Hydrogen generating apparatus using steam reforming reaction

A technology of steam reforming and hydrogen, applied in hydrogen/synthesis gas production, hydrogen, inorganic chemistry, etc., can solve the problems of weakening stability and durability, thermal deformation of supporting parts, etc., to improve overall durability and stability, Effect of preventing deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] Hereinafter, preferred embodiments of an apparatus for generating hydrogen using steam reforming according to the present invention will be described in detail with reference to the accompanying drawings.

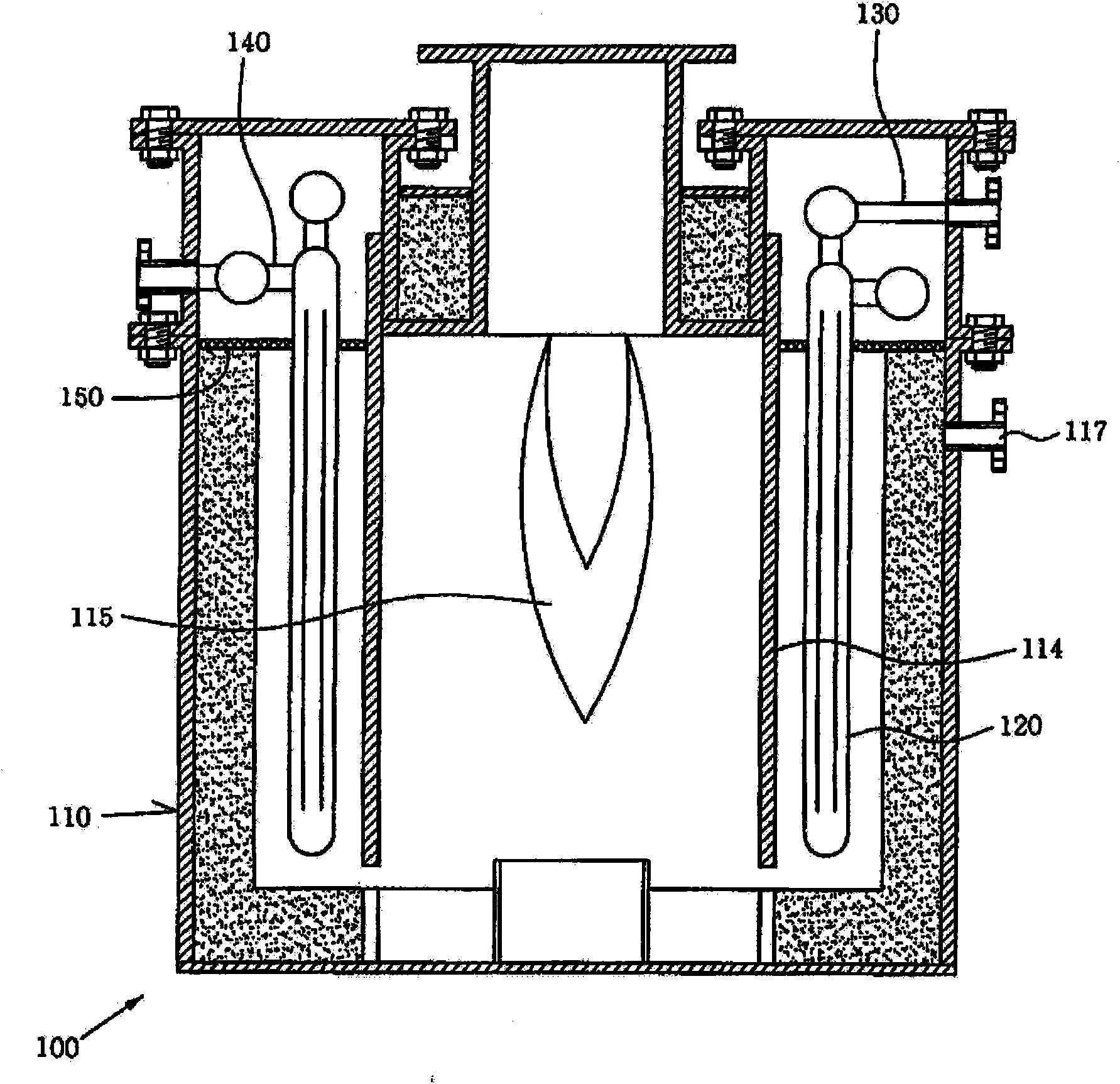

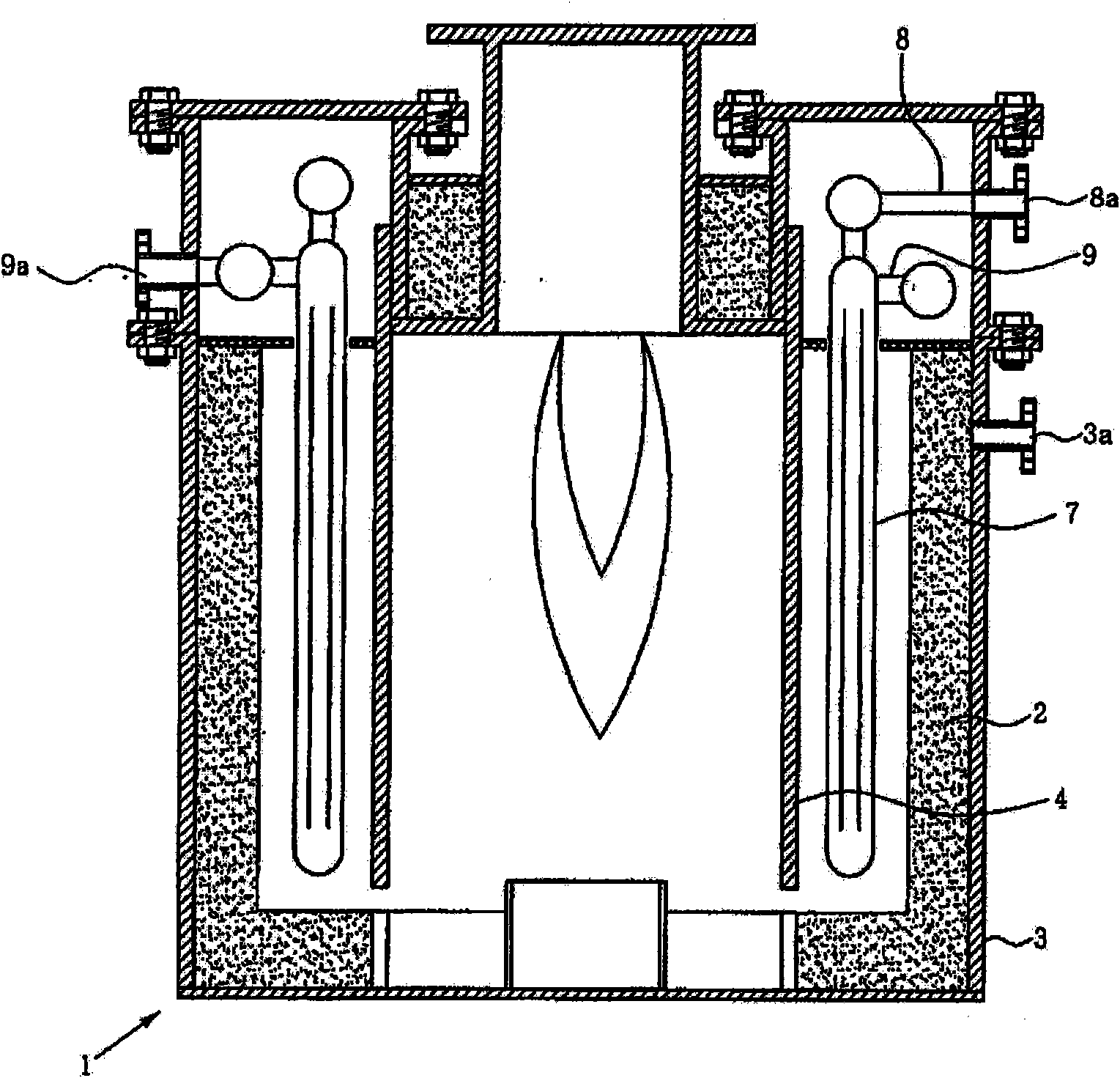

[0042] image 3 is a sectional view showing the configuration of an apparatus for generating hydrogen using steam reforming according to the present invention.

[0043] Such as image 3 As shown, the device 1 for generating hydrogen by steam reforming of the present invention roughly includes: a housing 3; a flame guide 4, which limits a combustion portion 5 disposed in the housing 3; a plurality of catalyst tubes 7, which are vertically disposed on In the space separated from the combustion part in the casing 3; the raw material supply manifold 8, which supplies the raw material to each catalyst tube 7; and the reformed product manifold 9, which discharges the reformed product obtained in each catalyst tube 7 to outside; and a support member 10 for supporting each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com