Patents

Literature

34results about How to "Heats up quickly and evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Three-section four-door long-tunnel energy-saving type microwave sintering furnace

InactiveCN101922862AHeats up quickly and evenlyIncrease temperatureFurnace typesMicrowave heatingVehicle frameProduct gas

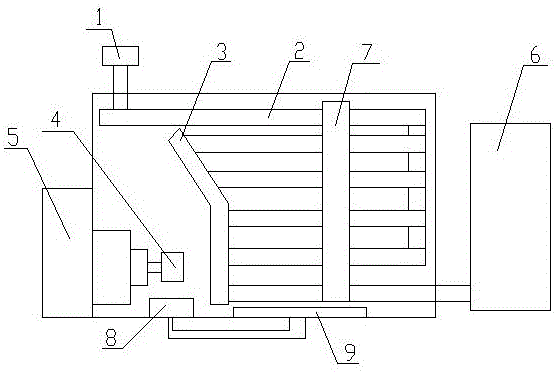

The invention relates to a microwave sintering furnace, in particular relating to a three-section four-door long-tunnel energy-saving type microwave sintering furnace, which comprises a microwave sintering tunnel furnace, tracks and a kiln car and is characterized in that the appearance of the furnace body is in a long box structure, a base is arranged under the furnace body, two tracks are paved, the side surfaces of the furnace wall are provided with equally spaced gate slots and square sliders, and four lifting type steel doors divide the furnace chamber into a cooling section, a sintering section and a preheating section; a hot gas pumping pipeline is arranged between the cooling section and the preheating section; the top part of the tunnel furnace body is provided with a waveguide port; the kiln car is in a box-combined structure and comprises track wheels, a carframe in a steel square frame type structure, an air inlet and a heat-resisting material layer, the front and rear ends of the kiln car are respectively provided with an auricled door bracket, a connecting piece and a groove, and a kiln car group is formed by connecting 1 to 5 kiln cars; and the microwave sintering furnace also comprises three groups of servo motors controlled synchronously and driven systems. Compared with the traditional kiln furnace, the microwave sintering furnace has high heating speed, saves power by 40-50%, shortens time by 1.5h, achieves the aims of saving energy and reducing consumption and improves economic benefit.

