Biologically-fermented complete compound feed

A bio-fermentation and compound feed technology, applied in animal feed, animal feed, applications, etc., can solve the problems of difficult digestion and absorption of animals, single nutritional components, high cost, etc., and achieve high cost performance, good quality, and high absorption and utilization rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

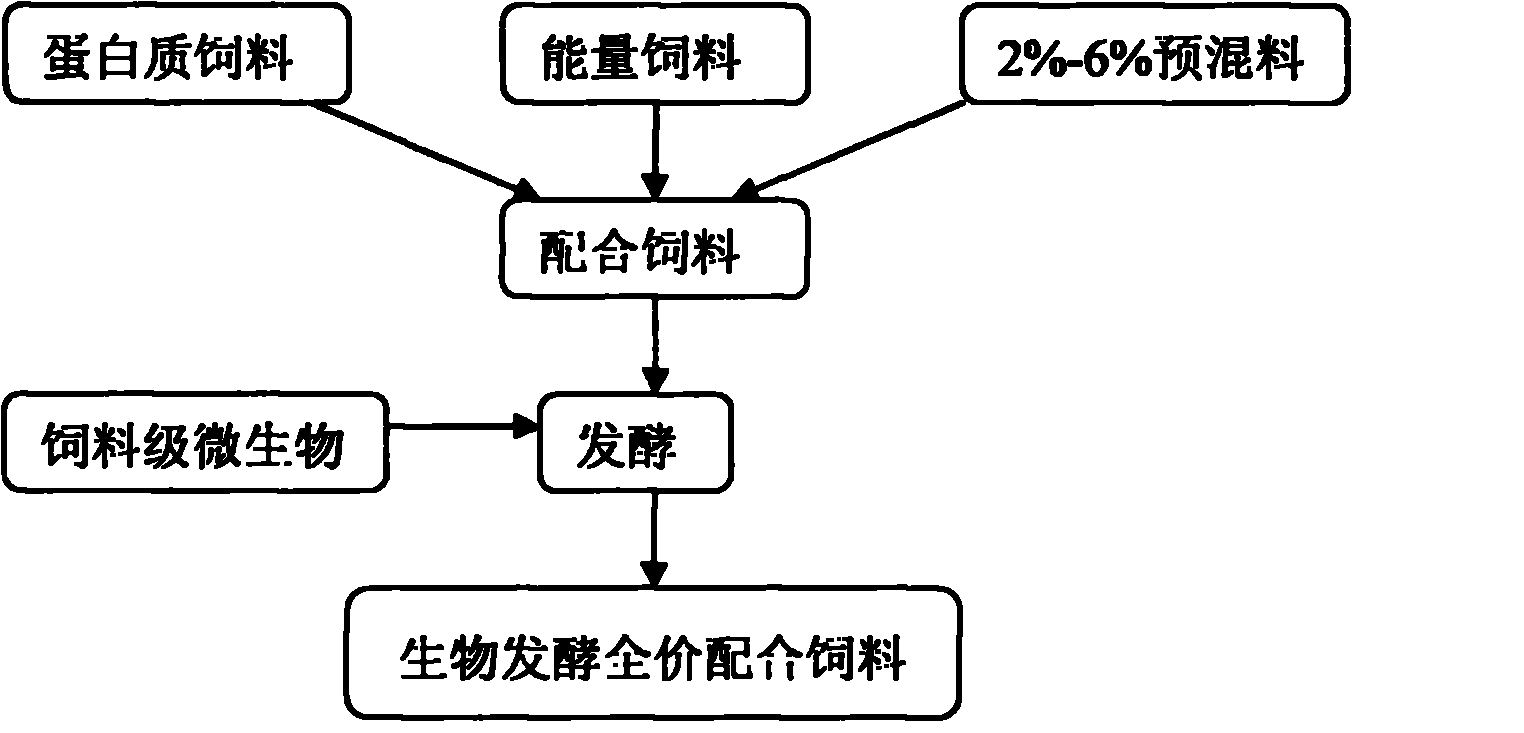

[0028] As shown in the attached figure, the two components of vegetable protein feed (soybean meal and cotton meal) and energy feed (corn) are fermented separately and then mixed together with the premix (vitamin) according to the needs of the livestock's survival or growth period made. The premix refers to the trace mineral compound premix, and the premix accounts for 2% of the total weight of the feed; the fermentation is by adding feed-grade microorganisms beneficial to the survival or growth period of the animals and livestock in the feed The biological fermentation carried out has a fermentation rate of 50%, and the fermented feed contains fermentation products and beneficial flora. The feed-grade microorganisms refer to one, two or several kinds of beneficial bacteria among bacteria, actinomycetes, fungi and rickettsia for feed.

Embodiment 2

[0030] As shown in the attached figure, the two components of protein feed (soybean meal, peanut meal and fish meal) and energy feed (rice and bran) are mixed and fermented together first, and then mixed with premix (trace mineral element compound) according to the living conditions of poultry. Or the growth period needs to be matched together. The premix refers to a vitamin premix, and the premix accounts for 4% of the total weight of the feed; the fermentation is by adding feed-grade microbial bacillus or bacillus beneficial to the survival or growth period of the animal and poultry in the feed The biological fermentation carried out by lactic acid bacteria, the fermentation rate is 70%, and the fermented feed contains fermentation products

[0031] substances and beneficial bacteria. Fermentation is carried out by adding feed-grade enzymes to the feed.

Embodiment 3

[0033] As shown in the figure, the three components of protein feed (rapeseed meal), energy feed (corn and wheat) and premix (trace mineral element compounds and vitamins) are combined according to the survival or growth period of aquatic animals. After fermentation. The premix refers to a compound premix, and the premix accounts for 6% of the total weight of the feed; the fermentation is achieved by adding feed-grade microbial yeast beneficial to the survival or growth period of the aquatic animals in the feed. The biological fermentation carried out has a fermentation rate of 90%, and the fermented feed contains fermentation products and beneficial flora.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com