Patents

Literature

86results about How to "Compensation for shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

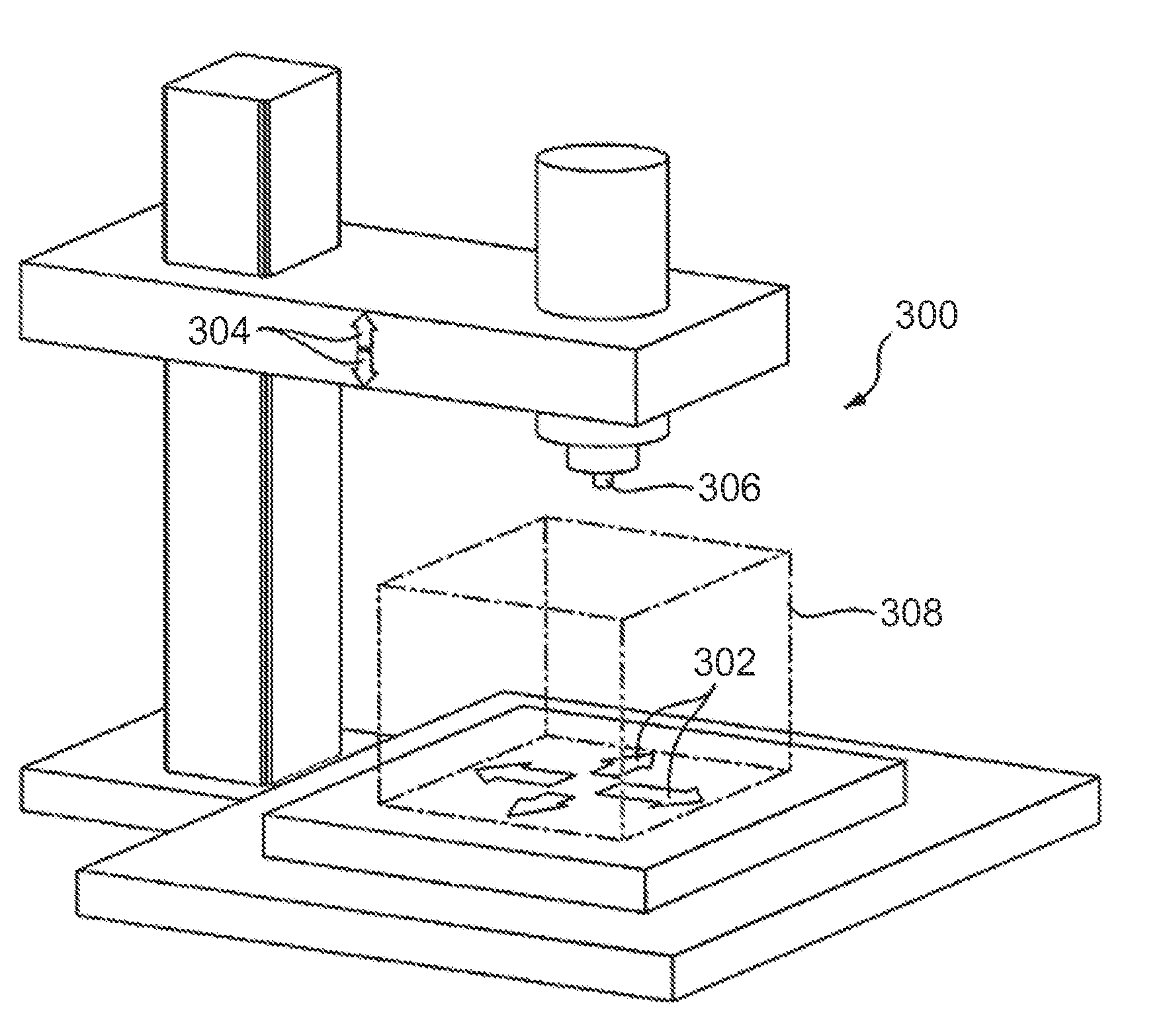

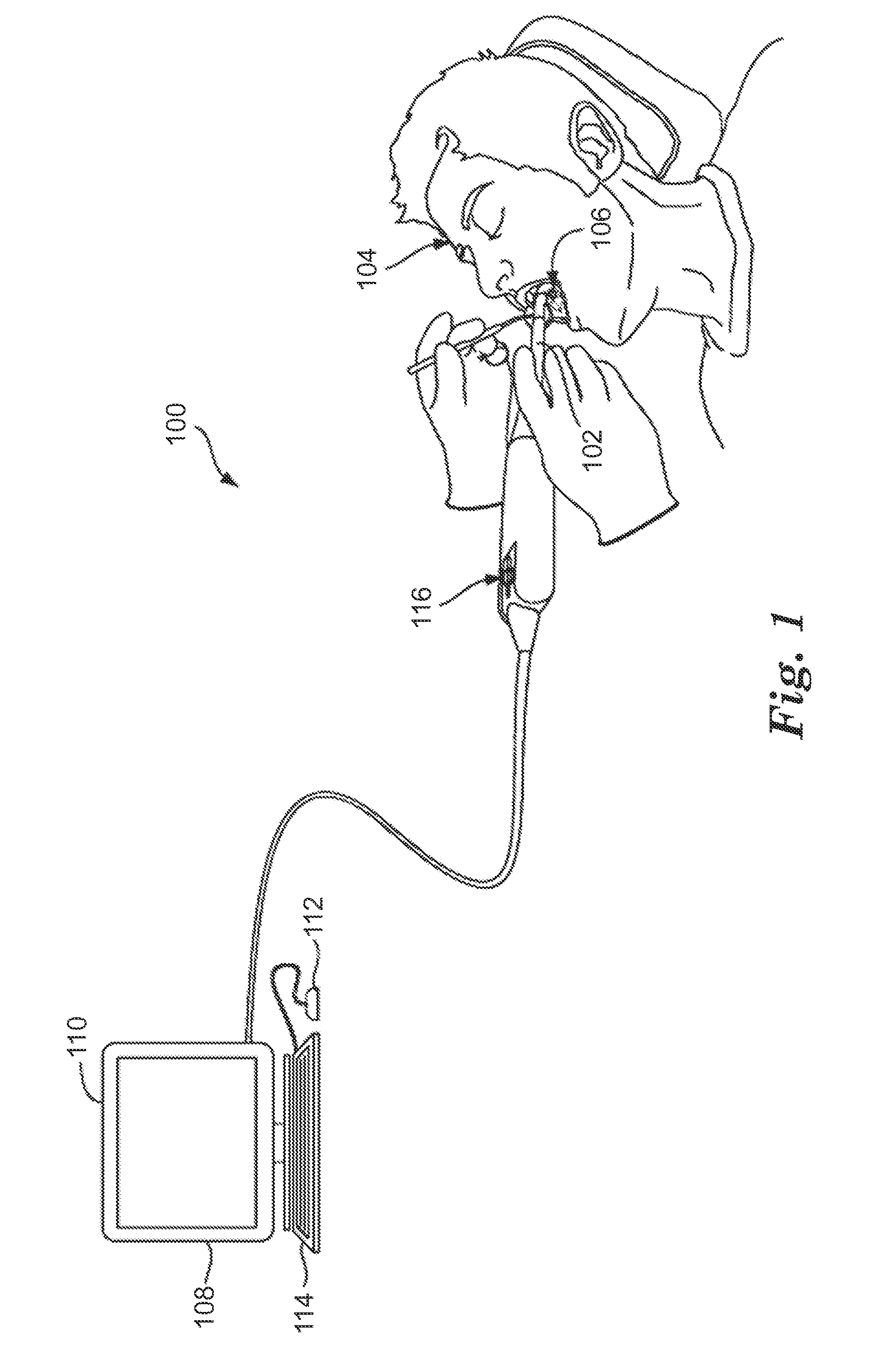

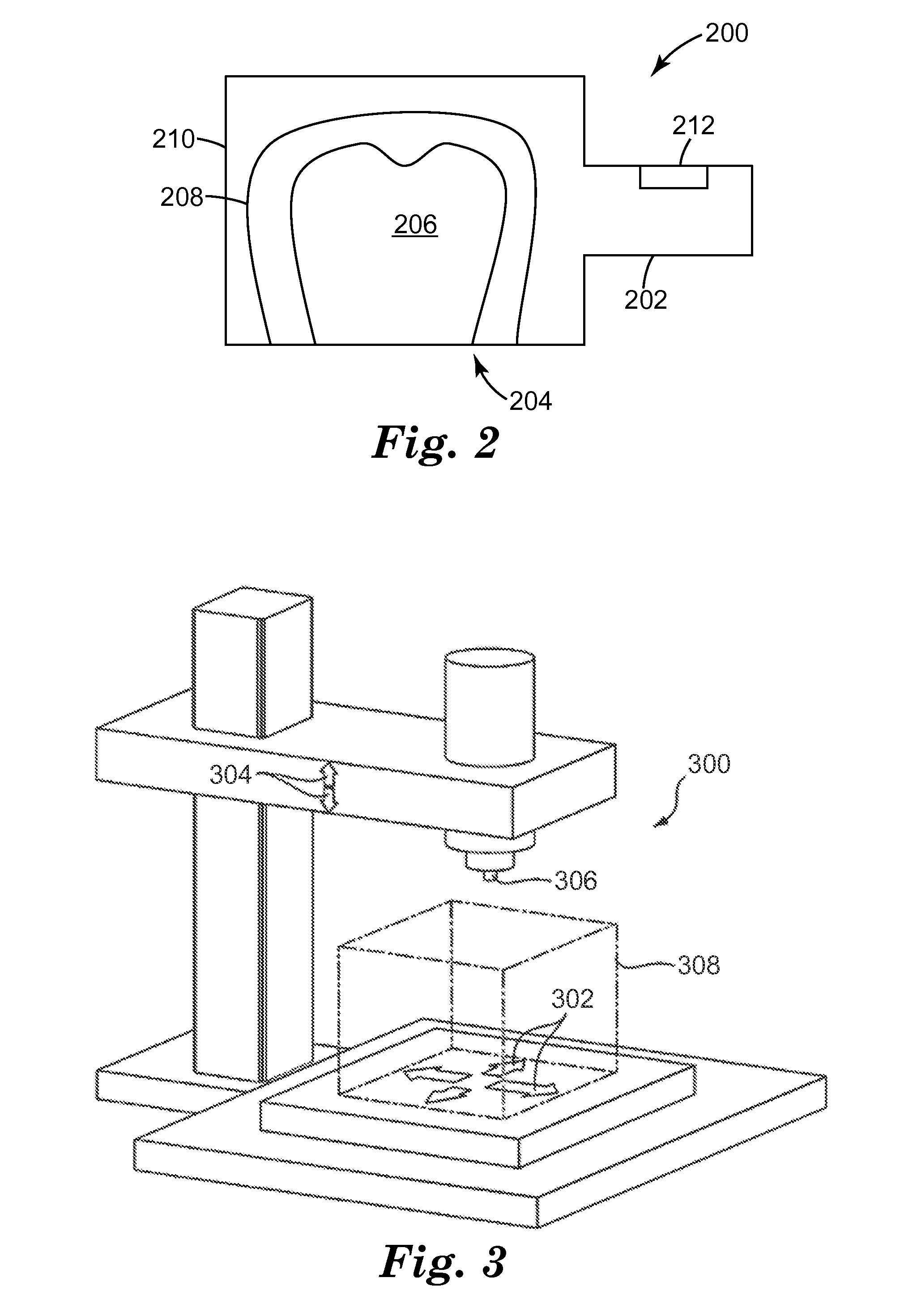

Digitally-machined smc dental articles

InactiveUS20100268363A1Sufficient malleabilityCompensation for shrinkageProgramme controlComputer controlComputer Aided DesignEngineering

A dental article is fabricated from an SMC material using three-dimensional data captured from natural dentition to guide a computer-controlled milling machine. The three-dimensional data may include scans of an original tooth structure and a prepared tooth surface to characterize all surfaces of a dental article, or certain features may be created within a computer-assisted design environment taking account of occlusion, proximal contacts, and the like. In addition the model applied to a computer-controlled milling machine may account for shrinkage of the SMC material during any post-milling curing steps in order to ensure an accurate fit to the prepared tooth surface.

Owner:3M INNOVATIVE PROPERTIES CO

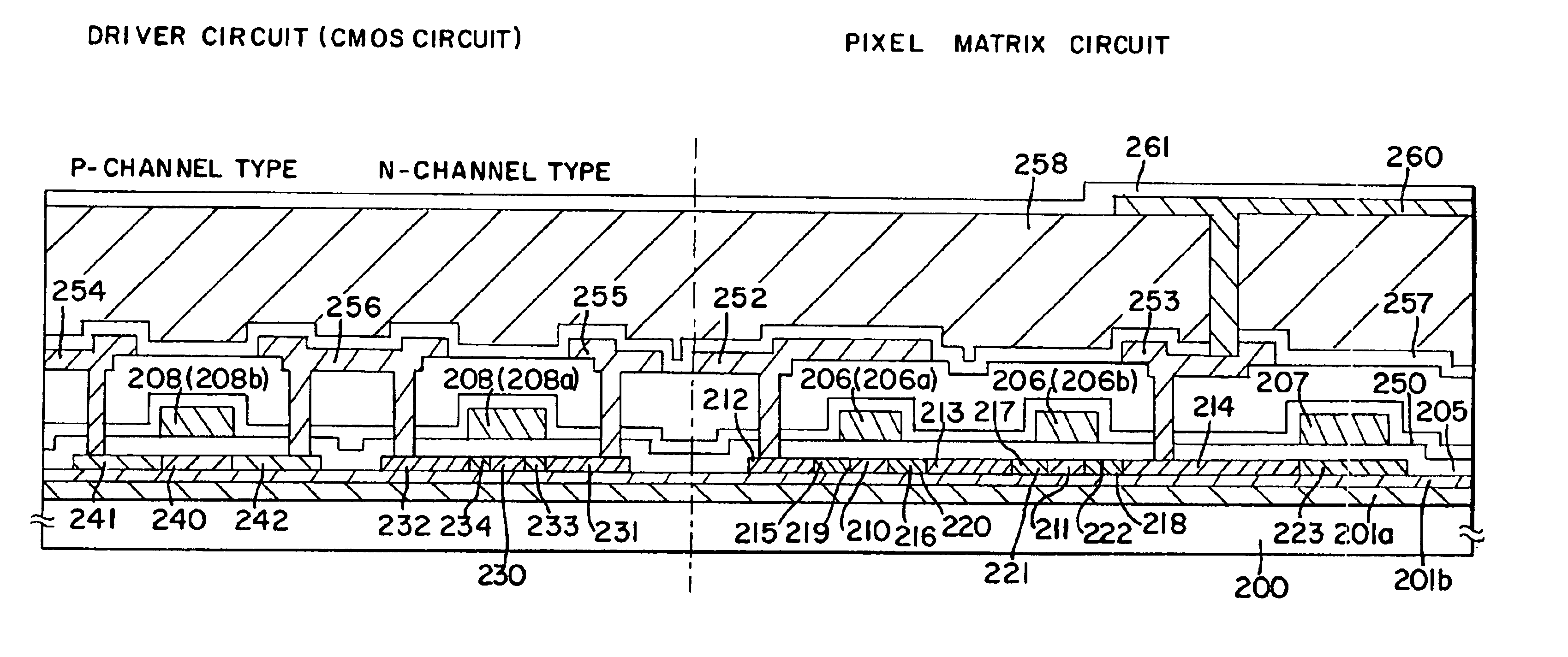

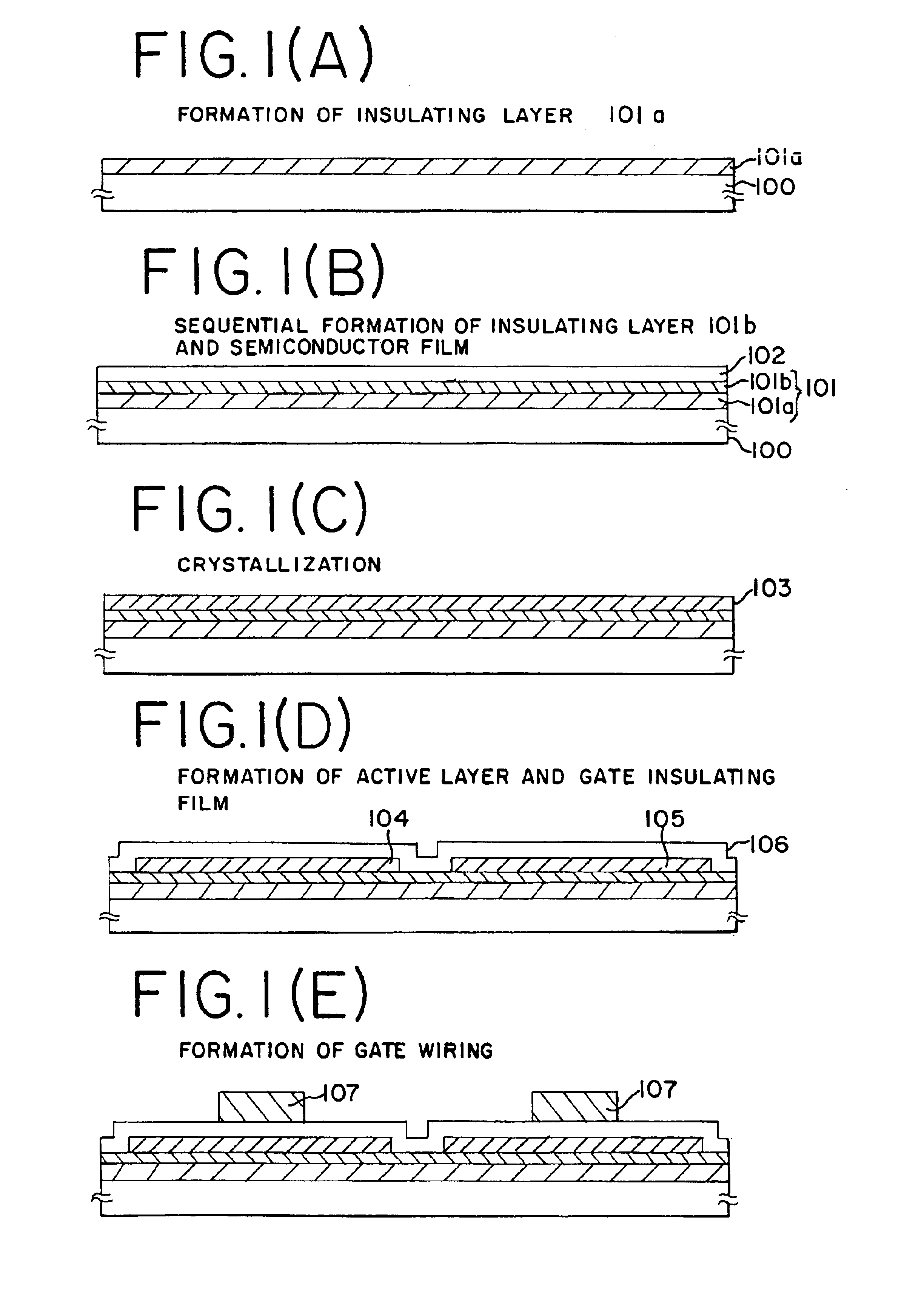

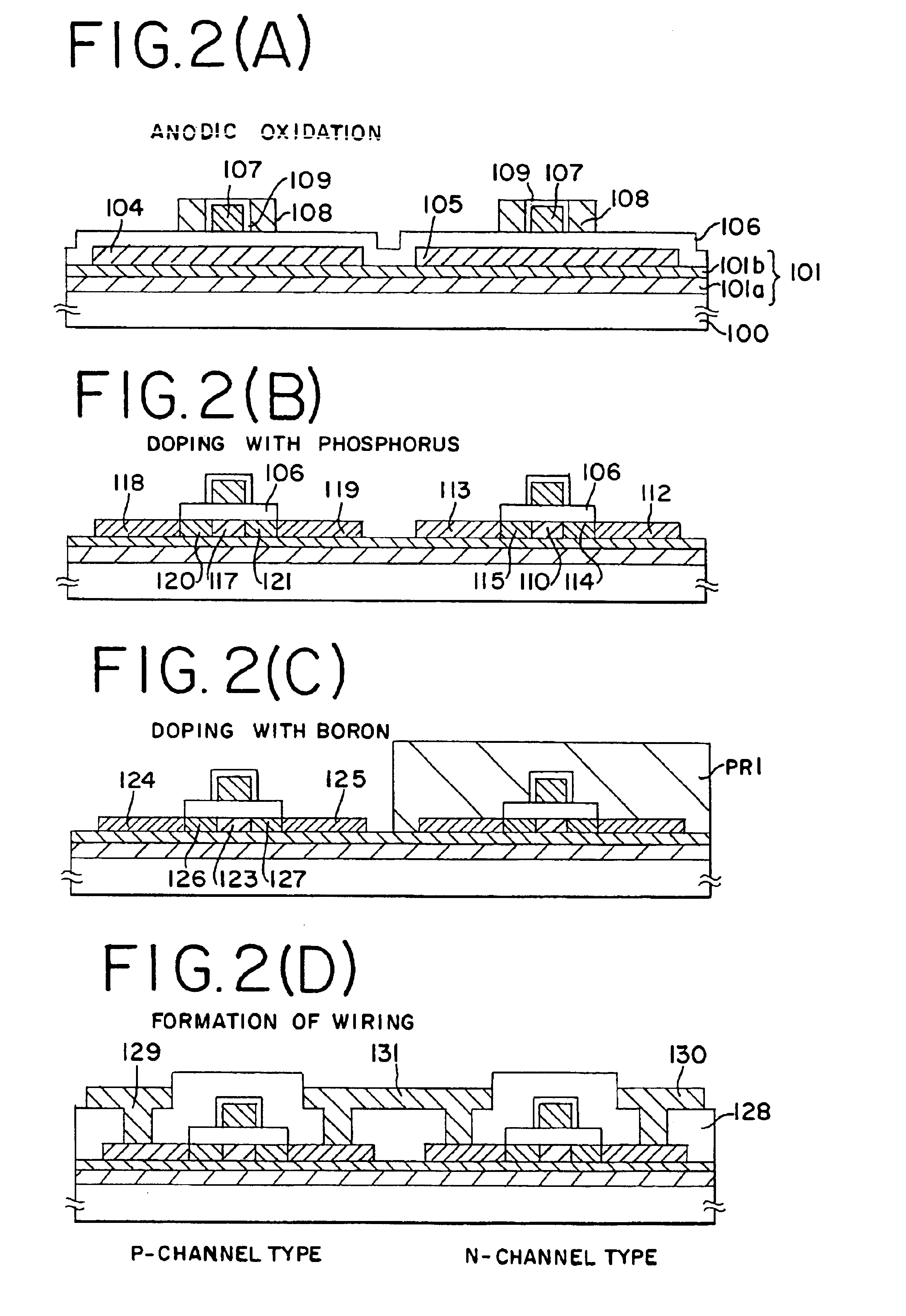

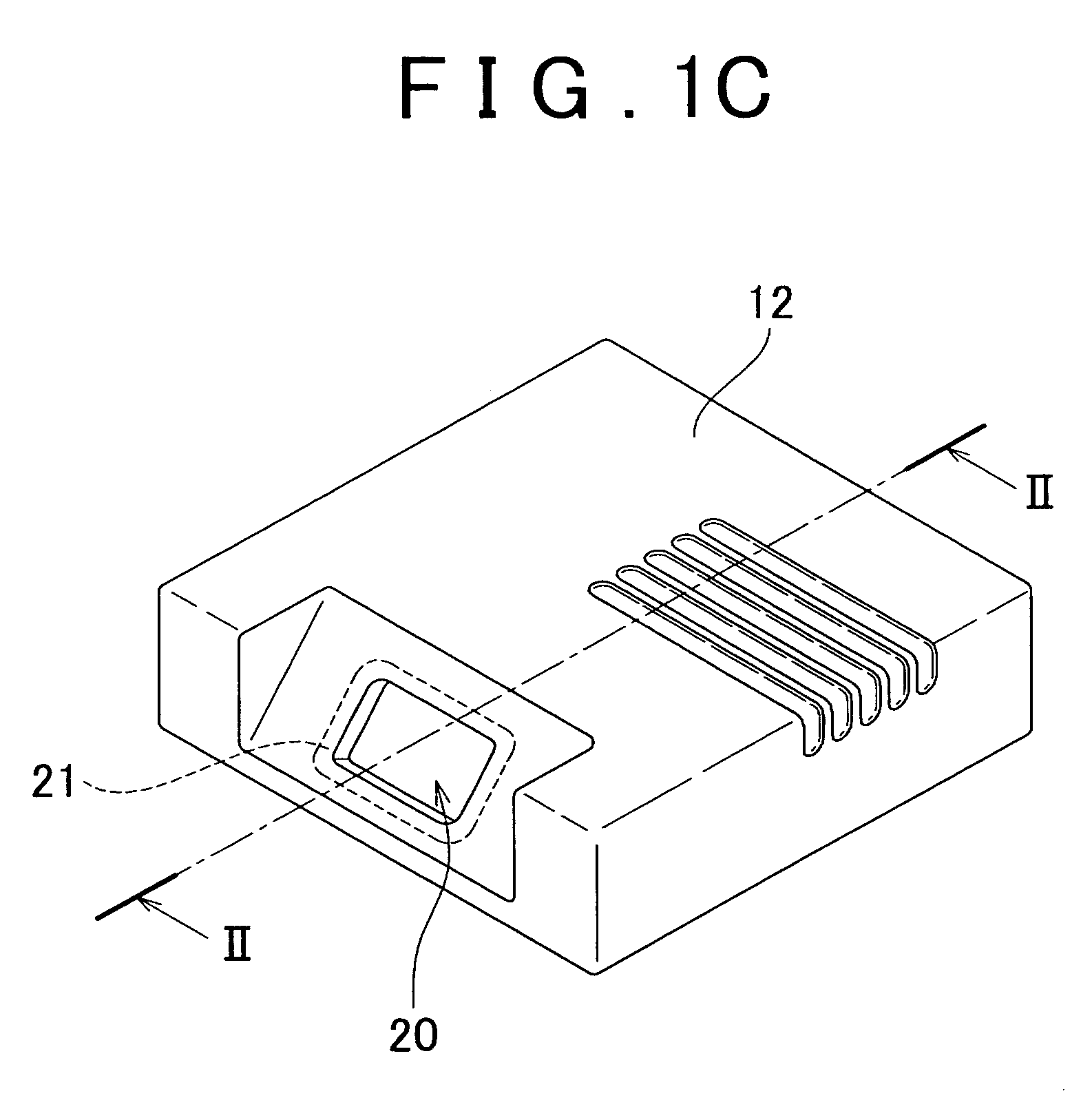

Semiconductor device and method for manufacturing the same

InactiveUS6858898B1Improve reliabilityEliminate the problemTransistorSemiconductor/solid-state device detailsDevice materialSilicon oxide

An object of the present invention is to prevent the deterioration of a TFT (thin film transistor). The deterioration of the TFT by a BT test is prevented by forming a silicon oxide nitride film between the semiconductor layer of the TFT and a substrate, wherein the silicon oxide nitride film ranges from 0.3 to 1.6 in a ratio of the concentration of N to the concentration of Si.

