silicon growth furnace

ActiveCN111826709ALight in massAvoid thermal unevennessBy pulling from meltCrystallographyTemperature control

The invention relates to the technical field of czochralski monocrystalline silicon, and discloses a czochralski monocrystalline silicon growth furnace which comprises a fixed box and a pyrometer. A heat preservation cylinder I is fixedly mounted at the left part of an inner cavity of the fixed box, a heating element is fixedly mounted on the inner wall of the heat preservation cylinder I, and a seed crystal is fixedly mounted on the right side of the top of the fixed box. Through the setting of the growth box, the melting of the polycrystalline silicon is separated from the pulling place of the monocrystalline silicon body; the polycrystalline silicon is continuously melted through the quartz crucible to form a melt to provide a raw material for pulling the monocrystalline silicon body from the interior of the growth box; the quality of the monocrystalline silicon body is prevented from being reduced due to non-uniform thermal field in the quartz crucible; the growth interface temperature in the growth box can be kept within a certain range, and the temperature control difficulty is reduced; meanwhile, the quartz crucible and the growth box are arranged to ensure the sufficiency of raw materials; and through the arrangement of a rotating device, the number of single crystal silicon bodies pulled at a time is increased, and the production efficiency is improved.

Owner:杭州飞宇磁电器材有限公司

Upper electrode assembly and semiconductor process equipment

PendingCN114203511AReduce the difficulty of temperature controlImprove temperature control effectElectric discharge tubesSemiconductor/solid-state device manufacturingProcess equipmentHeating effect

The invention discloses an upper electrode assembly and semiconductor process equipment, the upper electrode assembly comprises an upper electrode cover plate, and the upper electrode cover plate is used for being arranged on a top opening of a reaction chamber; the flow uniformizing piece is a heat conduction structural piece and is installed on the upper electrode cover plate, at least one part of the flow uniformizing piece is located on the side, facing the reaction cavity, of the upper electrode cover plate, and the flow uniformizing piece is provided with an annular containing groove; the contact electrode is arranged on the surface of the side, away from the upper electrode cover plate, of the flow uniformizing piece, and an opening of the annular containing groove is arranged away from the contact electrode; and the heating ring is arranged in the annular accommodating groove. According to the technical scheme, the problems that the heated effect of an existing contact electrode is poor, and the temperature of the upper electrode cover plate is high can be solved.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

High-temperature water cooling device and method

InactiveCN102839264ASpeed up coolingPrevent overcoolingQuenching devicesHigh pressure waterHigh pressure

The invention discloses a high-temperature and high-pressure water cooling device and a method, which can realize ultra-high-speed cooling and control the bottom cooling temperature flexibly at the same time. The method comprises the steps that cooling water (below 100 DEG C and at atmospheric pressure) with a great quantity of surplus heat generated in other production processes is heated in a high-pressure autoclave continuously to reach the required temperature, and sprayed to the surface of an object to be cooled (for instance, a steel plate) at high speed through a high-pressure water pump and a pipeline, and the object is cooled depending on instantaneous intensive vaporization of high-temperature water for heat absorption; and the intensity of cooling can be controlled by water temperature, water pressure and water flow. Since the high-temperature water is adopted for cooling, the cooled object is not subjected to undercooling; some industrial conditions requiring that the bottom cooling temperature is not less than a certain temperature (for instance, 150 DEG C) can be satisfied, and the cooling system difficult for the ordinary water cooling to accomplish is realized. Taking the step quenching of the steel plate as an example, the purposes of rapid cooling and controlling of the bottom cooling temperature are realized.

Owner:LAIWU IRON & STEEL GRP

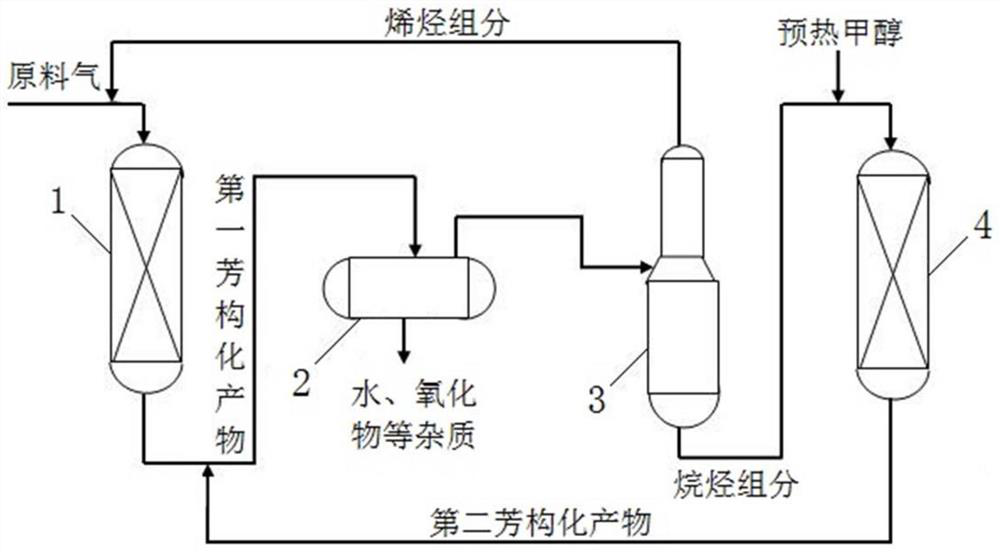

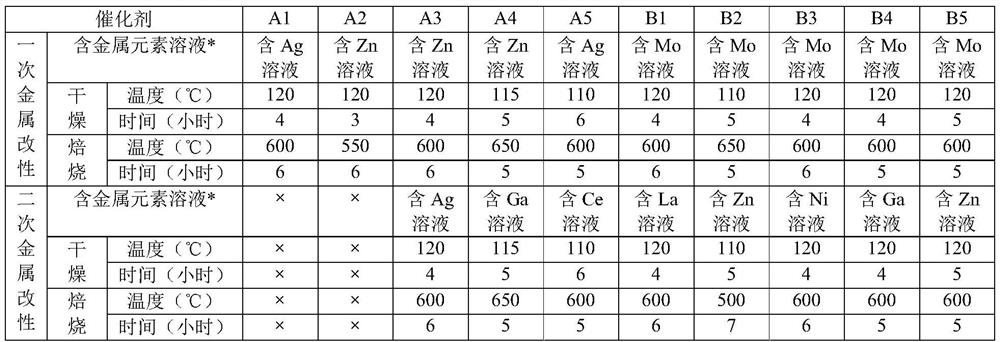

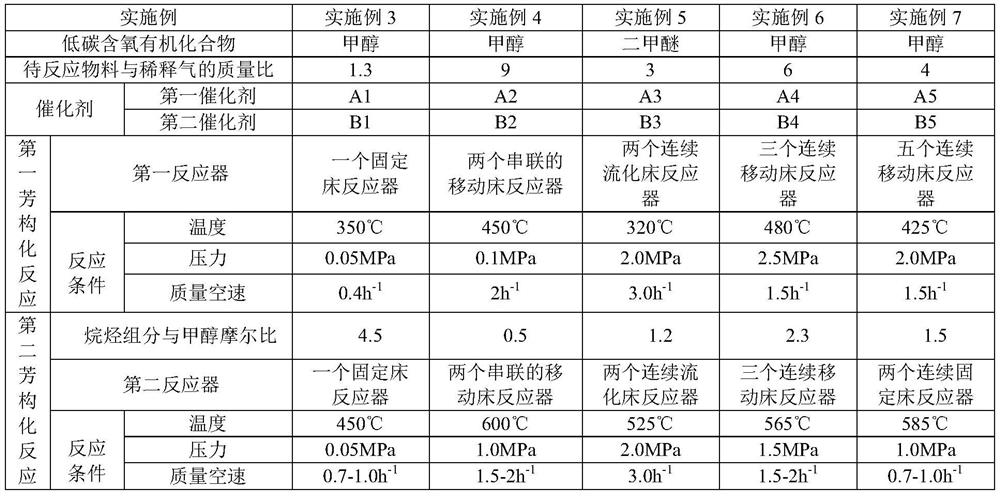

Method for producing light aromatic hydrocarbon

ActiveCN113121296AHigh yieldReduce the difficulty of heat exchange and reactor temperature controlMolecular sieve catalystsHydrocarbon from oxygen organic compoundsAlkaneMethanol

The invention provides a method for producing light aromatic hydrocarbon, which comprises the following steps: 1) in the presence of a first catalyst, carrying out first aromatization reaction on a to-be-reacted material containing a low-carbon oxygen-containing organic compound to obtain a first aromatization product; 2) separating the first aromatization product to separate an olefin component and an alkane component from the first aromatization product to obtain a target product; 3) returning the olefin component to the step 1) to carry out a first aromatization reaction; 4) in the presence of a second catalyst, carrying out a second aromatization reaction on the alkane component and methanol to obtain a second aromatization product; and 5) returning the second aromatization product and combining the second aromatization product into the first aromatization product for separation. The method for producing the light aromatic hydrocarbon has the advantages of high yield of the light aromatic hydrocarbon, great economic benefit and the like.

