Method for synthesizing polyol fatty acid ester by adopting falling-film evaporator

A falling film evaporator and fatty acid ester technology, which is used in the synthesis of ester compounds in organic chemistry, can solve the problems of low heat transfer efficiency, slow rightward shift of reaction balance, poor heat transfer effect, etc., and achieve high esterification efficiency , fast heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment a

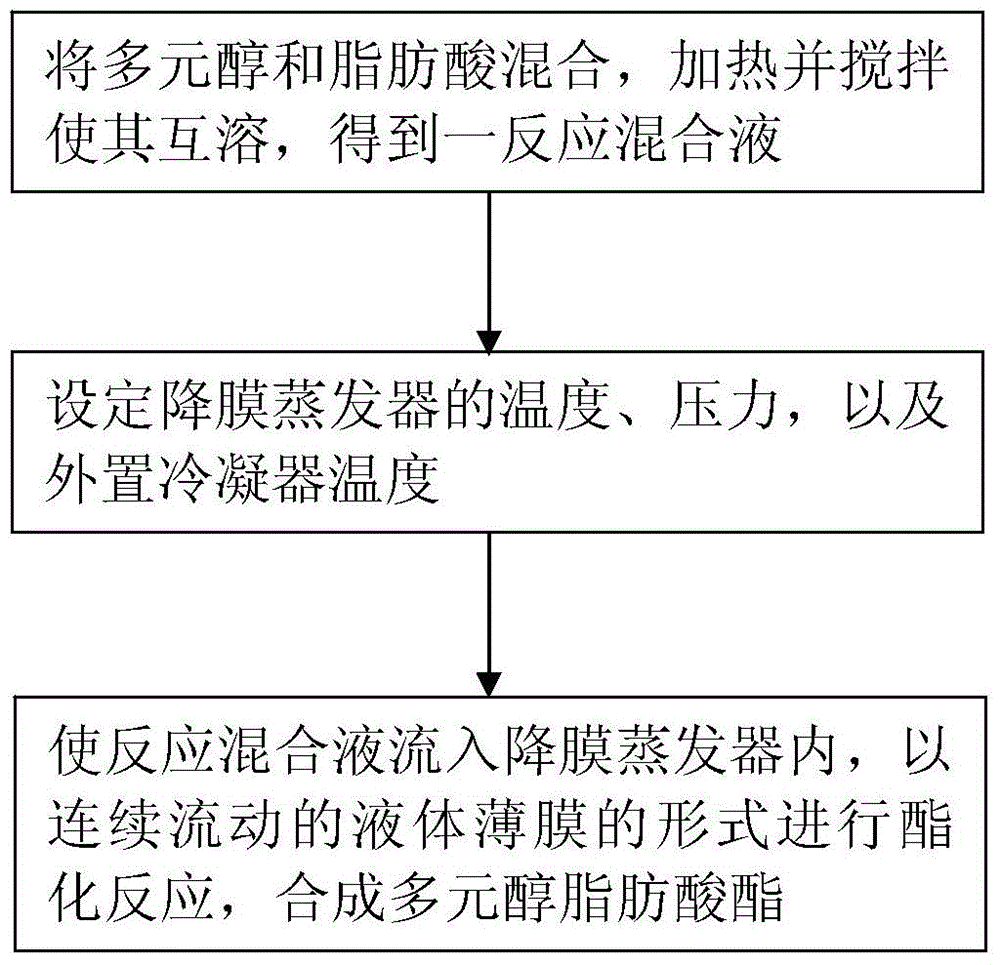

[0055] Present embodiment provides a kind of method that adopts falling film evaporator to synthesize polyol fatty acid ester, comprises the steps:

[0056] 1) Mix polyhydric alcohol and fatty acid according to the molar ratio of hydroxyl and carboxyl groups of 1:1, heat and stir to make them miscible, and obtain a reaction mixture; the polyhydric alcohol is trimethylolpropane; the fatty acid is simultaneously satisfied Saturated or double bond-containing, linear or branched, monobasic acids with 6-18 carbon atoms or mixed acids prepared from two or more monobasic acids (the preparation ratio is not limited);

[0057] 2) Set the temperature of the falling film evaporator to 180°C, the pressure to 5KPa, and the temperature of the external condenser to -20°C;

[0058] 3) Make the reaction mixture obtained in step 1) flow into the falling film evaporator, carry out the esterification reaction in the form of a continuous flowing liquid film, synthesize polyol fatty acid ester, and...

Embodiment b

[0060] Present embodiment provides a kind of method that adopts falling film evaporator to synthesize polyol fatty acid ester, comprises the steps:

[0061] 1) Mix polyhydric alcohol and fatty acid according to the molar ratio of hydroxyl and carboxyl groups of 1.6, heat and stir to make them miscible, and obtain a reaction mixture; the polyhydric alcohol is pentaerythritol; the fatty acid is saturated or contains double bonds at the same time , linear or branched monobasic acid with three conditions of 6-18 carbon atoms or a mixed acid prepared from two or more monobasic acids (the preparation ratio is not limited);

[0062] 2) Set the temperature of the falling film evaporator to 250°C, the pressure to 60KPa, and the temperature of the external condenser to 30°C;

[0063] 3) Make the reaction mixture obtained in step 1) flow into the falling film evaporator, carry out the esterification reaction in the form of a continuous flowing liquid film, synthesize polyol fatty acid es...

Embodiment c

[0065] Present embodiment provides a kind of method that adopts falling film evaporator to synthesize polyol fatty acid ester, comprises the steps:

[0066] 1) Mix polyhydric alcohol and fatty acid according to the molar ratio of hydroxyl and carboxyl groups of 1:1.1, heat and stir to make them miscible, and obtain a reaction mixture; the polyhydric alcohol is trimethylolpropane; the fatty acid is simultaneously satisfied Saturated or double bond-containing, linear or branched, monobasic acids with 6-18 carbon atoms or mixed acids prepared from two or more monobasic acids (the preparation ratio is not limited);

[0067] 2) Set the temperature of the falling film evaporator to 200°C, the pressure to 20KPa, and the temperature of the external condenser to 0°C;

[0068] 3) Make the reaction mixture obtained in step 1) flow into the falling film evaporator, carry out the esterification reaction in the form of a continuous flowing liquid film, synthesize polyol fatty acid ester, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com