Owner:SEMICON ENERGY LAB CO LTD

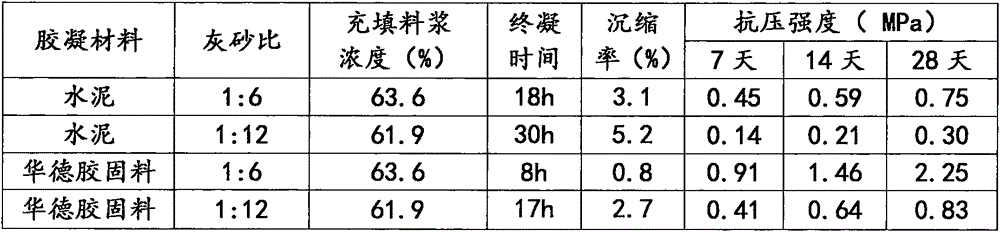

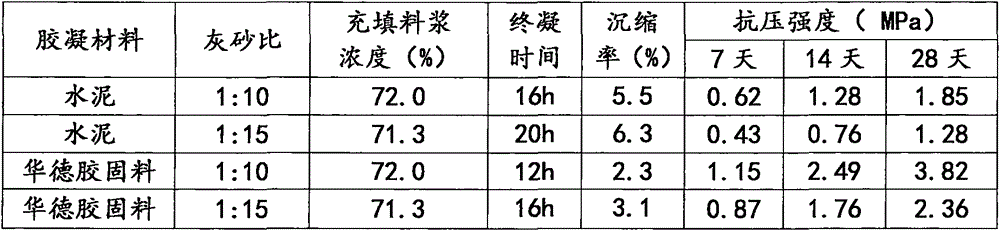

Low-shrinkage early-strength type mine filling cementing material

InactiveCN106746785AReduce surface tensionSmall shrinkageSolid waste managementCement productionGypsumSlag

The invention relates to a low-shrinkage early-strength type mine filling cementing material. The cementing material comprises the following components in percentage by weight: 50-90% of slag powder, 5-25% of cement or cement clinker, 1-30% of mineral additive, 0-10% of gypsum, 0.5-10% of alkali activator and 0.1-10% of shrinkage-reducing and cracking-resistant material. The invention solves the problem that fillers are prone to high shrinkage, cracking, slow setting and low strength when a slag-based alkali activation material is used for full tailing filling of a mine and the concentration of filling slurry is low especially in case of improper curing. The material is used instead of cement for mine filling, has favorable adaptability for tailings of different concentrations (55-80%), and has the advantages of fast filler setting, high strength and low shrinkage.

