Mask plate temperature control device and mask exposure device

A technology of temperature control device and mask plate, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, optics, etc., can solve the problems of low heat conduction and heat transfer efficiency, difficult temperature control of mask plate, etc., and reduce the difficulty of temperature control , Improve the effect of temperature stabilization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

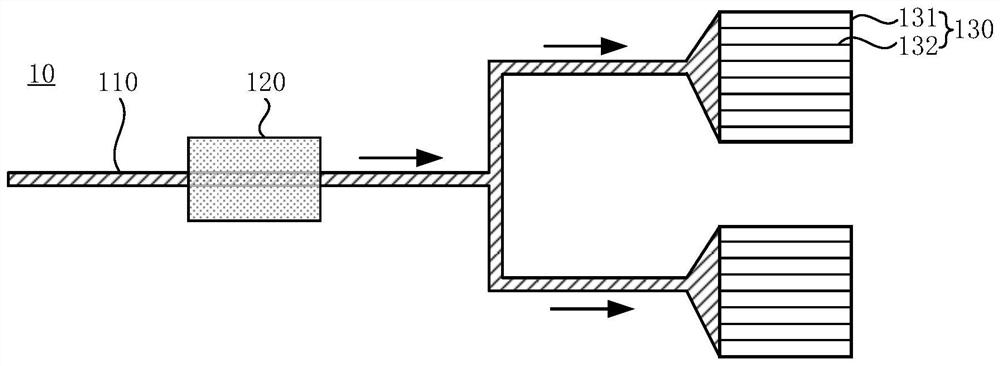

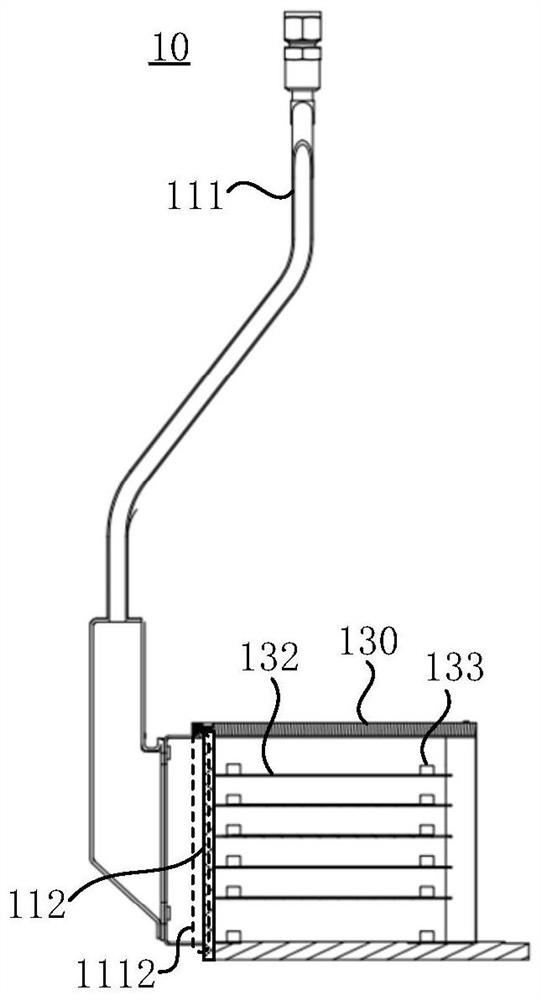

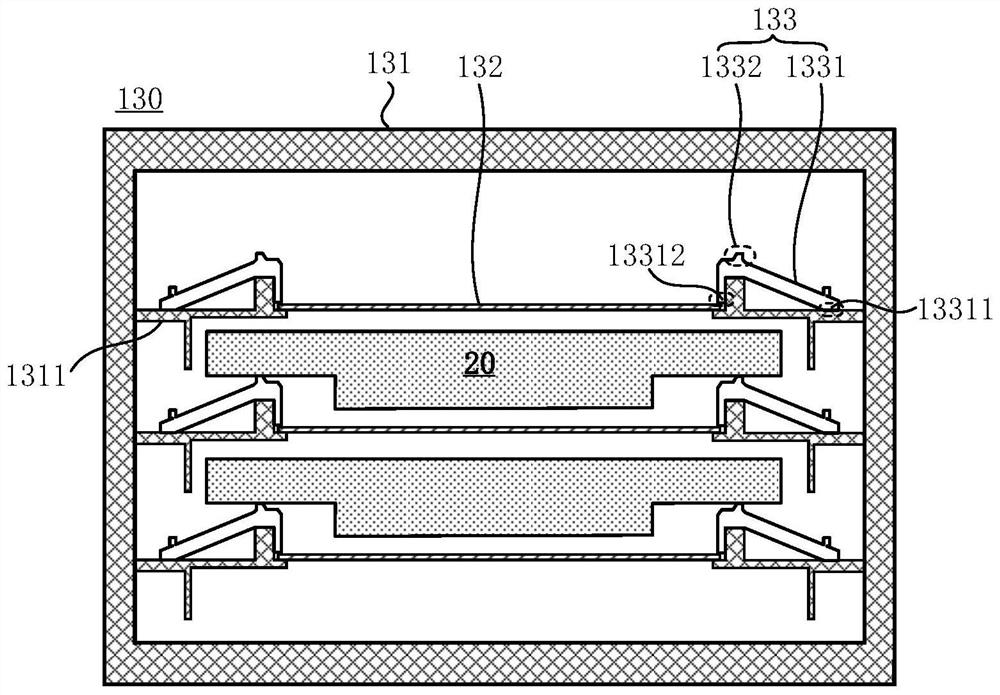

[0050] figure 1 It is a schematic structural diagram of a mask temperature control device provided by an embodiment of the present invention. Reference figure 1 , The mask temperature control device 10 includes: a gas delivery unit 110, a gas temperature control unit 120 and a mask storage unit 130; the gas delivery unit 110 is used to deliver a gas bath gas to the mask storage unit 130, and the gas temperature control unit 120 is used The temperature variation range of the gas bath gas transferred from the gas delivery unit 110 to the mask storage unit 130 is adjusted to a preset temperature range; wherein, the mask storage unit 130 includes a plate holder main body 131 and a partition 132, and the partition 132 is fixed on In the main body 131 of the plate holder, an accommodation space is formed between two adjacent partitions 132, and the accommodation space is used for placing the mask.

[0051] Wherein, the gas delivery unit 110 transmits the gas bath gas from the gas suppl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com