Owner:FUJIAN WANQI SANDT CERAMICS CO LTD

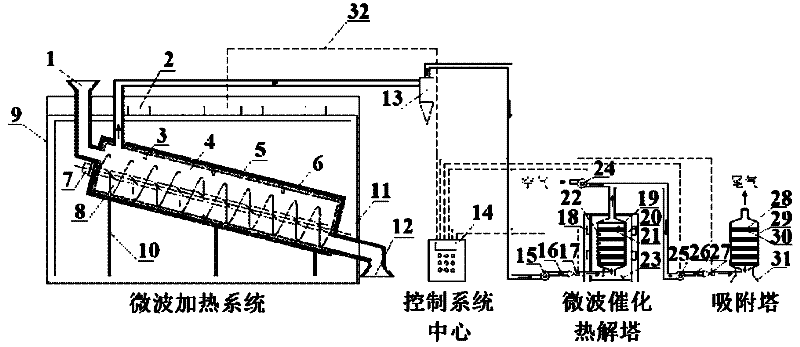

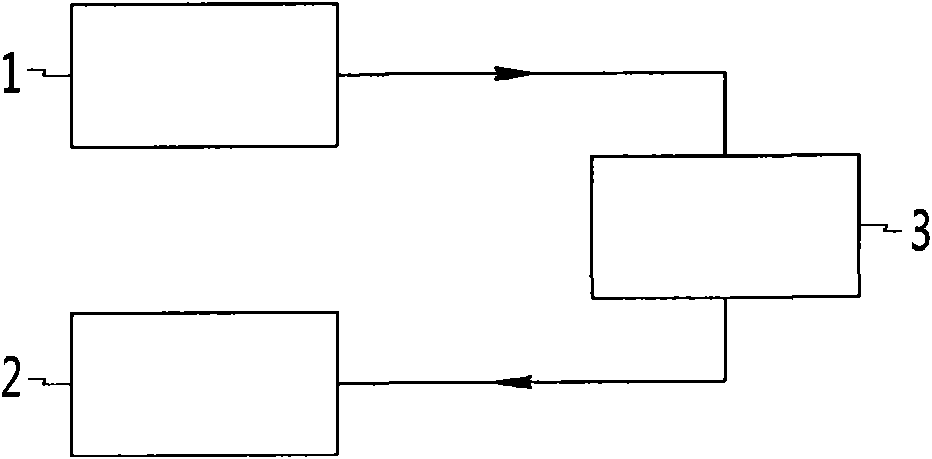

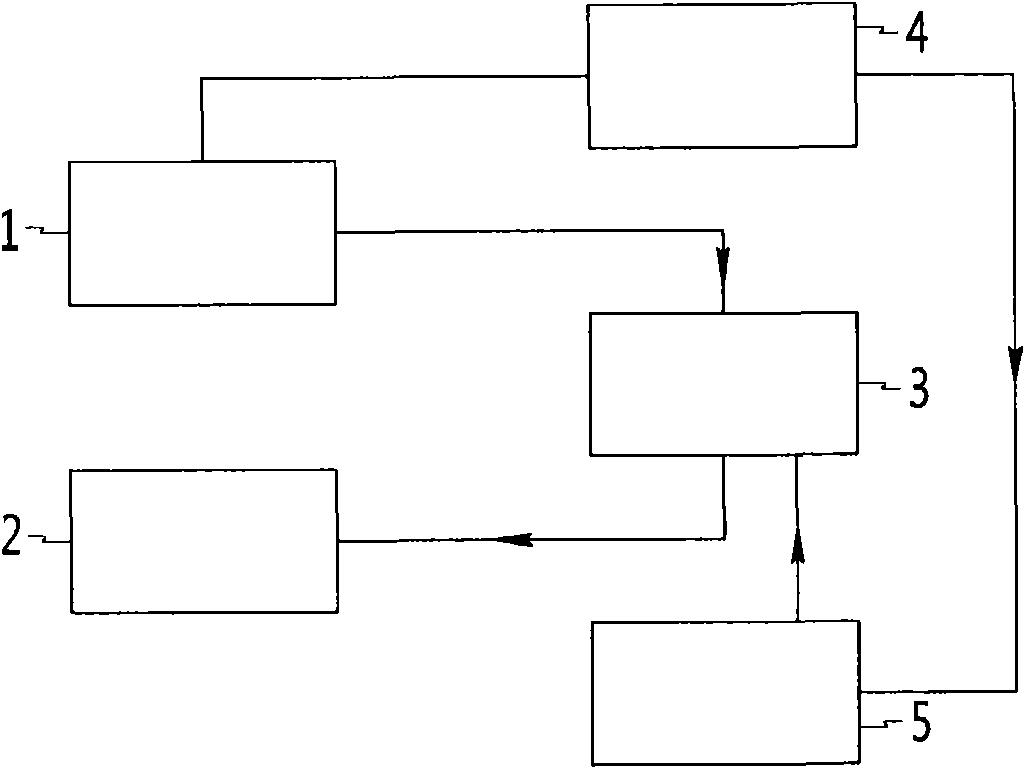

Microwave repair equipment for organic contaminated soil

ActiveCN102380507AMeet the requirement of heating up to 500°CMeet the requirements of heating up to 500°CDispersed particle separationContaminated soil reclamationCatalytic pyrolysisInsulation layer

The invention discloses microwave repair equipment for organic contaminated soil. The equipment comprises a charging and discharging system, a microwave heating system, a deduster, a tail gas treating system and a control system center, wherein, the charging and discharging system is arranged in the microwave heating system, and the microwave heating system, the deduster and the tail gas treatingsystem are connected sequentially. The microwave heating system comprises a first microwave generator and a cylindrical oven body, the inner layer of the cylindrical oven body is a silicon carbide layer, and the external layer of the cylindrical oven body is an alumina silicate heat-insulation layer; the tail gas treating system comprises a microwave catalytic pyrolysis tower and an adsorption tower, the microwave catalytic pyrolysis tower comprises a cylindrical alumina silicate insulation shell, multilayer silicon carbide porous filter boards and a catalyst, the multilayer silicon carbide porous filter boards are vertically inserted in the cylindrical alumina silicate insulation shell at equal distance, and the catalyst is arranged on the silicon carbide porous filter boards. The microwave repair equipment provided in the invention has the advantages of strong capability in treating organic contaminated soil, thorough treatment of tail gas, no secondary pollution, high efficiency, energy conservation and easy operation and control.