Owner:北京华德创业环保设备有限公司

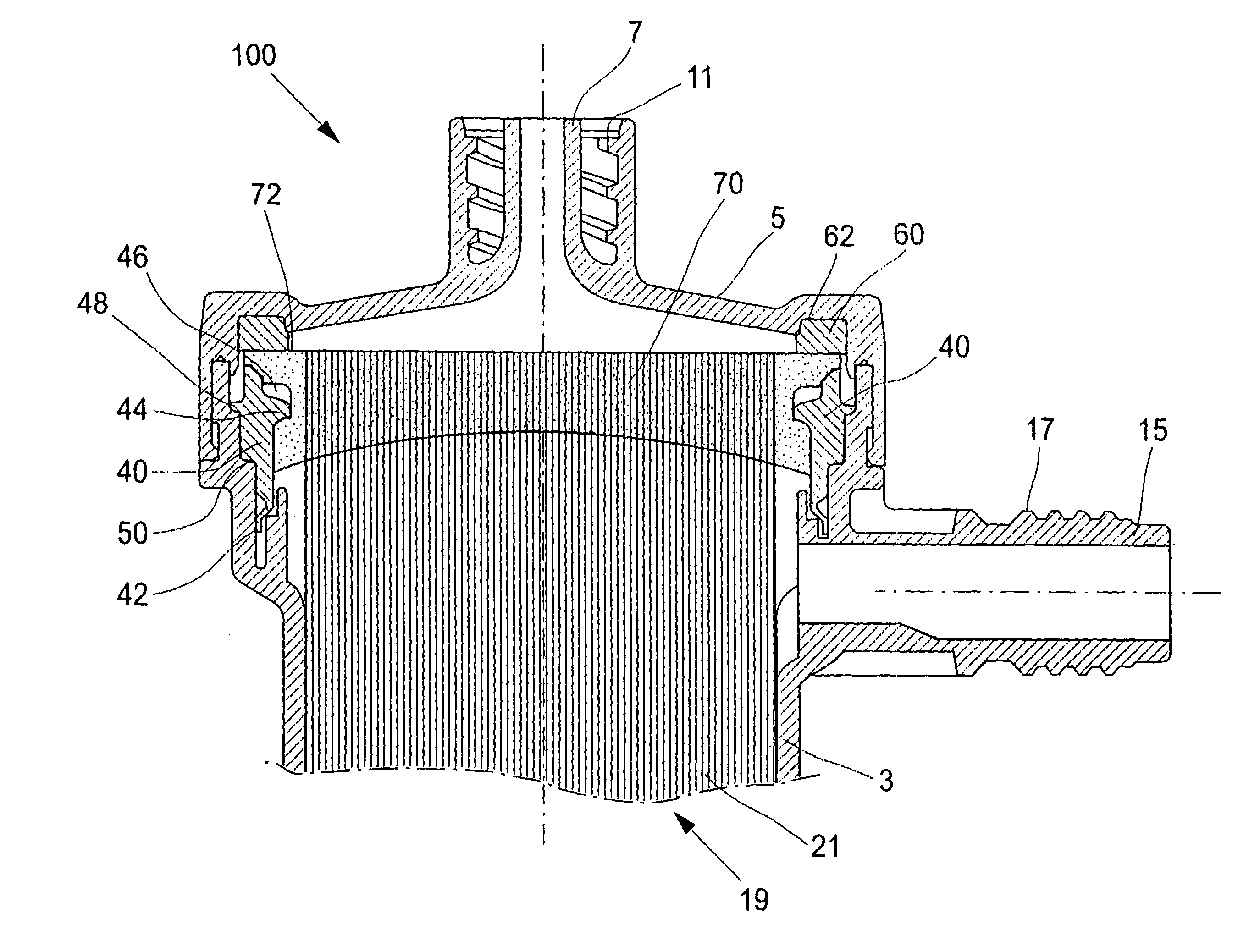

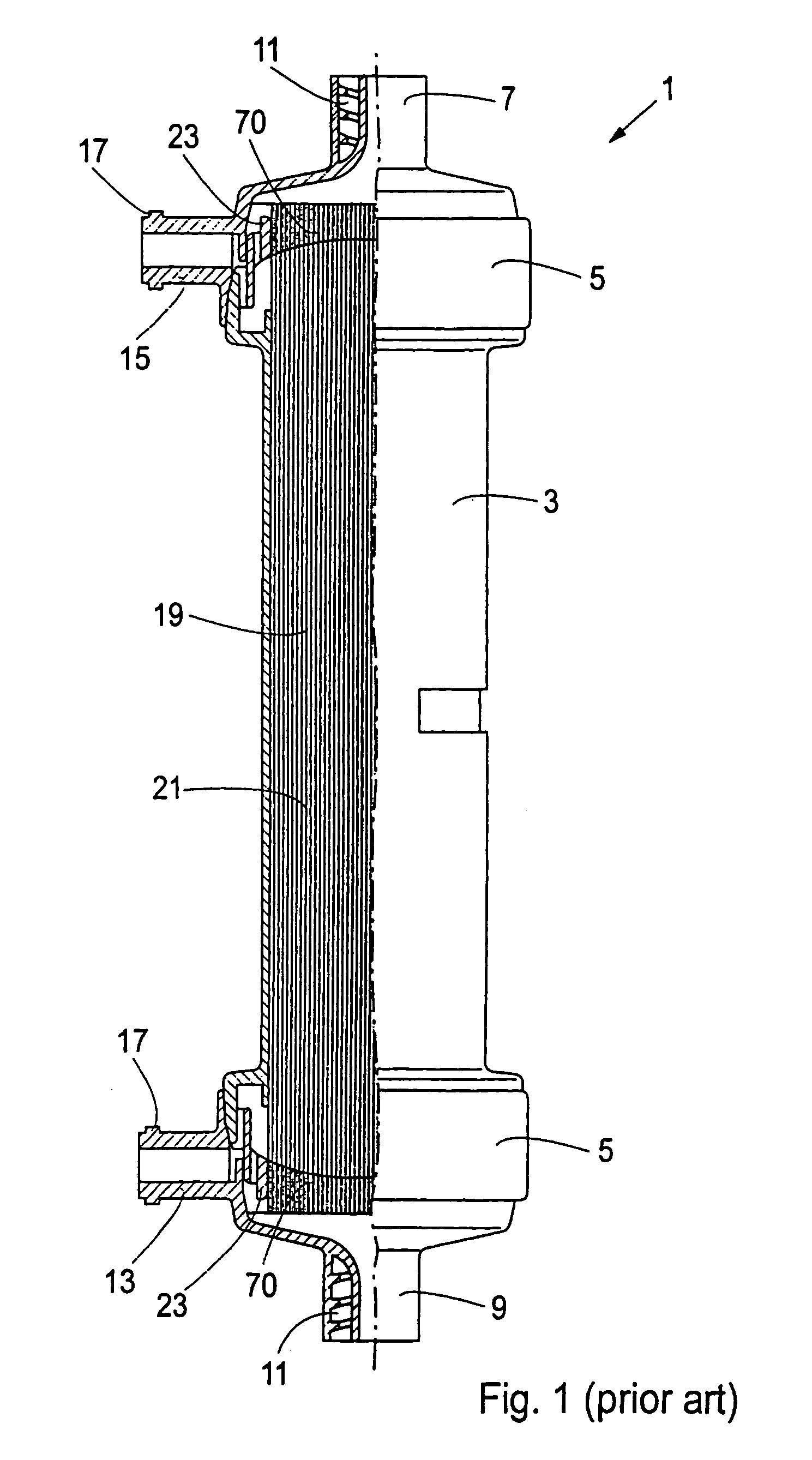

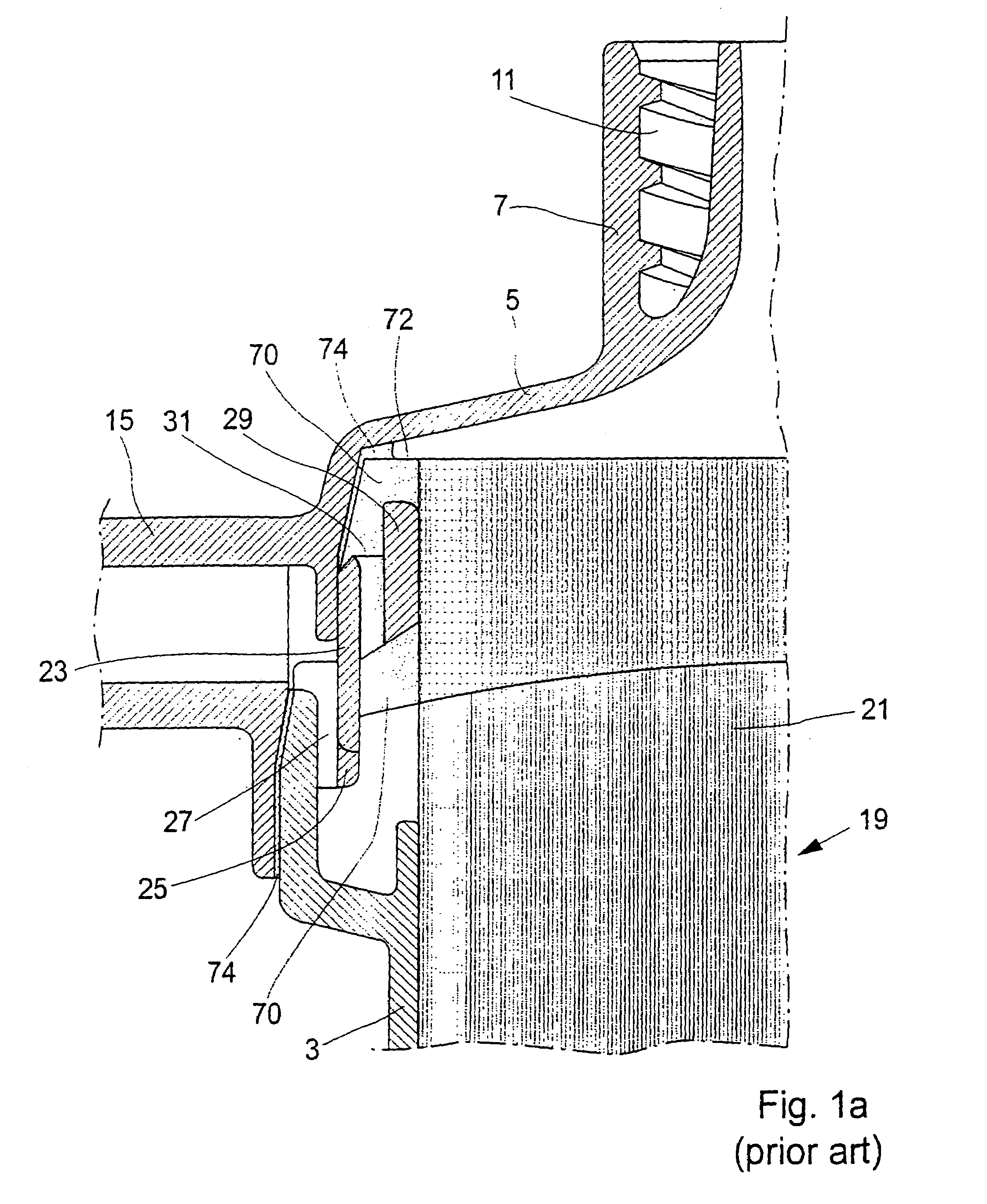

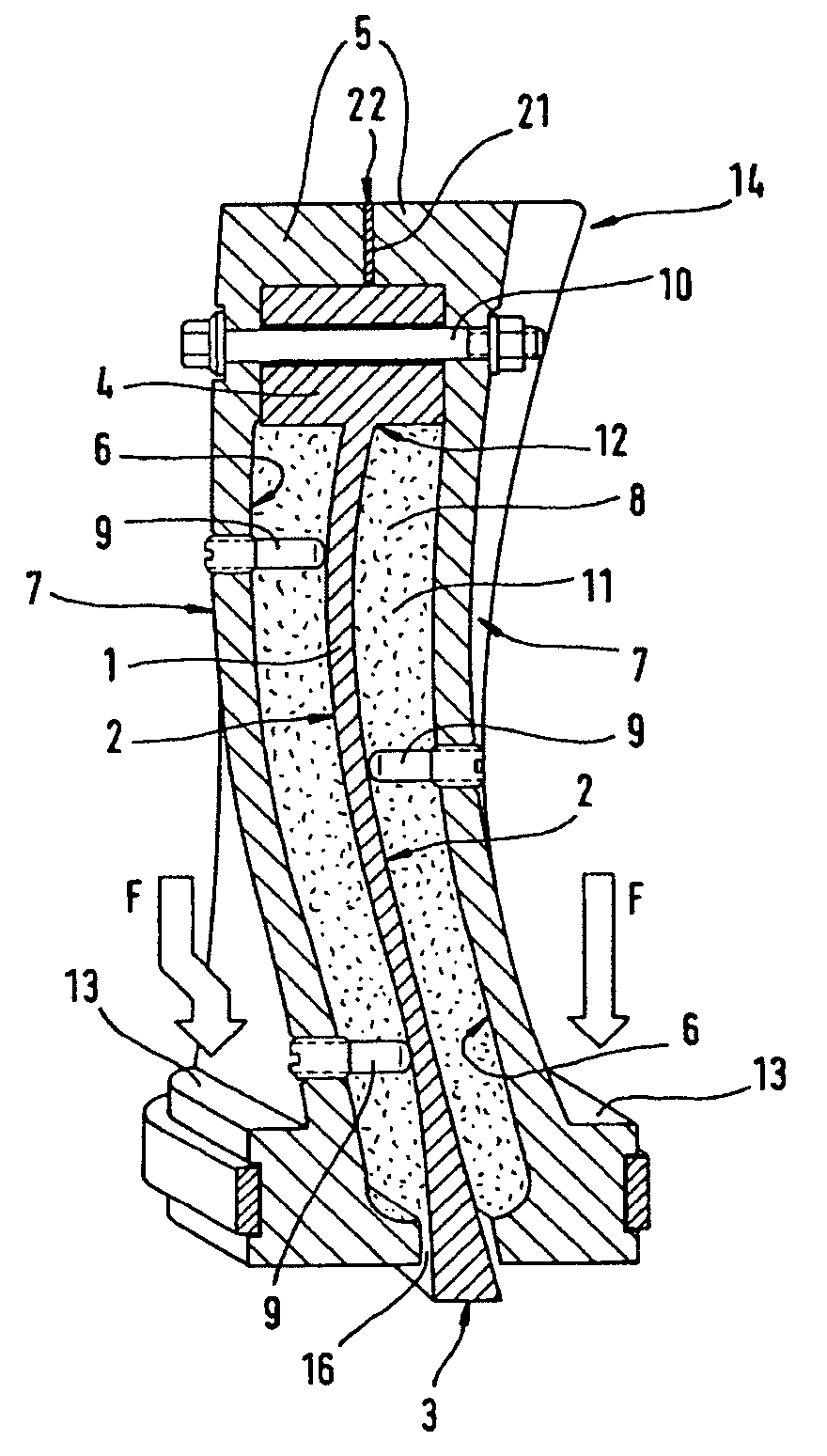

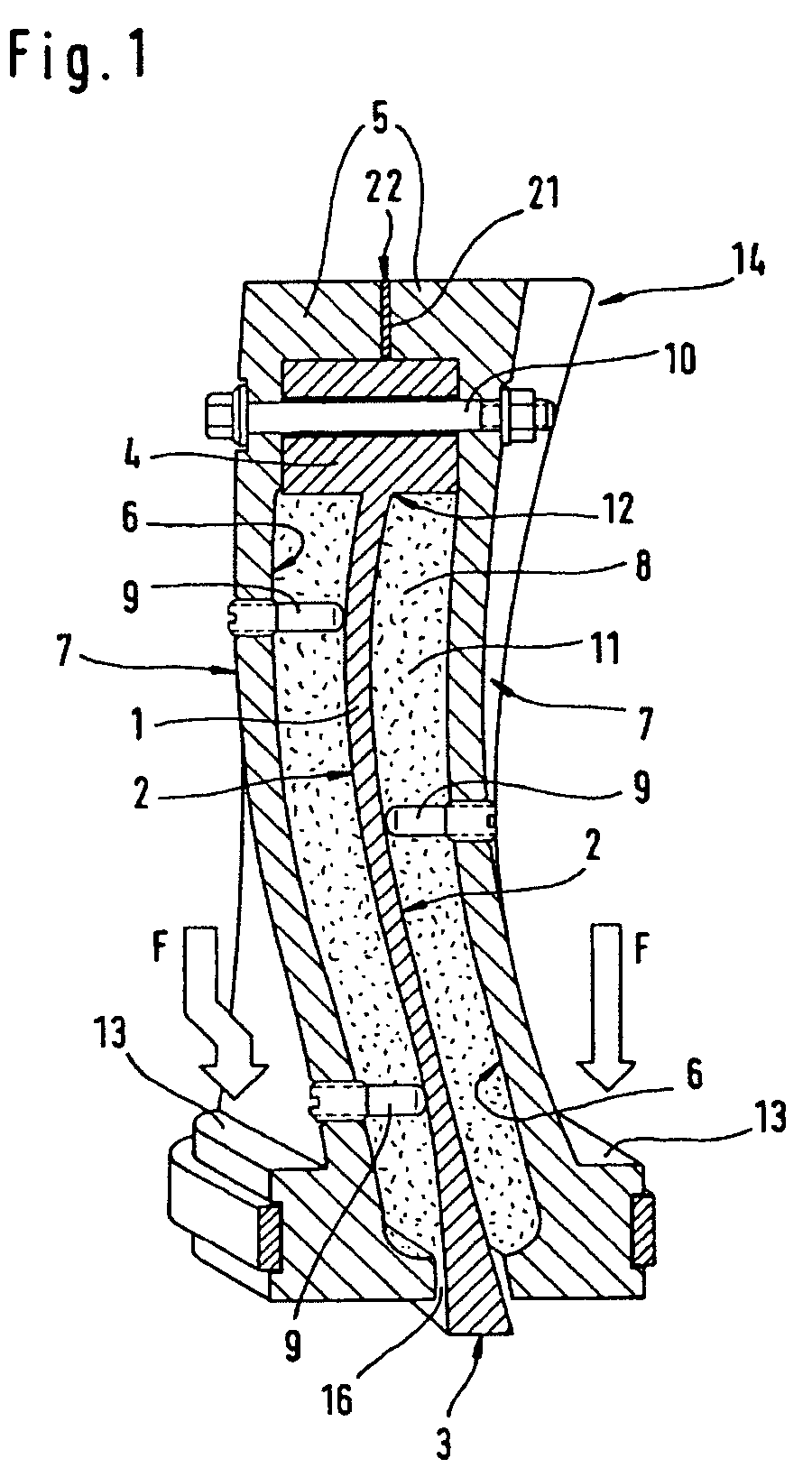

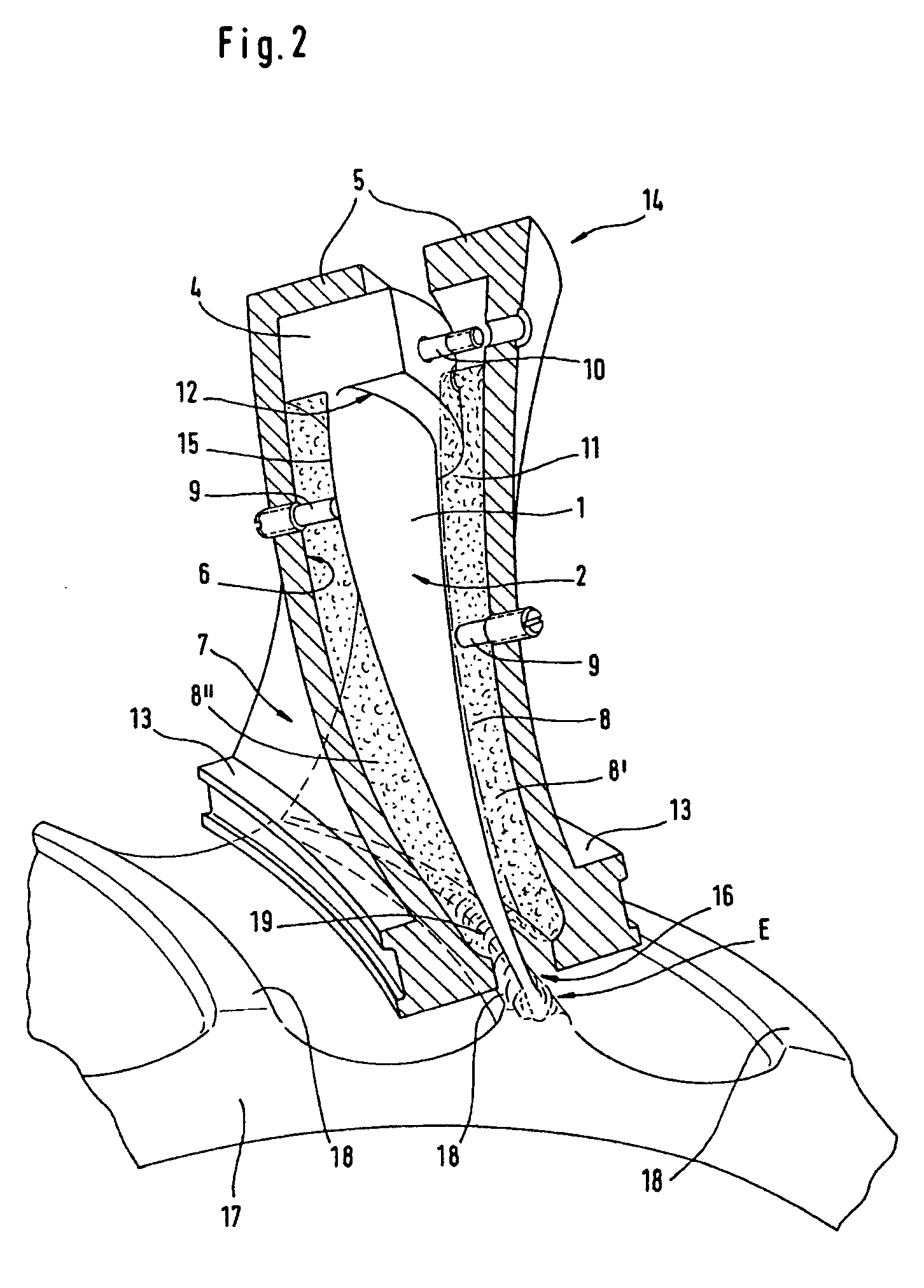

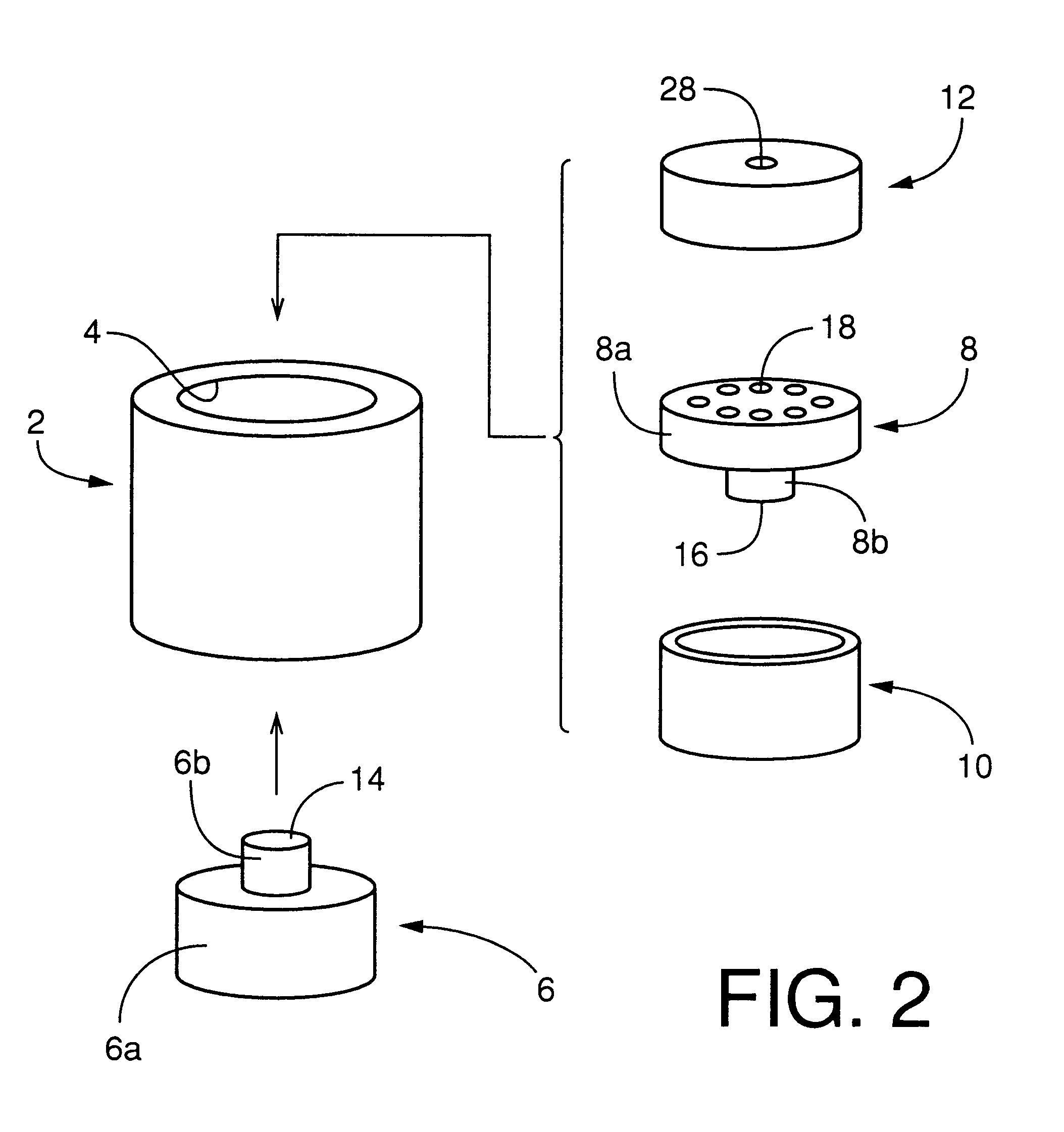

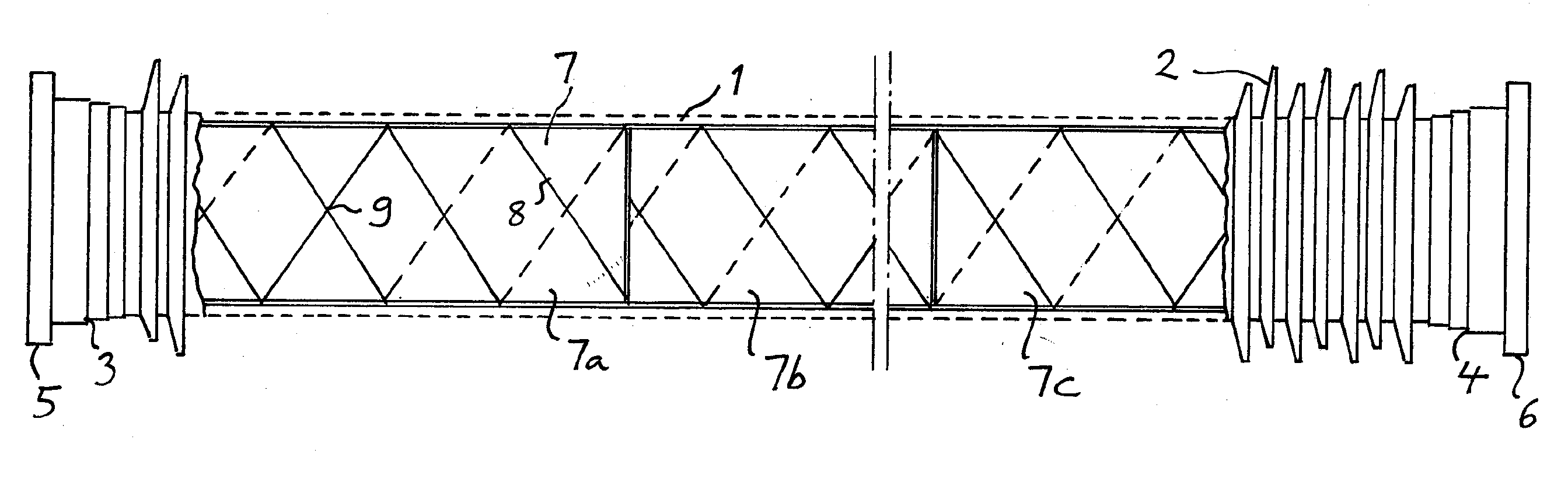

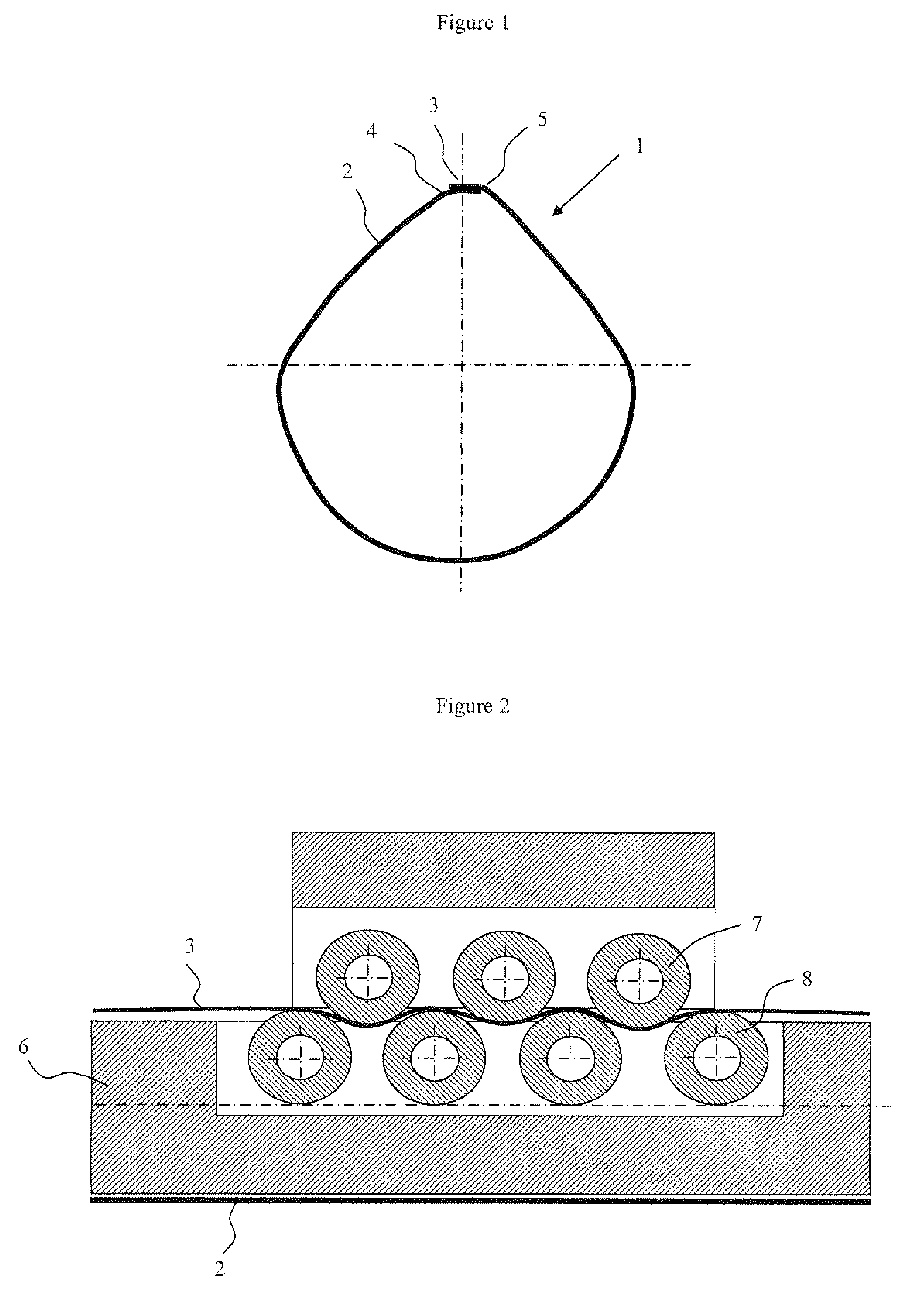

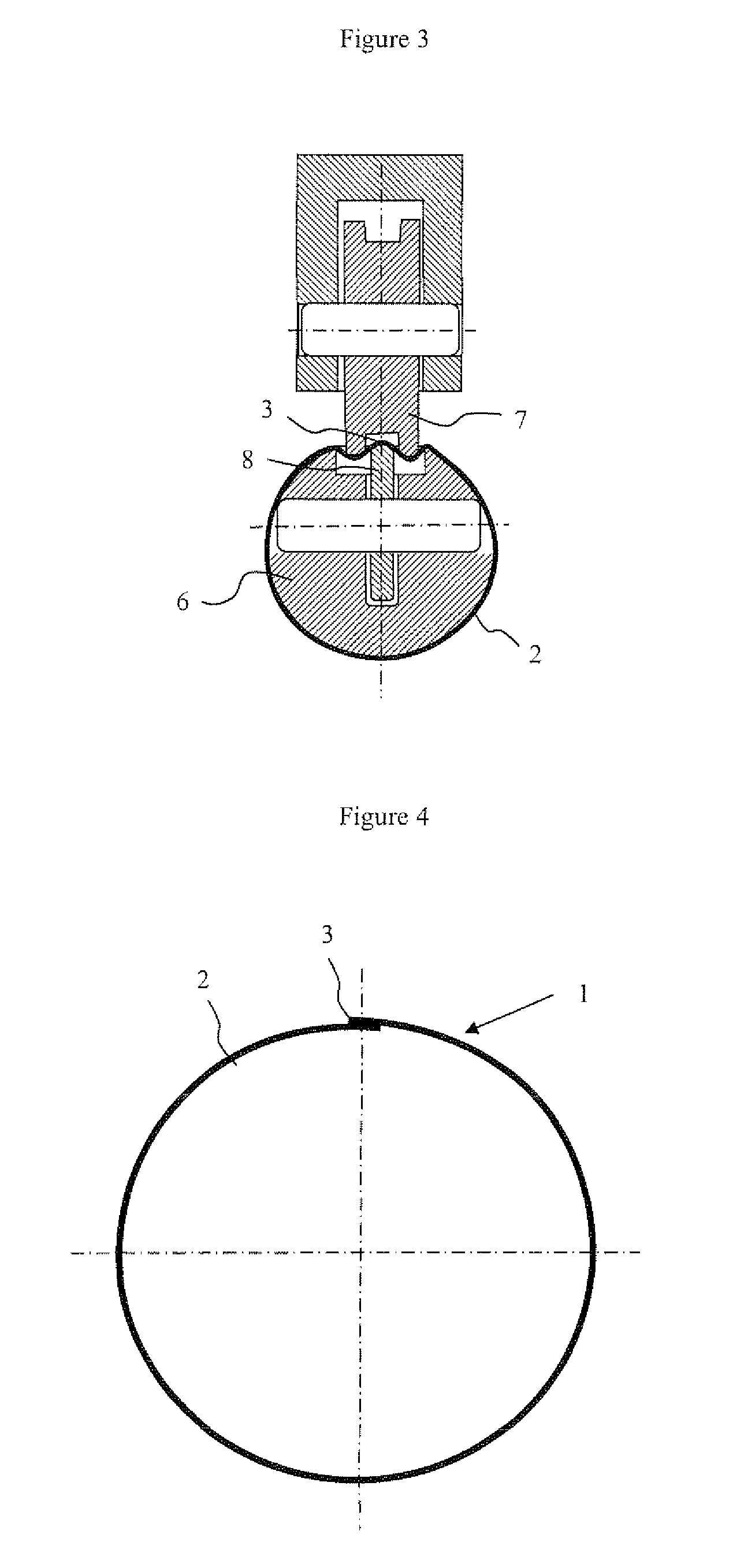

Filter comprising membranes made of hollow fibers

InactiveUS7014765B2Limited degree of movementCompensation for shrinkageSemi-permeable membranesIsotope separationHollow fibreFiber bundle

The invention relates to a filter comprising membranes made of hollow fibers in which the hollow fibers are arranged as a bundle in a tubular housing. The housing comprises an end cap on each of its ends, whereby the hollow fiber bundle is placed between the ends of the housing. The ends of the hollow fiber bundle each comprise a support ring that surrounds the same and are cast inside said support ring. The support rings are displaceably mounted in the housing in order to compensate for, among other things, axial contractions of the hollow fiber bundle occurring during heat sterilization.

Owner:GAMBRO DIALYSATOREN

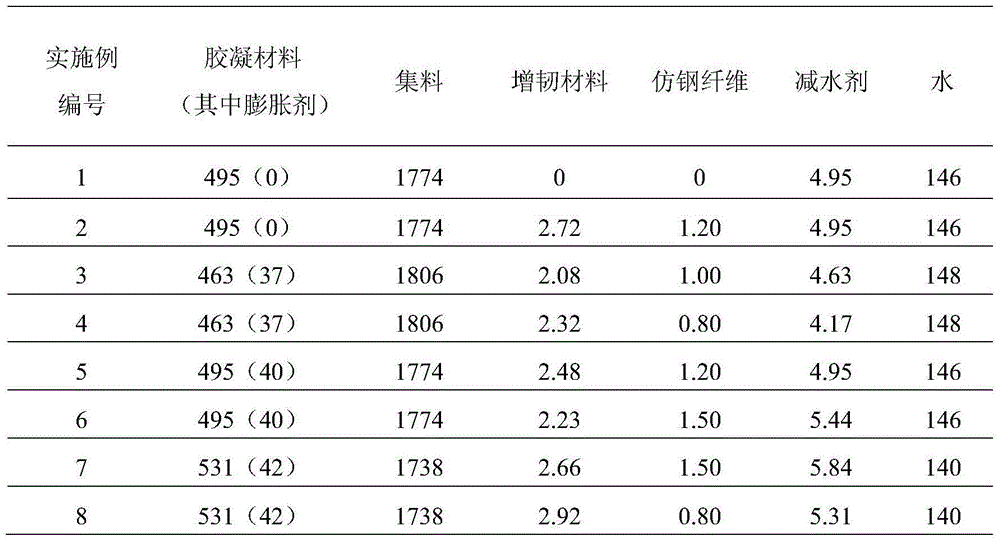

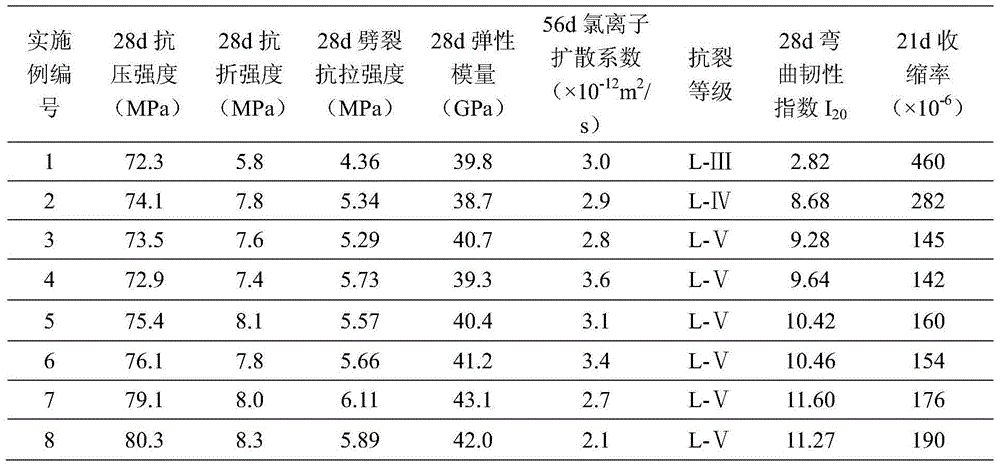

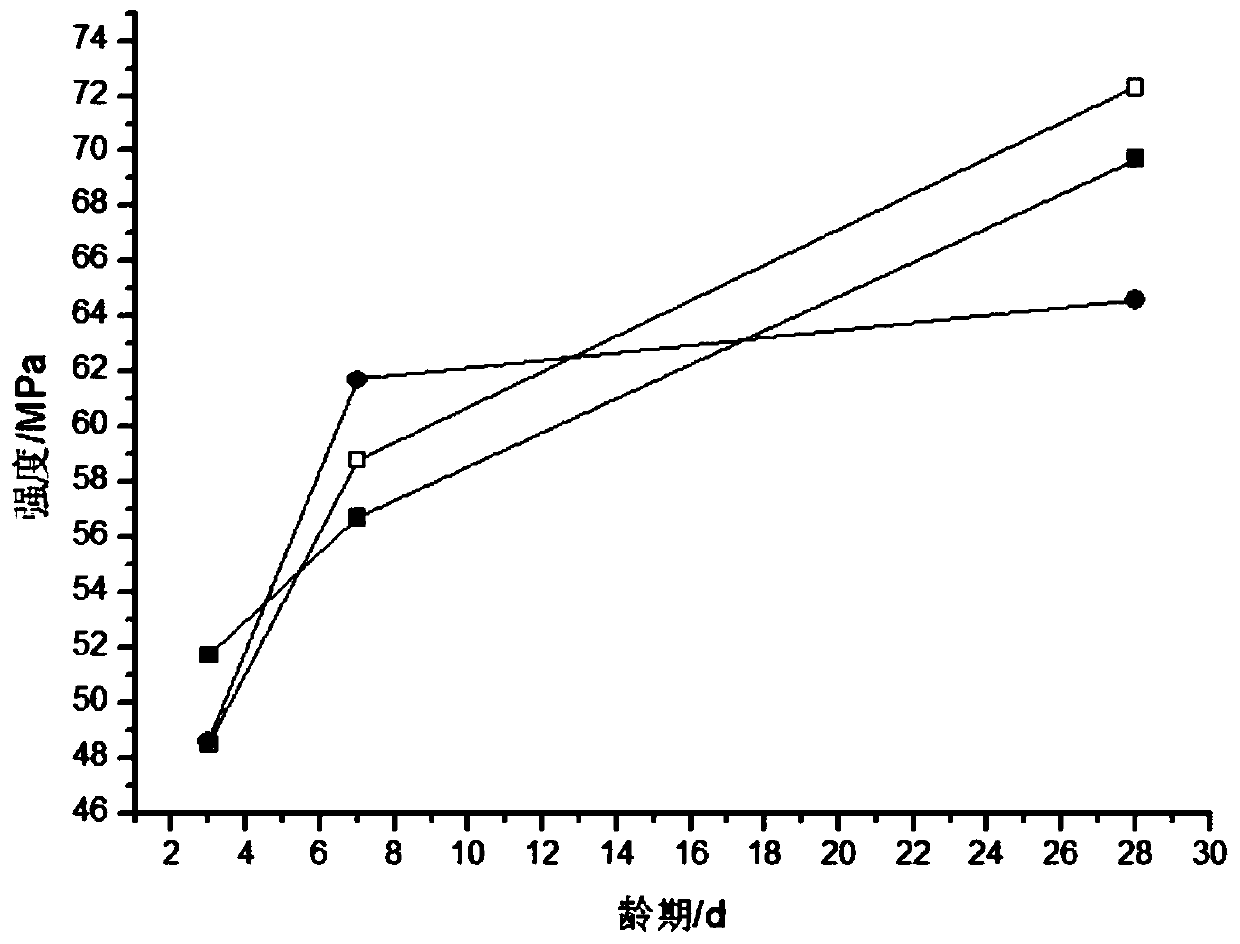

Micro-expansion fiber reinforced concrete and preparation method thereof

The invention discloses micro-expansion fiber reinforced concrete for a steel-concrete combined beam bridge panel wet joint and a preparation method of the micro-expansion fiber reinforced concrete, and relates to the preparation field of the micro-expansion fiber reinforced concrete. The micro-expansion fiber reinforced concrete comprises gel materials (cement, coal ash, slag powder and an expanding agent), aggregate, reinforcing materials, imitated steel fibers, a water reducer and water, wherein the 28 compressive strength of the micro-expansion fiber reinforced concrete is not lower than 69.0MPa, the 28d breaking strength of the micro-expansion fiber reinforced concrete is not lower than 7.0 MPa, the 28d splitting tensile strength of the micro-expansion fiber reinforced concrete is not lower than 5.0 MPa, the 28d elasticity modulus of the micro-expansion fiber reinforced concrete is not lower than 36.0 GPa, the cracking resistance level of the micro-expansion fiber reinforced concrete reaches L-IV level, the 28d bending toughness index I20 of the micro-expansion fiber reinforced concrete is not lower than 8, the 56d chlorine ion diffusion coefficient of the micro-expansion fiber reinforced concrete is lower than 4.0*10<-12>m<2> / s, the 21d shrinkage percentage of the micro-expansion fiber reinforced concrete is lower than 200*10<-6>. By using the preparation method, the shrinkage cracking of the micro-expansion fiber reinforced concrete can be effectively avoided, so that the reinforced concrete is relatively compact. The micro-expansion fiber reinforced concrete disclosed by the invention is relatively high in strength, relatively low in shrinkage percentage, good in bending toughness and durability, relatively low in cost and conveniently to widely use.

Owner:THE 2ND ENG CO LTD MBEC +1

Method and device for holding a metallic component to be connected, especially a gas turbine blade

InactiveUS20050205644A1No punctiform loading of its surfaceChange shapeTurbinesWelding/cutting auxillary devicesEngineeringMachining

A method for holding a metallic component of a gas turbine, which is to be connected, includes providing a metallic component having a surface and at least one machining or joining surface, providing a case having a cutout, which has an inner surface, for receiving the component, positioning the component in the case in such a manner that its surface is surrounded, at a distance, by the inner surface of the case, so as to form a closed volume and so that its machining or joining surface does not face the volume, filling the volume with a foamable material, foaming the material and cooling so as to form a dimensionally stable foam, structure. An apparatus for holding the metallic component and a method for connecting the metallic component to a further component are also provided.

