Thermal shock resistant ceramic tube mold and preparation method thereof

A ceramic tube, heat-resistant technology, applied in the field of metallurgical casting and smelting, can solve the problems affecting the quality and economic benefits of centrifugal casting ductile iron pipe products, low production efficiency of mechanization and automation level, poor quality of outer surface of ductile iron pipe, etc. Reduce thermal stress accumulation, good spalling resistance, good flexural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

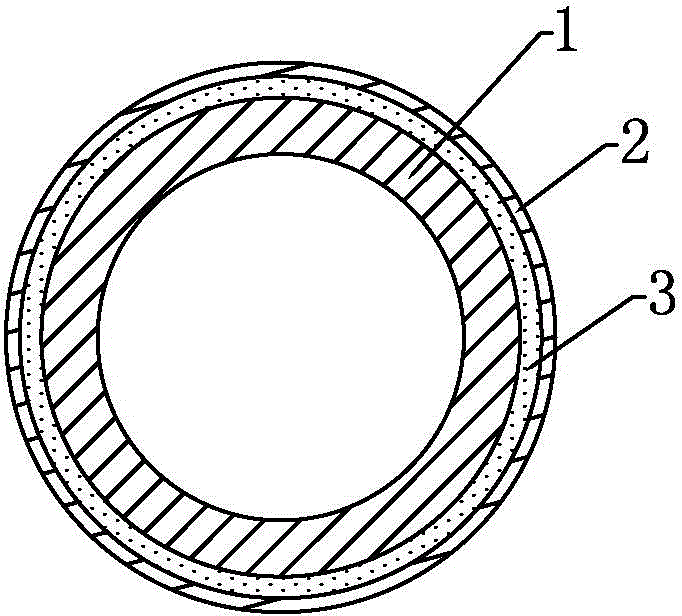

[0033] The heat-shock-resistant ceramic pipe mold includes a ceramic pipe inner mold 1, a steel pipe mold skin 2 is set on the outer side of the ceramic pipe inner mold 1, and self-flowing refractory castables are filled between the ceramic pipe inner mold 1 and the steel pipe mold skin 2 3. The ceramic tube inner mold 1 is made of the following raw materials: 4500 kg of silicon carbide powder, 2500 kg of silicon powder, 2150 kg of primary aluminum nitride powder, 200 kg of graphite powder, 200 kg of zirconia powder, and 100 kg of yttrium oxide powder. kg, 50 kg of absolute ethanol, 150 kg of polyvinyl alcohol and 150 kg of water glass.

[0034] The preparation method of the heat-shock-resistant ceramic pipe mold adopts the following steps:

[0035] 1) Add 2500 kg of silicon powder, 200 kg of zirconia micro-powder, 100 kg of yttrium oxide micro-powder, 50 kg of absolute ethanol and 150 kg of polyvinyl alcohol into a high-speed mixer, fully stir, and mix evenly;

[0036] 2) Af...

Embodiment 2

[0044] The heat-shock-resistant ceramic pipe mold includes a ceramic pipe inner mold 1, a steel pipe mold skin 2 is set on the outer side of the ceramic pipe inner mold 1, and self-flowing refractory castables are filled between the ceramic pipe inner mold 1 and the steel pipe mold skin 2 3. The ceramic tube inner mold 1 is made of the following raw materials: 4000 kg of silicon carbide powder, 2400 kg of silicon powder, 2390 kg of primary aluminum nitride powder, 420 kg of graphite powder, 300 kg of zirconia powder, and 50 kg of yttrium oxide powder. kg, 40 kg of absolute ethanol, 250 kg of coal tar and 150 kg of water glass.

[0045] The preparation method is the same as in Example 1.

Embodiment 3

[0047] The heat-shock-resistant ceramic pipe mold includes a ceramic pipe inner mold 1, a steel pipe mold skin 2 is set on the outer side of the ceramic pipe inner mold 1, and self-flowing refractory castables are filled between the ceramic pipe inner mold 1 and the steel pipe mold skin 2 3. The ceramic tube inner mold 1 is made of the following raw materials: 5000 kg of silicon carbide powder, 2100 kg of silicon powder, 2000 kg of primary aluminum nitride powder, 270 kg of graphite powder, 220 kg of zirconia powder, and 62 kg of yttrium oxide powder. kg, 28 kg of absolute ethanol, 100 kg of polyvinyl alcohol and 220 kg of high alumina cement.

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com