Owner:PETROCHINA CO LTD

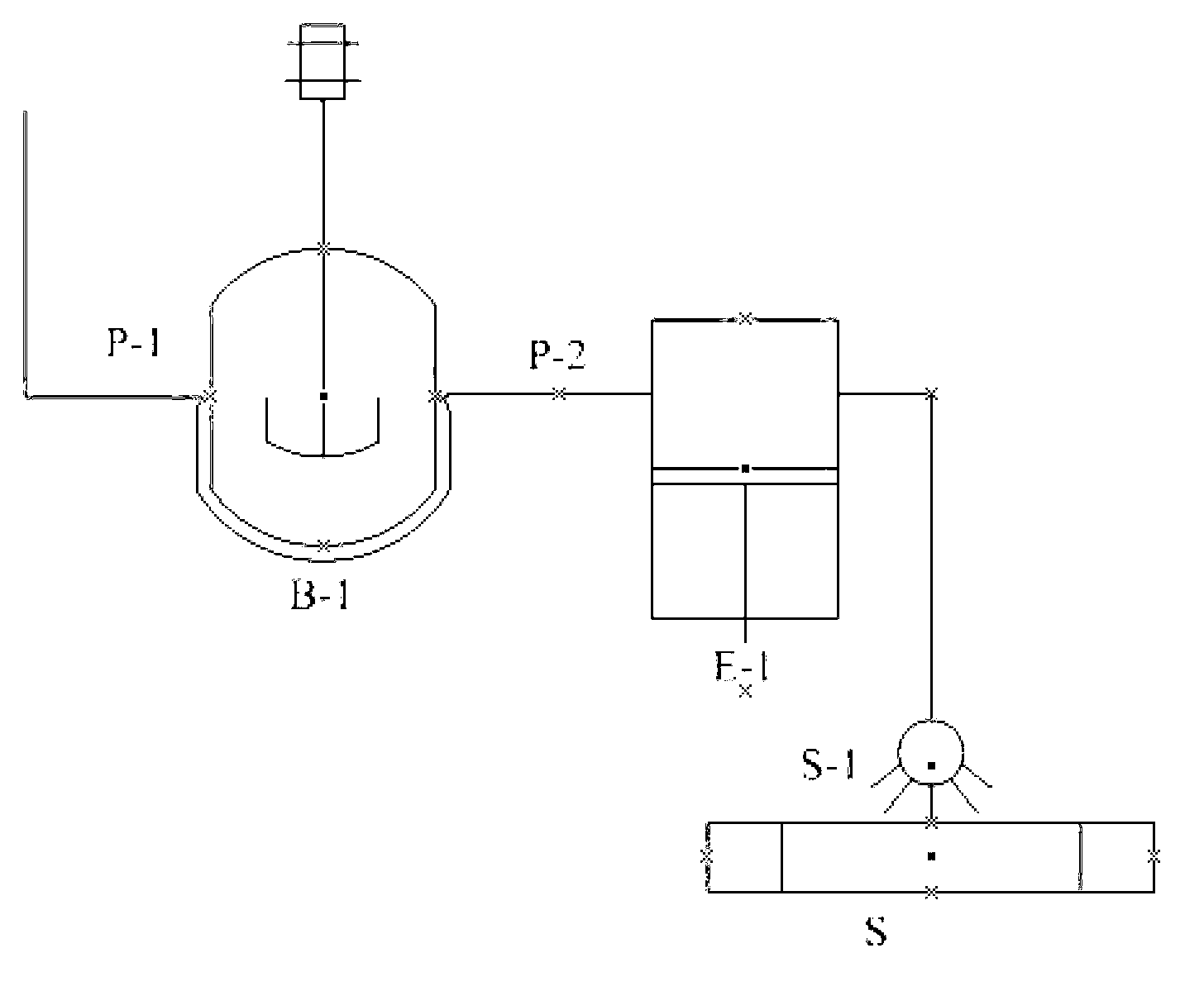

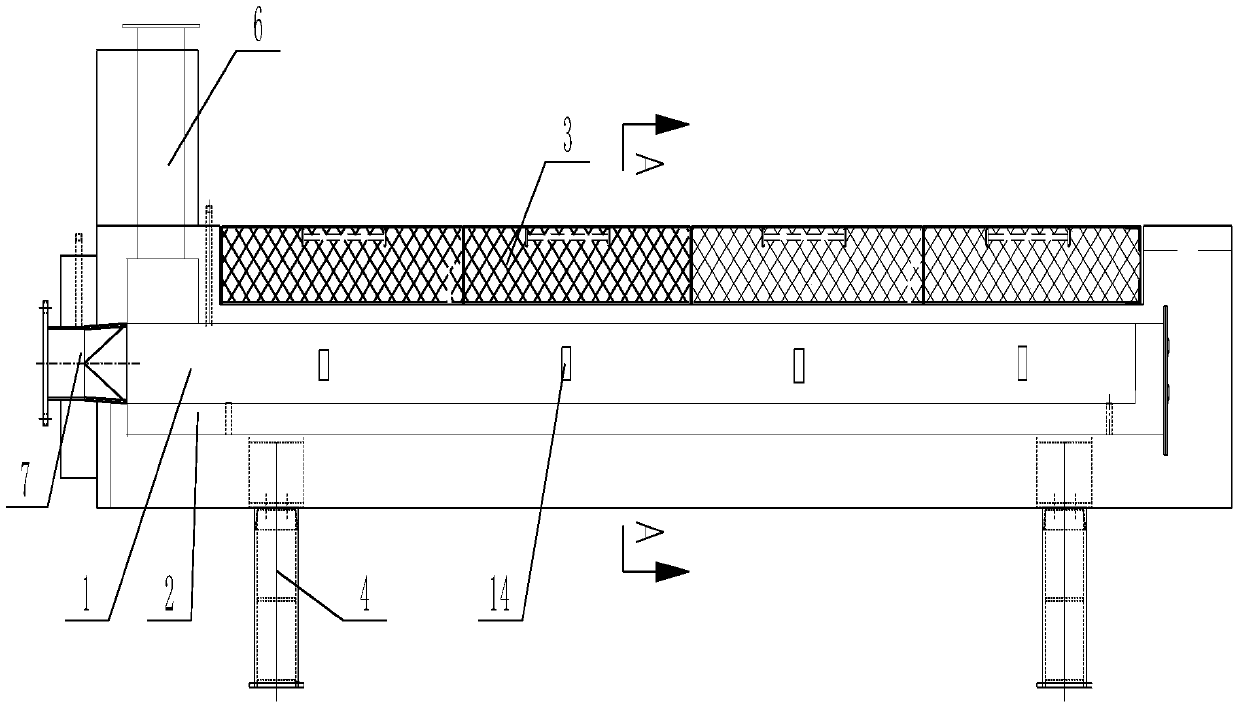

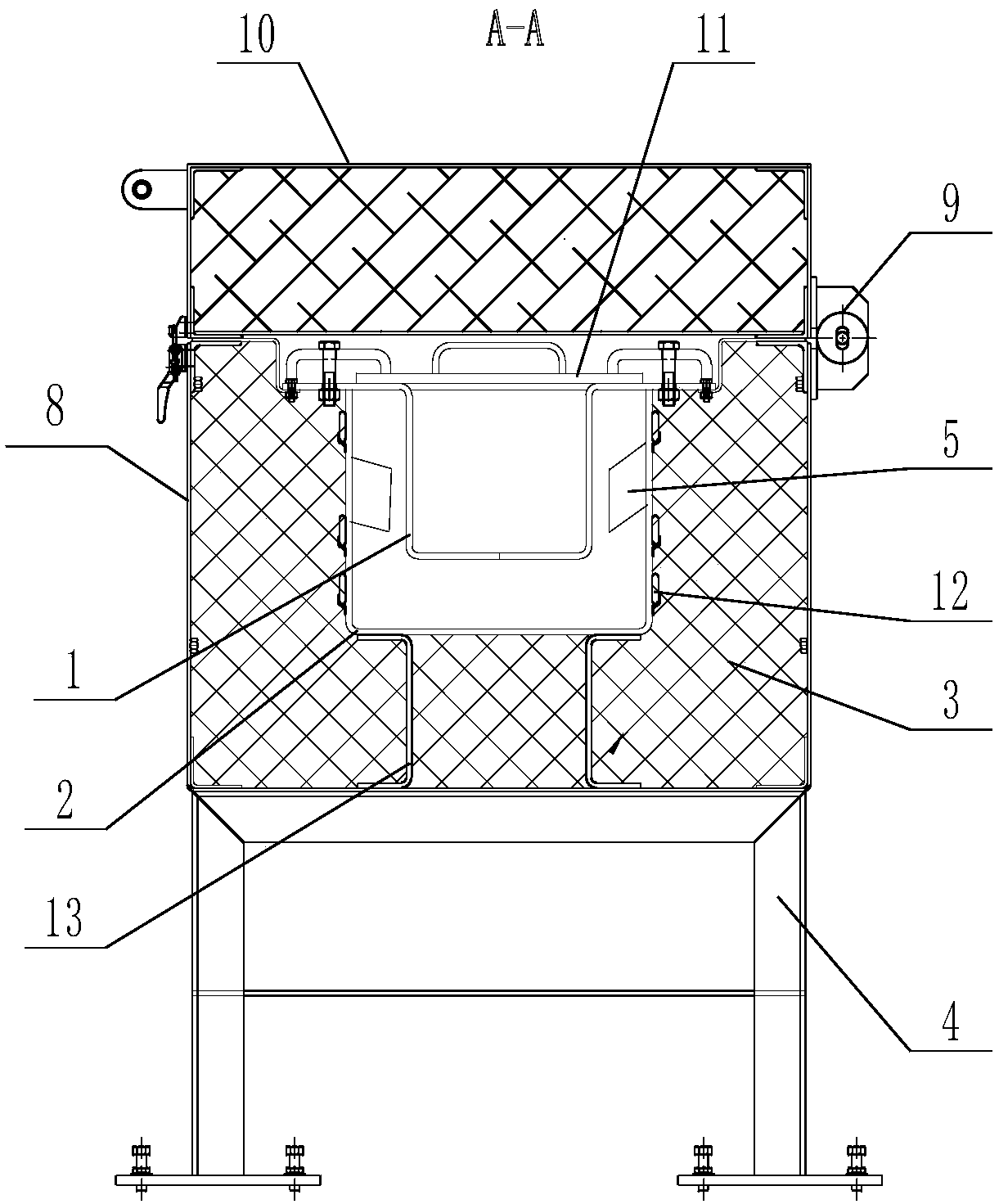

Pilot equipment for catalyst detection

InactiveCN109557239AReduce flow rateIncrease utilization and soak timeChemical analysis using catalysisThermal insulationElectric heating

The invention relates to the field of catalyst test devices, in particular to pilot equipment for catalyst detection. The pilot equipment comprises a box, a top cover, a catalyst cabin, a smoke backflow cabin, a sealing cover and a base, wherein the box is fixed on the base; the smoke backflow cabin is mounted in the box; the catalyst cabin is fixed in the smoke backflow cabin; the top cover covers the box; and thermal insulation layers are arranged in the top cover and the box. Smoke in the pilot equipment for catalyst detection is reacted and filtered in the catalyst cabin and then backflowsfrom the smoke backflow cabin, the catalyst cabin is thermally insulated and heated, and the electric energy for heating is reduced, so that afterheat reutilization is realized; and a baffle plate and an electric heating plate are added to reduce the flow speed of the smoke in the backflow process and carry out temperature compensation, so that the catalyst cabin is better thermally insulated andthe afterheat utilization rate is increased.

Owner:HUADIAN QINGDAO ENVIRONMENTAL TECHNOLOCY CO LTD

A Collimator Wavefront Aberration Precompensation Device Based on Adaptive Optics

ActiveCN104238110BImprove calibration accuracyEliminate non-common optical path aberrationsOptical elementsBeam splittingOptoelectronics

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

Indirect process of preparing light calcium carbonate based on medium strengthening

InactiveCN103539187BWide variety of sourcesLow costCalcium/strontium/barium carbonatesAtherion elymusCalcite

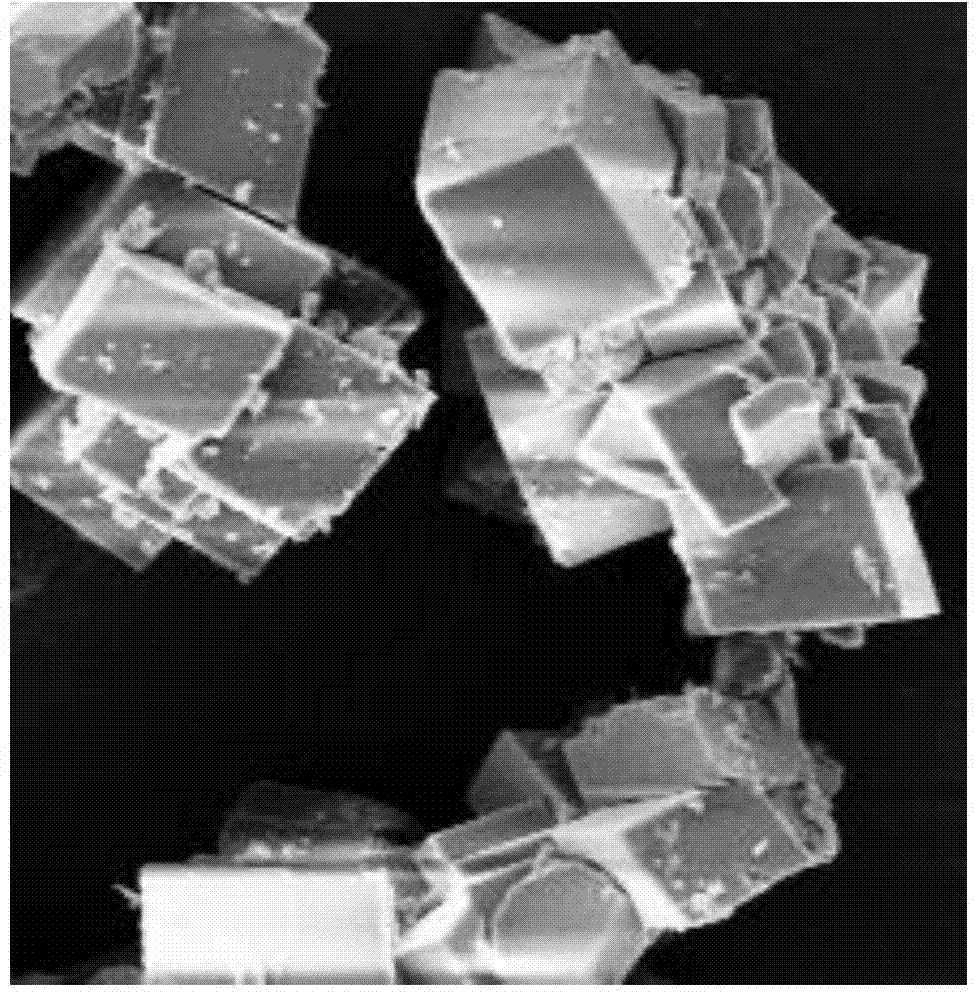

The invention relates to an indirect process of preparing light calcium carbonate based on medium strengthening. The indirect process comprises the following steps of: adding calcium-rich ion liquor containing inorganic soluble calcium salt into insoluble organic amine as well as a phase regulator, stirring to uniformly mix the liquor until pH of the mixed liquor is kept stable, wherein pH of the mixed liquor is over 9.5; ventilating a CO2 gas or purified industrial smoke gas into the mixed liquor to react with the mixed liquor, controlling a reaction temperature at 5 DEG C-40 DEG C, and stopping the reaction when pH is lowered to 7-8; filtering, drying and grinding the prepared calcium carbonate precipitates to obtain calcium carbonate of different crystalline forms. According to the indirect process disclosed by the invention, the liquor rich in calcium ions and carbon dioxide react under a higher pH environment and an oil-water mixed state which are respectively provided and created by insoluble organic amine and the phase regulator; temperature is controlled, so that preparation of calcite type as well as vaterite type fine light calcium carbonate is realized.