Owner:MTU AERO ENGINES GMBH

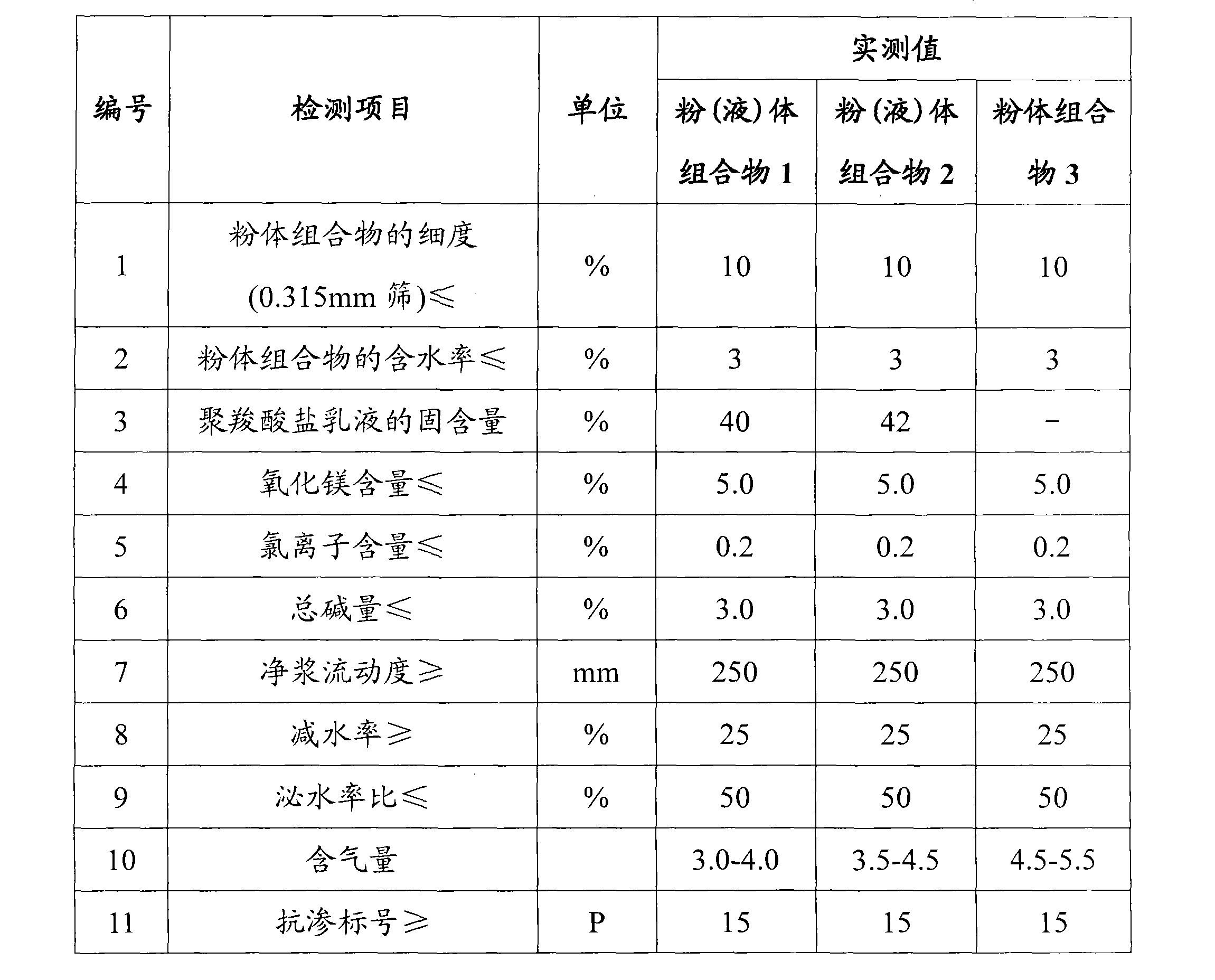

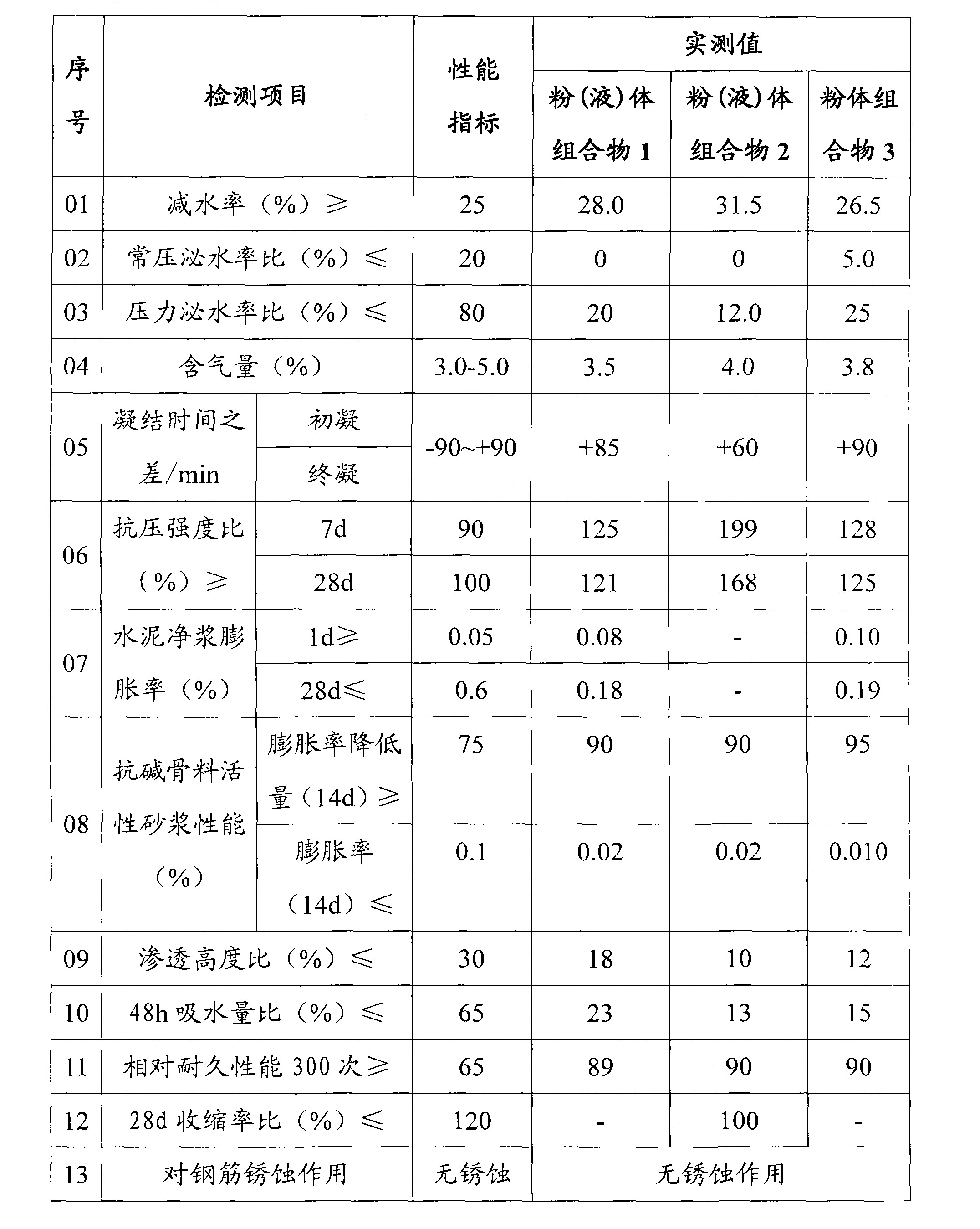

Composition for inhibiting concrete alkali aggregate reaction and preparation thereof

The invention belongs to the technical field of concrete engineering, and in particular relates to a composition for inhibiting concrete alkali-aggregate reaction and a preparation method thereof. The composition for inhibiting the concrete alkali-aggregate reaction comprises the following compositions: 10 to 50 percent of plasticizing agent, 10 to 70 percent of aluminate and 10 to 30 percent of alkali metal salt or alkaline-earth metal salt, wherein the alkali metal salt or the alkaline-earth metal salt is selected from at least one group of lithium compounds, barium compounds or calcium-magnesium compounds, and the total content of various compositions is 100 percent. The composition can cover or coat active elements of aggregate, prevent or isolate contact reaction between alkali metal ions such as K<+> and Na<+> and the active elements of the aggregate, prevent generation of soluble swelled gel and generation of insoluble compounds, and further eliminate alkali-aggregate reaction and improve the durability of concrete.

Owner:苏笮斌

Preparation method of waterproof concrete

Provided is a preparation method of a waterproof concrete; raw material components comprising cement, sand, carpolite, water, a water reducing agent, a swelling agent and fly ash are stirred and mixed and cured to obtain the waterproof concrete; the swelling agent allows the concrete to swell in a constrained environment, communication holes in the concrete are significantly reduced, the anti-permeability waterproof properties are enhanced, and the strength is also increased significantly; with addition of the water reducing agent, the stability and performance of the concrete are enhanced, problems of common dissociation and water segregation and collapsed slump loss of large-liquidity pumped concrete are avoided, a non-vibrating self-compacting effect is achieved, and construction is convenient; with the use of the fly ash, concrete pores and capillary pores are filled, and with the addition of the fly ash, a pore structure of the concrete is improved and the compactness is increased; and the prepared waterproof concrete is good in self-compacting performance and excellent in anti-permeability and anti-crack performance, and has the later strength improved significantly.

Owner:XIJING UNIV

Method of molding ophthalmic lens product, and mold assembly used in the method

InactiveUS6355190B1Improve configuration accuracyPrevent evaporationFoundry mouldsOptical articlesMonomer compositionLiquid state

A method of molding an ophthalmic lens product by using a mold assembly which has a mold cavity, the lens product having a configuration corresponding to that of an ophthalmic lens or a precursor of the ophthalmic lens and being obtained by polymerizing a liquid monomer composition in the mold cavity to provide a polymer product which gives the lens product, the method comprising the steps of: preparing the mold assembly having a monomer storage space for storing the liquid monomer composition, which storage space is held in fluid communication with the mold cavity; filling the mold cavity of the mold assembly with the liquid monomer composition while the liquid monomer composition is accommodated in the monomer storage space; and polymerizing the liquid monomer composition at a temperature of 10-80° C. while a pressure higher than the atmospheric pressure is applied directly to a liquid surface of a mass of the liquid monomer composition accommodated in the monomer storage space.

