Crack-resistant mass concrete and preparation method thereof

A technology of mass concrete and crack resistance, applied in the field of mass concrete, can solve the problems of cumbersome operation process, achieve good fluidity, compensate for early shrinkage, and compensate for shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

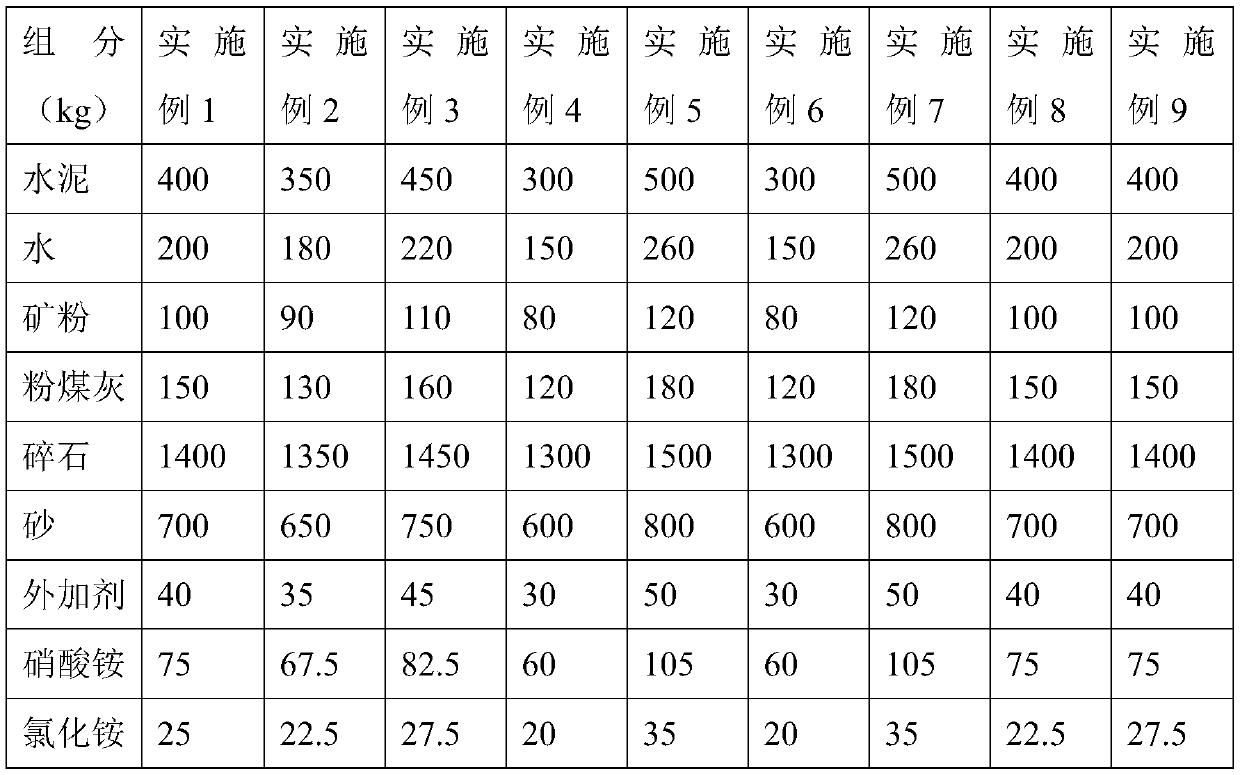

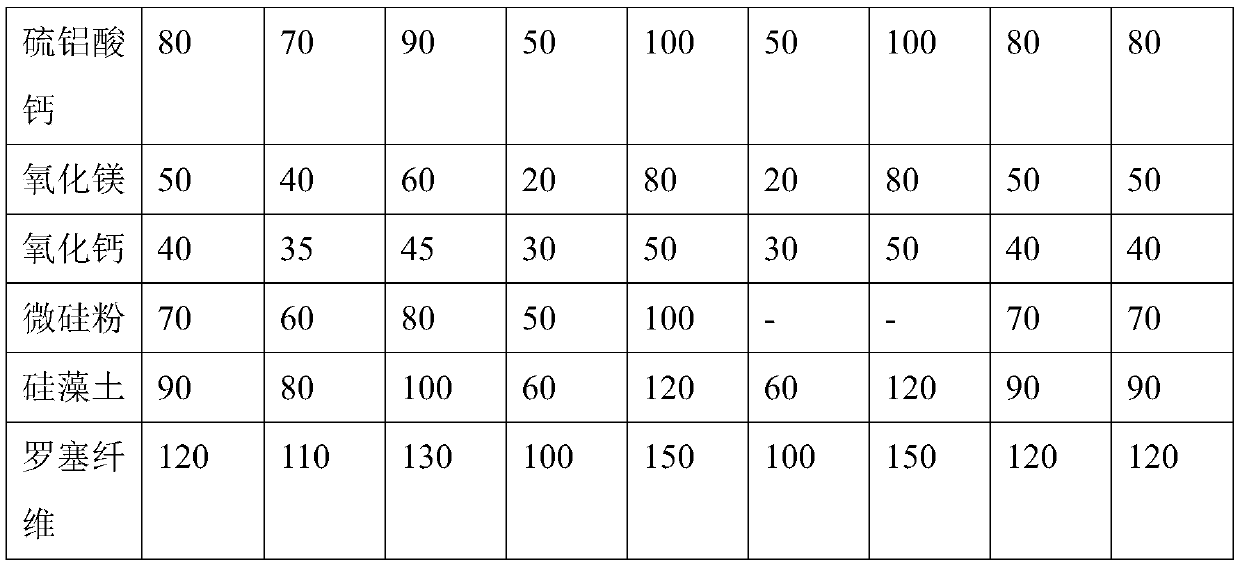

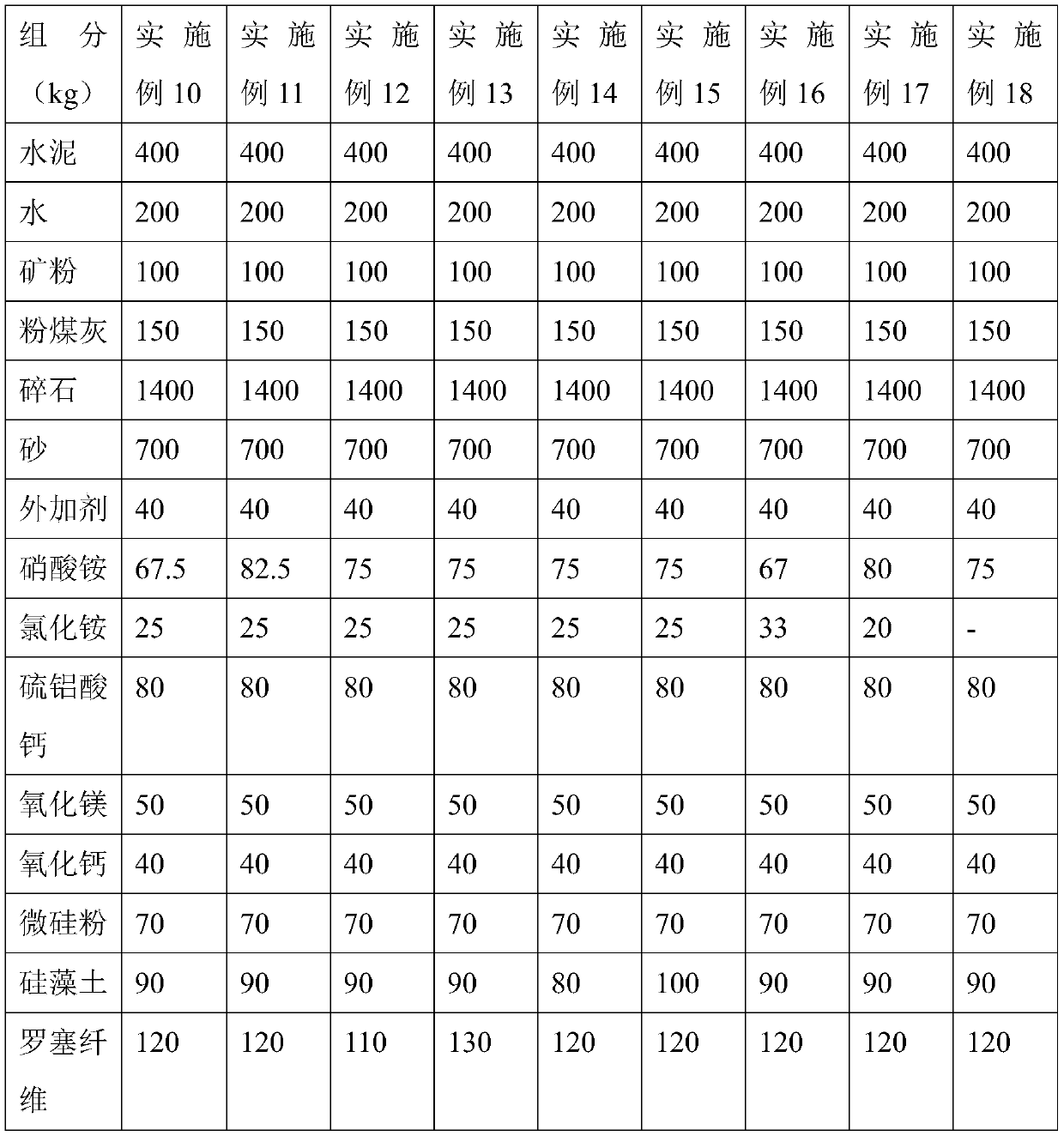

[0030] The invention provides a crack-resistant mass concrete and a preparation method thereof. The crack-resistant concrete is made of raw materials containing the following parts by weight:

[0031] 300-500 parts of cement, 150-260 parts of water, 80-120 parts of mineral powder, 120-180 parts of fly ash, 1300-1500 parts of crushed stone, 600-800 parts of sand, 30-50 parts of admixture, 80-140 parts 100-230 parts of