Owner:SHANDONG UNIV

Spheroidizing annealing method for carbon tool steel roller hearth type annealing furnace for automobile

PendingCN114182070AEasy to controlGuaranteed to disappearFurnace typesProcess efficiency improvementTemperature controlResidual oxygen

The invention discloses a spheroidizing annealing method of a roller hearth type annealing furnace for carbon tool steel for automobiles, which comprises the following steps of: subdividing a heating section of a continuous furnace into 13 sections from the head to the tail, controlling, charging when residual oxygen in the furnace is stabilized to be less than 5ppm, paving steel in the continuous furnace in a multi-layer tiling manner, setting the roller speed to be 3.0-7.0 m / h in the spheroidizing annealing process, and controlling the spheroidizing annealing temperature to be 20-30 DEG C; the frequency of the fan is set to be 2-10 Hz, and it is guaranteed that the spheroidizing rate of the steel discharged out of the furnace reaches 80% or above. Compared with an existing periodic spheroidizing annealing process, the method has the advantages that the production period is shortened, the operation is convenient, the heating area temperature control difficulty is greatly reduced, and the control precision is remarkably improved.

Owner:NANJING IRON & STEEL CO LTD

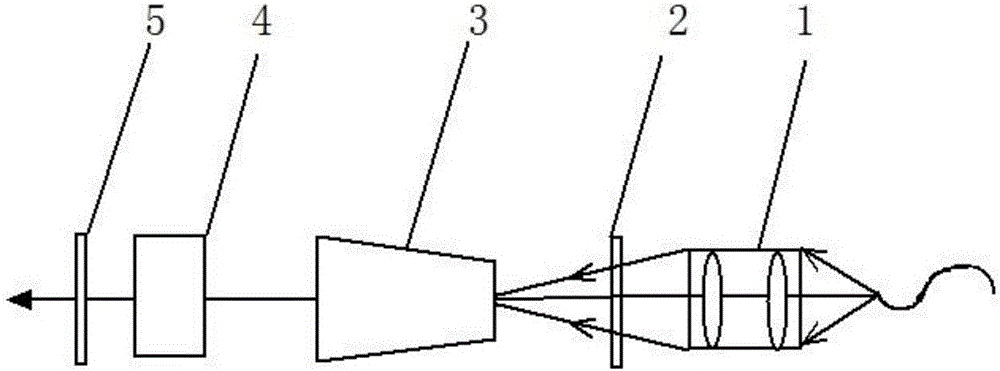

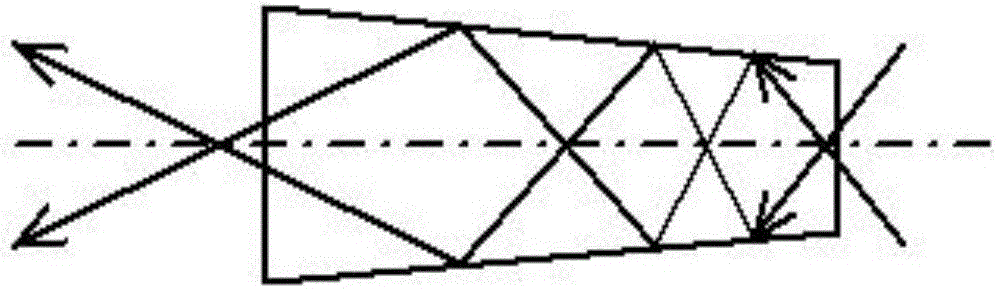

Laser with high power and high beam quality

InactiveCN105896304APrevent self-excited lightFully absorbedActive medium materialLight beamOptoelectronics

The invention relates to a laser with high power and high beam quality. The laser comprises a fiber coupling system, a front cavity mirror, a laser crystal, an acoustic-optic Q-switched device and a rear cavity mirror arranged in sequence along an optical path; the fiber coupling system is composed of a pumping source, a transmission fiber and a focusing coupling system; the laser crystal has two ends with unequal sizes and a uniform transition variable section in the axial direction, wherein the small end is arranged in the front of the optical path; the outer surface of the laser crystal is a polished surface, two end faces are separately plated with an anti-reflection film for pumping light and fundamental frequency light, and the side surface of the laser crystal is plated with a high-reflection film for pumping light. By adopting the laser, the pumping light can be sufficiently absorbed after being reflected several times inside the laser crystal, so that the energy storage performance of the laser crystal and the conversion efficiency of the pumping light are improved; and under the condition that the laser output power is the same, the length of the laser crystal is shortened, the doping concentration and the thermal gradient are reduced, the thermal lens effect is improved, the beam quality is improved, and laser with high power and high beam quality is obtained.