Owner:MENICON CO LTD

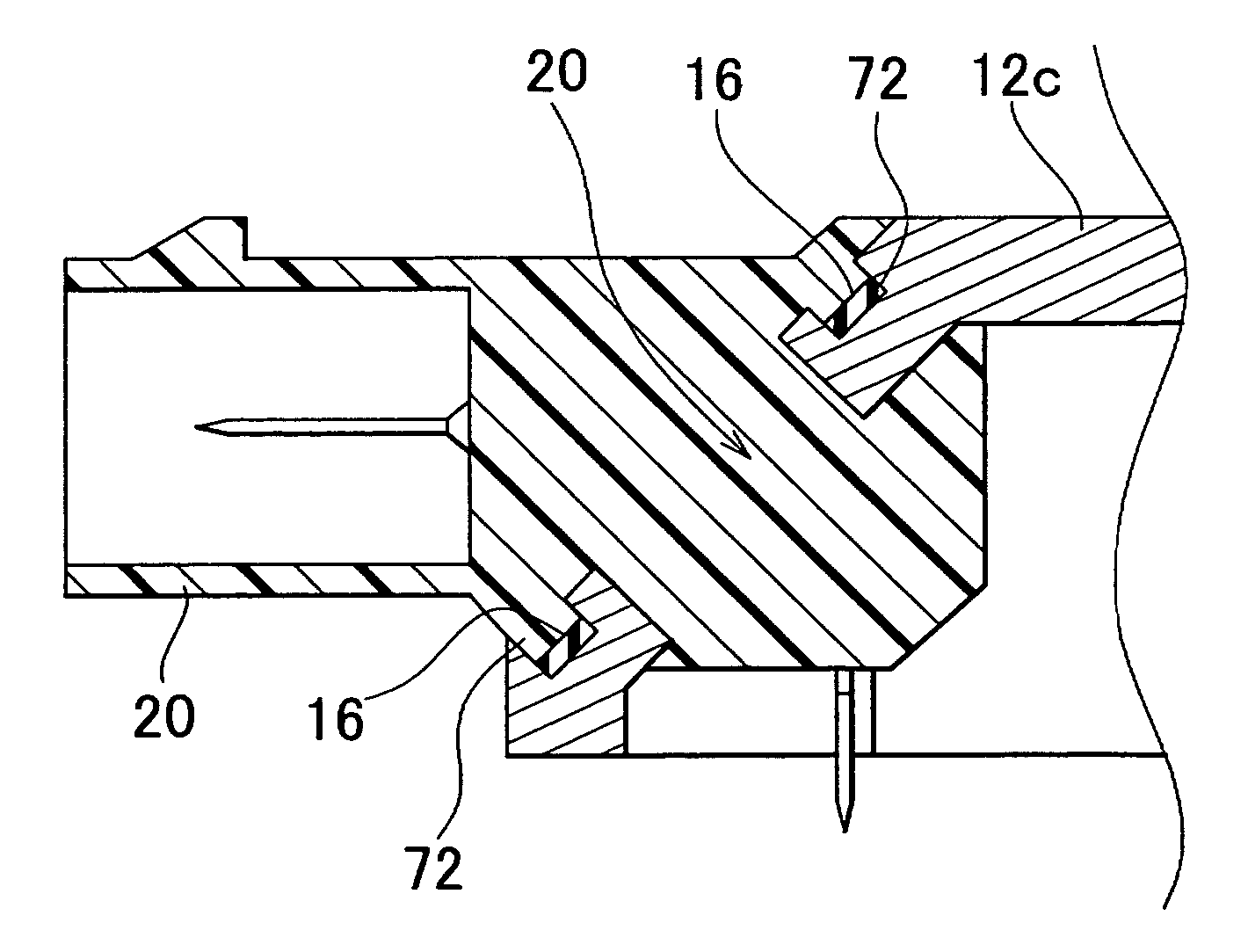

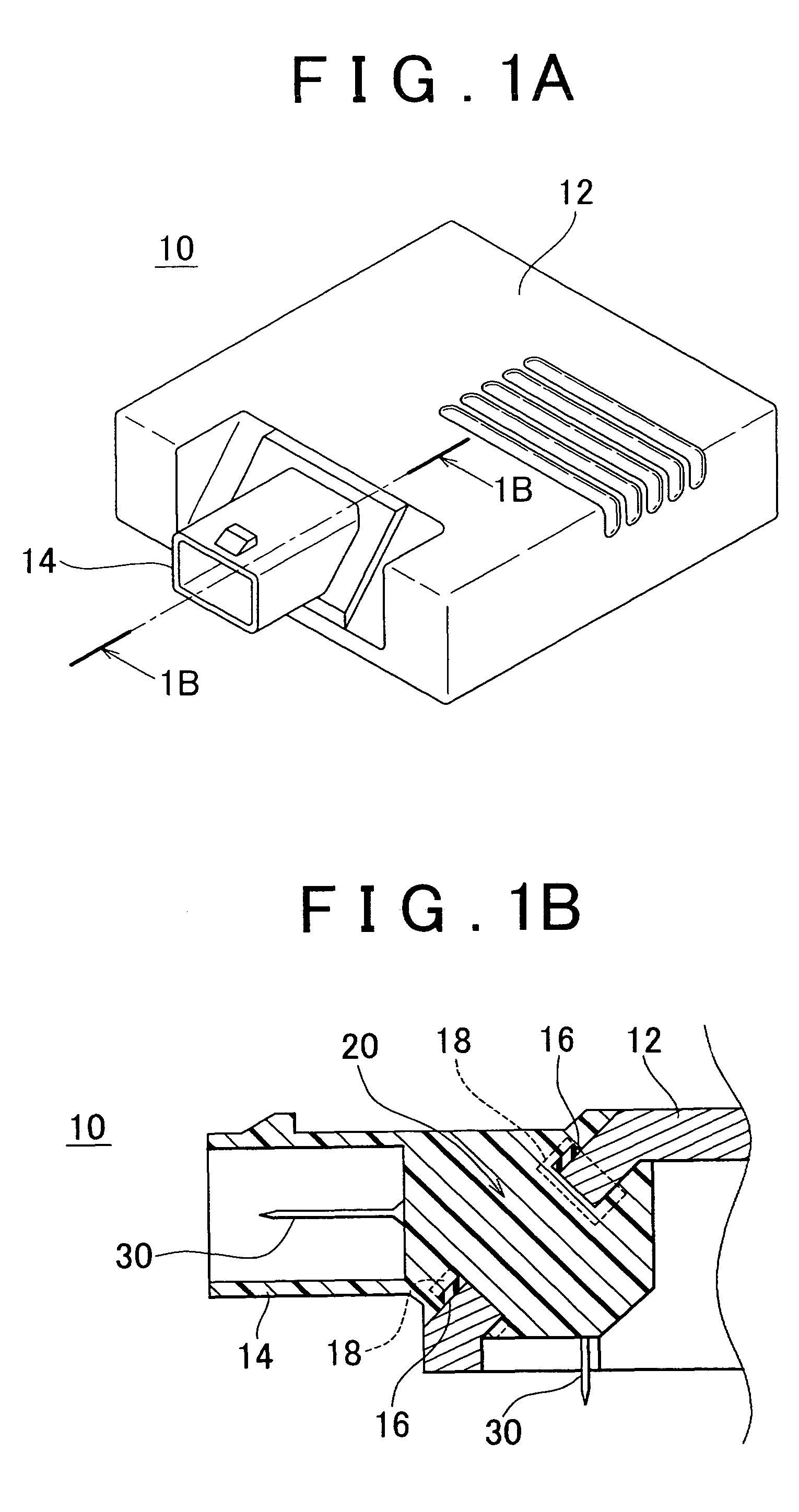

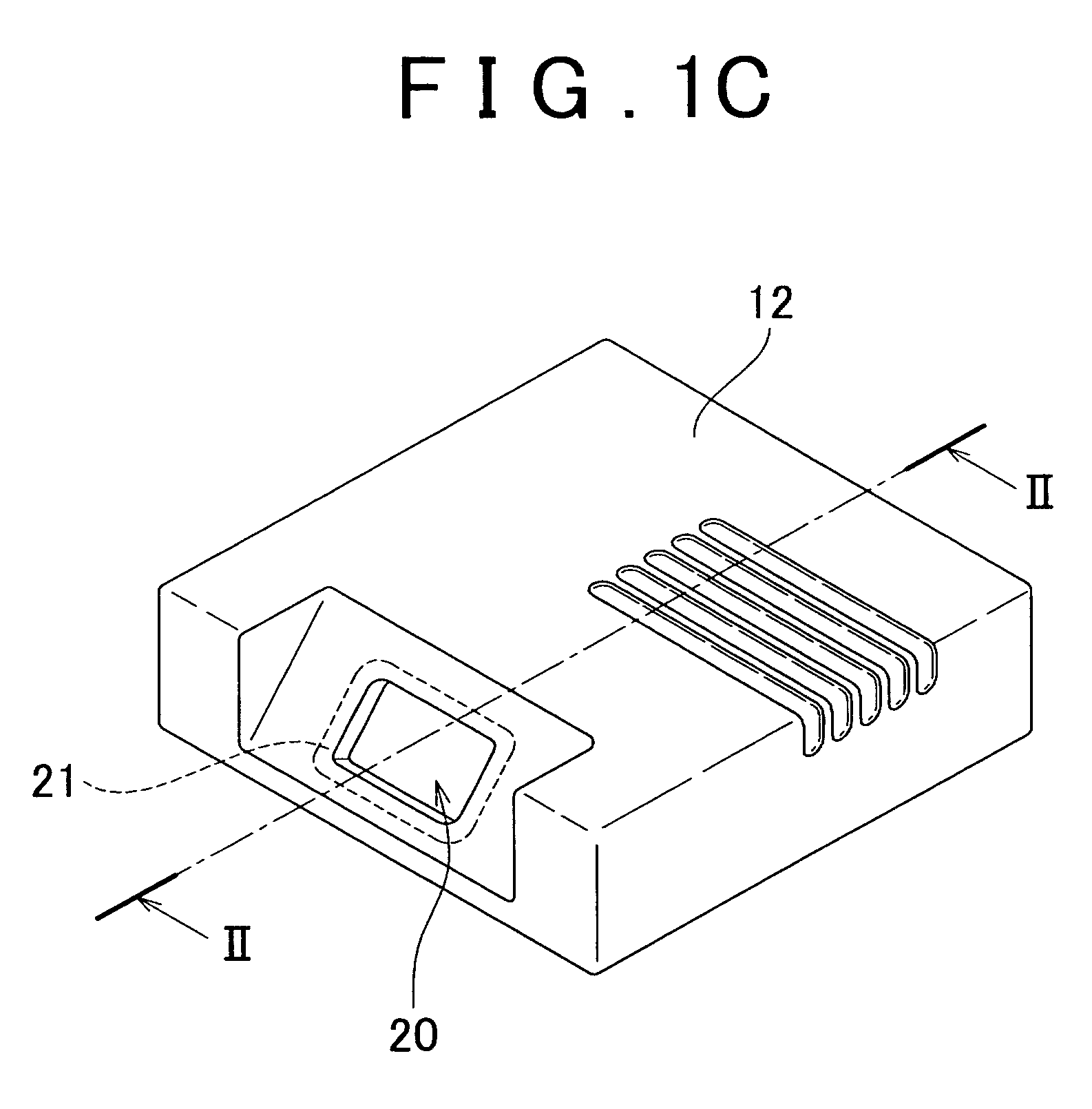

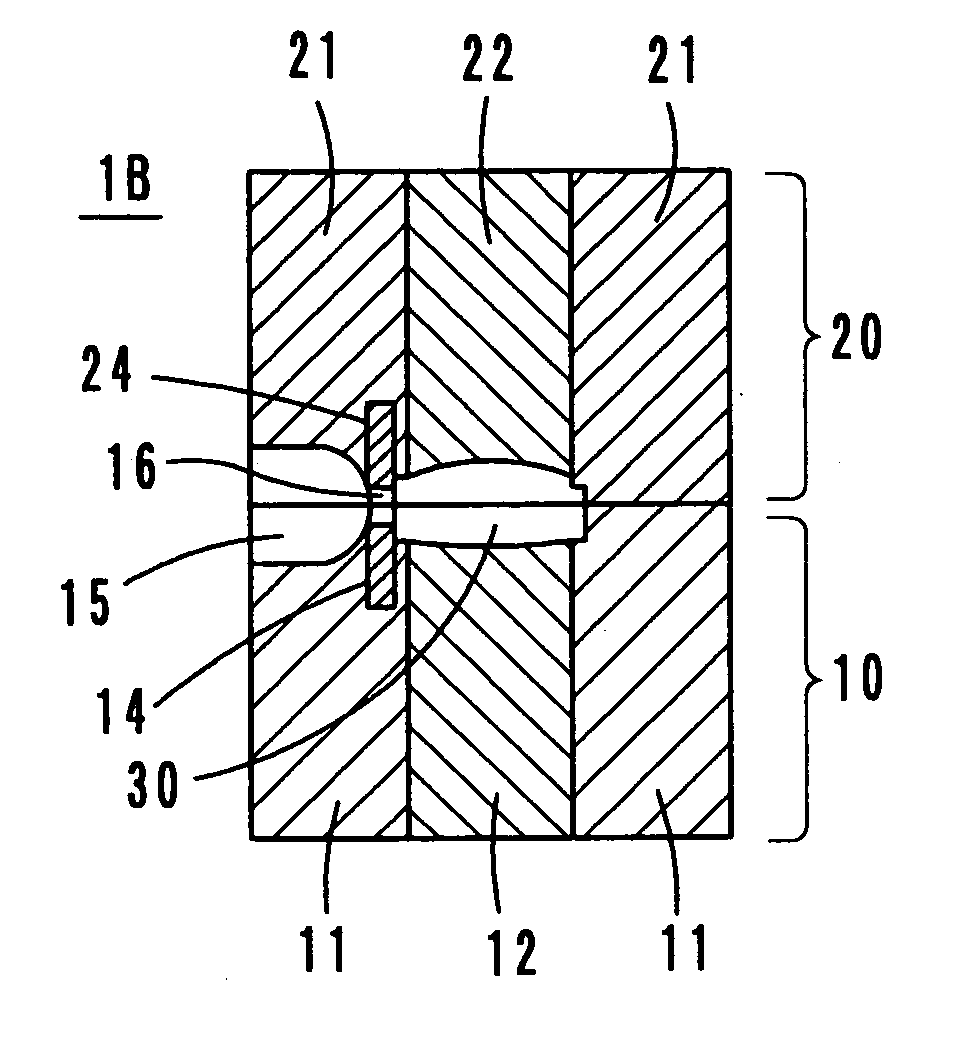

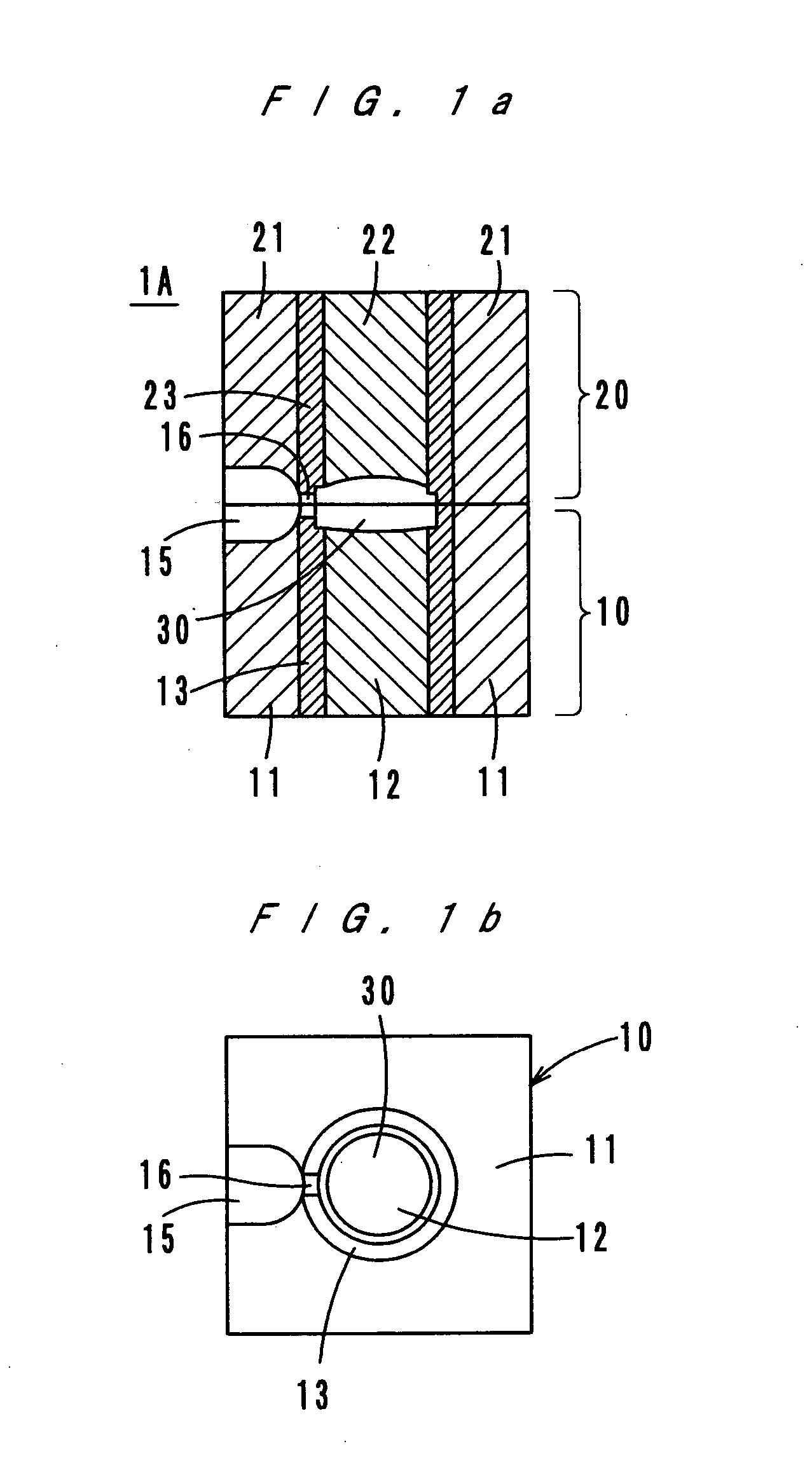

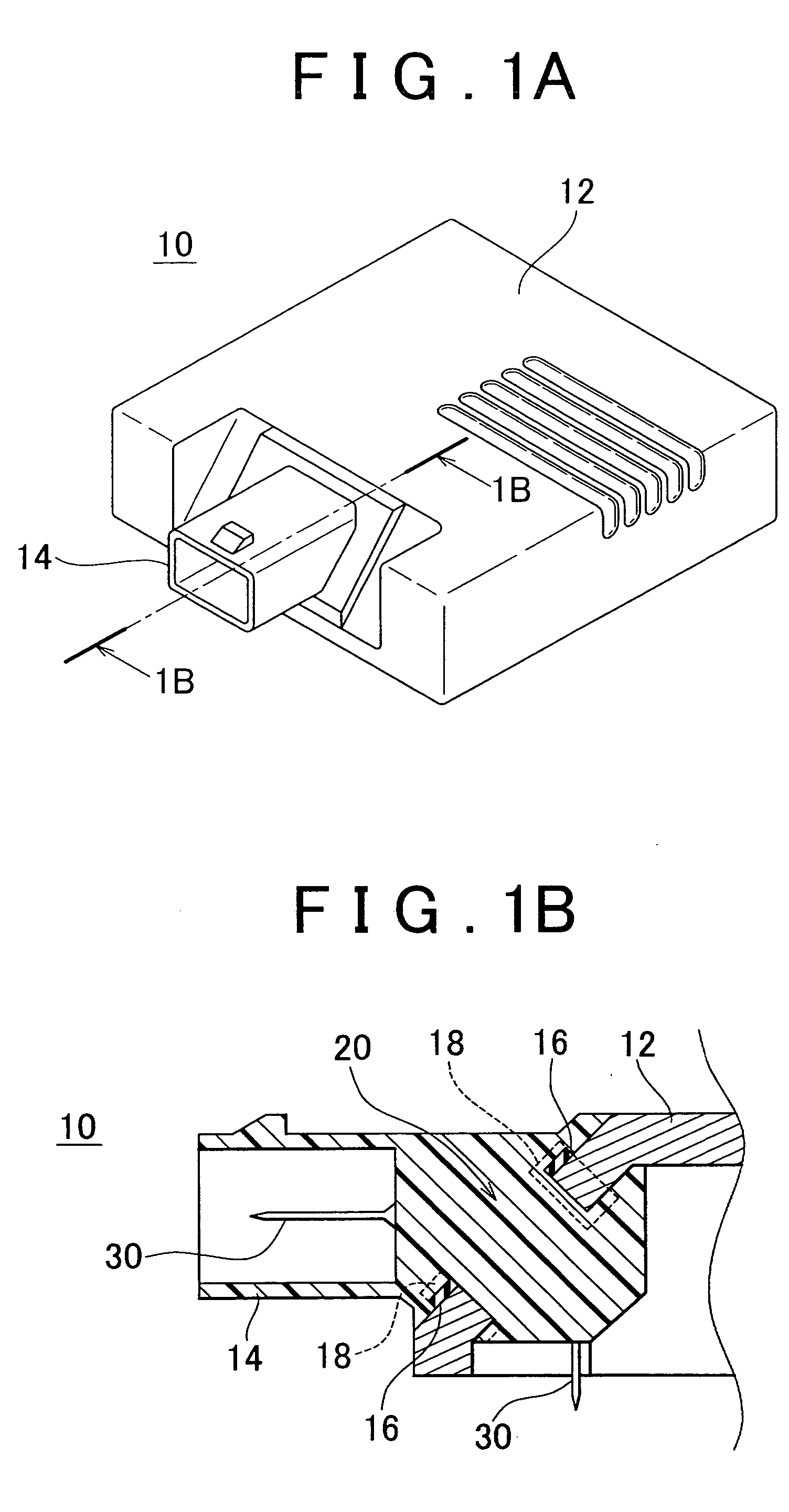

Molded article production method and molded article

InactiveUS8038914B2Improve air tightnessCompensation for shrinkageContact member assembly/disassemblyMouldsPolymer scienceShell molding

In a method for producing a molded article having a resin part, the resin part is injection-molded to an opening of a main body part and the molded article has an excellent air-tightness between the resin part and the main body part. A foam sealant is attached to a peripheral portion around the opening of the main body part. Attached to the main body part is a retainer made of the same kind of resin as injected resin and adapted to keep the foam sealant compressed in its thickness direction. The main body part is placed within a mold so that the retainer is exposed inside a cavity of the mold. A molten resin is injected into the cavity of the mold. The injected resin and the retainer are integrated into the resin part.

Owner:TOYOTA JIDOSHA KK +1

Composite ceramic block

ActiveUS20110229858A1High strengthImprove permeabilityDental implantsImpression capsComposite ceramicBlock method

Methods of producing a composite block intended for the production of a dental prosthesis including the following steps: a) impregnating a porous support with a liquid resin and b) curing the liquid resin impregnating the support are provided. In such methods of producing a composite block intended for the production of a dental prosthesis, a volume of liquid resin that is greater than the volume of the open pores of the support by at least 2% is caused to penetrate into the support and to cure therein, said volumes being measured at a temperature of 20° C. and at a pressure of 1 bar.

Owner:SADOUN MICHAEL

Injection mold and injection molding apparatus

InactiveUS20050287243A1High transmission accuracyRelieve stressFood shapingCoatingsMaterials science

An injection mold and an injection molding apparatus having a movable mold and a fixed mold. Each of the movable / fixed molds has bases, and a runner, a gate and a cavity are formed. The gate is composed of recesses made in mutually opposite end surfaces of sleeve-like heat insulators provided for the bases. Thereby, the gate is heat-insulated, and resin in the gate is prevented from cooling down during a pressure retention step. Thus, the resin keeps fluidity longer.

Owner:KONICA MINOLTA OPTO

Concrete water-retaining agent

The invention belongs to the technical field of concrete admixtures, in particular to a concrete water-retaining agent, made from the following materials according to parts by weight: 30-50 parts of hydroxypropyl methylcellulose, 10-18 parts of diatomaceous earth, 5-15 parts of glyceryl monostearate, 3-15 parts of calcium sulfoaluminate and 2-10 parts of alkyl glycoside. The concrete water-retaining agent of the invention has high water-retaining rate and stable properties and can improve the strength, cracking resistance and durability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

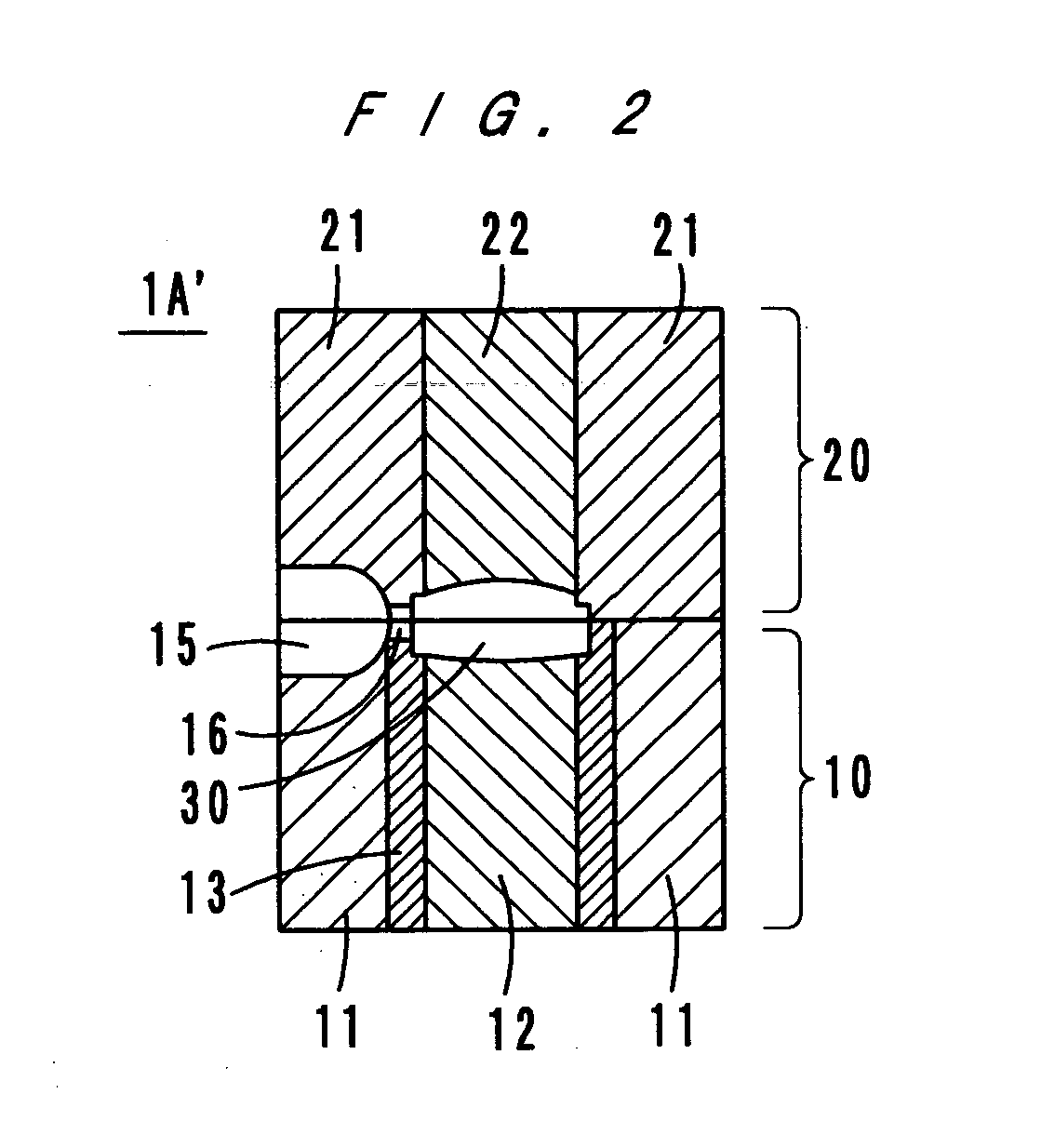

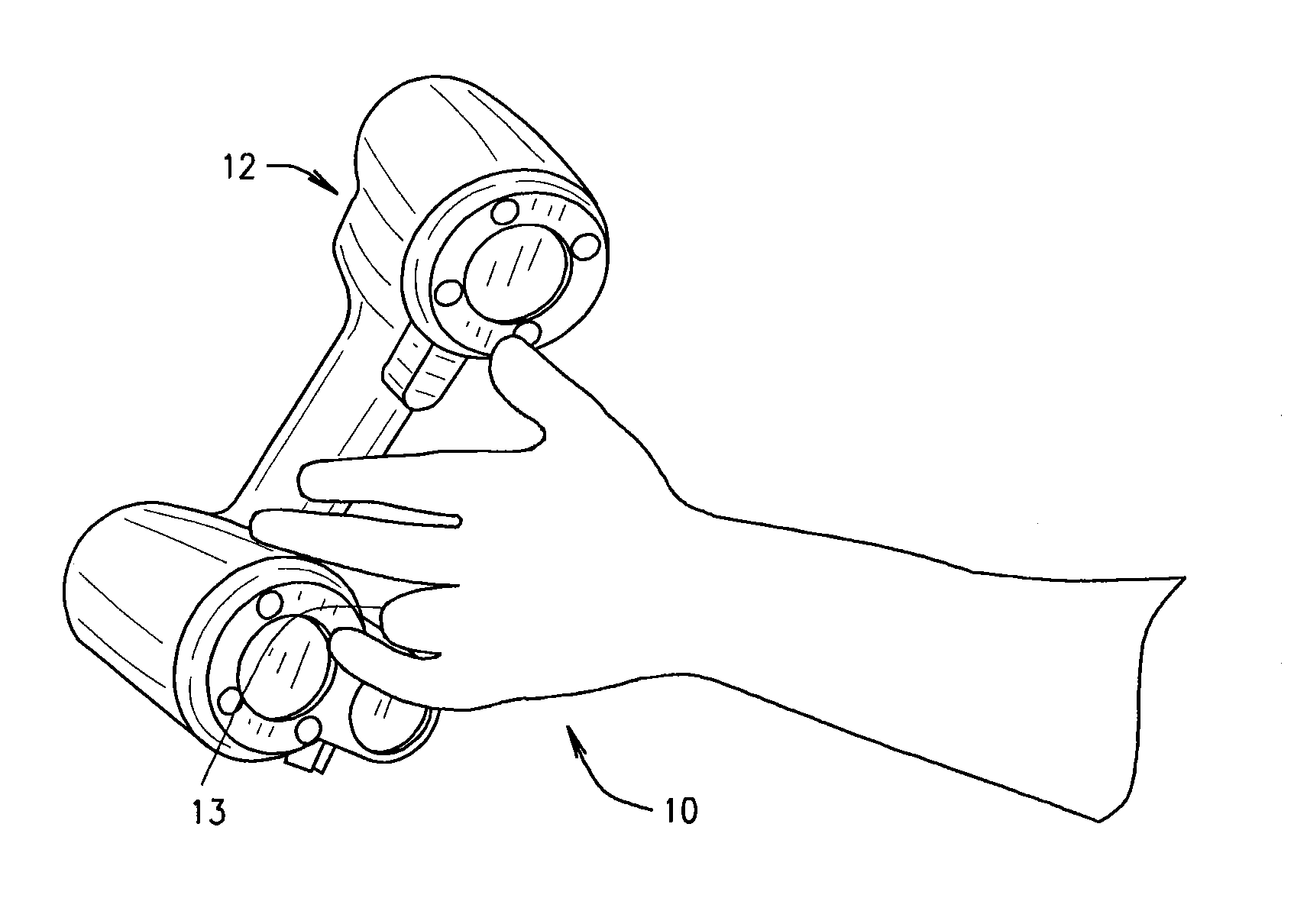

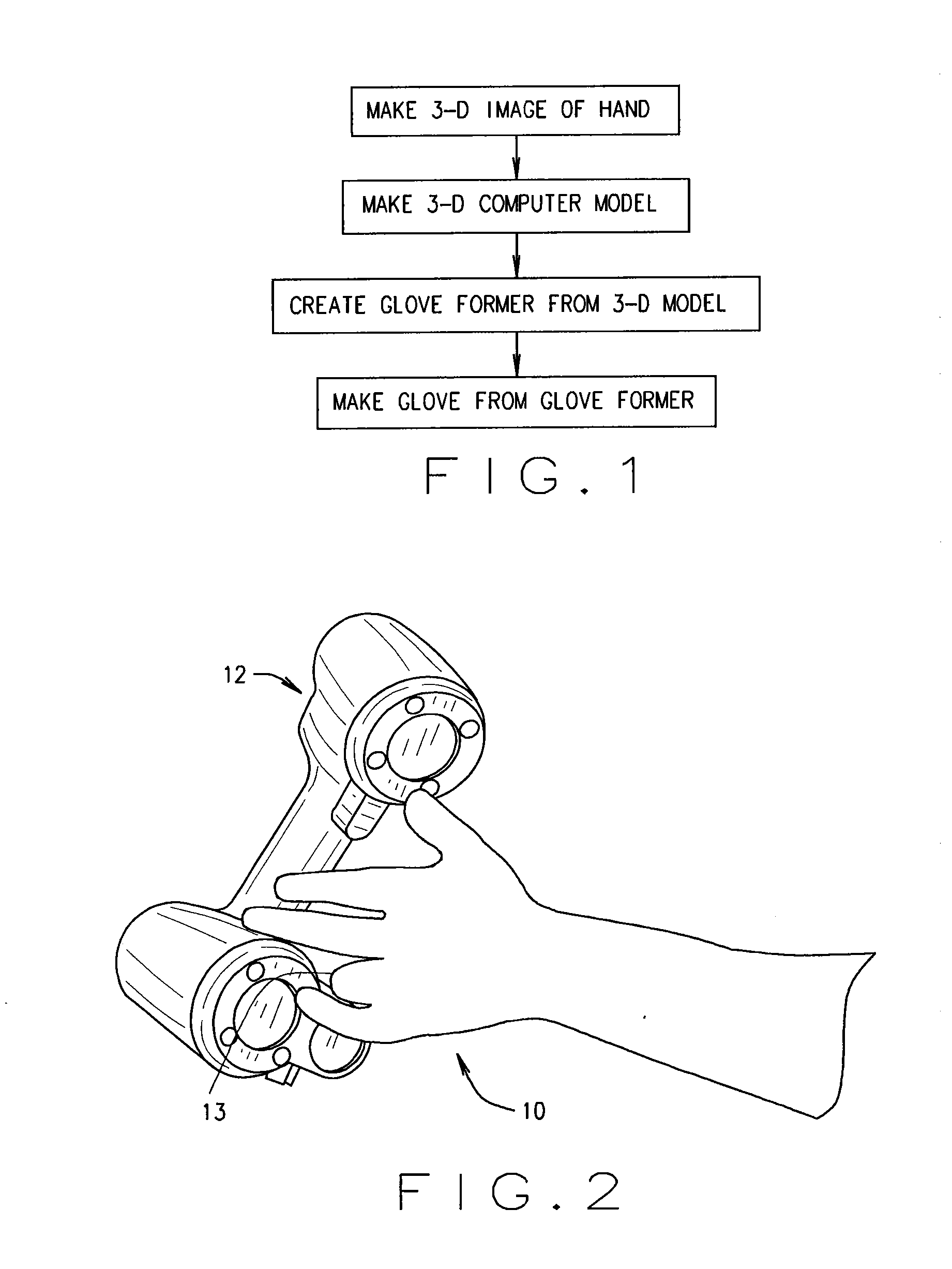

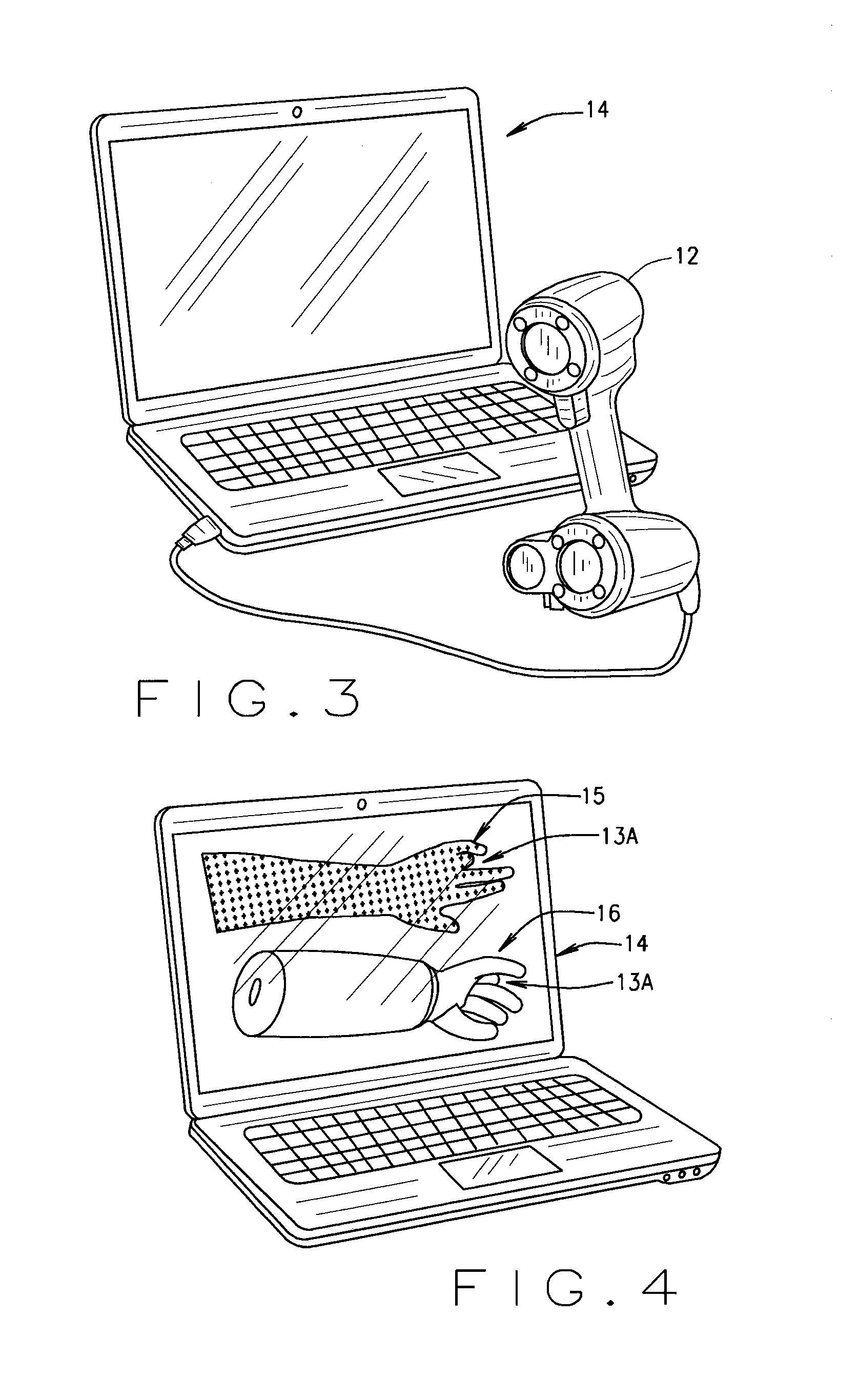

Process for making custom configured electrical lineman's gloves

InactiveUS20150374051A1Compensation for shrinkageProgramme controlAdditive manufacturing apparatusEngineeringRubber glove

A process for producing an electrical rated glove configured to fit the hand of an individual, comprising the steps of making a three dimensional image of the individual's hand; using an appropriately programmed computer to create a three-dimensional model from the image; using the three-dimensional model to create, through the three dimensional printer, a 3-dimensional glove former corresponding to the 3-dimensional image of the wearer's hand; dipping the glover former in a rubber to form a rubber glove on the former corresponding to the shape to the glove former, thus corresponding to the wearer's hand. In another aspect, the process comprises making a three dimensional image of and individual's hand; constructing a mold based upon the three dimensional image of the hand; molding a glove former in the mold; and forming a rubber glove on the glove former.

Owner:GATO ASSETS

Composite ceramic block

ActiveUS8507578B2High strengthImprove permeabilityDental implantsImpression capsComposite ceramicBlock method

Methods of producing a composite block intended for the production of a dental prosthesis including the following steps: a) impregnating a porous support with a liquid resin and b) curing the liquid resin impregnating the support are provided. In such methods of producing a composite block intended for the production of a dental prosthesis, a volume of liquid resin that is greater than the volume of the open pores of the support by at least 2% is caused to penetrate into the support and to cure therein, said volumes being measured at a temperature of 20° C. and at a pressure of 1 bar.

Owner:SADOUN MICHAEL

Steel slag sulphoaluminate-based expanding type base layer stabilization special cement and preparation method thereof

The invention discloses steel slag sulphoaluminate-based expanding type base layer stabilization special cement, which is prepared from the following ingredients in parts by weight: 10 to 45 parts of steel slag, 20 to 60 parts of portland cement clinker, 10 to 25 parts of sulphoaluminate cement clinker and 3 to 15 parts of gypsum. The portland cement clinker and the sulphoaluminate cement clinker are used in a compound way; solid wastes such as the steel slag and the gypsum are effectively used; the initial setting time of the cement material is greater than or equal to 6h; the final setting time is smaller than or equal to 10h; the 7-day linear expansivity is greater than or equal to 0.15 percent; the 28-day free expansivity is smaller than or equal to 1.0 percent; after popularization and application, the important significance is realized for promoting the comprehensive utilization of the steel slag and improving the anti-cracking performance and the strength of a pavement base layer; meanwhile, the cement production cost is effectively reduced.

