High-temperature water cooling device and method

A water-cooling device and water-cooling technology, applied in quenching devices, heat treatment equipment, manufacturing tools, etc., can solve the problems of small heat absorption, size and specification restrictions, laminar cooling cannot be realized, etc., and achieve the goal of preventing overcooling and high cooling speed Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

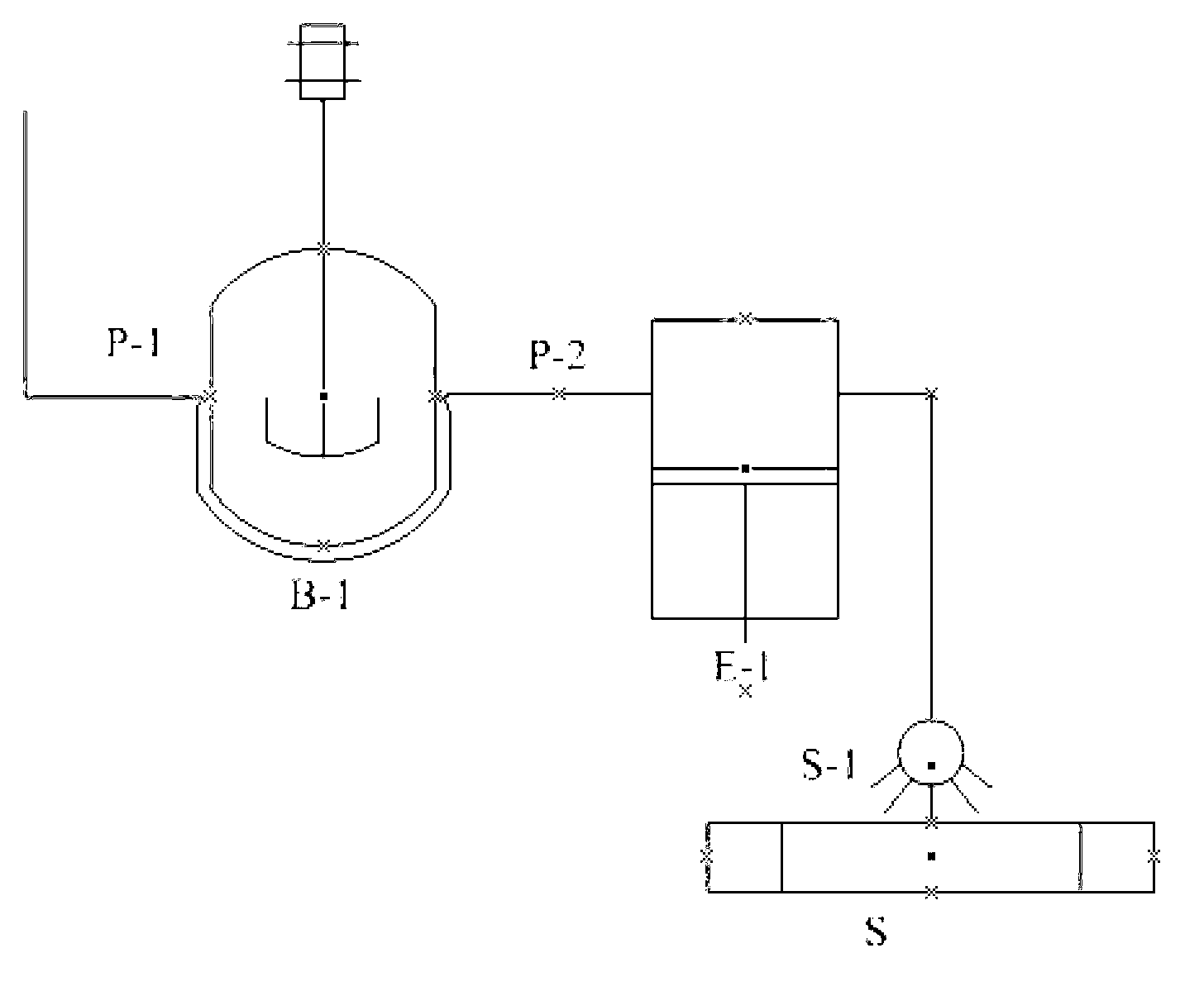

[0017] as attached figure 1 As shown, in this example, a steel plate with a thickness of 30mm and a temperature of 800°C is to be quenched to 180°C at the fastest possible cooling rate, and the temperature at the end of quenching needs to be controlled at 180°C without overcooling.

[0018] The device includes: an autoclave B-1, a water pump E-1 and a nozzle S-1, wherein the cooling water inlet P-1 is connected to the autoclave, the autoclave is connected to the water pump, and the water pump is connected to a high temperature and high pressure nozzle , There is also a stirring motor in the autoclave to ensure uniform temperature. All devices except P-1 can withstand a pressure of 30MPa and a temperature of 235°C.

[0019] The cooling process is detailed as follows:

[0020] Lead the cooling water (60°C, normal pressure) at the outlet of the continuous casting crystallizer into the autoclave and heat it to 180°C. At this time, the steam pressure in the autoclave reaches 1.003...

example 2

[0022] In this example, a steel plate with a thickness of 30 mm and a temperature of 800 °C is to be quenched to 190 °C at the fastest possible cooling rate, and the temperature at the end of quenching must be controlled at 190 °C without overcooling.

[0023] The device includes: an autoclave B-1, a water pump E-1 and a nozzle S-1, wherein the cooling water inlet P-1 is connected to the autoclave, the autoclave is connected to the water pump, and the water pump is connected to a high temperature and high pressure nozzle , There is also a stirring motor in the autoclave to ensure uniform temperature. All devices except P-1 can withstand a pressure of 30MPa and a temperature of 235°C.

[0024] The cooling process is detailed as follows:

[0025] Lead the cooling water (60°C, normal pressure) at the outlet of the continuous casting crystallizer into the autoclave and heat it to 190°C. At this time, the steam pressure in the autoclave reaches 1.256MPa, which is about 12.5 atmosph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com