Owner:HUAZHONG UNIV OF SCI & TECH

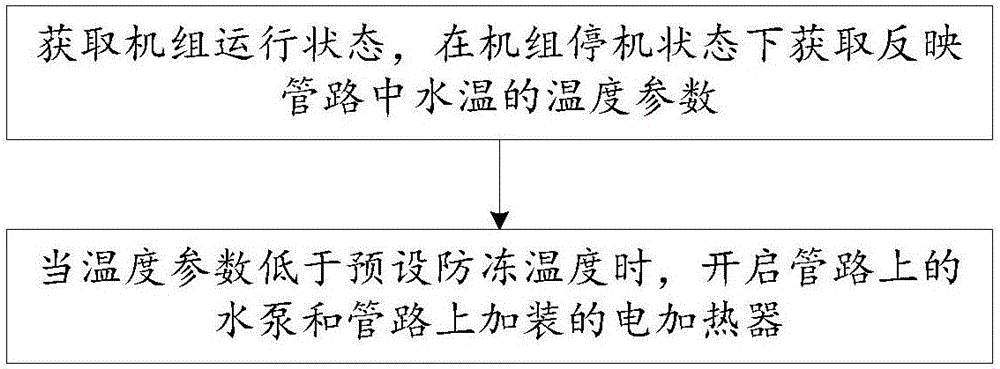

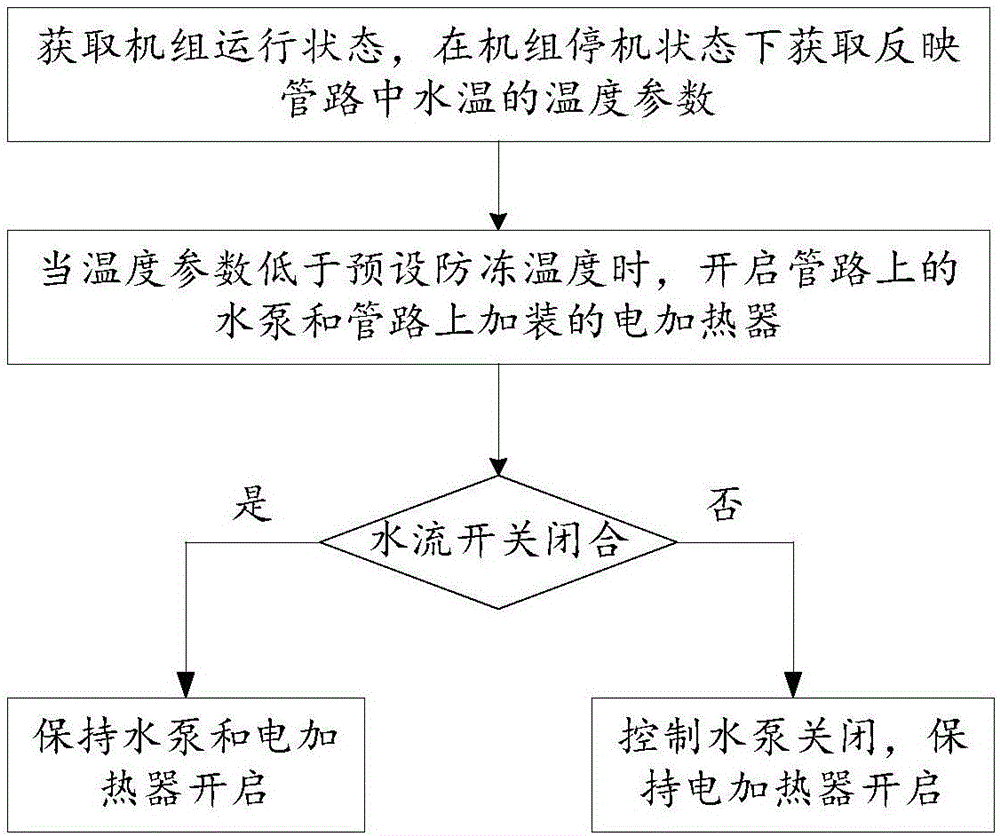

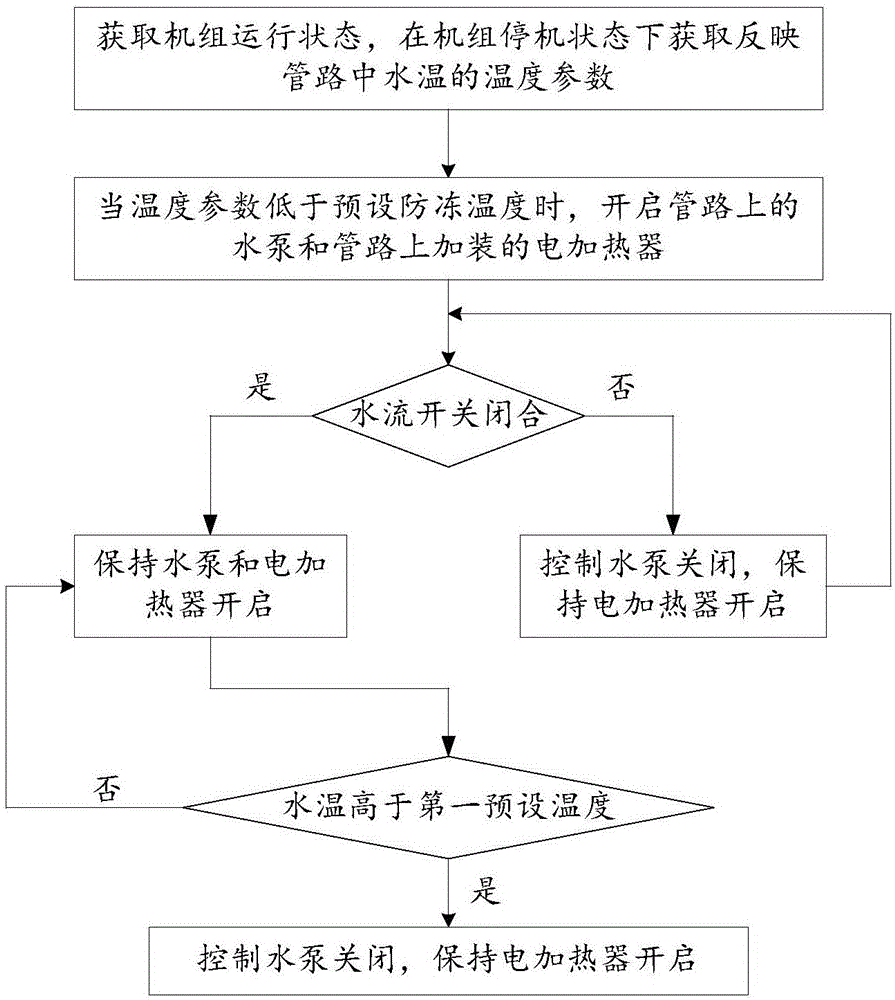

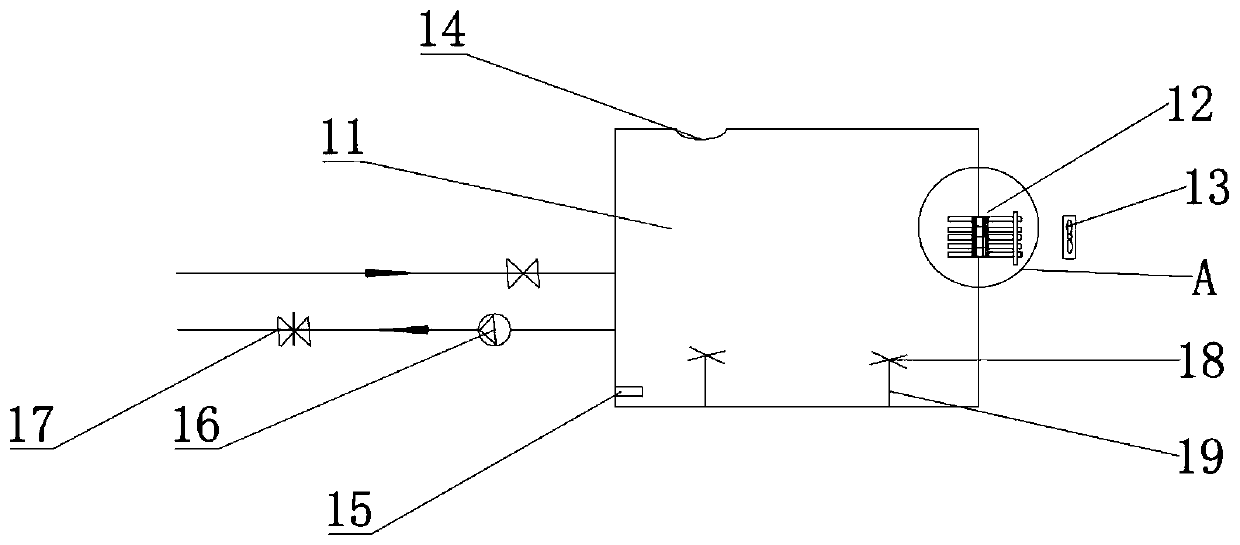

Air conditioner and pipeline anti-freezing control method and device thereof

InactiveCN106765889AFlexible detection methodExtended service lifeMechanical apparatusSpace heating and ventilation safety systemsAnti freezingEngineering

The invention relates to an air conditioner and a pipeline anti-freezing control method and device thereof. The pipeline anti-freezing control method includes the steps that the running state of a unit is acquired, and a temperature parameter reflecting the temperature of water in a pipeline is acquired in the shutdown state of the unit; and when the temperature parameter is lower than a preset anti-freezing temperature, a water pump on the pipeline and an electric heater additionally arranged on the pipeline are started. The pipeline anti-freezing control method achieves that under the situation that the unit is not used, the situation that the water in the pipeline ices when the air temperature is too low is avoided in a simple, safe and efficient manner, and especially it is avoided that water in a heat exchanger ices, the volume expands, and the heat exchanger is damaged.