Owner:WUHAN UNIV OF TECH

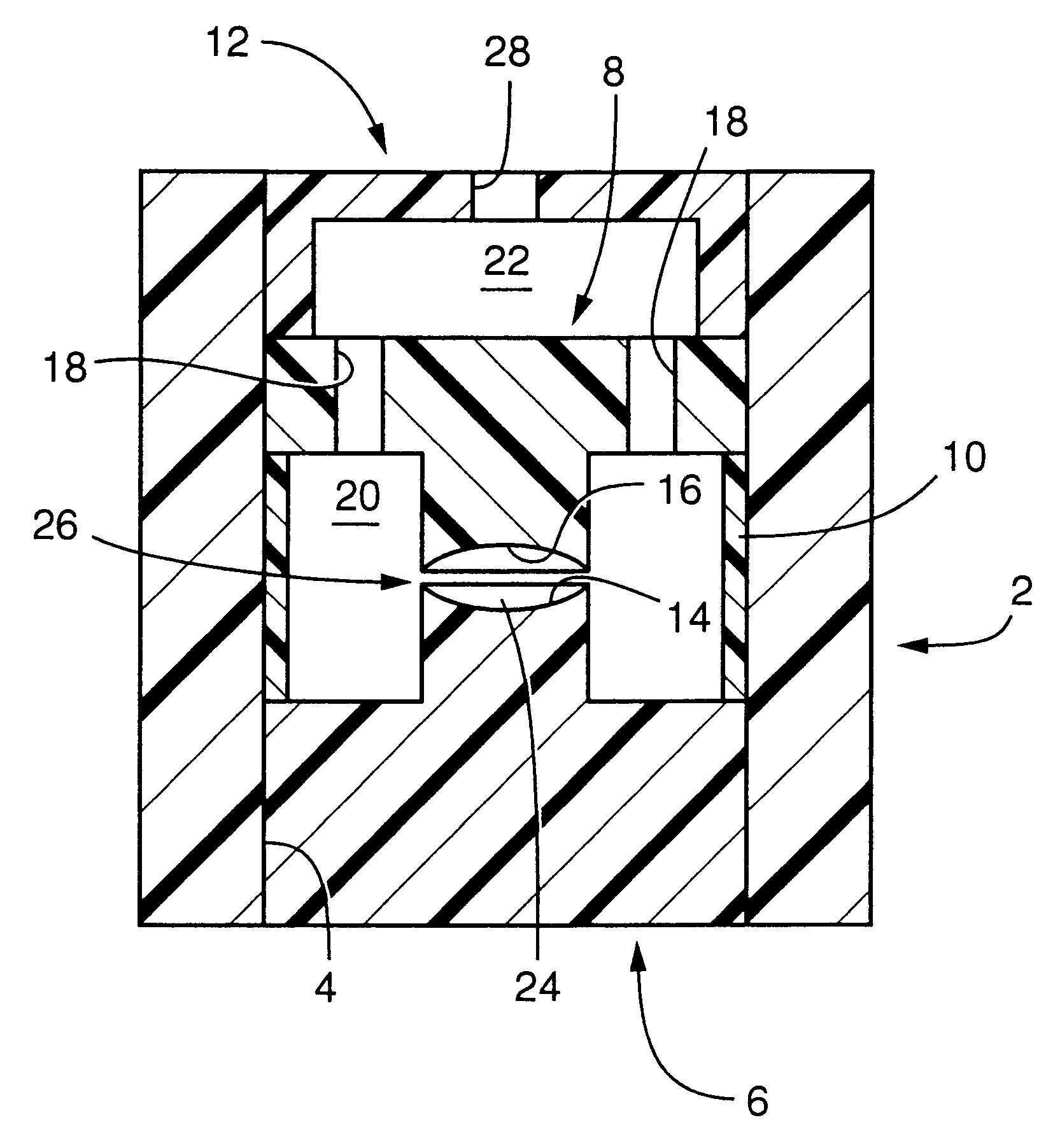

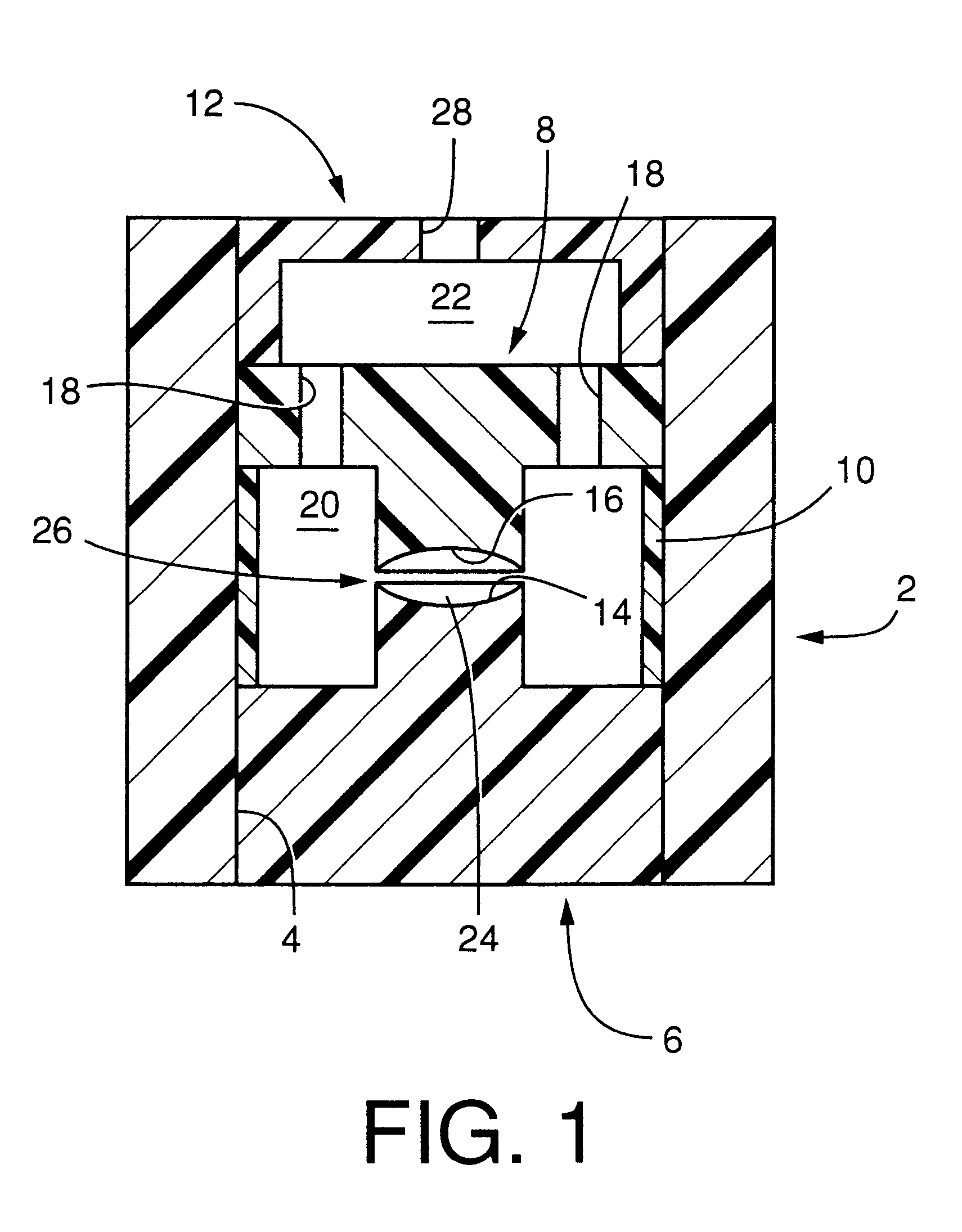

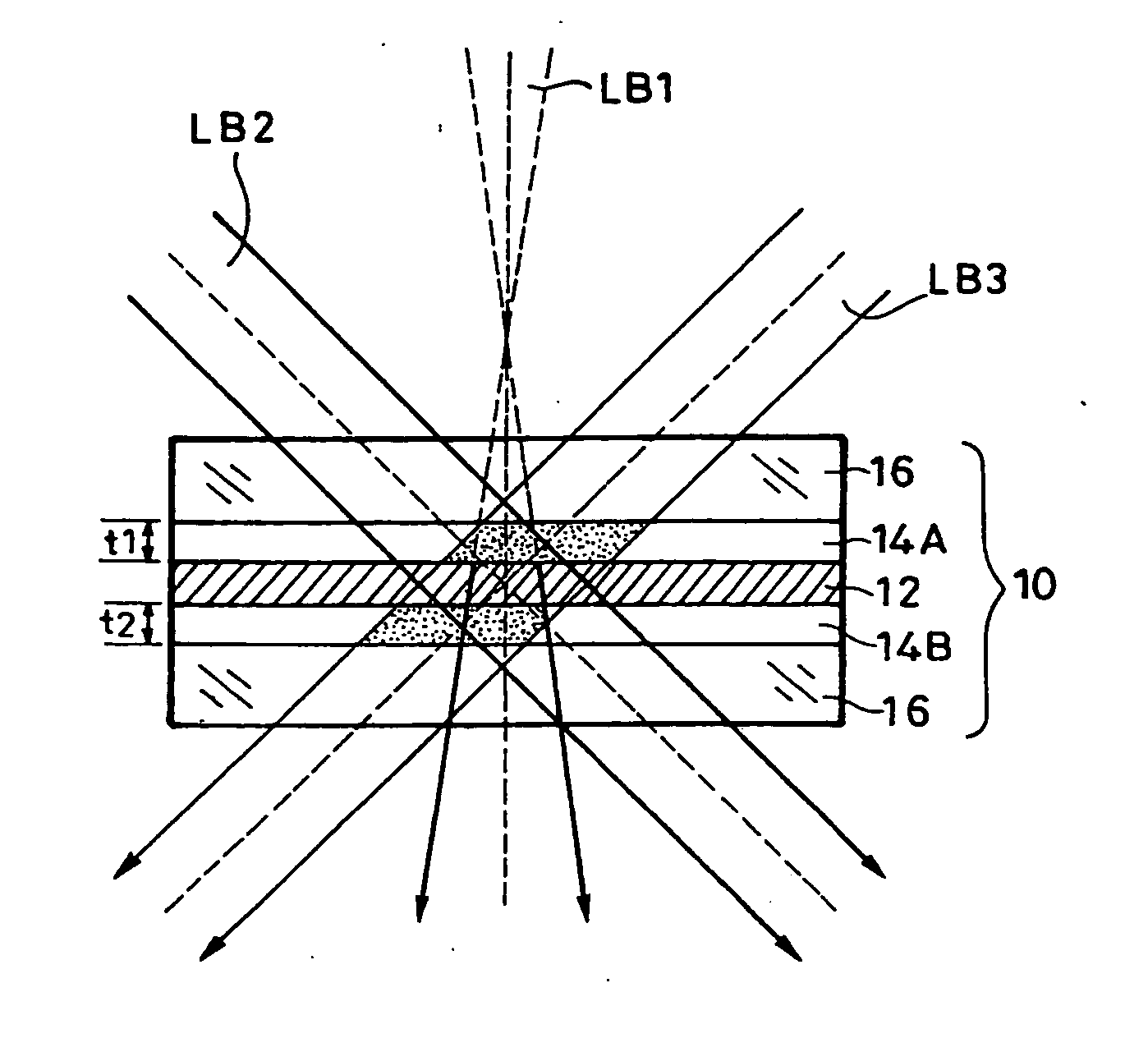

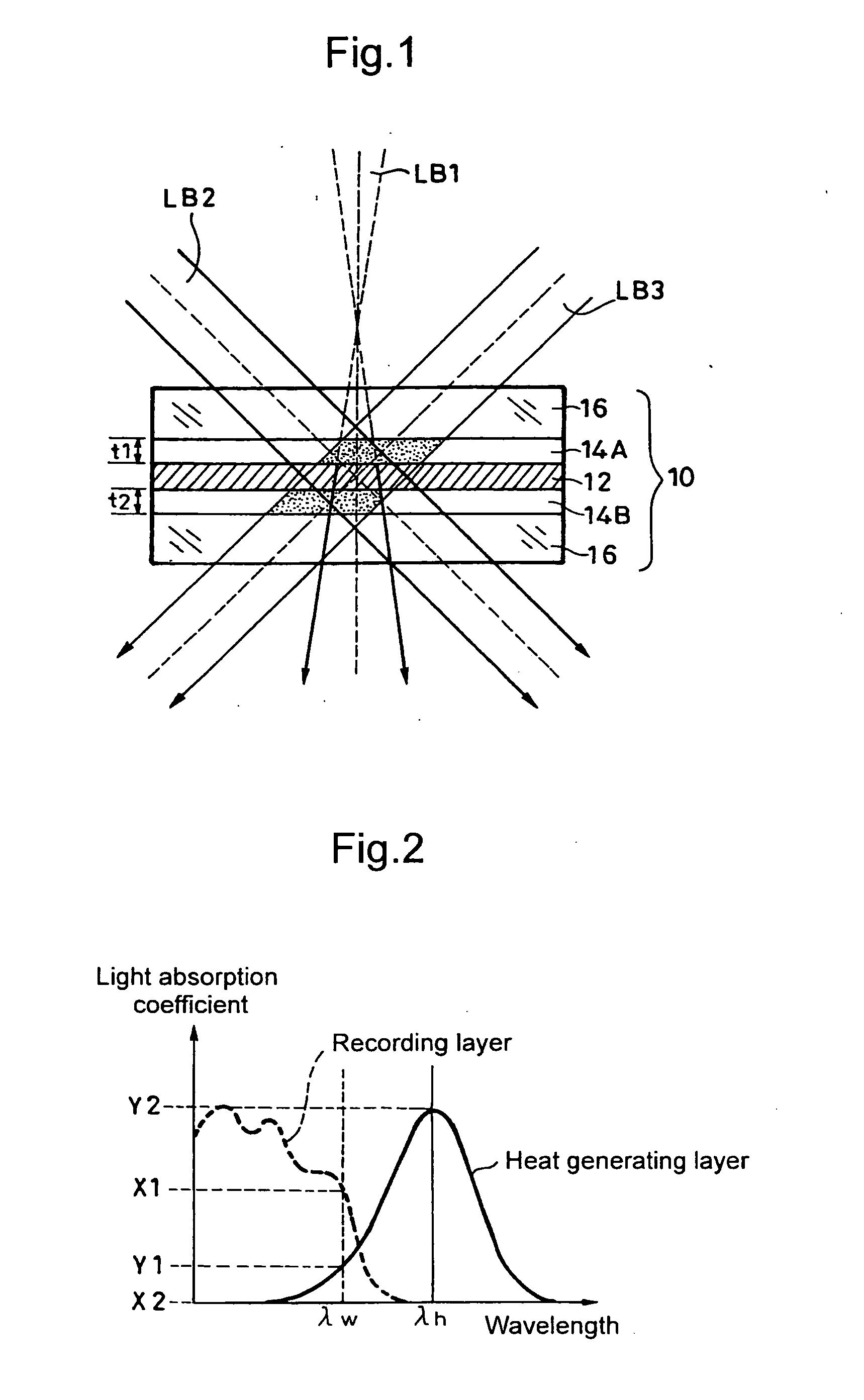

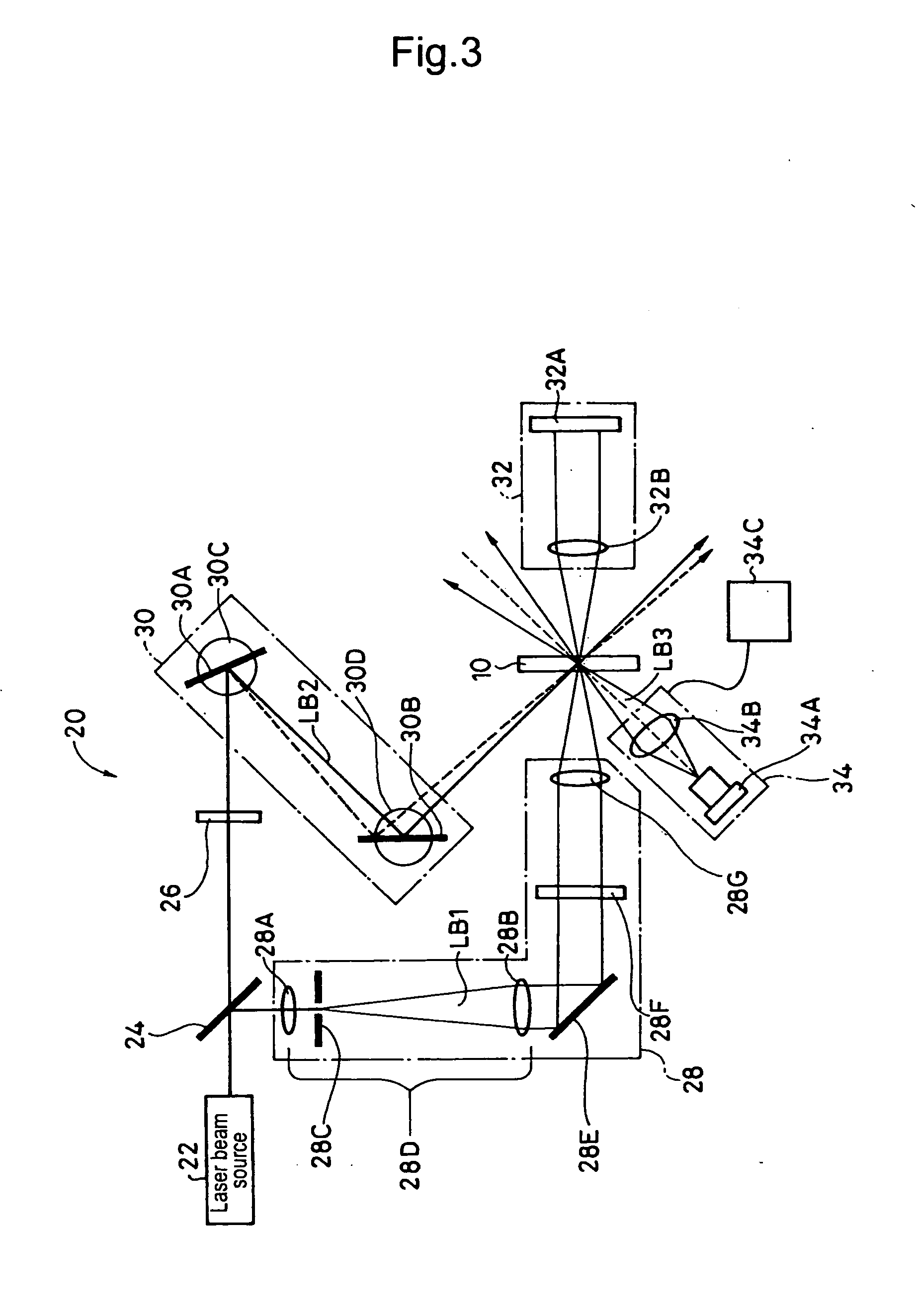

Holographic Recording Medium, Method for Recording and Reproducing the Same, and Reproducing Apparatus

InactiveUS20070206448A1Compensation for shrinkageRecord information storageOptical beam guiding meansPhysicsLaser beams

A holographic recording medium 10 is configured to have a recording layer 12 on which information can be recorded as holograms; and first and second heat generating layers 14A and 14B provided in a pair so as to sandwich the recording layer 12. Then, the first and second heat generating layers 14A and 14B are allowed to generate heat by being irradiated with a heat generating laser beam LB3 having a wavelength that is different from that of a signal beam LB1 or a reference beam LB2 for reproducing or recording information. The holographic recording medium and a method for recording and reproducing the same, and a recording and reproducing apparatus can compensate for shrinkage of the recording layer due to recording or variations in temperature, thereby allowing for reproduction of the holograms under optimum conditions.

Owner:TDK CORPARATION

Environment-friendly decoration cement

The invention discloses environment-friendly decoration cement and belongs to the technical field of building materials. The environment-friendly decoration cement is prepared from the following raw materials in parts by weight: 45-60 parts of Portland cement, 0-4 parts of an expanding agent, 4-10 parts of metakaolin, 2-6 parts of silicon powder, 1-3 parts of crystal whiskers, 5-10 parts of redispersible emulsion powder, 1-2 parts of a water reducer, 0.3-1.0 part of a defoaming agent, 0.1-0.15 part of cellulose ether, 5-10 parts of ground calcium carbonate and 10-15 parts of an environment-friendly material. The environment-friendly decoration cement disclosed by the invention has no problems such as alkali efflorescence and cracking and has good peaceability, corrosion resistance and environment-friendly performance.

Owner:JIAHUA SPECIAL CEMENT

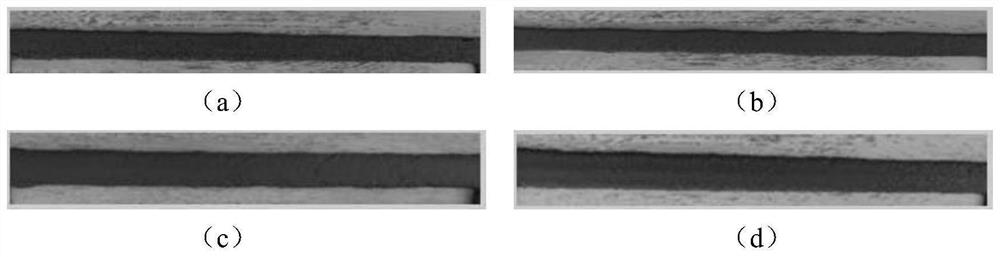

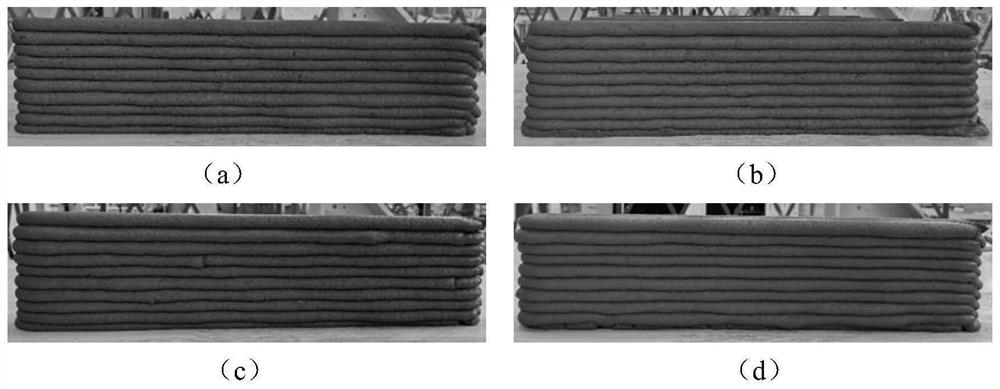

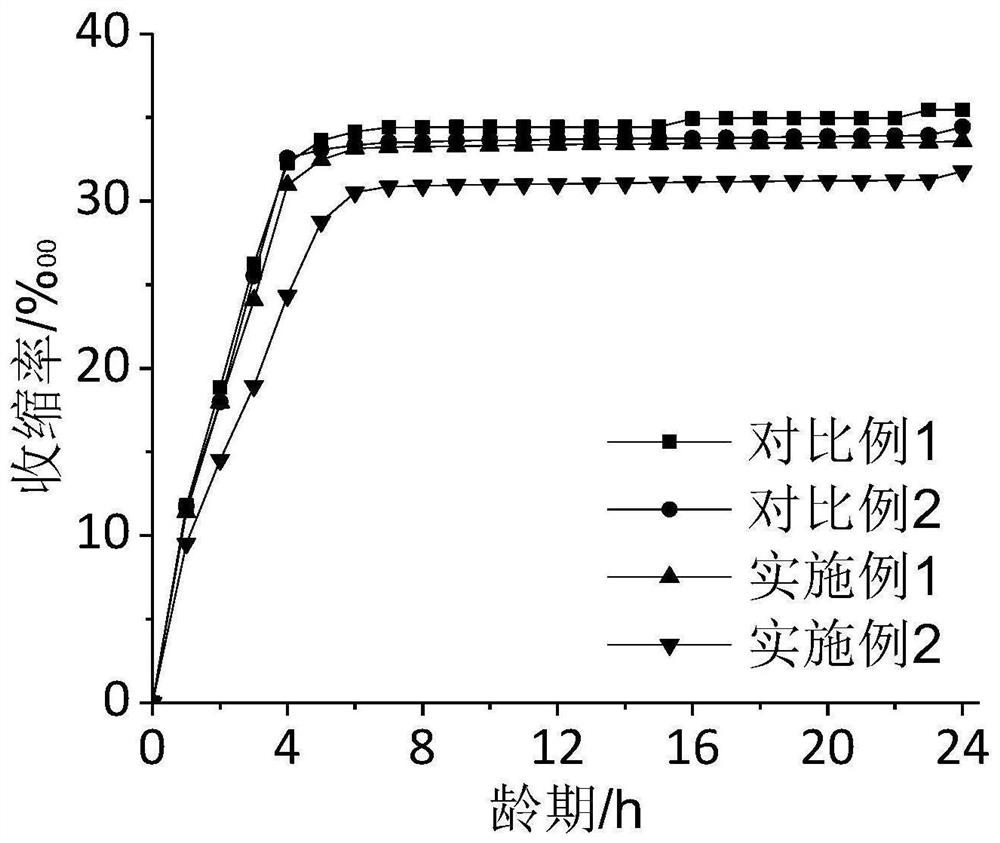

Low-shrinkage 3D printing concrete co-doped with lignin fibers and preparation method of low-shrinkage 3D printing concrete

ActiveCN113372074ASmall shrinkage deformationImprove early crack resistanceAdditive manufacturing apparatusSolid waste managementFiberAluminate

The invention discloses low-shrinkage 3D printing concrete co-doped with lignin fibers and a preparation method of the low-shrinkage 3D printing concrete. The concrete comprises the following components: high belite sulphoaluminate cement, ordinary Portland cement, lignin fibers, a UEA expanding agent, silica fume, quartz sand, water and an additive. The lignin fibers are applied to the 3D printing concrete for the first time, the effects of internal curing and fiber toughening are achieved, shrinkage deformation of the 3D printing concrete in all ages can be effectively reduced, the early-stage cracking resistance is improved, the interlayer bonding performance of the 3D printing concrete is effectively improved, and meanwhile the humidity balance of a concrete material can be adjusted. The high belite sulphoaluminate cement and the ordinary Portland cement are mixed according to a proper proportion to serve as a cementing material of the 3D printing concrete. The printability of the concrete can be optimized and the early strength of the concrete can be improved due to the characteristics of quick setting and early strength of the high belite sulphoaluminate cement, and the shrinkage deformation of the 3D printing concrete in the later period can be reduced due to the characteristic of low shrinkage.