Owner:ANSHAN ZY LASER TECH

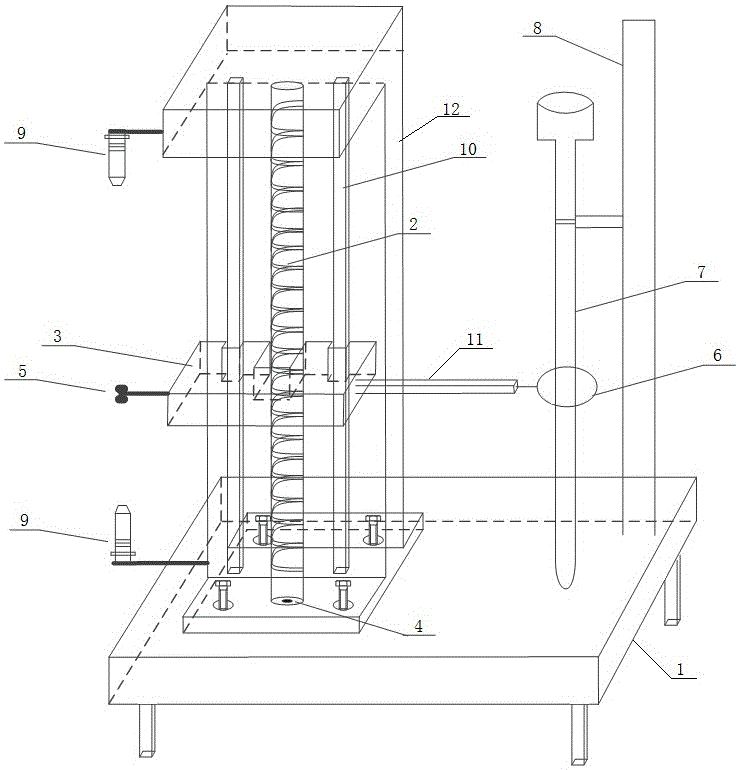

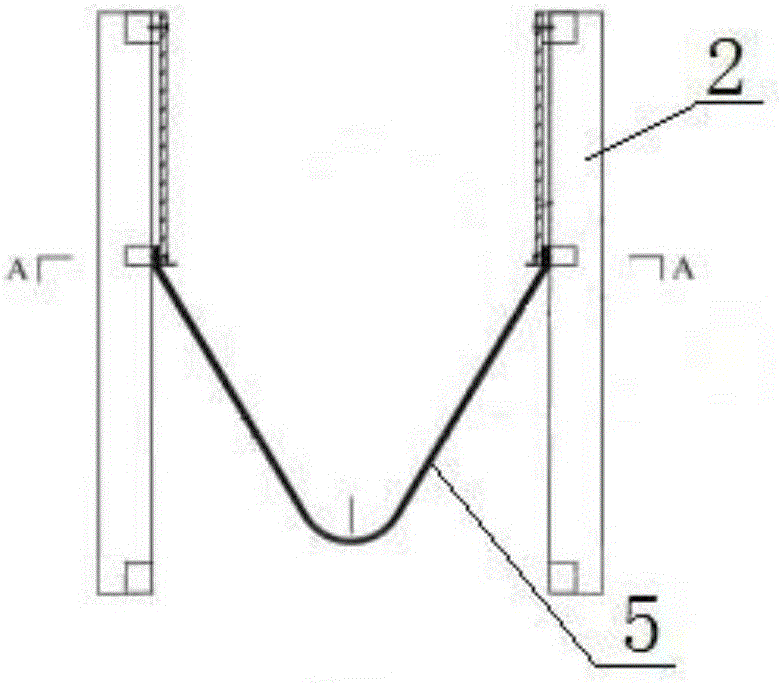

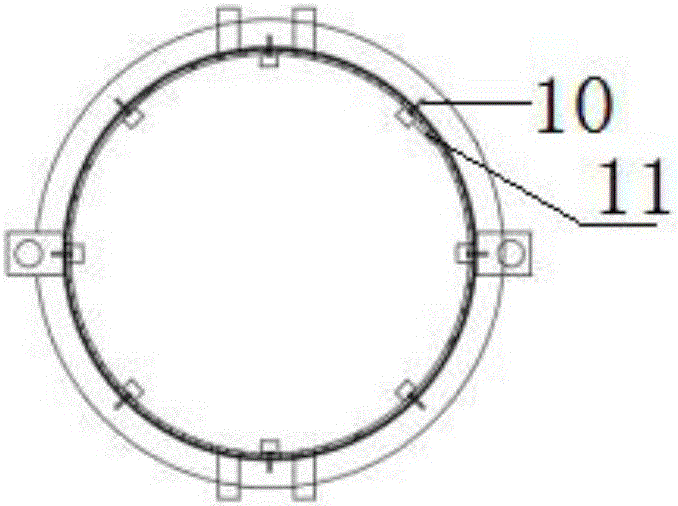

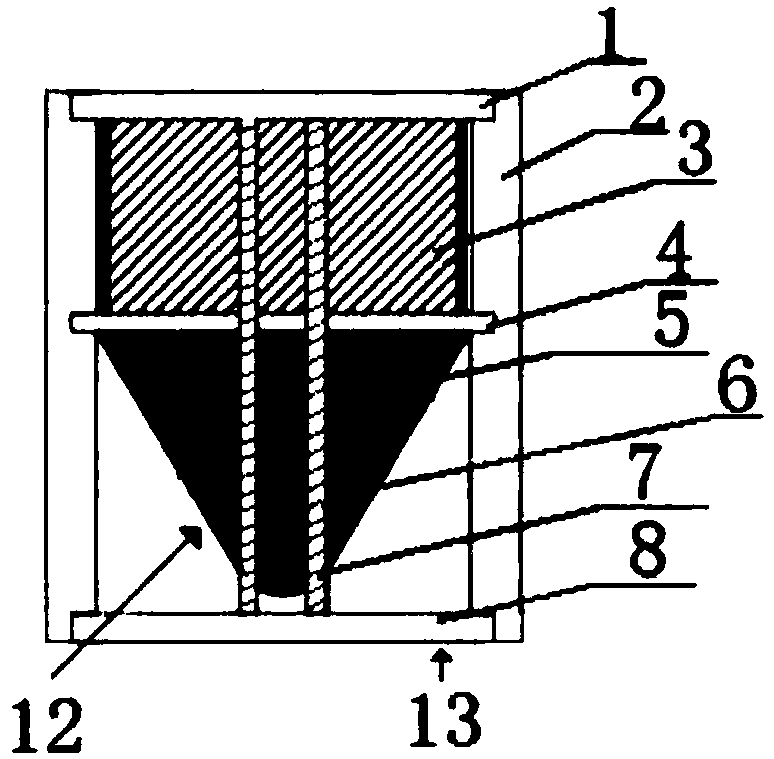

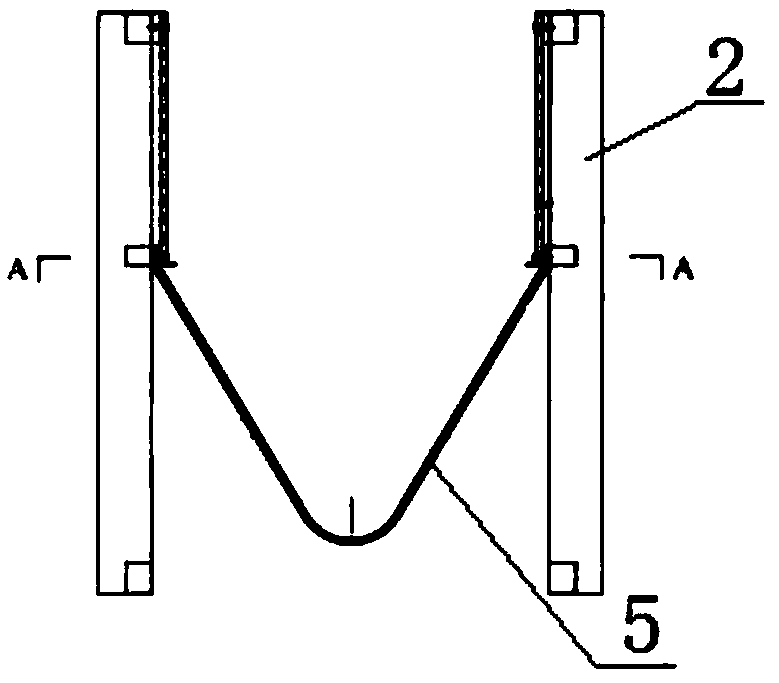

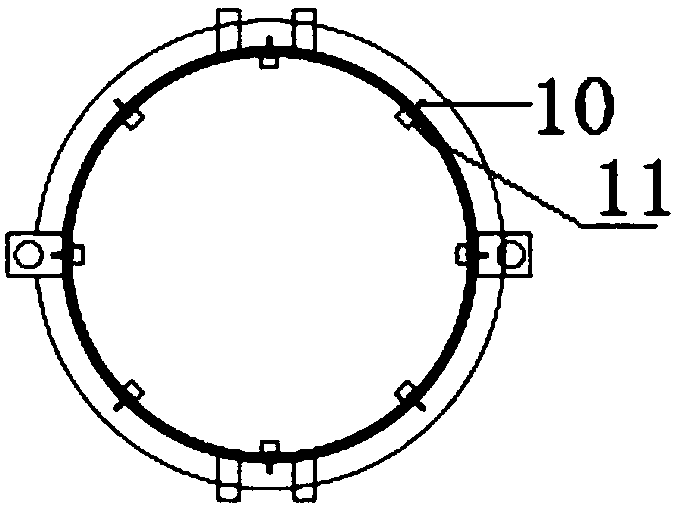

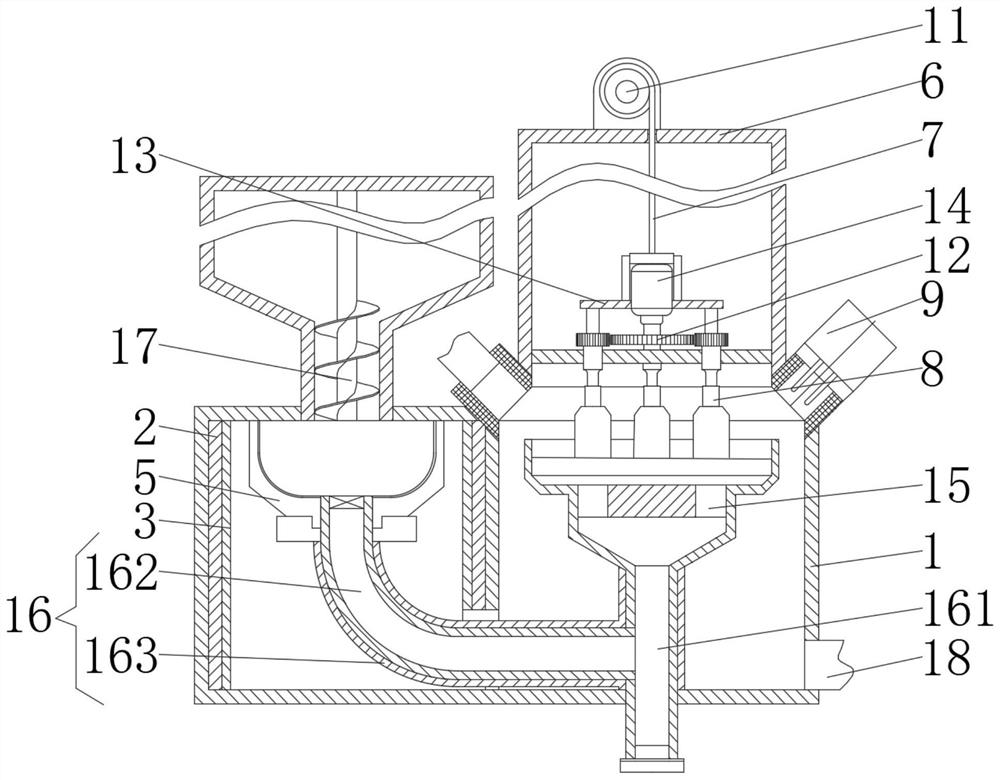

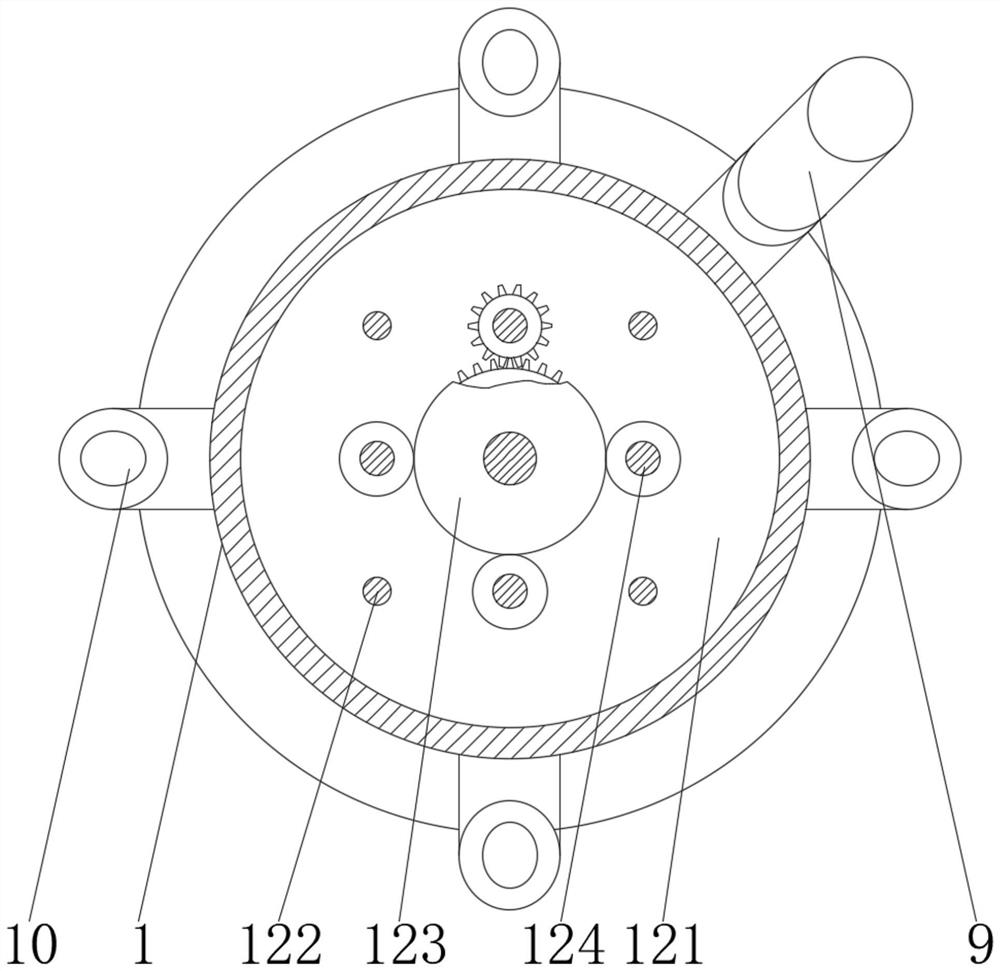

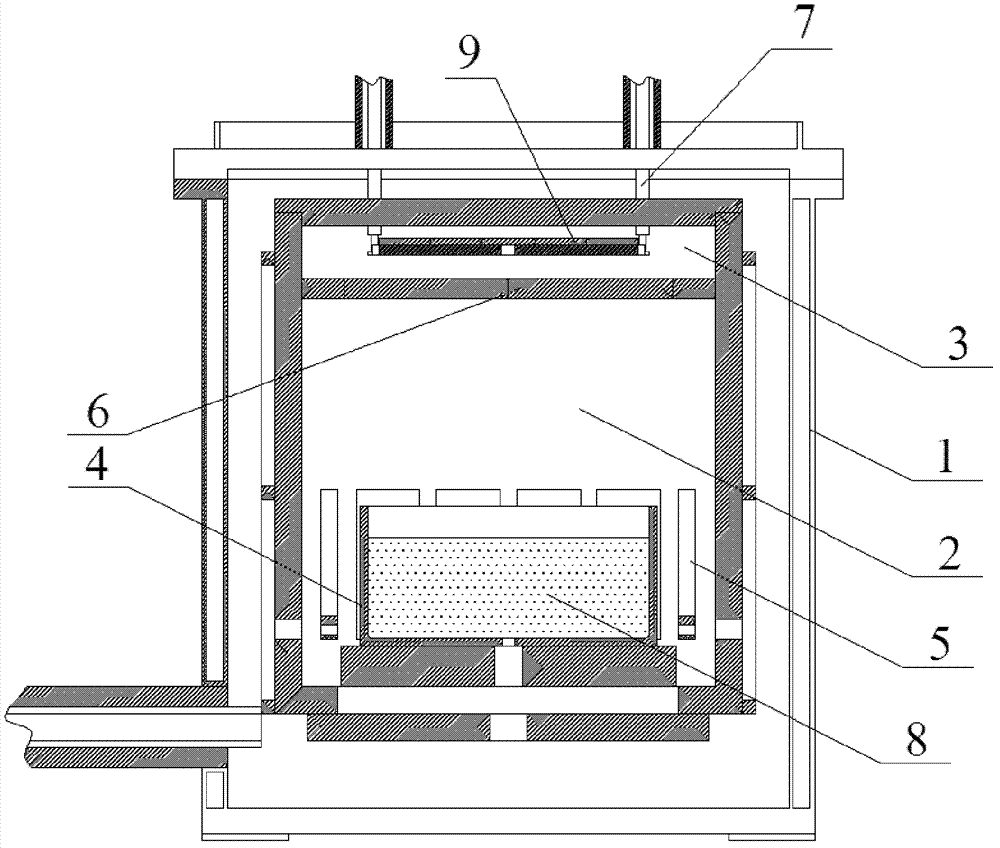

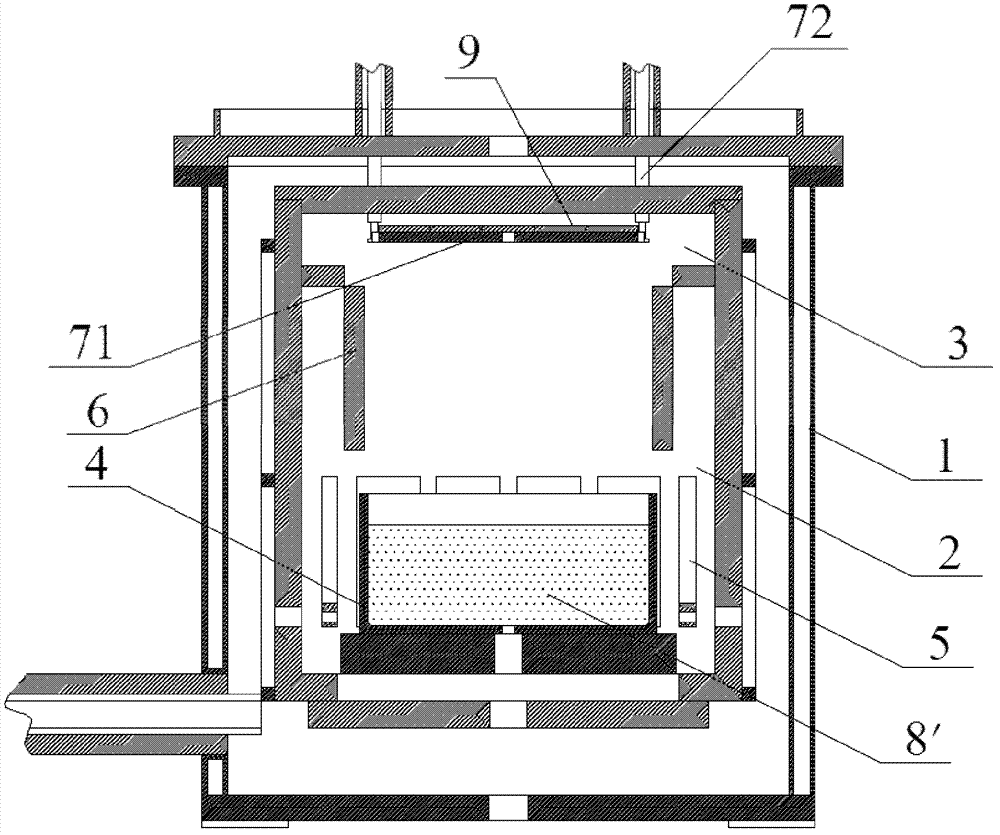

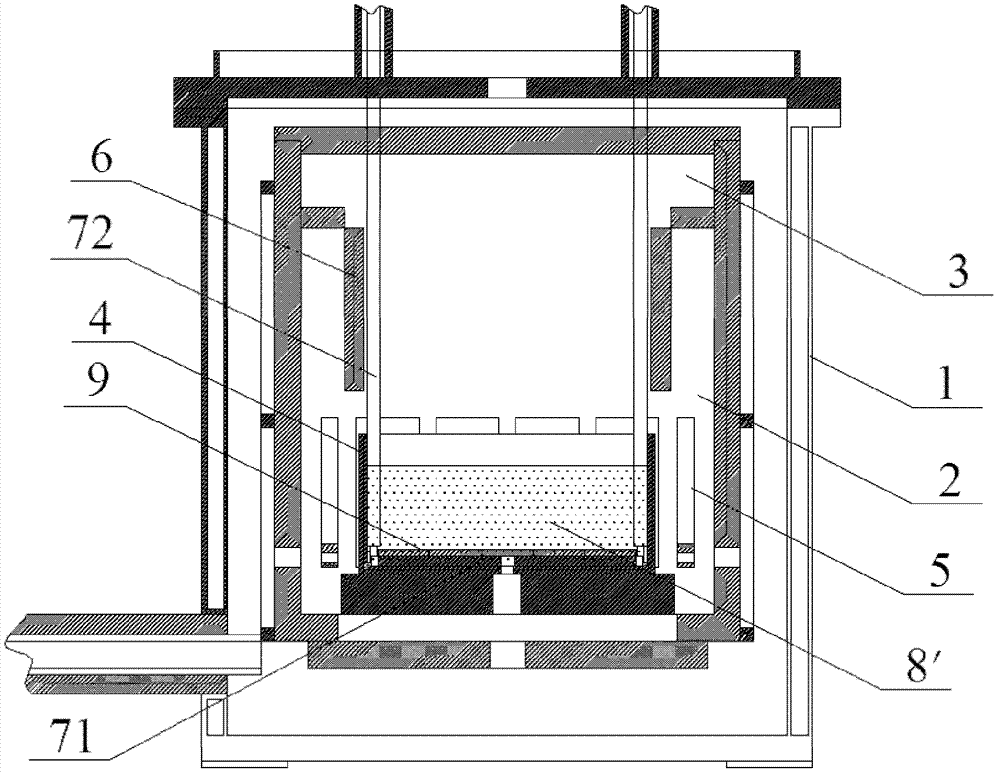

An organic solid purification device based on the principle of zone smelting

InactiveCN104907006BImprove accuracyIncrease the level of automationHeat treatmentsAutomatic controlRing device

The invention relates to an organic solid purification device based on a zone melting principle. The device comprises a base (1), a lead screw (2), a sliding block (3), a stepping motor (4), a motion controller, a metal contact (5), a heating ring device (6), a test tube (7), a test tube fixing frame (8), a vacuuming device, two proximity switches (9), and at least one guide rail (10). Based on the technical scheme disclosed by the invention, the hardware modules are connected, so that the organic solid purification device based on the zone melting principle is formed; based on a zone melting technology, the organic solid purification device is used for solving the problems that the structure is complex, the size is large, the reliability is low, the efficiency is low, and the automation level is low in the prior art; an advanced automation control technology is adopted, so that the device has the advantages that the automation level is relatively high, the reliability is high and the operation is easy, and can be used for completing the purification of a small quantity of organic solids and effectively improving the accuracy of experimental results of purification of organic matter in labs.

Owner:NANJING UNIV OF POSTS & TELECOMM

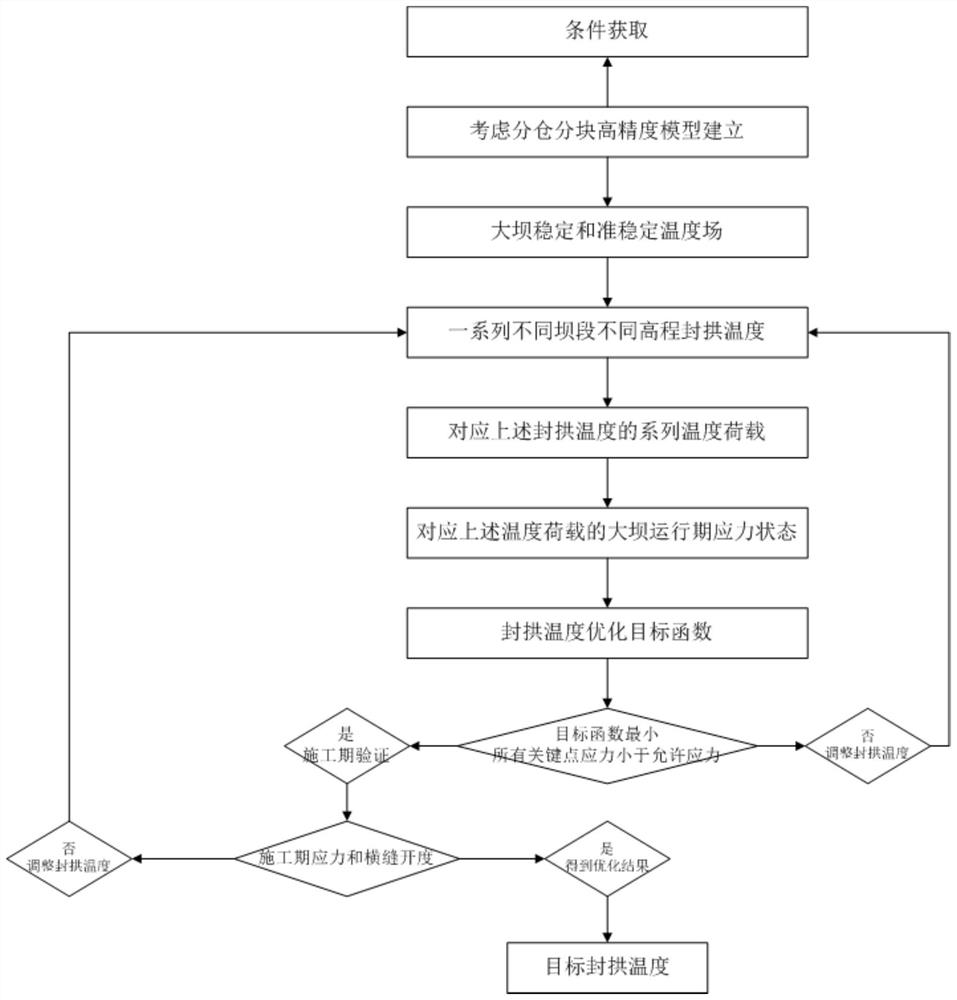

