Compound steel base pouring tank

A technology of plastic tanks and steel seats, which is applied in the field of concrete construction equipment, can solve problems such as the adverse impact on the quality of concrete pouring, the heavy weight of the concrete hanging tank body, and the impact on the efficiency of concrete lifting, so as to reduce the number of lifting and running times, and equipment The effect of improving the guarantee rate of safe operation and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention are clearer and easier to understand through the description.

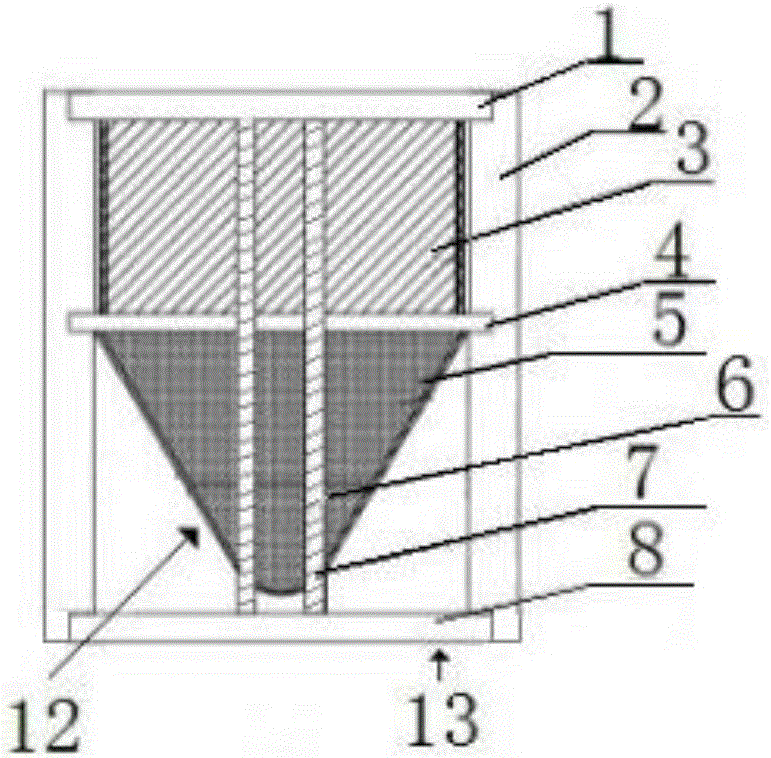

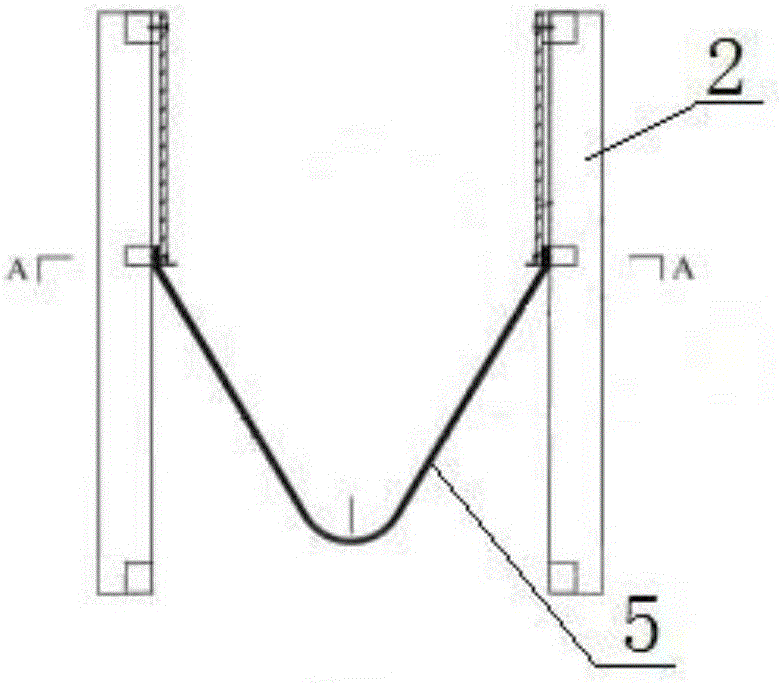

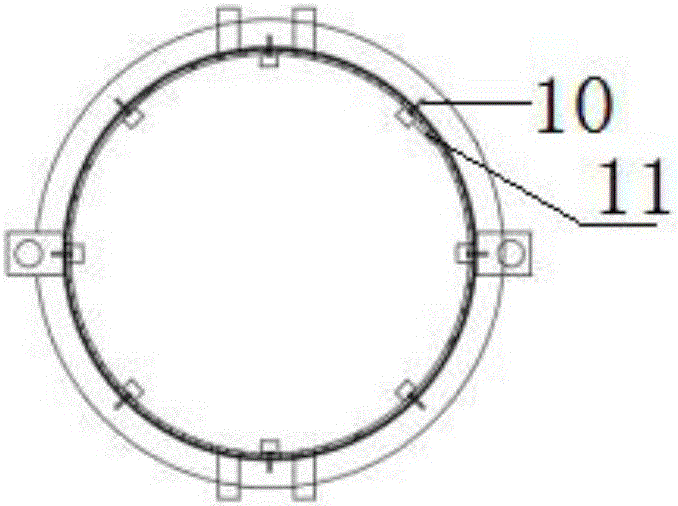

[0025] Referring to the accompanying drawings, it can be seen that the synthetic steel base plastic tank includes a tank body structure system 12, a hanging tank support connection system 13, a cone upper end baffle plate 9, and an angle iron 11; the tank body structure system 12 includes a cylinder body 3, a cone body 5 and the upper end baffle plate 9 of the cone; the hanging tank supporting connection system 13 includes a support frame 2, an upper ring beam 1, a middle ring beam 4, a lower ring beam 8, a channel steel bracket 6, a buffer sleeper 7, bolts 10 and The angle iron 11; the upper end of the cylinder 3 is either welded, or fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com