Owner:HEBEI UNIV OF TECH +1

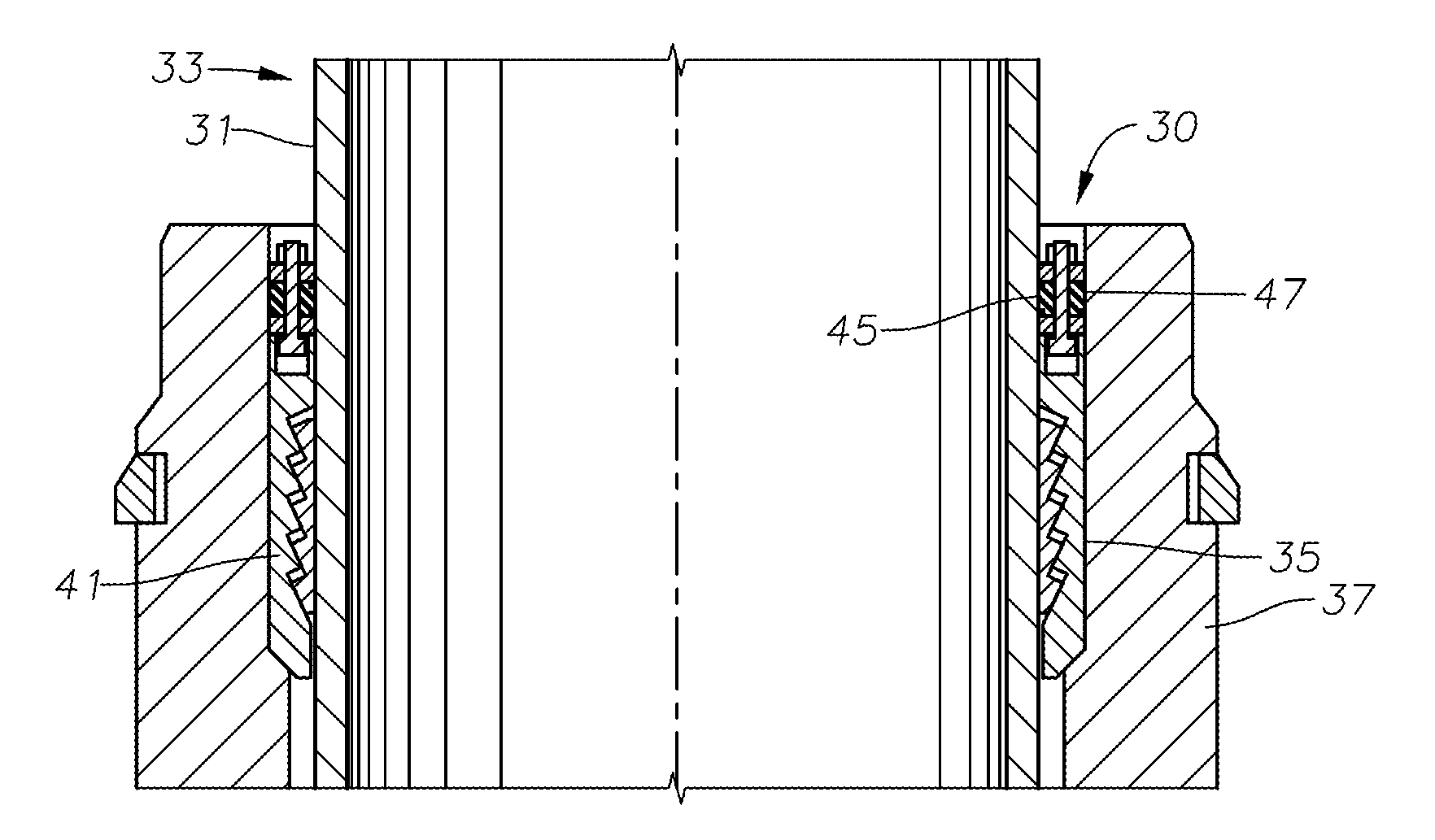

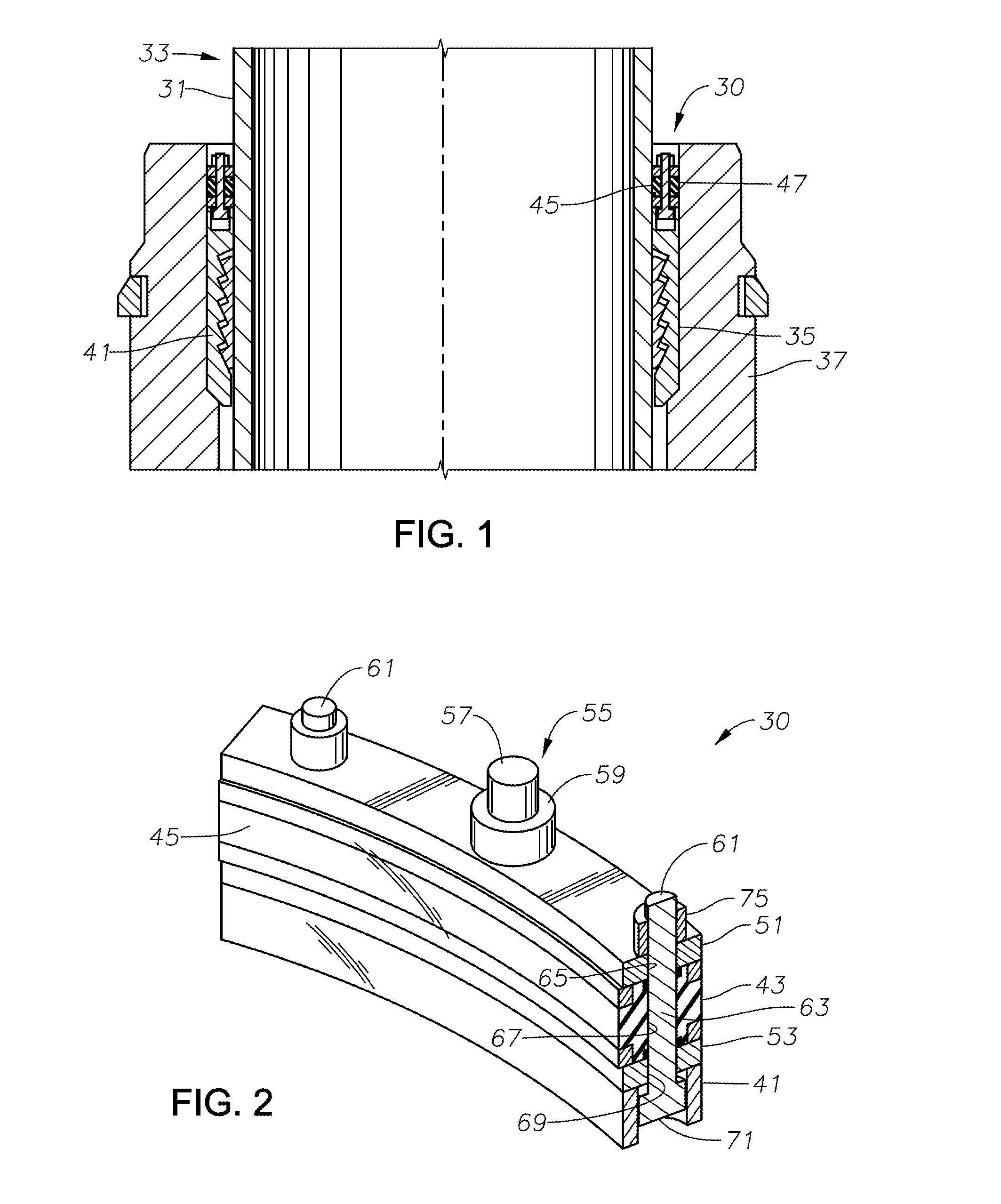

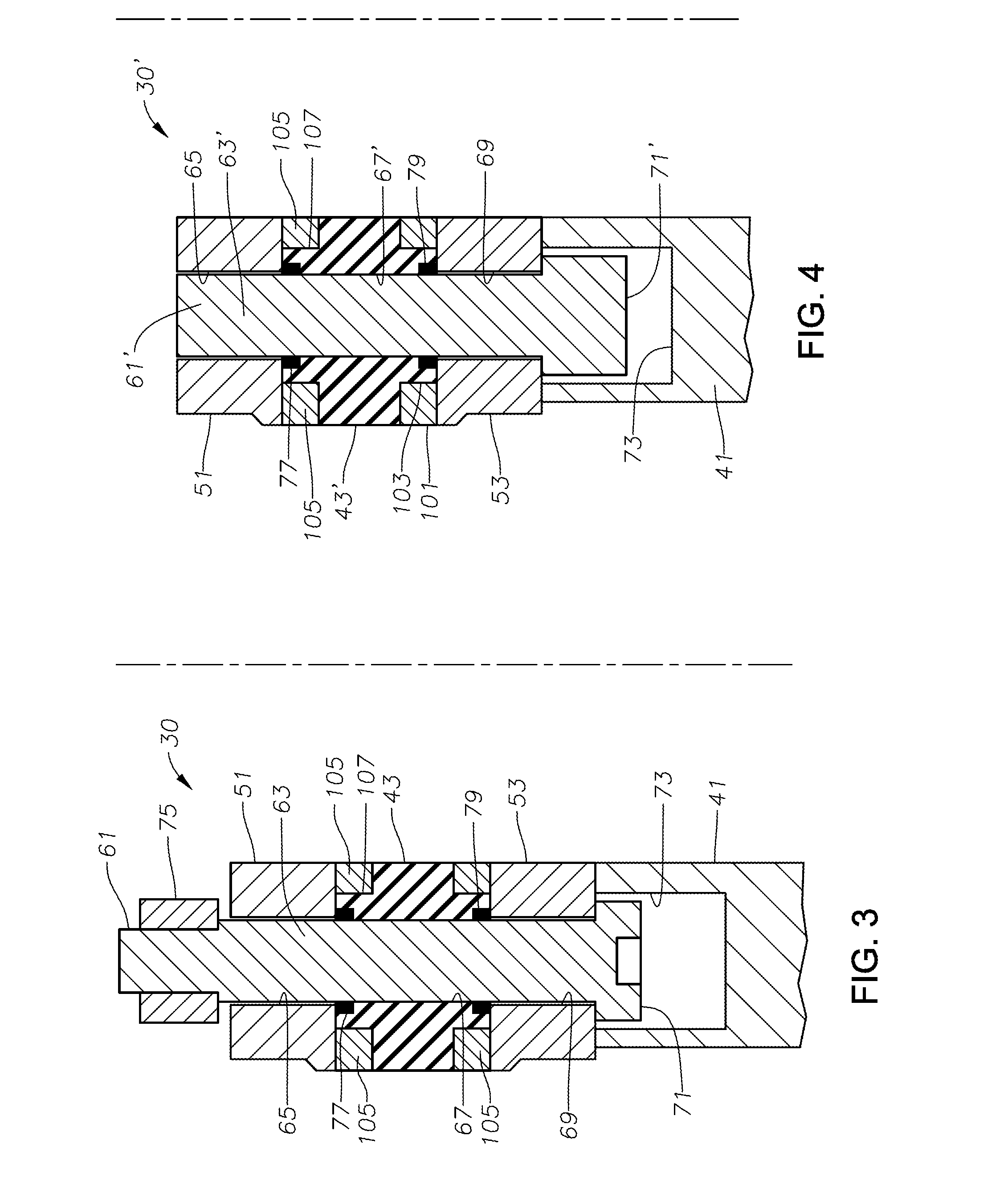

Shrinkage compensated seal assembly and related methods

InactiveUS20140131954A1Reduce decreaseLow costSleeve/socket jointsEngine sealsEngineeringCompression member

Shrinkage compensated seal assemblies and methods of compensating for shrinkage of a seal due to temperature variations, are provided. According to an exemplary shrinkage compensated seal assembly, the assembly includes a seal, a first compression member for engaging the upper surface of the seal, a second compression member for engaging the lower surface of the seal, and a plurality of pin members each having an elongate body and a head portion. The elongate body of each separate one of the plurality of pin members slidably extends through a different one of a plurality of sets of apertures in the first compression member, the seal, and the second compression member to provide for maintaining a substantially constant pressure on the seal at given pressure under varying temperature conditions that result in variations in the volume size of the seal.

Owner:VETCO GRAY

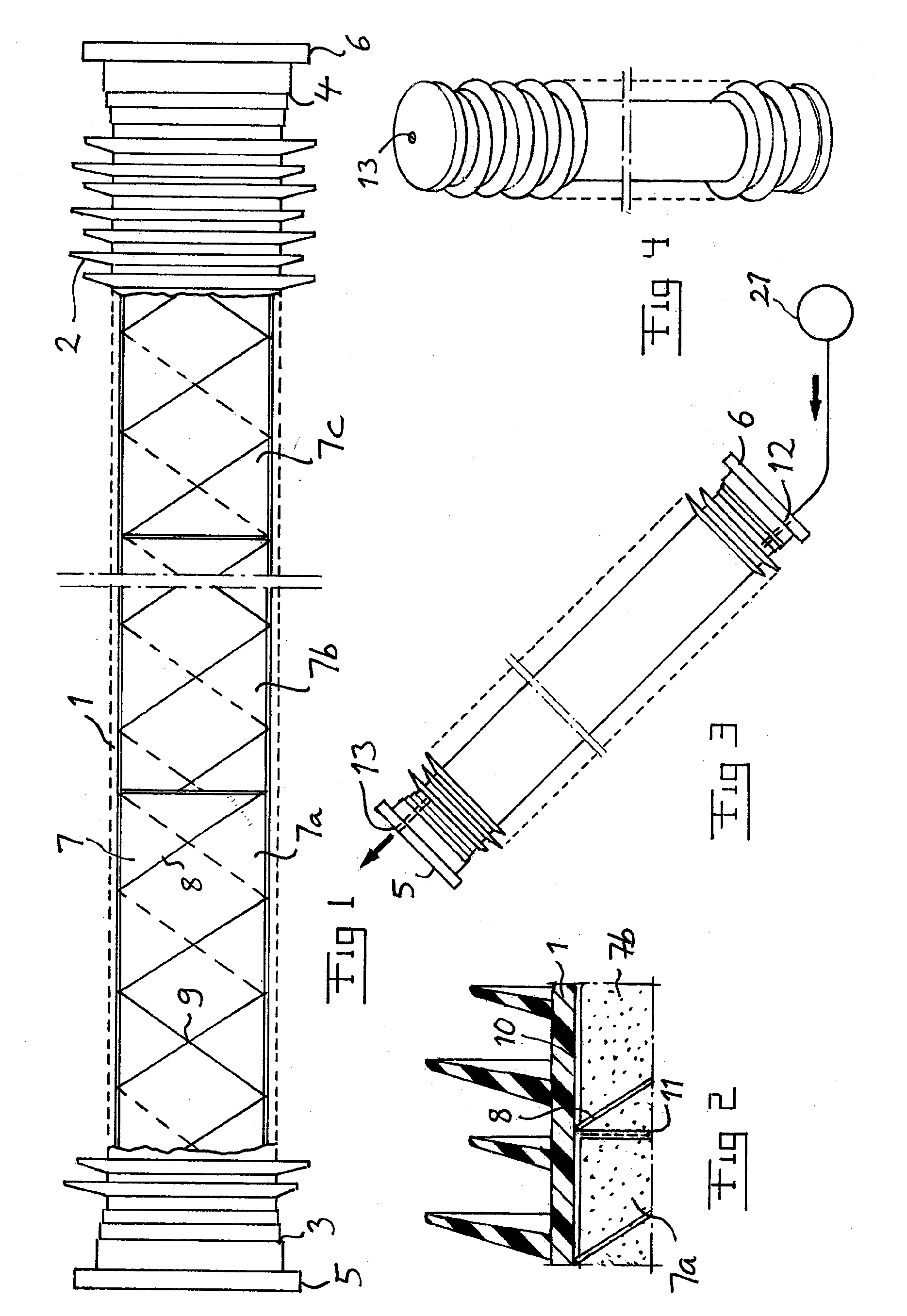

Method For Manufacturing a Post Insulator and a Post Insulator

A method for manufacturing a post insulator. A core is introduced into a tube of an insulating stiff material while leaving a small circumferential space separating the core and inner walls of the tube. Adhesive is introduced under an overpressure into an interior of the tube and is cured while maintaining an overpressure in the interior of the tube.

Owner:ABB TECH AG

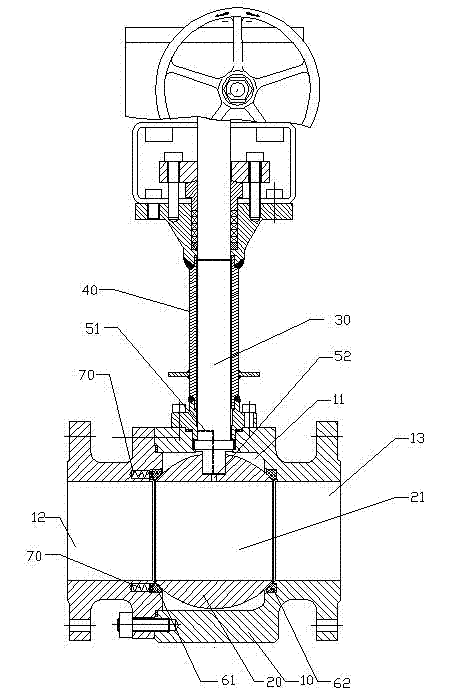

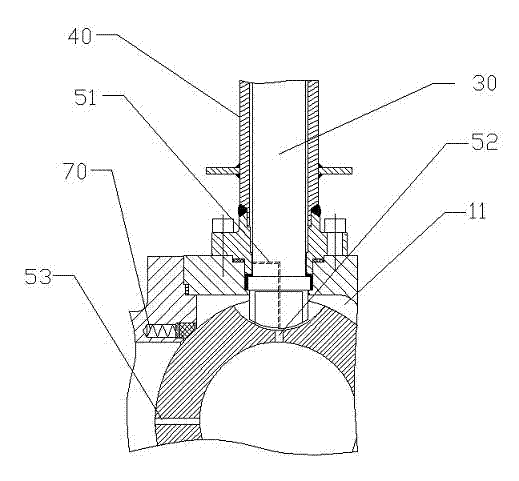

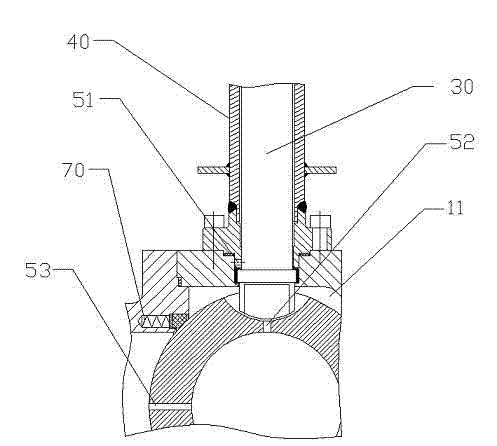

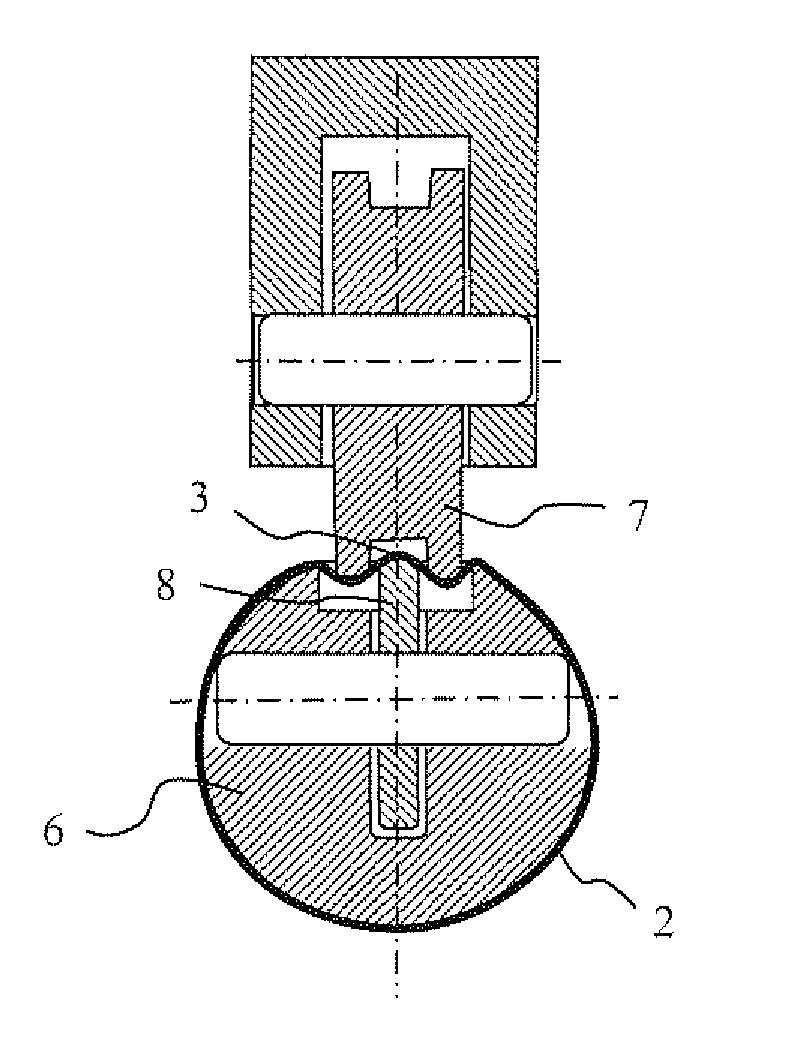

Low-temperature ball valve

ActiveCN102818043AAvoid the risk of abnormal boostStable pressurePlug valvesRotational axisEngineering

A low-temperature ball valve comprises a valve body (10), a ball spool (20) and a valve rod (30). Axis of the valve rod (30) is coaxial with a rotary axis of the spool (20) and is fixedly connected with the spool (20). One end of a tubular support (40) is fixed on the valve body (10) and coaxially sleeved on the valve rod (30) to support the valve rod (30). A gap is reserved between the valve rod (30) and the tubular support (40). A decompression passage for communicating the gap with a through hole (21) is further arranged. In the prior art, the decompression passages of the low-temperature ball valves discharges hazardous gases during decompression and is high in cost. The low-temperature ball valve is environment-friendly and low in cost.

Owner:NEWAY VALVE SUZHOU

Self-compacting concrete applicable to joint section of steel structure concrete composite beam

The invention discloses self-compacting concrete applicable to the joint section of a steel structure concrete composite beam. The concrete is prepared from the following components in parts by mass:100 to 150 parts of water, 450 to 500 parts of cement, 50 to 55 parts of a mineral admixture, 675 to 725 parts of fine aggregate, 1000 to 1100 parts of coarse aggregate, 5 to 10 parts of a high-performance polycarboxylate superplasticizer and 50 to 55 parts of a composite expanding agent, wherein the cement is ordinary Portland cement with a grade of 42.5 or above; the mineral admixture is fly ashwith a grade of national standard I or above; the fine aggregate is natural medium sand or machine-made sand; the coarse aggregate is broken stone with a particle size of 5-25 mm; the water reducingrate of the high-performance polycarboxylate superplasticizer has to be 25% or above. According to the invention, automatic compaction and no shrinkage of concrete in the joint section of a hybrid beam are realized; and the concrete has stable working performance and mechanical performance, and can be applied to concrete structure construction under occasions like construction space is narrow, only self-compaction concrete pouring can be adopted and concrete can only be conveyed from the outer side.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD +1

Alkali-activated cementing material doped with high-silicon iron tailings and red mud and preparation method of alkali-activated cementing material

The invention belongs to the field of alkali-activated inorganic nonmetal cementing materials, and particularly relates to an alkali-activated cementing material doped with high-silicon iron tailings and red mud and a preparation method of the alkali-activated cementing material. The material comprises the following raw materials: 30 to 50 parts of high-silicon iron tailings; 15 to 20 parts of red mud; 20 to 35 parts of coal gangue; 10 to 15 parts of alkaline residues; and 1-5 parts of an alkaline activator. The preparation method comprises the following steps: adding the high-silicon iron tailings, the red mud and the coal gangue into a stirrer, performing uniform stirring, dissolving the alkaline residues into the alkaline exciting agent, adding the mixture into the stirrer after the alkaline residues are completely dissolved, performing stirring and mixing at a low speed, pouring the standard sand into a stirring pot, stopping stirring, and performing stirring again to obtain alkali-activated cementing material slurry; injecting the obtained alkali-activated cementing material slurry into a mold, carrying out coagulation and hardening to remove the mold, and performing curing in a curing device to obtain the target product. The concrete is good in gelling property, ideal in impermeability and high in compressive strength, and has a micro-expansion compensation function.

Owner:NORTHEASTERN UNIV +1

Light-weight anti-corrosion concrete for light steel structure wall body and preparation method thereof

The invention discloses light-weight anti-corrosion concrete for a light steel structure wall body and a preparation method thereof, and relates to the technical field of a building material. The light-weight anti-corrosion concrete for the light steel structure wall body is prepared from the following ingredients in parts by weight: 170 to 190 parts of ordinary Portland cement, 114 to 139 parts of fly ash, 35 to 50 parts of expanding agents, 0.5 to 1.0 part of hydroxypropyl methyl cellulose, 0.8 to 1.2 parts of redispersible powder, 8.5 to 9.5 parts of EPS particles, 3.7 to 4 parts of water reducing agents and 135 to 140 parts of water. The concrete provided by the invention has the advantages that the concrete cracking is reduced; the moisture seepage is prevented; the sulphate corrosionresistance is realized.

