Secondary-fermentation black tea as well as production method and production device thereof

A technology of secondary fermentation and production method, applied in the field of tea, can solve the problems of thrombus formation, product inhomogeneity, and high blood lipid content, and achieve the effects of less stimulation, good taste and more times.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

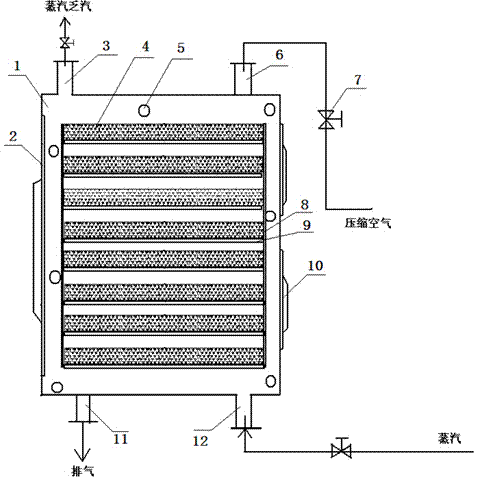

Image

Examples

Embodiment 1

[0048] 1、 For one fermentation, the fresh tea leaves of Yunnan big-leaf tea picked from the tree are removed from the yellow leaves, branches and miscellaneous grasses, and the hot air tea greening machine is used. After 10 minutes, the green leaves should be cooled immediately after taking off the machine. It is best to use a fan to cool them down, so that they can quickly disperse water, reduce the temperature of the leaves, and prevent the leaves from turning yellow and producing watery smell. After finishing, the water content of the tea leaves is 50-70% and can be kneaded with a kneading machine. The degree of kneading should be curled into strips and uniform. The initial stage of kneading must be gently kneaded, and then gradually strengthened. The total kneading time is 5 -10 minutes. After rolling, the block should be quickly disassembled and dried in time. After drying, the moisture content of the tea leaves is 88-94%. Then pile up, stack the tea leaves, and then sp...

Embodiment 2

[0051] 1. For one fermentation, the mixed tea leaves picked from the tree can be fresh tea leaves of several kinds of tea leaves, yellow leaves, branches and weeds are removed, and the hot air tea greening machine is used to control the pot temperature in the range of 220°C to 280°C Within 7-10 minutes, the greening time is 7-10 minutes. After the greening leaves are off the machine, they should be cooled immediately. It is best to use a fan to cool them down, so that they can quickly disperse moisture, reduce the temperature of the leaves, and prevent the leaves from turning yellow and producing watery smell. After finishing, the water content of the tea leaves is 50-60%, which can be kneaded with a kneading machine. The degree of kneading should be curled into strips and uniform. The initial stage of kneading must be lightly kneaded, and then gradually strengthened. The total kneading time is 7 -10 minutes. After kneading, the block should be quickly disassembled and dried i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com