ammonium salt, 100-230 parts of expansion agent, 50-100 parts of microsilica, 60-120 parts of diatomaceous earth and 100-150 parts of rose fiber. Ammonium salt includes one or both of ammonium nitrate and ammonium chloride. The expansion agent includes 50-100 parts of calcium sulfoaluminate, 20-80 parts of magnesium oxide, and 30-50 parts of calcium oxide.

[0032] The preparation method is as follows: first put in crushed stone, then put in rose fiber soaked in water for 10 minutes, then put in sand and diatomaceous earth and stir for 5-10 minutes, then put in ce...

Embodiment 1

[0043] A preparation method for crack-resistant mass concrete, comprising the following steps:

[0044] First put in 1400kg of gravel, then put in 120kg of rose fiber, then put in 700kg of sand and 90kg of diatomaceous earth and stir for 8 minutes, then put in 400kg of cement, 150kg of fly ash, 100kg of mineral powder, 70kg of silica fume and 170kg of expansion agent, and stir for 12 minutes , then dissolve 40kg of admixture in 200kg of water and add, after stirring for 5 minutes, add 100kg of ammonium salt, and stir for 25 minutes to obtain;

[0045] Among them, the ammonium salt includes ammonium chloride and ammonium nitrate with a mass ratio of 1:3, the expansion agent includes 80kg of calcium sulfoaluminate, 50kg of magnesium oxide, and 40kg of calcium oxide, and the rose fiber is soaked in water for 10 minutes before being added.

[0046] Table 1:

[0047]

[0048]

[0049] Continuation of Table 1:

[0050]

Embodiment 2-18

[0052] A method for preparing crack-resistant mass concrete is carried out according to the method in Example 1, except that the raw materials are added according to the ratio of raw materials in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com