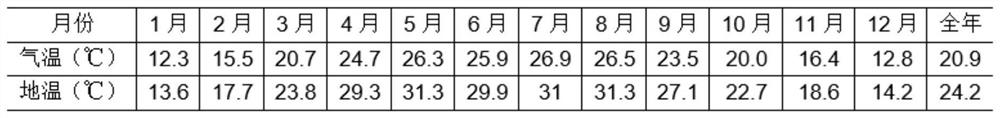

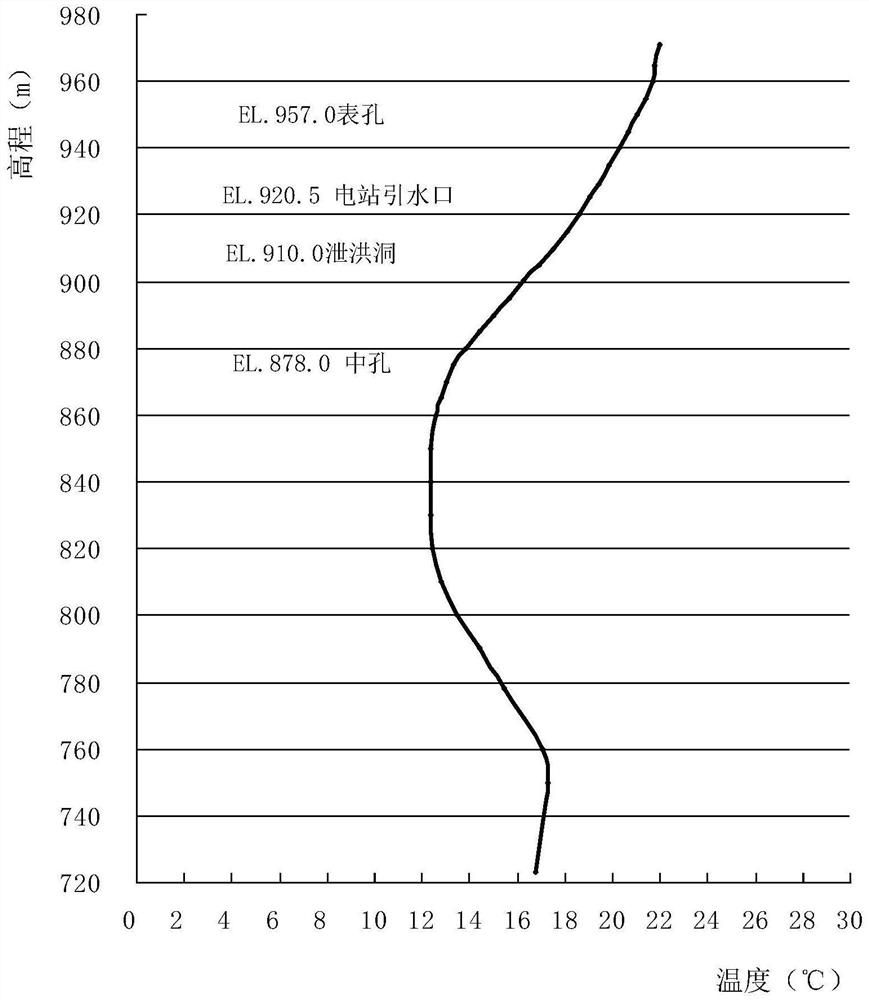

Arch sealing temperature optimization method suitable for intelligent water supply

PendingCN114239118ASafe from stressReduce the difficulty of temperature controlGeometric CADDesign optimisation/simulationTemperature controlCrack resistance

The invention provides an arch sealing temperature optimization method suitable for intelligent water supply. The arch sealing temperature optimization method comprises the steps that an arch dam grid model reflecting dam bin block characteristics is established; calculating by adopting a numerical simulation method to obtain a stable temperature field and a quasi-stable temperature field of the arch dam under a control water level condition; the arch sealing temperature is determined according to different elevation partitions of different dam sections; calculating a temperature load initial value in an operation period; drawing up different elevation partition arch sealing temperature coefficients of different dam sections, and adjusting each elevation arch sealing temperature value of each dam section; calculating by adopting a numerical simulation method to obtain a group of dam stress fields; establishing an arch sealing temperature optimization objective function; when the target function value is minimum, the optimal solution in the selected working condition is obtained; carrying out simulation on the whole process of dam construction to obtain the crack resistance safety and the transverse joint opening condition in the dam concrete construction period; and when the anti-cracking safety of dam concrete meets the conventional requirement and the opening degree of the transverse joint before grouting meets the requirement, the arch sealing temperature is the final arch sealing temperature. Accurate control over the arch sealing temperature is achieved, and the temperature control difficulty is lowered.

