Full pre-stressing solid square pile end board

A prestressed and solid technology, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, can solve the problems of producing fully prestressed solid square piles, etc., so as to improve the economic benefits of enterprises, improve production efficiency, and ensure the progress of projects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

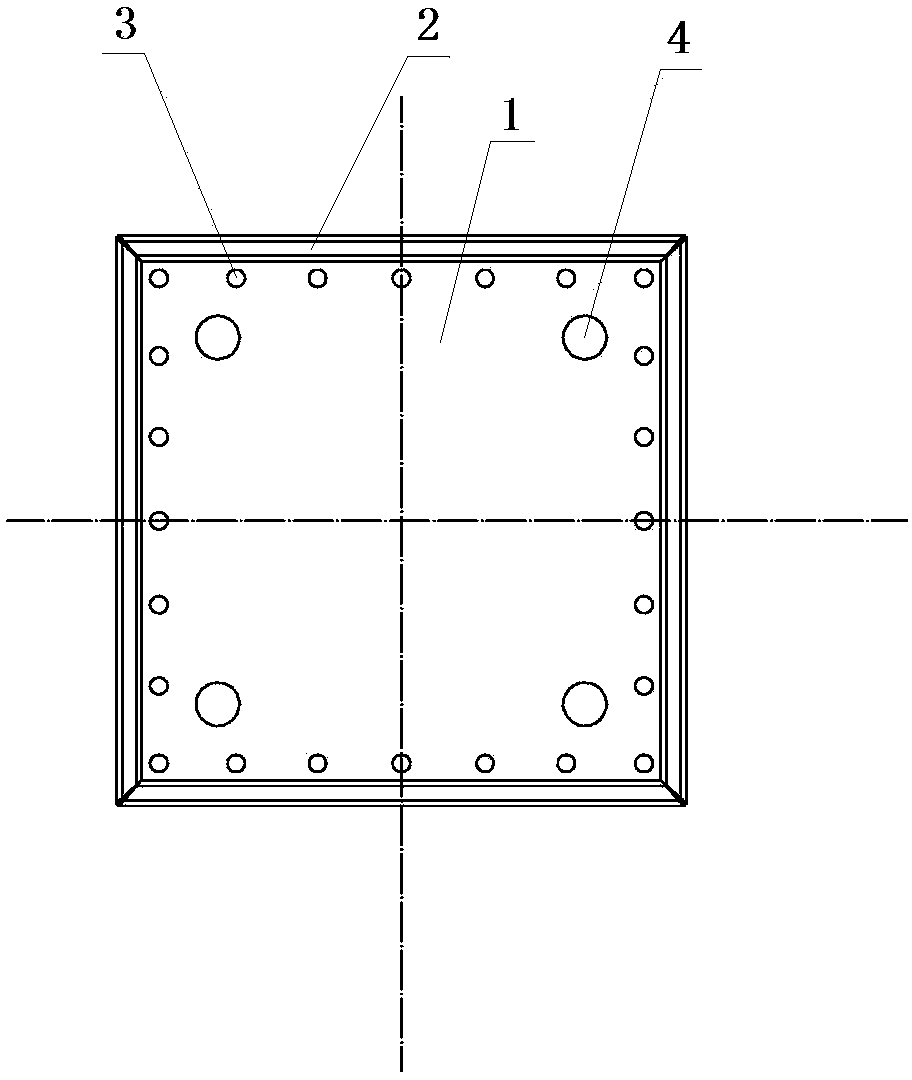

[0009] Such as Figure 1-2 As shown, a fully prestressed solid square pile end plate, including a square bottom plate 1, is provided with 24 threading holes 3 around the bottom plate 1 for passing steel bars. The diameter of the threading holes 3 is 16mm, and the inner side of the threading holes 3 An anchor hole 4 for the pile connection is provided, and the diameter of the anchor hole 4 for the pile connection is 45 mm. The outer edge 2 of the bottom plate 1 is folded up so that the angle between the bottom plate and the outer edge is 115 degrees. The thickness of the bottom plate 1 is 4.0mm.

[0010] The above is only a preferred embodiment of the present invention, but the scope of protection of the present invention is not limited thereto. Anyone familiar with the technical field within the technical scope disclosed in the present invention, according to the technical solution of the present invention Any equivalent replacement or change of the inventive concepts th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com