Air cooling device for connecting rod

An air-cooling device and connecting rod technology, which is applied in the furnace type, furnace, heat treatment furnace and other directions, can solve the problems of affecting the cooling effect, the limited coverage area of the blower outlet, and the uneven cooling of the connecting rod, so as to expand the air supply area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

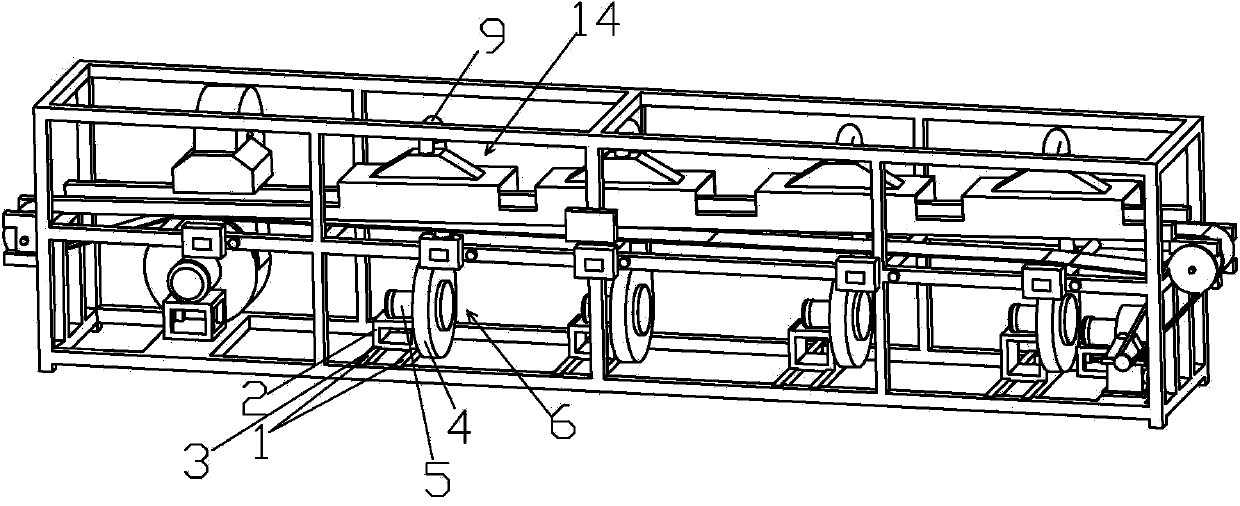

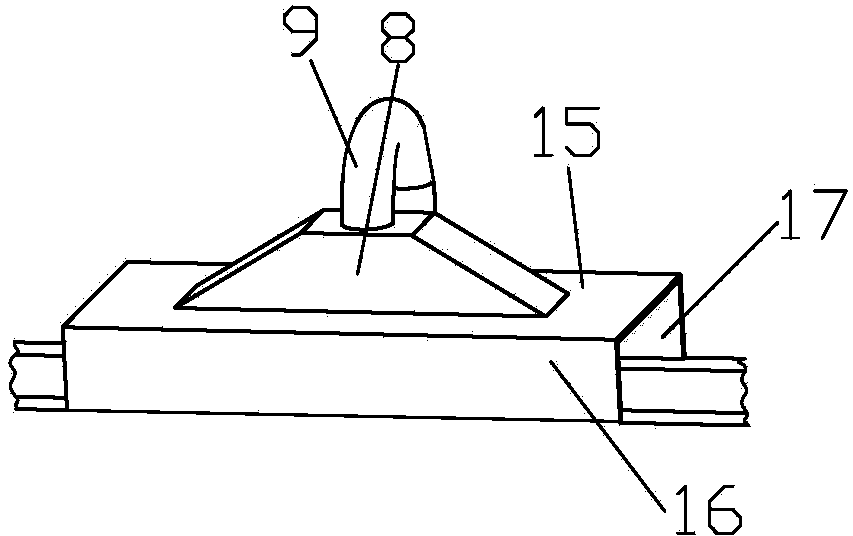

[0014] Embodiment: a kind of air cooling device for connecting rod, such as figure 1 , 2 As shown, the air blower 6 is included, and a bell mouth 8 arranged vertically downward is formed at the blower mouth of the air blower 6 air outlet pipe 9, and a windshield 14 is connected below the bell mouth 8, and the windshield 14 includes The rectangular top plate 15 connected to the bell mouth 8 is horizontally arranged, and side plates A16 and B17 extend downwards on both sides of the rectangular top plate 15 to reflect crosswinds.

[0015] The blower 6 includes a blower body 4 and a motor 5 perpendicular to it, and a fan bracket is arranged beside the motor 5. The fan bracket includes two slide rails 1 arranged in parallel at intervals, and a support seat is slid on the slide rail 1 2. The support seat 2 is in the shape of a rectangle as a whole, and the support seat 2 is hollow inside. On both sides of the bottom surface of the support seat 2, a slot 3 is provided along the leng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com