Laser with high power and high beam quality

A high beam and laser technology, applied in the field of lasers, can solve the problems of restricting the development of miniaturization and integration of lasers, increasing the cost and cycle of laser production, and increasing the length of the laser cavity, so as to promote the process of miniaturization and integration and improve the thermal lens effect. , the effect of reducing the difficulty of design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

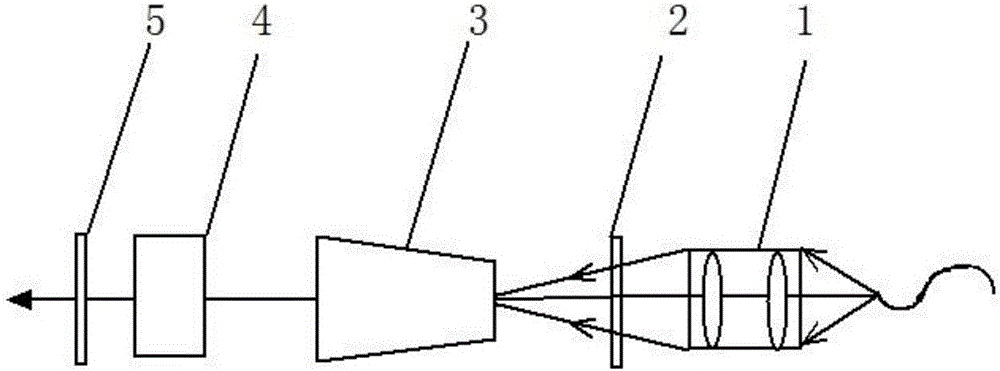

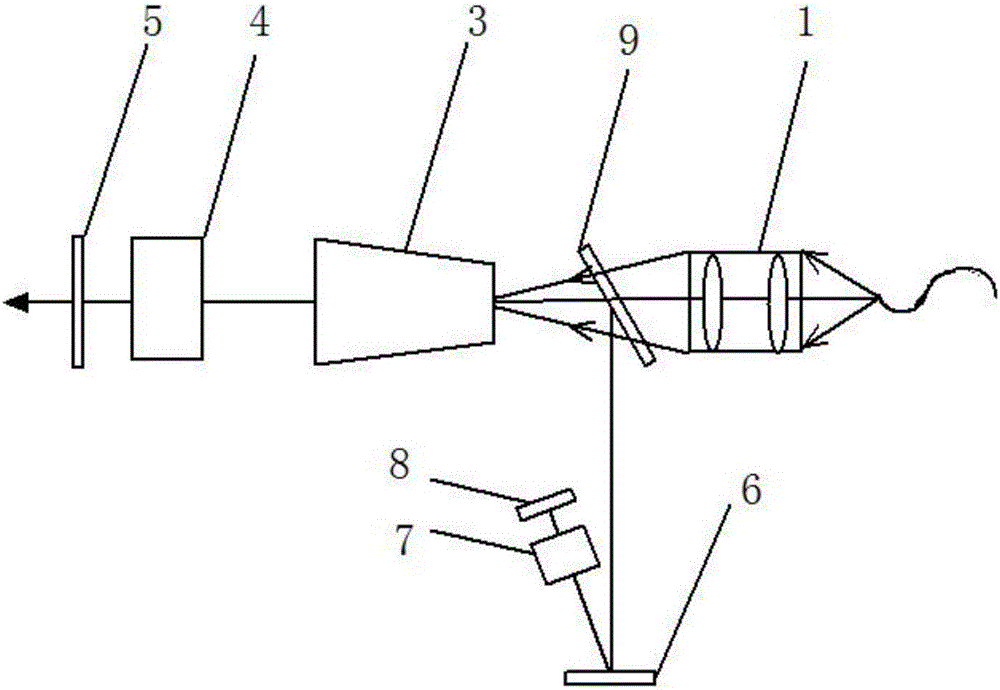

[0049] Such as image 3 As shown, it is a laser form based on the basic structure of the present invention. The 808nm pump light is emitted by the fiber coupling system 1 and focused on the 3Nd: YVO4 laser crystal 3; The fundamental frequency light is modulated by the acousto-optic Q-switching device 4 .

[0050] In this embodiment, the front cavity mirror 2 is a 45° total reflection mirror 9, which converts the straight cavity into a folded cavity; then uses the 0° HR1064HT532 lens 6 to fold the optical path, and forms a resonant cavity with the rear cavity mirror 8, and utilizes frequency doubling Crystal 7 doubles the frequency of 1064nm fundamental frequency light to 532nm green light, which is output by 0° HR1064HT532 lens 6 .

[0051] In this embodiment, due to the high beam quality and high energy density of the fundamental frequency light, the light-to-light conversion efficiency is improved and the loss is small. The finally obtained 532nm laser has narrow pulse widt...

Embodiment 2

[0053] Such as Figure 4 As shown, in this implementation, on the basis of the structure of [Example 2], a sum frequency crystal 9 is added in front of the frequency doubling crystal 7, the 0°HR1064HT532 lens 6 is replaced by a 0°HR1064&532HT355 lens 11, and the 1064nm light After frequency doubling and summing, 355nm ultraviolet light is obtained.

[0054] The ultraviolet light obtained in this embodiment has the advantages of short wavelength, easy focusing, high energy, and good mode, and is an ideal laser light source for micro-drilling and laser marking; this light source is used in ultra-high-density optical drives, precision material processing, optical printing, etc. Wide range of applications.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com