Connection structure of end part of cantilever made of carbon-fiber composite materials

A composite material and connection structure technology, applied to cranes and other directions, can solve problems such as weak connection strength and easy damage, and achieve the effect of increased load transmission capacity and enhanced connection reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

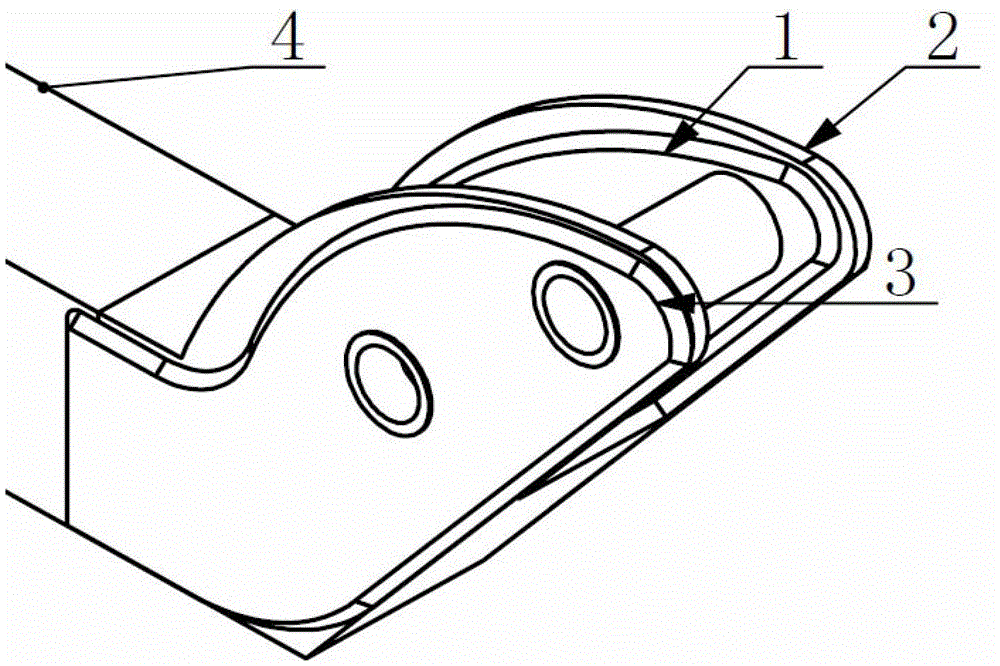

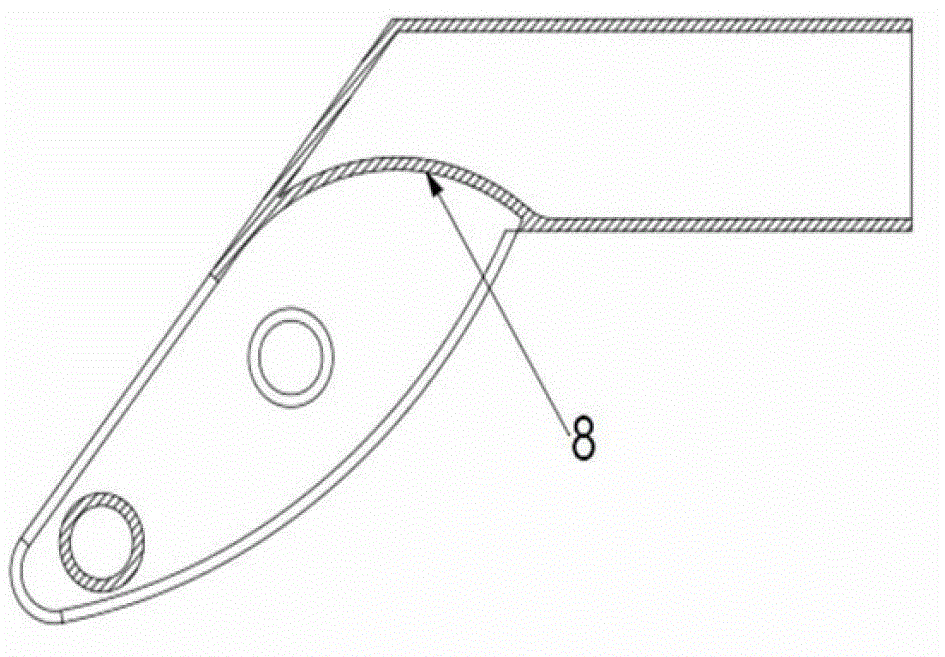

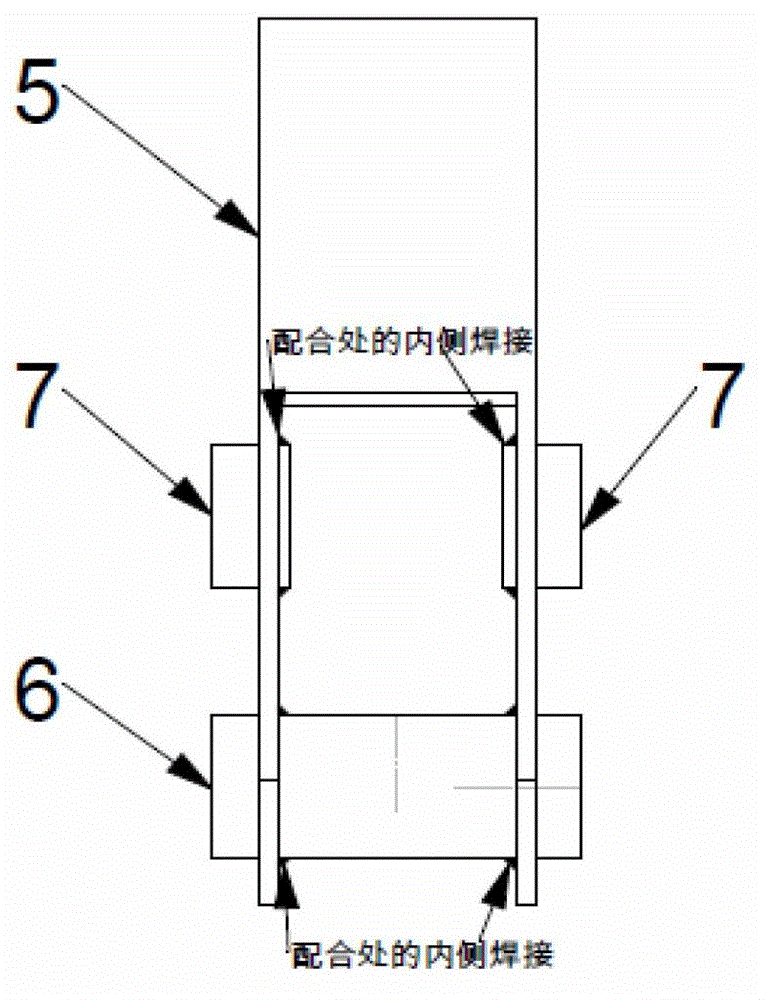

[0026] The connection structure at the end of the carbon fiber composite boom provided by the present invention adopts the form of steel clip carbon fiber, such as Figure 1 to Figure 9 As shown, it adopts the metal inner layer 1 inside, the carbon fiber reinforced layer 2 in the middle, and the metal outer plate 3 on the outside. Sandwich structure connected by welding. The metal inner layer 1 is made up of a long metal tube 6, two short metal tubes 7 and a frame 5, one end of the frame 5 is a square frame body, and the other end is a U-shaped joint, between the square frame body and the U-shaped joint There is an arc-shaped reinforcing liner 8, and two hinge holes are arranged at the U-shaped joint, one of which is formed by a long metal tube 6 passing through and connected with the U-shaped joint, and the other hinge hole is formed by It consists o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com