Owner:CHONGQING MIDEA GENERAL REFRIGERATING EQUIP +1

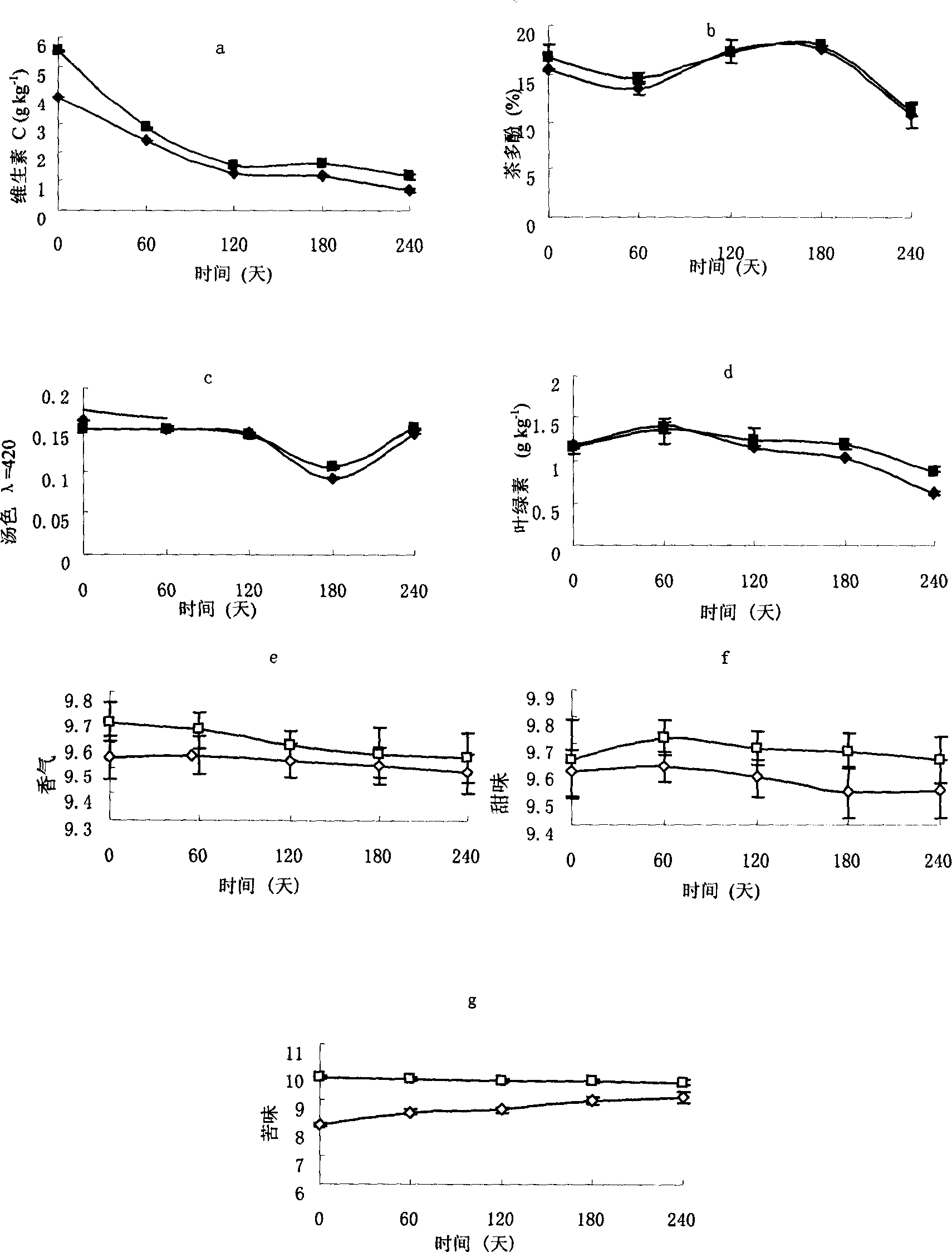

Green tea microwave processing and fresh-retaining method

InactiveCN1709092APromote migrationIncrease nutritional contentPre-extraction tea treatmentVitamin CMicrowave

The present invention relates to a green tea microwave processing fresh-keeping method. Said method includes the following steps: spreading fresh leaves, then utilizing microwave enzyme-inactivating green-retaining equipment to make enzyme-inactivating green-retaining process, its power is 5950 W, continuously changing speed within 2 min., spreading, drying, pneumatic separation and sorting so as to obtain the invented green tea. Said invention can raise vitamin C content of tea, as compared with traditional processing method its effective convenient components can be raised by above 10%.

