Low-shrinkage early-strength type mine filling cementing material

A technology for mine filling and cementitious materials, applied in the field of mine filling, can solve the problems of easy settling time, shrinkage and cracking, and achieve the effects of low cost, prevention of dry shrinkage and reduction of cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

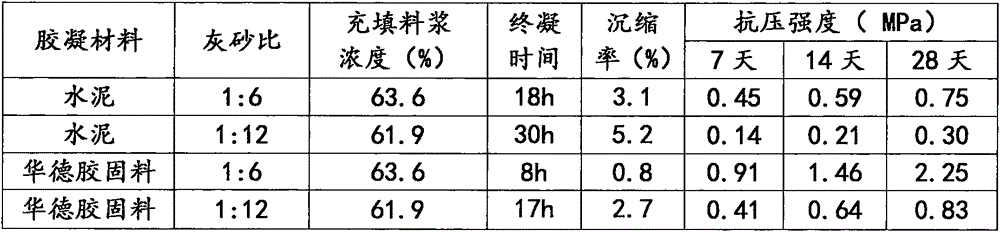

Embodiment 1

[0011] The composition and ratio are 66.5% slag powder, 10% Portland cement, 6% aluminate cement, 10% fly ash, 5% gypsum, 2% sodium metasilicate and 0.5% polypropylene with a length of 4mm The fibers are evenly mixed to prepare the slag-based alkali excitation material. When the concentration of tailing sand (the tailing sand is relatively fine) is 60%, the material with different lime-sand ratios (1:6, 1:12) is evenly mixed with the tailing sand. Check the physical properties of the material. The table below shows the comparison between the slurry prepared with this material and the slurry prepared with cement.

[0012]

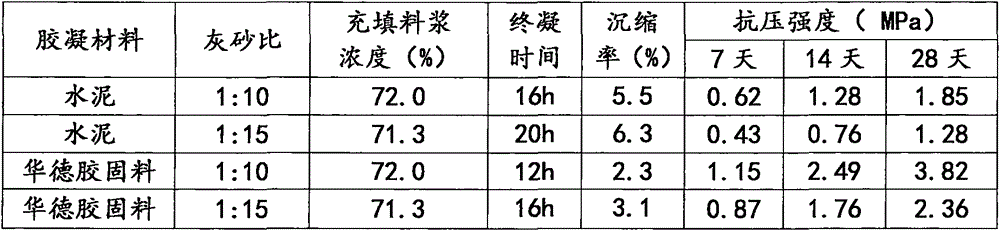

Embodiment 2

[0014] The composition and ratio are 64% slag powder, 10% Portland cement, 5% silica fume, 5% gypsum, 10% quicklime and 6% expansion agent, and are evenly mixed to prepare the slag-based alkali excitation material. When the tailings concentration is 70%, the material with different lime-sand ratios (1:10, 1:15) is mixed evenly with the tailings. Check the physical properties of the material. The table below shows the comparison between the slurry prepared with this material and the slurry prepared with cement.

[0015]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com