Owner:CHINA INST OF WATER RESOURCES & HYDROPOWER RES +1

Application method and preparation method of a kind of bacteriostatic microbial fermentation agent

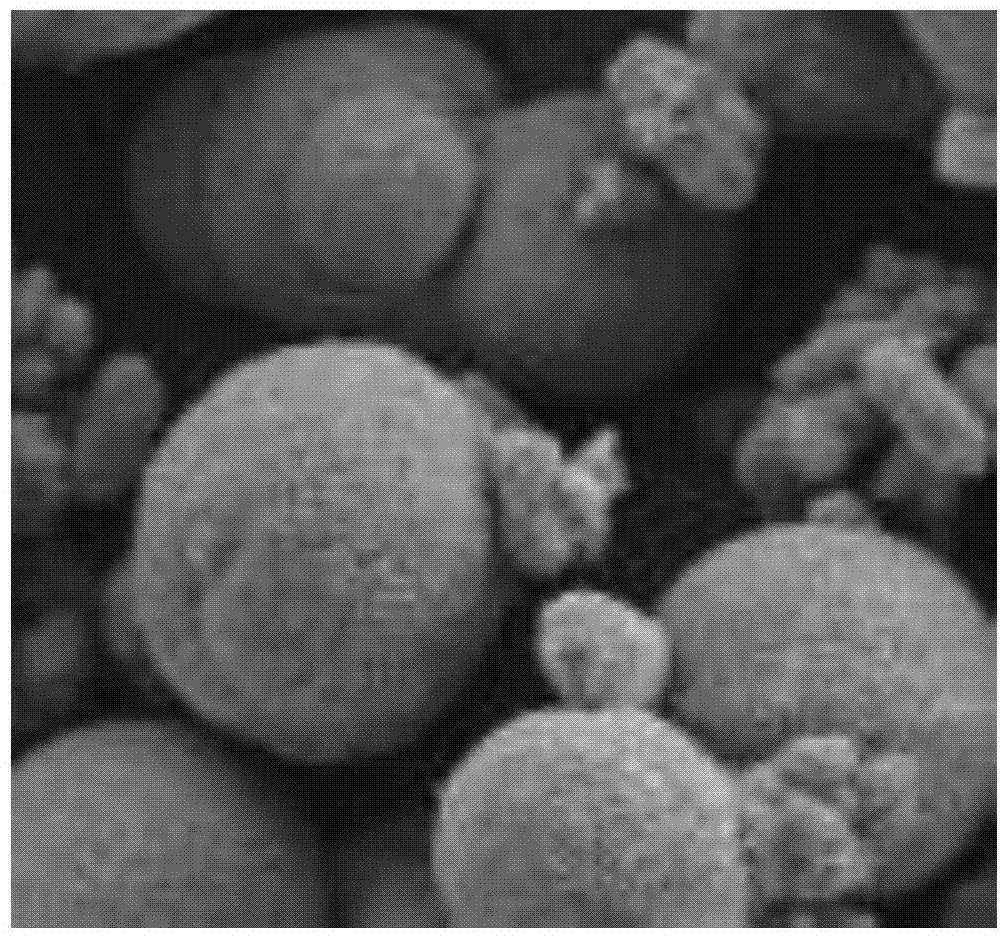

ActiveCN108546661BGood antibacterial effectImprove securityFungiBacteriaBiotechnologyBacillus licheniformis

The invention belongs to the technical field of microorganisms, and in particular relates to an application method of a bacteriostatic microbial starter and a preparation method thereof. The bacteriostatic type microbial fermentation agent contains Bacillus pumilus, Bacillus licheniformis, Saccharomyces bradis, Enterococcus faecium, Streptococcus thermophilus and Lactobacillus acidophilus, and the number of live bacteria is 1.05×10 10 ~1.5×10 10 cfu / g. After the fermented agent prepared by the present invention is used for fermentation, antibacterial substances are produced in the fermented feed, and the fermented bacteria themselves also have antibacterial effects, which can realize the purpose of antibiotic substitutes, and the fermented agent of the present invention can improve the utilization rate of feed materials , promote animal growth, can ferment and improve the nutritional value of low-value agricultural and sideline products, and alleviate the problem of human and livestock competition for food.

Owner:湖北华大瑞尔科技有限公司

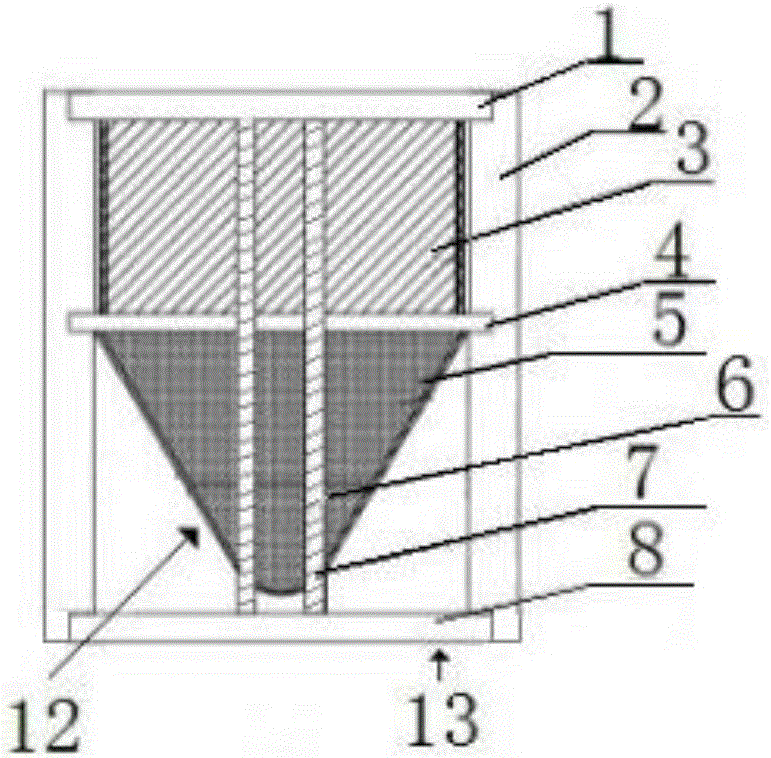

Compound steel base pouring tank

ActiveCN106245648AShorten the construction periodReduce the number of liftingFoundation engineeringEconomic benefitsEngineering

The invention discloses a compound steel base pouring tank. The compound steel base pouring tank comprises a tank body structure system, a hanging tank supporting and connecting system, a conical body upper end baffle and angle iron. The tank body structure system comprises a barrel, a conical body and the conical body upper end baffle. The hanging tank supporting and connecting system comprises a supporting frame, an upper ring beam, a middle ring beam, a lower ring beam, a box iron support, buffer sleepers, bolts and the angle iron. The barrel is made from rubber or other substitute materials with the specific gravity being smaller than that of steel. The supporting frame, the upper ring beam, the middle ring beam and the lower ring beam are made from titanium alloy or other substitute materials with the specific gravity being smaller than that of steel according to requirements. The defects that in the prior art, a tank body is high in self weight, the single tank hoisting capacity is poor, the construction period is long, and the construction quality is not ensured are overcome. The compound steel base pouring tank has the advantages of being low in hoisting tank body structure self weight, short in construction period, safe in equipment operation and high in economic benefits.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

Synthetic steel plastic tank

ActiveCN106245648BReduce the weight of the structureLose weightFoundation engineeringEconomic benefitsTitanium alloy

The invention discloses a plastic tank with a synthetic steel seat, which comprises a tank body structure system, a tank hanging support connection system, a baffle plate at the upper end of a cone, and an angle iron; the tank body structure system includes a cylinder body, a cone body, and the cone body The upper end baffle; the supporting connection system of the hanging tank includes a support frame, an upper ring beam, a middle ring beam, a lower ring beam, a channel steel bracket, a buffer sleeper, bolts, and the angle iron; the cylinder can be made of rubber or Made of other alternative materials whose specific gravity is lower than steel; the support frame, the upper ring beam, the middle ring beam, and the lower ring beam are made of titanium alloy or other alternative materials whose specific gravity is lower than steel. It overcomes the shortcomings of the prior art that the tank body has a large dead weight, low single-tank lifting capacity, long construction period, and unguaranteed construction quality; it has the advantages of light weight of the hanging tank body structure, short construction period, safe operation of equipment, and high economic benefits The advantages.