Owner:NANJING AGRICULTURAL UNIVERSITY

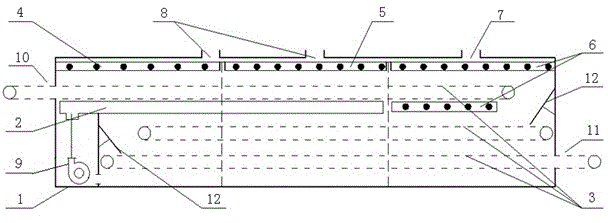

Ginger rapid drying device

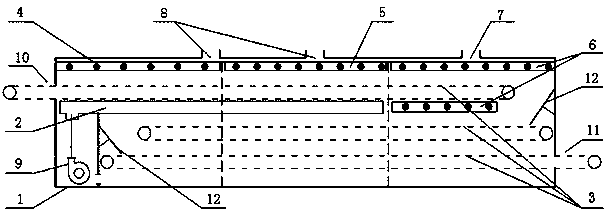

InactiveCN102721271AHeats up quickly and evenlyMaintain moisture contentDrying solid materials with heatDrying machine combinationsFluidized bedEngineering

The invention discloses a ginger rapid drying device, which comprises a machine body, a fluidized bed and a ginger conveying wire belt penetrating the machine body, wherein the machine body is sequentially divided into a shortwave infrared heating area, a medium-wave infrared heating area and a far-infrared heating area, a shortwave infrared heating pipe nest is arranged on the inner upper part of the shortwave infrared heating area, a medium-wave infrared heating pipe nest is arranged on the inner upper part of the medium-wave infrared heating area, a far-infrared heating pipe nest is arranged on the inner upper part of the far-infrared heating area, the top of the far-infrared heating area is provided with an air inlet, and the top of the shortwave infrared heating area and the top of the medium-wave infrared heating area are respectively provided with an air outlet; and the fluidized bed comprises a bed body and a blower, wherein the blower is communicated with the bed body, the bed body is provided with an air blowing hole, and the bed body of the fluidized bed is arranged inside the shortwave infrared heating area and the medium-wave infrared heating area and is closely abutted against the lower side of the ginger conveying wire belt. By adopting a way combining the infrared heating and the fluidized bed as well as the hot air circulation, a purpose for rapidly drying ginger is realized, and simultaneously the ginger can be prevented from being discolored.

