Spheroidizing annealing method for carbon tool steel roller hearth type annealing furnace for automobile

A technology of carbon tool steel and spheroidizing annealing, which is applied in the field of metallurgy, can solve the problems of high temperature setting in the heating zone, low fan frequency, and difficult control, etc., to achieve improved control accuracy, improved production efficiency, and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

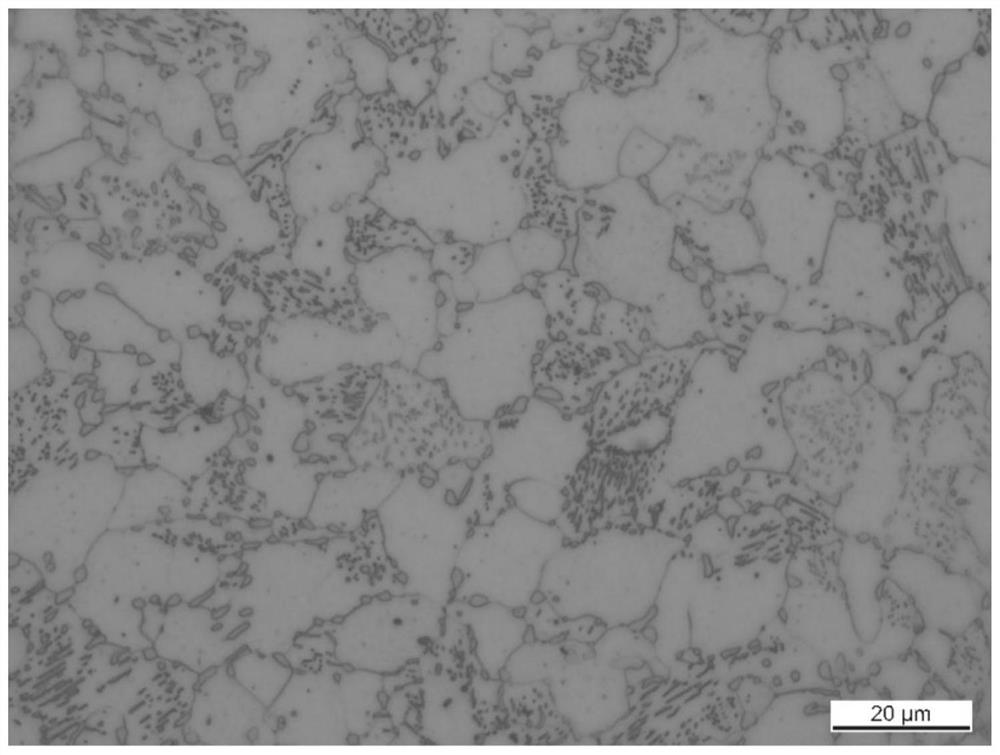

[0016] This embodiment provides a spheroidizing annealing method for carbon tool steel (C35R) for automobiles in a roller hearth annealing furnace, which is characterized in that the following methods are used to ensure that the spheroidizing rate of the steel out of the furnace reaches more than 80%:

[0017] The roller hearth annealing furnace adopts a continuous furnace, and the continuous furnace is divided into 13 heating sections from the beginning to the end. Heating section 730℃±5℃, 4th heating section 730℃±5℃, 5th heating section 730℃±5℃, 6th heating section 730℃±5℃, 7th heating section 730℃±5℃, 8th heating section Heating section 730°C±3°C, 9th heating section 720°C±3°C, 10th heating section 710°C±3°C, 11th heating section 700°C±3°C, 12th heating section 670°C±3°C, 13th heating section The heating section is 630°C±3°C. Among them, the 1st-3rd section is a heating section, and the heating time is 2.9 hours; the 4th-8th section is a heat preservation section, and the ...

Embodiment 2

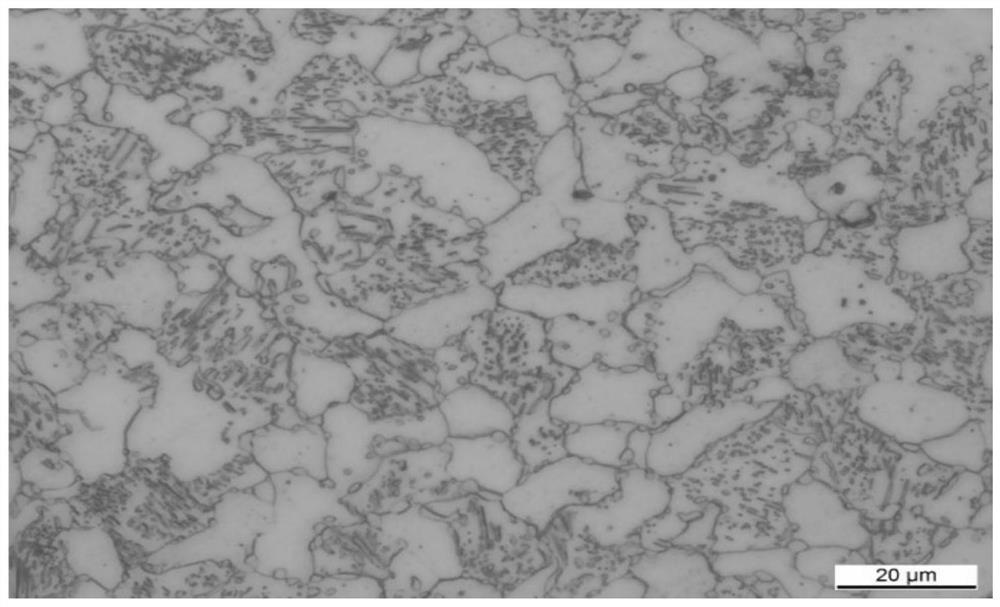

[0022] This embodiment provides a method for spheroidizing annealing of carbon tool steel for automobiles in a roller hearth annealing furnace, which is characterized in that the following methods are used to ensure that the spheroidizing rate of the steel produced from the furnace reaches more than 80%:

[0023] The roller hearth annealing furnace adopts a continuous furnace, and the continuous furnace is divided into 13 heating sections from the beginning to the end. Heating section 730℃±5℃, 4th heating section 730℃±5℃, 5th heating section 730℃±5℃, 6th heating section 730℃±5℃, 7th heating section 730℃±5℃, 8th heating section Heating section 730°C±3°C, 9th heating section 720°C±3°C, 10th heating section 710°C±3°C, 11th heating section 700°C±3°C, 12th heating section 670°C±3°C, 13th heating section The heating section is 630°C±3°C. Among them, the 1st-3rd section is a heating section, and the heating time is 3.2 hours; the 4th-8th section is a heat preservation section, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| spheroidization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com