Owner:CHANGJIANG SURVEY PLANNING DESIGN & RES

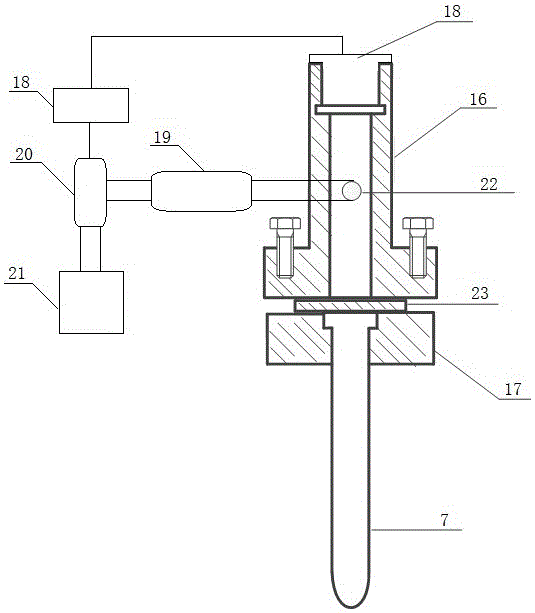

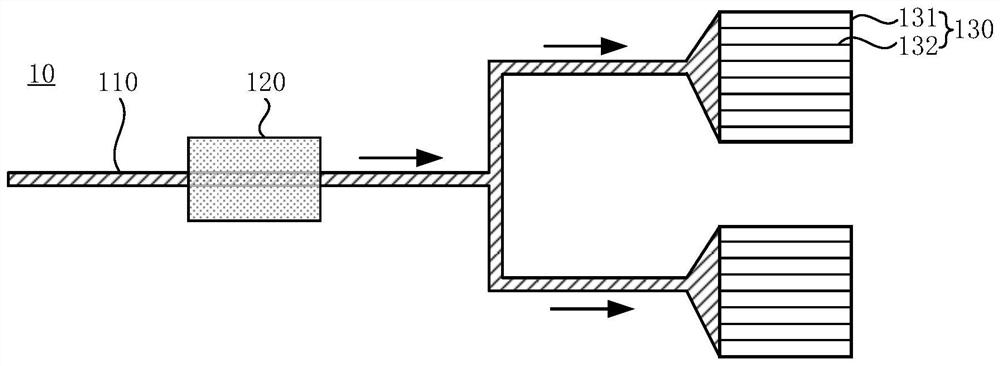

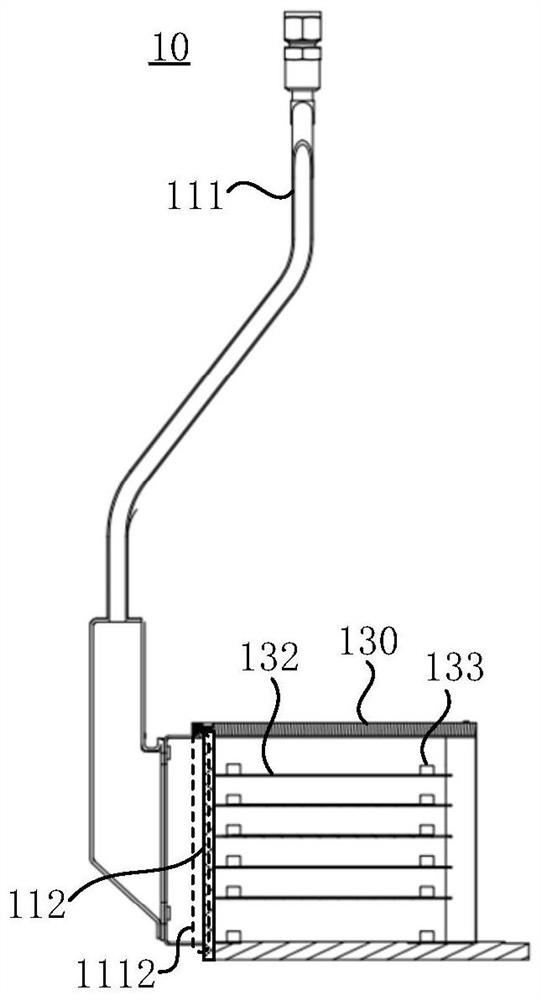

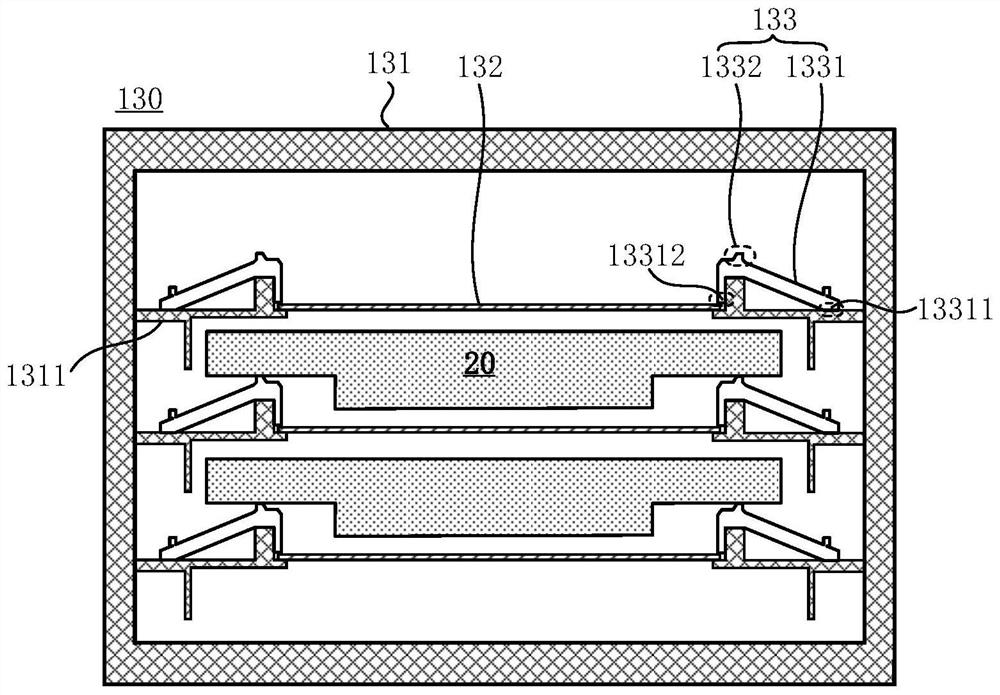

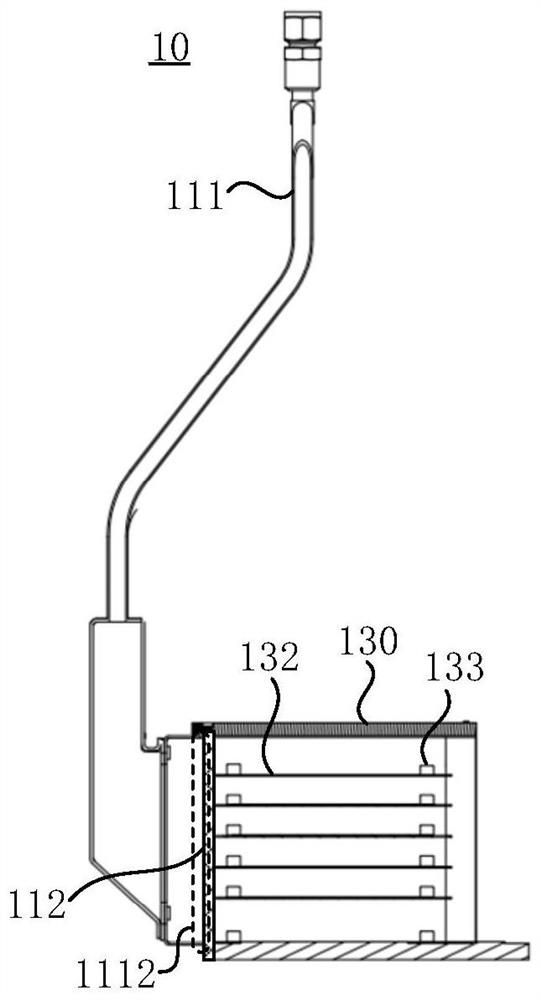

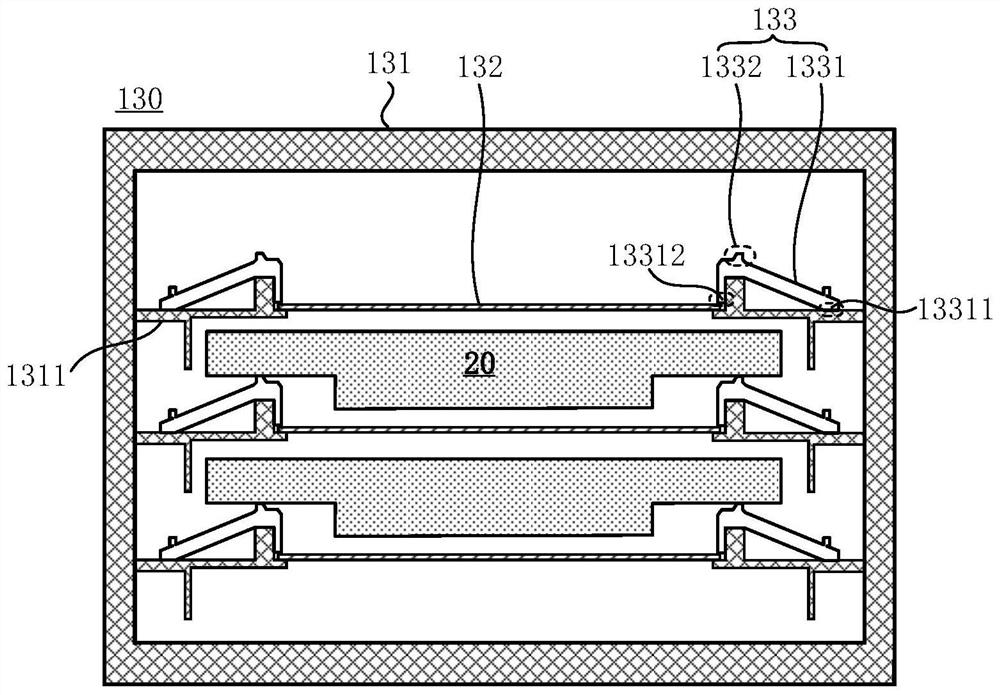

Mask plate temperature control device and mask exposure device

ActiveCN111948907AReduce the difficulty of temperature controlPromote circulationPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsEngineering

The invention discloses a mask plate temperature control device and a mask exposure device. The mask plate temperature control device comprises a gas temperature control unit, a gas conveying unit anda mask storage unit, wherein the gas conveying unit is used for conveying gas bath gas to the mask storage unit, and the gas temperature control unit is used for adjusting the temperature change range of the gas bath gas conveyed to the mask storage unit by the gas conveying unit to a preset temperature range; the mask storage unit comprises a plate frame main body and partition plates, the partition plates are fixed in the plate frame main body, a containing space is formed between every two adjacent partition plates, and the containing spaces are used for containing mask plates. According to the technical scheme, the temperature control difficulty of the mask plate can be reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Mask plate temperature control device and mask exposure device

ActiveCN111948907BReduce the difficulty of temperature controlPromote circulationPhotomechanical exposure apparatusMicrolithography exposure apparatusTemperature controlElectrical and Electronics engineering

The invention discloses a mask plate temperature control device and a mask exposure device. The mask plate temperature control device includes: a gas temperature control unit, a gas delivery unit, and a mask storage unit; the gas delivery unit is used to deliver gas bath gas to the mask storage unit, and the gas temperature control unit is used to The temperature variation range of the air bath gas transported by the gas delivery unit to the mask storage unit is adjusted to a preset temperature range; wherein, the mask storage unit includes a frame main body and a partition, and the partition is fixed on In the frame main body, an accommodating space is formed between two adjacent partitions, and the accommodating space is used for placing a mask. The technical scheme of the invention can reduce the difficulty of controlling the temperature of the mask plate.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

Reconfigurable optical add-drop multiplexer structure for realizing 16 channels with multiple orders

InactiveCN101552648BImprove response rateReduce the difficulty of temperature controlWavelength-division multiplex systemsTemperature controlFrequency spectrum

The invention discloses a reconfigurable optical add-drop multiplexer (an ROADM structure) for realizing 16 channels with multiple orders. The ROADM structure comprises an input part, a first-order filtration area, a second-order filtration area, a local download area, a combiner and an output part which are connected through nanometer wire waveguides. The ROADM structure has a certain width by utilizing the free spectral width of a micro-ring resonator and filters a plurality of paths of incident wavelengths with respective orders so as to ensure that the wavelength number in each download waveguide is reduced progressively and finally realize the single wavelength download in each output port, thereby reducing the temperature control difficulty and improving the response speed of devices.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

A Czochralski method single crystal silicon growth furnace

ActiveCN111826709BLight in massAvoid thermal unevennessBy pulling from meltCrystallographyTemperature control

The invention relates to the technical field of Czochralski monocrystalline silicon, and discloses a Czochralski monocrystalline silicon growth furnace, which includes a fixed box and a pyrometer. A heating element is fixedly installed on the inner wall of cylinder one, and a seed crystal is fixedly installed on the top right side of the fixed box. Through the setting of the growth chamber, the melting of polysilicon is separated from the place where the single crystal silicon body is pulled, and the melting of polysilicon through the quartz crucible to form a melt provides raw materials for pulling the single crystal silicon body inside the growth chamber, avoiding The uneven thermal field in the quartz crucible reduces the quality of the single crystal silicon body, ensures that the temperature of the growth interface in the growth chamber can be kept within a certain range, and reduces the difficulty of temperature control. At the same time, the setting of the quartz crucible and the growth chamber ensures sufficient raw materials , and through the setting of the rotating device, the number of monocrystalline silicon bodies pulled at one time is increased, and the production efficiency is increased.

Owner:杭州飞宇磁电器材有限公司

Quasi monocrystalline silicon casting device and method

InactiveCN103194794ASimple structureLow costPolycrystalline material growthFrom frozen solutionsIngotSeed crystal

The invention relates to a quasi monocrystalline silicon casting device. The device comprises a casting chamber and a seed crystal storage chamber arranged in the shell, an insulation door arranged between the seed crystal storage chamber and the casting chamber, and a seed crystal addition device capable of moving the seed crystal from the storage chamber through the insulation door to a crucible in the casting chamber. The invention also relates to a quasi monocrystalline silicon casting using the device. The method is as below: first heating the crucible and silicon material therein by a heating device; completely melting the silicon raw material into molten silicon, and controlling temperature to a molten silicon state before crystallization; moving the seed crystal from the seed crystal storage to the casting chamber by the crystal addition device; and growing crystal to form a silicon ingot. The quasi monocrystalline silicon casting device and method provided by the invention greatly reduce the difficulty in controlling temperature, and avoid the problems in prior art, such as difficulty in accurate control of crucible bottom temperature and complete melting or failure in melting of the seed crystal, thereby improving production efficiency and effectively guaranteeing the rate of finished products.