Owner:CHONGQING TECH & BUSINESS UNIV

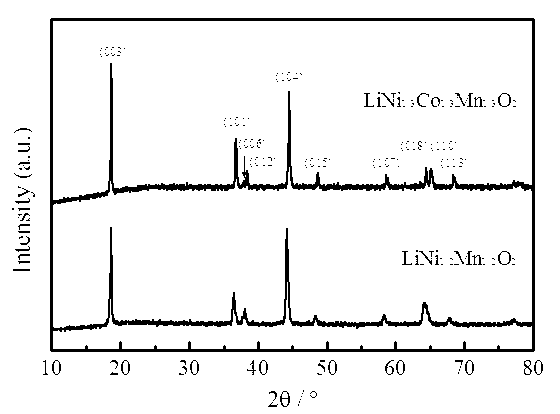

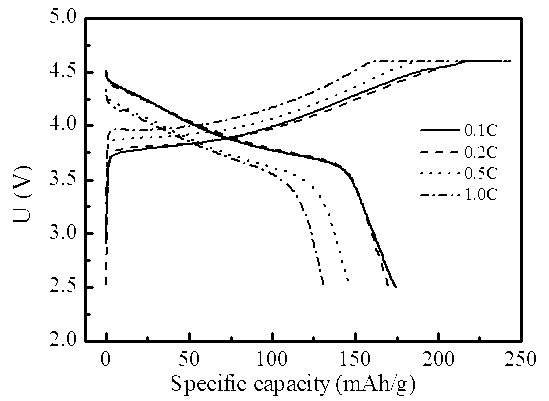

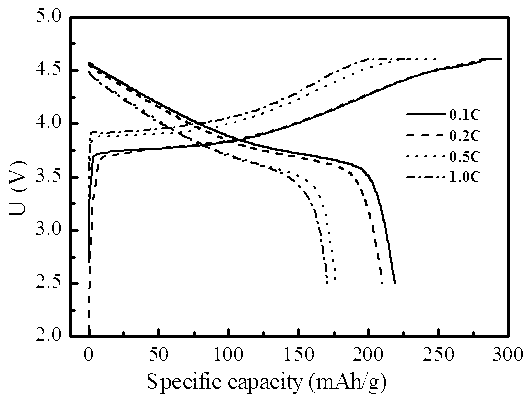

Method for rapid synthesis of multi-element layered positive material of lithium-ion battery

The invention discloses a method for rapid synthesis of a multi-element layered positive material of a lithium-ion battery. The method comprises the following steps of: adopting lithium acetate as a lithium source, adopts nitrate or / and acetate of Ni, Co, Mn, Fe and Cr with the melting point of being lower than 200 DEG C as a transition metal source, weighing materials accurately according to the chemical metering ratio of target products, and putting the materials into a corundum crucible (the target products are multi-element positive materials LiMO2 with layered structures, and M is two or more in Ni, Co, Mn, Fe and Cr); heating the materials in an electric furnace or water bath, enabling the materials to be melted to form uniform liquid, then moving the liquid into the constant-temperature electric furnace with the temperature of being 400-600 DEG C, and enabling the liquid to generate combustion reaction; carrying out collection, grinding and 100-mesh sieving on combustion reaction products, pressing into round pieces, putting into a microwave oven, insulating for 5-200 minutes at the temperature of 600-1000 DEG C, and then cooling along with the furnace; and finally, taking out the round pieces, and carrying out grinding and 300-mesh sieving to obtain a target product. The method disclosed by the invention has the advantages that water is not needed, the energy and the time are saved, the process is simple, the operation is easy, and the synthesized multi-element layered positive material has good electrochemical property.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

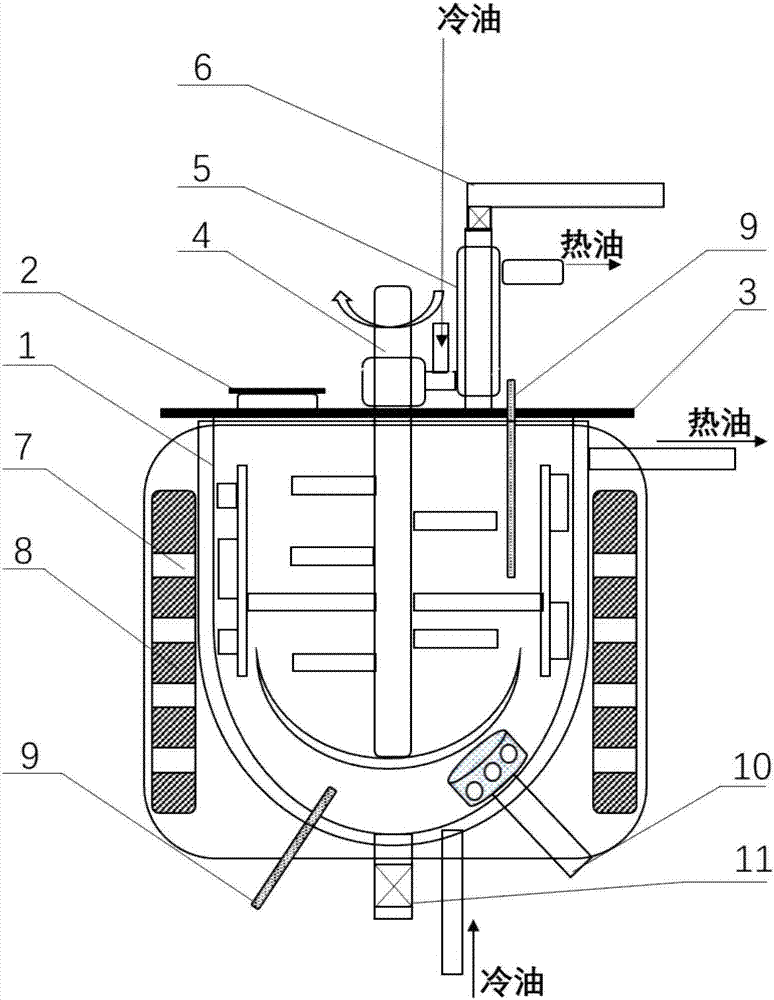

Method and device for preparing polyurethane water-resistant paint by microwave reaction

