An organic solid purification device based on the principle of zone smelting

An organic solid, purification device technology, applied in heat treatment, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of low automation level, low reliability, complex structure, etc., and achieve high automation level and high reliability. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

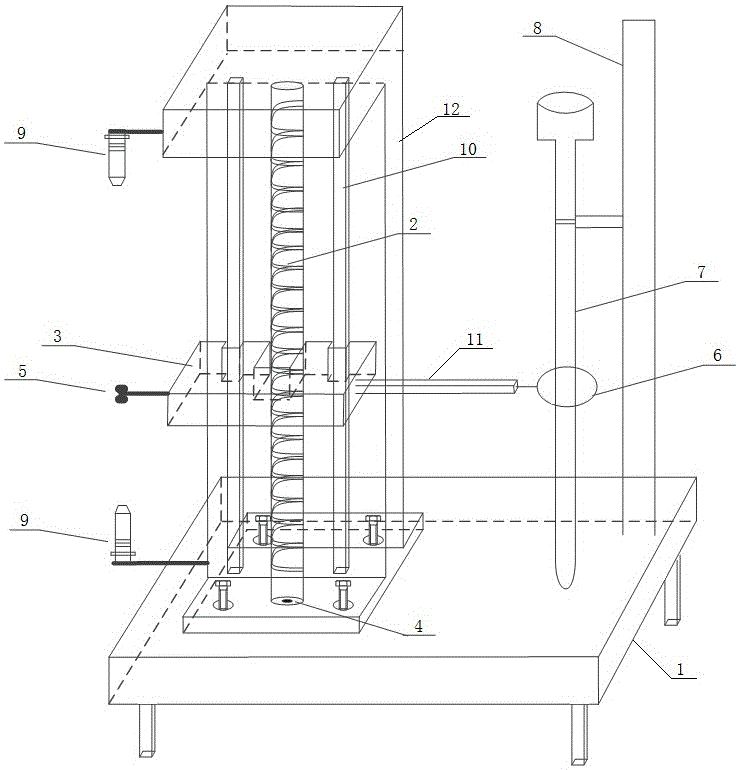

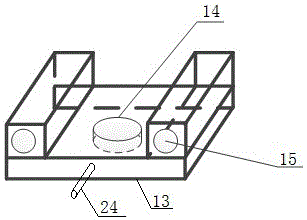

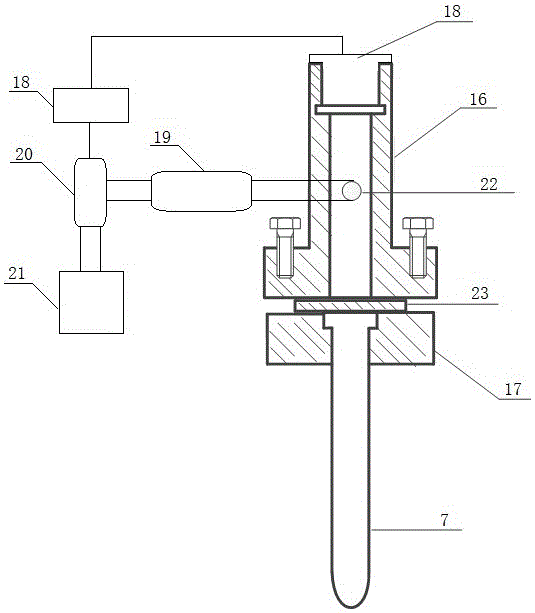

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] Such as figure 1As shown, the present invention designs an organic solid purification device based on the principle of zone smelting, including a device base 1, a lead screw 2, a slider 3, a stepping motor 4, a motion controller, a metal contact 5, and a heating coil device 6. Test tube 7, test tube holder 8, vacuum pumping device, fixed top seat 12, pulse signal generator, thermal insulation cotton, two proximity switches 9, at least one guide rail 10; wherein, test tube holder 8 is arranged on the device base 1, the test tube 7 is detachably connected with the test tube holder 8, and is vertically arranged through the test tube holder 8, and the mouth of the test tube 7 is upward; The surfaces are connected, and each guide rail 10 is vertically arranged, and each slide groove corresponding to the shape and posi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com