Owner:HEFEI GUORUI INTEGRATED CONSTR TECH CO LTD

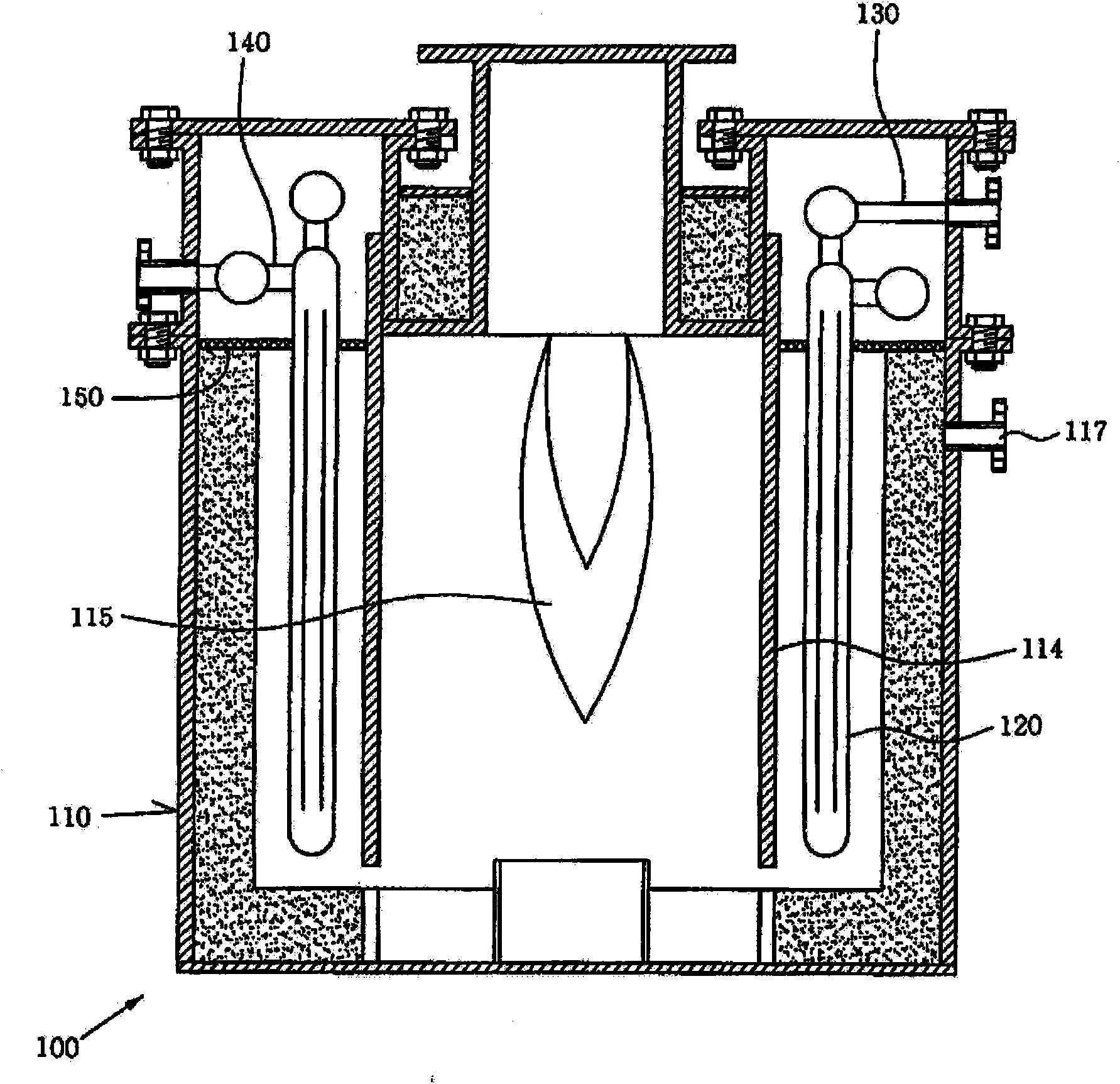

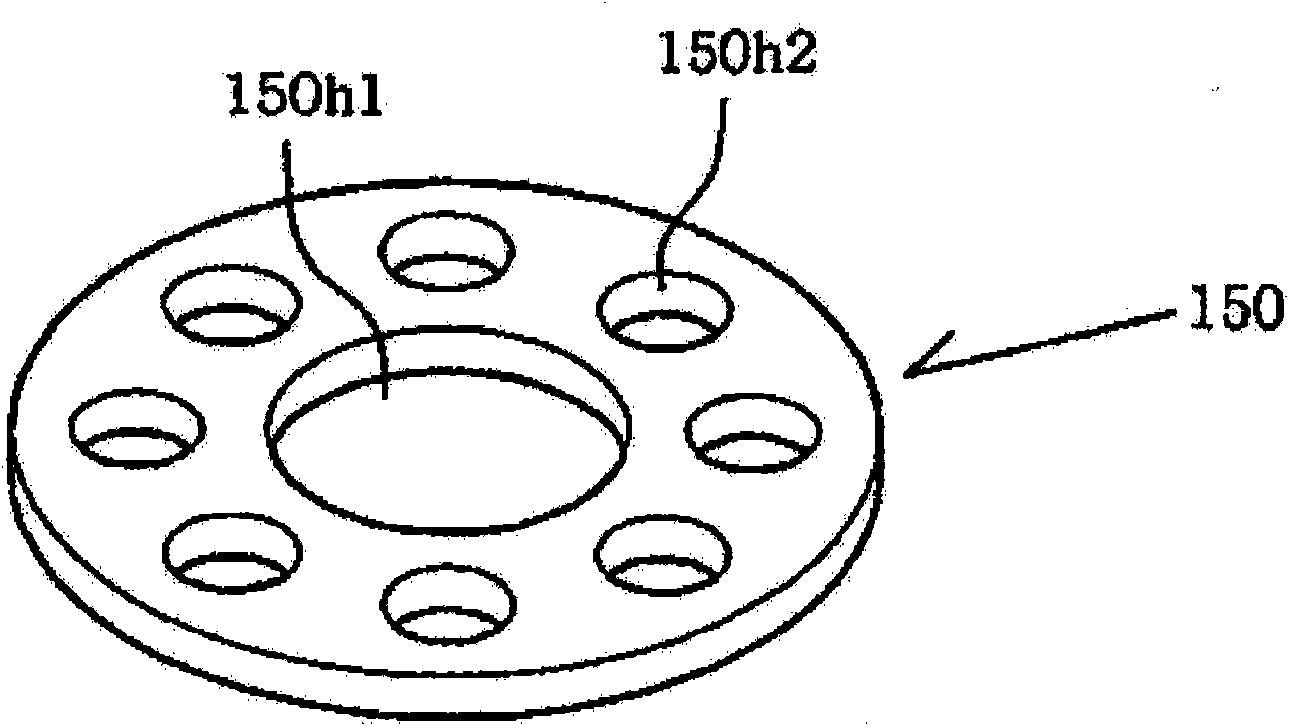

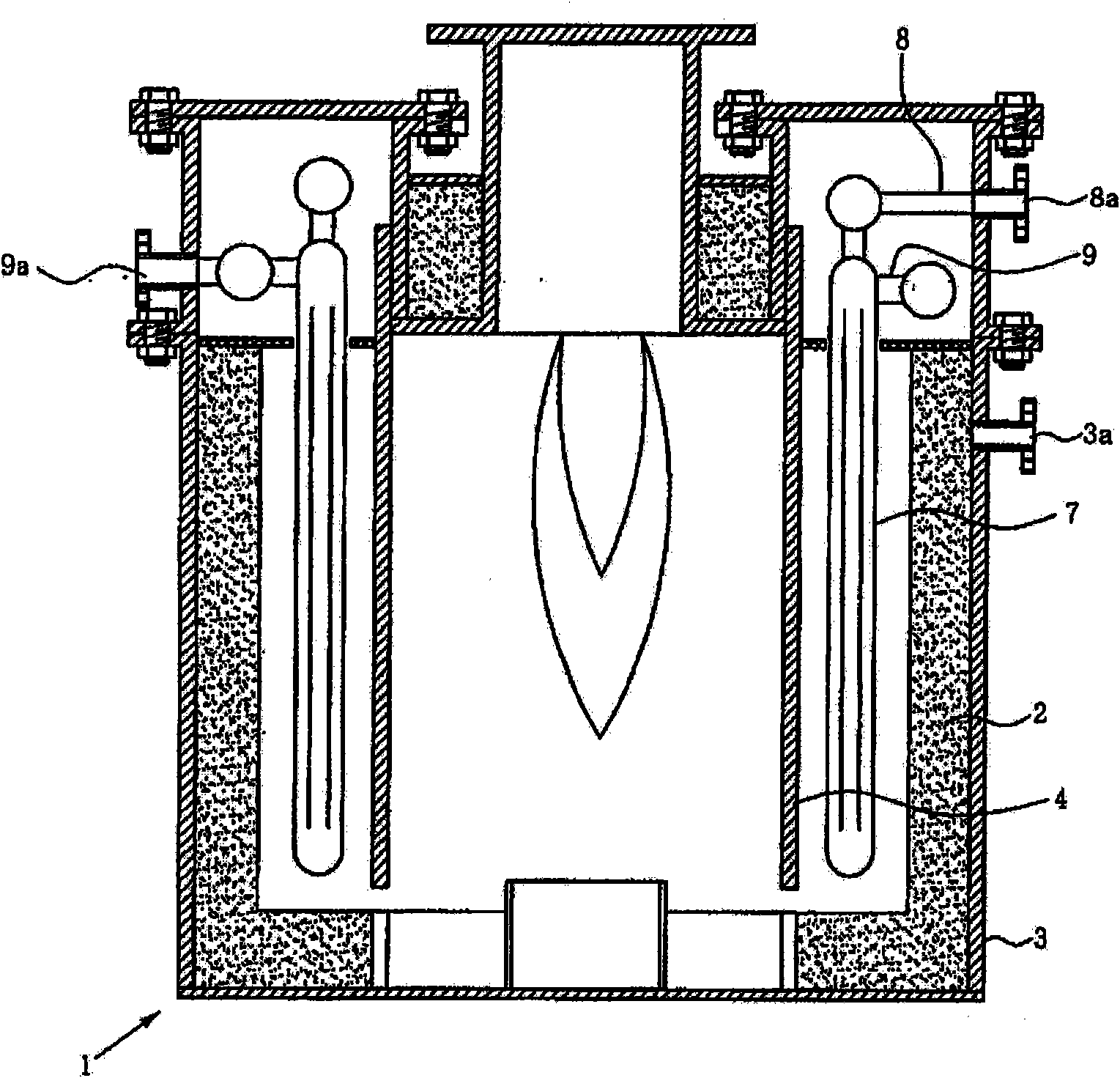

Hydrogen generating apparatus using steam reforming reaction

ActiveCN101842316AIncreased durabilityImprove stabilityHydrogenHydrogen/synthetic gas productionSteam reformingHydrogen

Disclosed herein is an apparatus for generating hydrogen by steam reforming. The apparatus comprises: a casing having provided in the central portion thereof a combustion section for producing high-temperature reaction heat; a flame guide provided such that it forms the outer wall of the combustion section while a space is provided outside thereof; a plurality of catalytic tubes arranged concentrically with respect to the combustion section in the space outside the flame guide; a feed supply manifold disposed at one side of the inside of the casing so as to distribute a feed supplied from the outside of the apparatus to each of the catalytic tubes; a reformate manifold connected with one end of each of the catalytic tubes so as to discharge a reformate obtained by the reforming reaction to the outside of the apparatus; and a support member which consists of an inner ring plate formed at one side of the inside of the casing and an outer ring plate disposed concentrically around the outer circumference of the inner ring plate and which has formed at the boundary between the inner and outer ring plates tube holes into which one end of each of the catalytic tubes is inserted. In the hydrogen generating apparatus, the structure of the support member supporting the plurality of catalytic tubes is simply divided into the inner ring plate and the outer ring plate, such that the expansion and shrinkage of the support member by thermal stress can be efficiently compensated for. As a result, deformation and breakdown of the support member caused by thermal stress can be prevented, thus improving the overall durability and stability of the hydrogen generating apparatus.

Owner:SK INNOVATION CO LTD

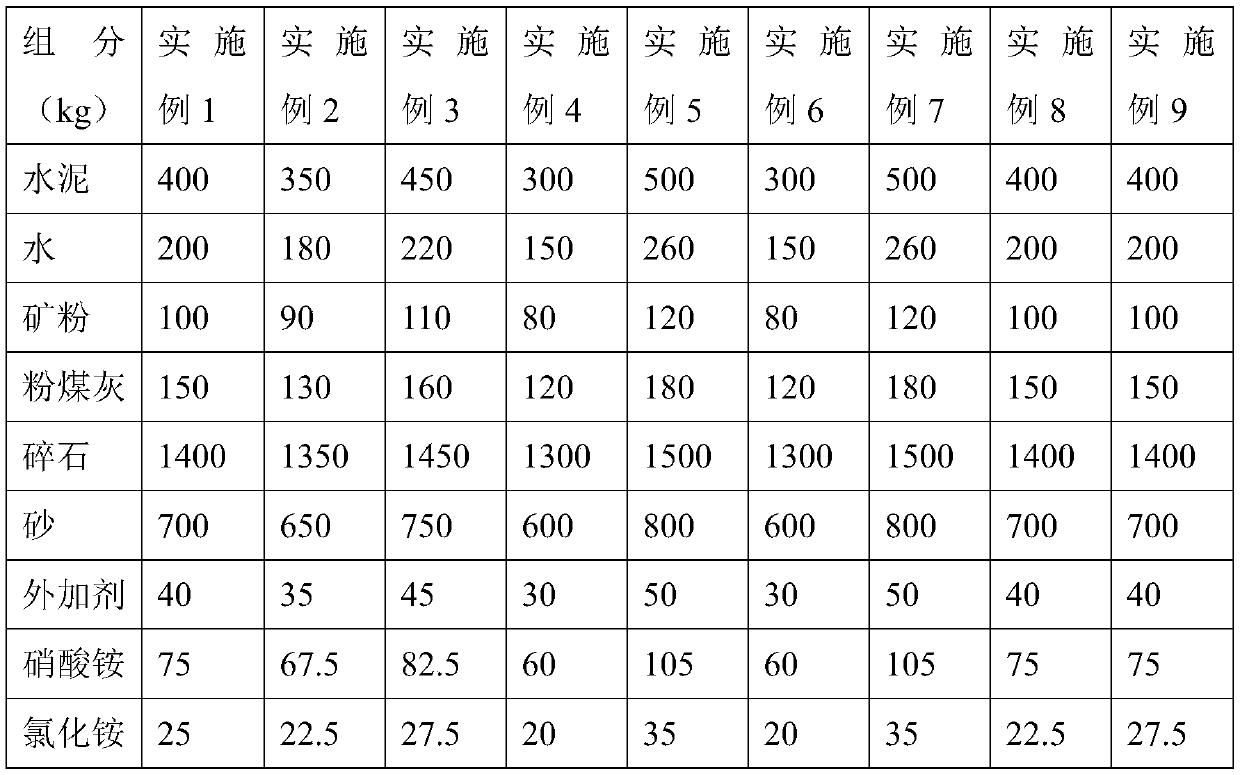

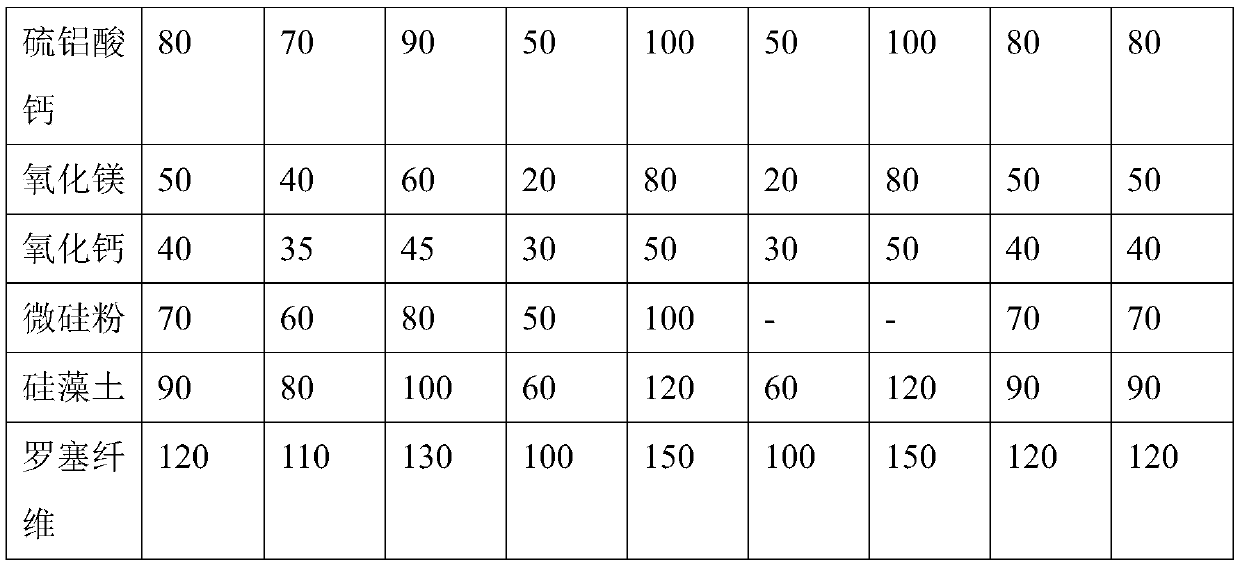

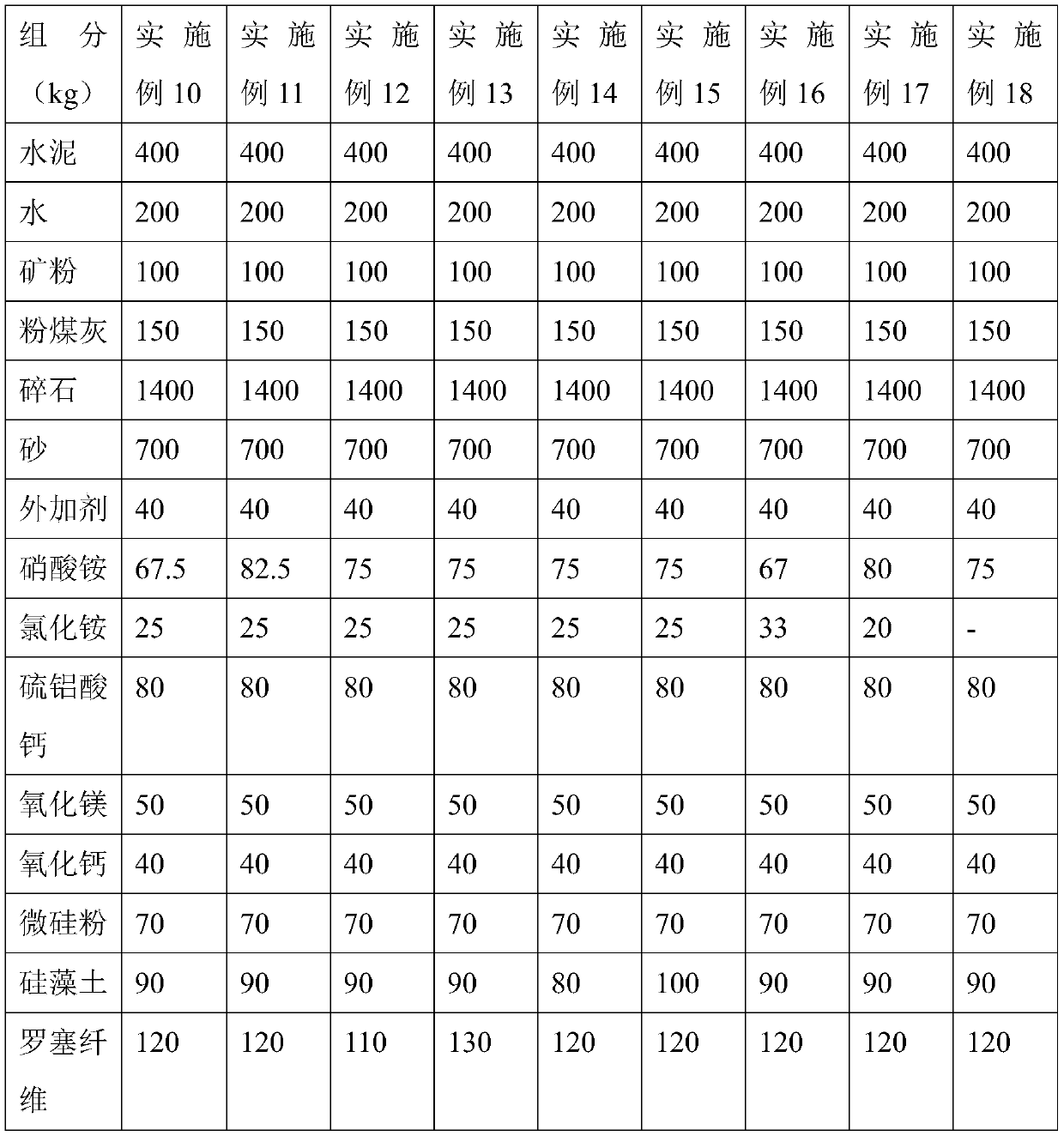

Crack-resistant mass concrete and preparation method thereof

InactiveCN110467413AImprove cracking strengthReduce the temperature difference between inside and outsideFiberCrack resistance

The invention discloses crack-resistant mass concrete and a preparation method thereof, wherein the crack-resistant mass concrete is prepared from the following raw materials by weight: 300-500 partsof cement, 150-260 parts of water, 80-120 parts of mineral powder, 120-180 parts of fly ash, 1300-1500 parts of crushed stone, 600-800 parts of sand, 30-50 parts of an admixture, 80-140 parts of an ammonium salt, 100-230 parts of an expansion agent, 60-120 parts of diatomite, and 100-150 parts of Roycele fiber, wherein the ammonium salt comprises one or two selected from ammonium nitrate and ammonium chloride. The preparation method comprises: pouring crushed stone, pouring Roycele fiber, pouring sand and diatomite, stirring for 5-10 min, pouring cement, fly ash, mineral powder and an expansion agent, stirring for 10-15 min, dissolving an admixture in water, adding the dissolved admixture, stirring for 5 min, adding an ammonium salt, and stirring for 20-30 min to obtain the product. According to the present invention, the prepared concrete has advantages of low hydration heat, high strength and excellent crack resistance.

Owner:北京城建九秋实混凝土有限公司

Self-flowing castable prepared from blast furnace iron runner cover waste and preparation method thereof

The invention discloses a self-flowing castable prepared from blast furnace iron runner cover waste and a preparation method thereof. The self-flowing castable is prepared from the following components in parts by mass: 15-25 parts of iron runner cover waste, 30-60 parts of brown fused alumina clinker, 10-20 parts of white fused alumina, 15-25 parts of silicon carbide, 4-9 parts of silica powder,5-10 parts of activated alumina powder, 3-8 parts of pure calcium aluminate cement, 3-5 parts of an expanding agent, 0.5-1 part of a water reducing agent and 0.05-1 part of an anti-explosion agent. The preparation method of the self-flowing castable comprises the following steps: selecting materials, crushing, screening, mixing, packaging and warehousing. According to the invention, the waste blast furnace iron runner cover material is recycled, the production cost is reduced, the compactness and strength of the castable after pouring are improved, the erosion resistance is enhanced, the service life of the iron runner cover is prolonged, and the preparation method is simple and suitable for industrial popularization.

Owner:TANGSHAN JINSHAN TENGYU SCI & TECH

Method for manufacturing tubes by welding

ActiveUS20100193125A1Increase the areaImprove roundnessLaminationLamination apparatusEngineeringMechanical engineering

The invention relates to a method of welding a laminate for the production of flexible tubular plastic bodies, which method comprises the following operations:a laminate is shaped around a welding rod;the ends of the laminate to be welded are heated;said ends are pressed together and at least partly cooled;the welded zone is deformed so as to increase its area; andthe welded zone is cooled.The invention also relates to a device suitable for using the aforementioned method.

Owner:AISAPACK HLDG SA

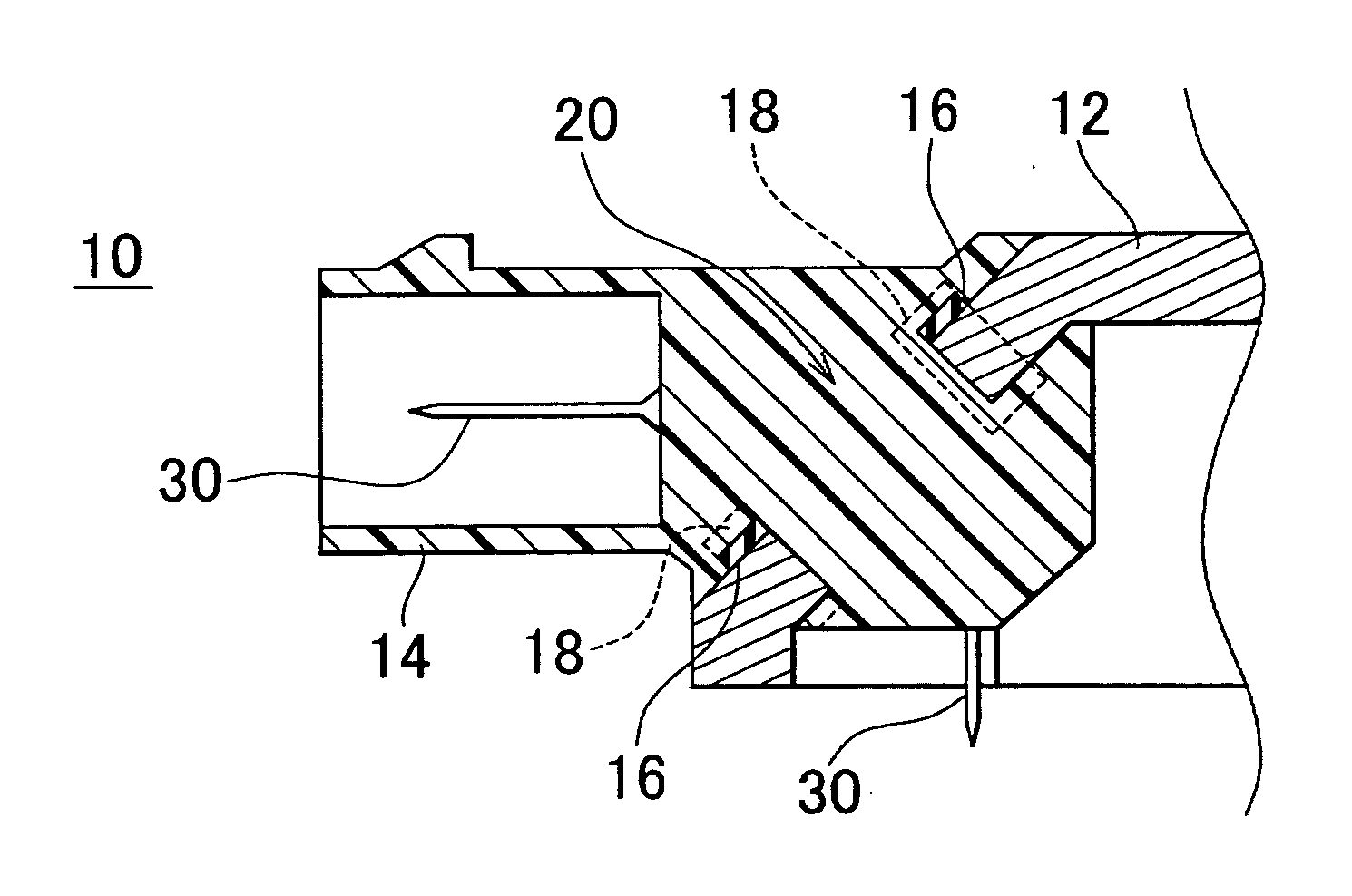

Molded article production method and molded article

ActiveUS20070120287A1Improve air tightnessCompensation for shrinkageContact member assembly/disassemblyMouldsPolymer scienceAir tightness

In a method for producing a molded article having a resin part, the resin part is injection-molded to an opening of a main body part and the molded article has an excellent air-tightness between the resin part and the main body part. A foam sealant is attached to a peripheral portion around the opening of the main body part. Attached to the main body part is a retainer made of the same kind of resin as injected resin and adapted to keep the foam sealant compressed in its thickness direction. The main body part is placed within a mold so that the retainer is exposed inside a cavity of the mold. A molten resin is injected into the cavity of the mold. The injected resin and the retainer are integrated into the resin part.

Owner:TOYOTA JIDOSHA KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com