Owner:徐传兴

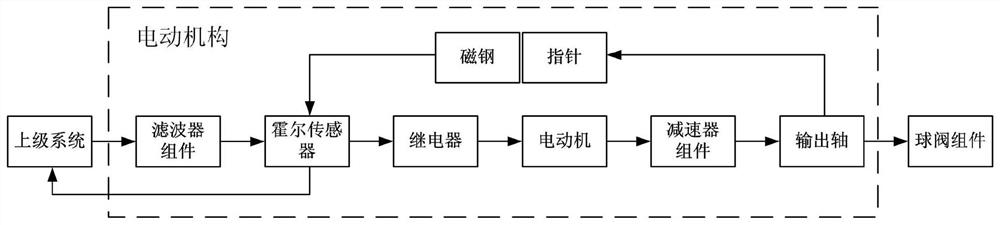

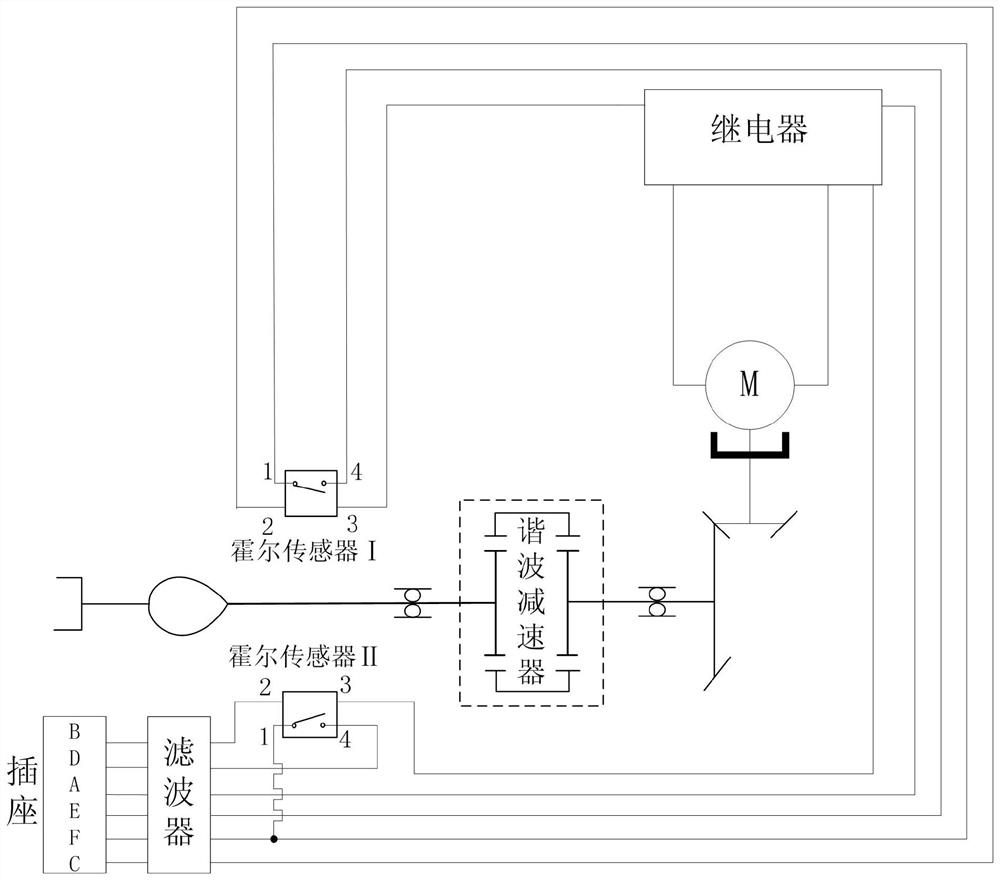

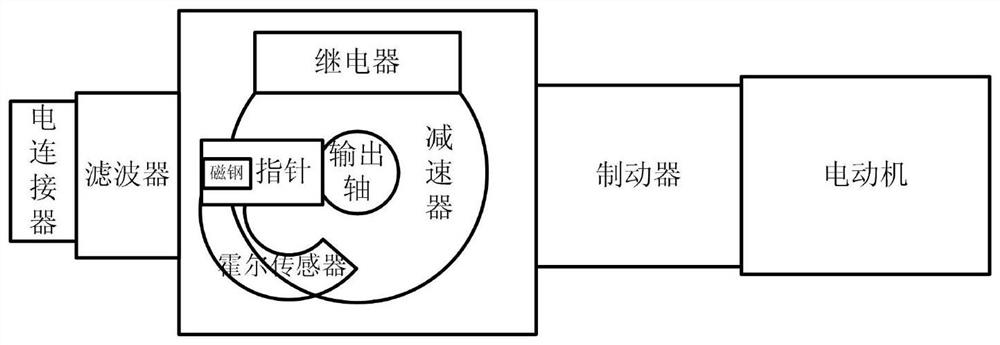

Electric mechanism for aviation fuel valve

PendingCN113864508AReduce usageGuaranteed normal operationOperating means/releasing devices for valvesAviationReduction drive

The invention provides an electric mechanism for an aviation fuel valve, and belongs to the technical field of valve adjustment control. The electric mechanism comprises a motor, a shell, a speed reducer, magnetic steel, a pointer, a Hall sensor, a relay and an electric connector; the output end of the motor is connected with the speed reducer; the pointer is coaxially fixed with the output end of the speed reducer; the magnetic steel is fixedly connected with the pointer and coaxially rotates; the Hall sensor is arranged along the movement track of the pointer; and the electric connector is connected with a power supply, a superior system of the host and the relay. After the electric mechanism for the aviation fuel valve receives a specified position signal of a superior system, the current shaft locking position of an output shaft is judged according to position signal combinations of Hall sensors at different positions, then the current opening and closing position of a ball valve assembly is judged, and the rotating direction of a motor is judged after the current opening and closing position is compared with a given position, and the reversing operation of the motor is realized through the relay. Compared with the prior art, the invention has the advantages of high reliability and strong anti-interference capability, and meets the requirements of reliability and long endurance of aviation products.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS

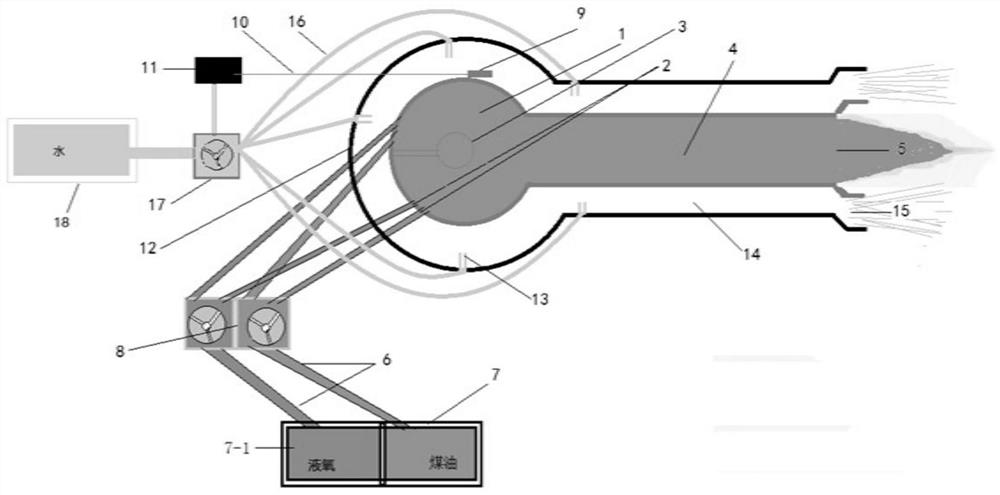

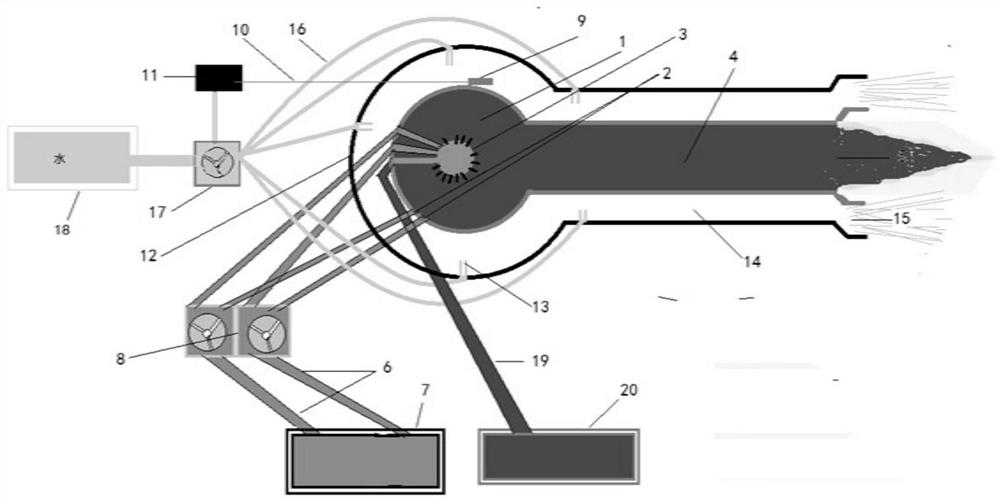

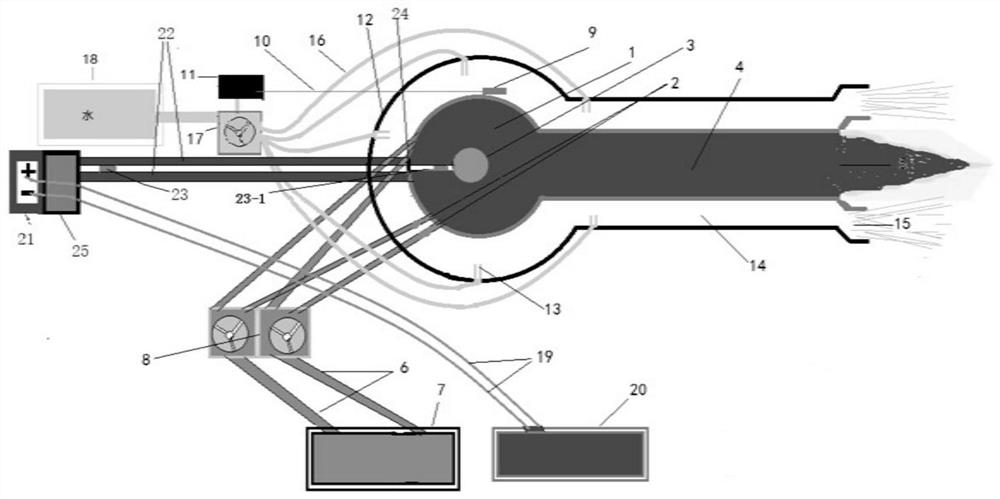

A cooling-to-energy aerospace engine

ActiveCN113513427BReduce the difficulty of temperature controlGuaranteed structural strengthTurbine/propulsion engine coolingGas turbine plantsCombustion chamberWorking fluid

The invention discloses a cooling-to-energy aerospace engine. There is an ignition or energy emission device in an energy chamber (combustion chamber) for igniting or imparting energy to a working medium; small holes are distributed on the wall of the energy chamber, and the small holes pass through devices such as conduits. Input working fluid; the energy chamber is connected with the inner nozzle through the inner nozzle; the outer wall of the energy chamber and the outer wall of the inner nozzle have temperature detectors, and the temperature signal line is connected with the temperature controller; a cooling cover is installed on the energy chamber and the inner nozzle, And there is a cavity between them to form an outer spray pipe and an outer spray port; the inner wall of the cooling cover is distributed with small hole spray pipes, one end of which is connected with a water pressure regulator and a constant temperature water tank with a cooling water pipe. The cooling cover and piping and other devices convert heat dissipation into propulsion energy, increase the engine structure and material strength, create conditions for the use of new technology and high-energy working fluid, and greatly increase the energy density and working temperature of the working medium in the energy chamber. Increase the specific impulse, can run for a long time, repeated use, suitable for various space tasks.

Owner:曹建峰

Tail gas treatment method and tail gas treatment device of vanadium-base alloy rotary kiln production line and application of tail gas treatment device

InactiveCN110763037AReduce the probability of accidental releasesAvoid the problem of not being able to enter the dust collection systemIncinerator apparatusWaste heat treatmentTemperature controlProduction line

The invention provides a tail gas treatment method and a tail gas treatment device of a vanadium-base alloy rotary kiln production line and application of the tail gas treatment device and relates tothe technical field of tail gas treatment. The tail gas treatment method of the vanadium-base alloy rotary kiln production line includes the step that temperature regulating, dust removing and combustion treatment are conducted on tail gas in sequence, wherein in temperature regulating, the temperature of tail gas is controlled to be 120 DEG C to 480 DEG C. The tail gas treated through the methodcan meet the environment-friendly requirement, in addition, system building investment and material losses are reduced, and the cost is better reduced.

Owner:盐边县向阳钒业有限公司

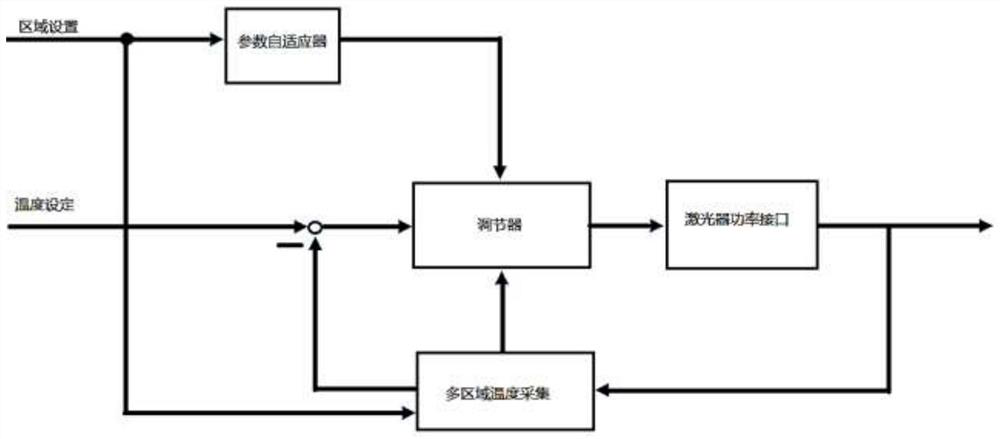

Temperature control method based on variable region dynamic temperature acquisition and data fusion

PendingCN112230693AQuick and accurate controlRealize dynamic temperature acquisitionTemperatue controlIr reflectionTemperature control

The invention relates to the technical field of temperature control, in particular to a temperature control method based on variable region dynamic temperature acquisition and data fusion. The methodcomprises the following steps: S1, reflecting infrared radiation on the surface of an object to a temperature measuring head of an infrared temperature measuring sensor through an infrared reflector capable of rotating at a high speed, enabling the infrared reflector to rotate at a high speed along a set movement path, measuring temperatures of different points on the surface of the object in realtime; and S2, grouping regions according to the minimum unit area, and realizing data fusion according to a method of calculating the average temperature on the unit area through Gaussian distribution. Regional information is added into an algorithm, data fusion is realized according to a method of calculating the average temperature on a unit area through Gaussian distribution, different response speeds are set according to parameters of a regional size self-adaptive regulator and regions with different surface connection sizes, and the power of a laser is regulated, therefore, the temperature of the local area of the surface of the measured object is rapidly, comprehensively and accurately controlled, the temperature control difficulty is reduced, and the temperature control accuracy isimproved.

Owner:WUHAN BO UNION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com