InactiveCN107088392AAvoid the disadvantages of temperature inconsistencySynchronization of heatingPolyurea/polyurethane coatingsChemical/physical/physico-chemical stationary reactorsRefluxPolymer science

The invention provides a method and device for preparing polyurethane water-resistant paint by microwave reaction. The method comprises the following steps: 1, microwave dehydration: charging the raw materials polyether glycol, a pigment, fillers and a dispersant into a microwave reaction kettle provided with a microwave heating device, a condensing reflux device, an anchor-type wall-scraping stirrer, a high-speed shearer, a quick cooling device and a vacuum device, and starting the microwave heating device; 2, cooling: starting the cooling device for reducing the temperature of the materials to 50-70DEG C, charging isocyanate and starting the microwave heating device; 3, cooling: charging a catalyst, a curing agent and a solvent; 4, vacuum defoamation; 5, discharging; and 6, washing of a tank: charging the solvent, starting the condensing reflux device and the heating device, and controlling the temperature. When used for preparing the polyurethane water-resistant paint, the method provided by the invention has the advantages of high heating rate, high cooling rate, short reaction time, stable properties of final products, large production capacity, low cost and the like.

Owner:LIAONING JIUDING HONGTAI WATERPROOF TECH CO LTD

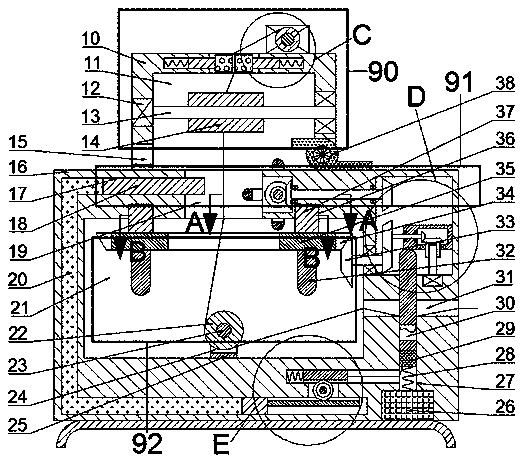

Intelligent temperature-control mattress

InactiveCN109907583ARefrigeration is difficultMeet warmingStuffed mattressesPhysical therapyTemperature controlLiquid-crystal display

The invention discloses an intelligent temperature-control mattress. The intelligent temperature-control mattress comprises a mattress body and a main engine, wherein the mattress body is provided with a ventilation layer, a lining layer, a temperature control layer, a filling layer and an anti-slip layer in sequence from top to bottom; a water circulation pipe is laid in the temperature control layer; the temperature control layer is provided with a sleep monitor and a first temperature sensor; the main engine comprises a water tank assembly, a control panel, a heat dissipation opening, a water feeding opening and a liquid crystal display screen arranged on the control panel; the water tank assembly comprises a water tank, a semiconductor cooler, a fan, a water feeding opening of a watertank, a second temperature sensor, a water pump, a self-operated electric control temperature adjusting valve and a stirring part. The intelligent temperature-control mattress disclosed by the invention has the advantages that the semiconductor cooler can meet the requirements of heating and cooling the mattress at the same time, and is simple in structure and good in safety.

Owner:深圳市弘楚源科技发展有限公司

Boiling-off coloring device for textile fibers

ActiveCN110396788AGood colorImprove the efficiency of impurity removalLiquid/gas/vapor removalTextile treatment machine arrangementsTextile fiberWax

The invention relates to a boiling-off coloring device for textile fibers. The device comprises a first device body, a first cavity is formed in the first device body, a boiling-off additive and caustic soda are added into the first cavity, and the boiling-off additive, the caustic soda and impurities, such as waxy substances and cotton seed hulls, in the textile fibers can be subjected to a chemical degradation reaction. According to the device, the textile fibers are subjected to boiling-off, dried and colored, the device conducts stirring while boiling-off is conducted, so that the boiling-off additive and caustic soda are sufficiently mixed with the textile fibers, the efficiency of removing the impurities of the textile fibers is high, and convenience is provided for following coloring for the textile fibers; the direction of the extrusion force generated by an L-shaped long plate on the surfaces of the textile fibers is opposite to the movement direction of the textile fibers, the device has a good extrusion effect, the boiling-off additive and caustic soda are recovered into the first cavity for recycling, the device is environmentally friendly, the textile fibers are dried,so that micropores in the fibers are heated to be expanded, diffusion during following coloring is quick and even, and the device has a good coloring effect, is high in overall automation degree andcan achieve circulation production.

Owner:扬州丽铂环保材料有限公司

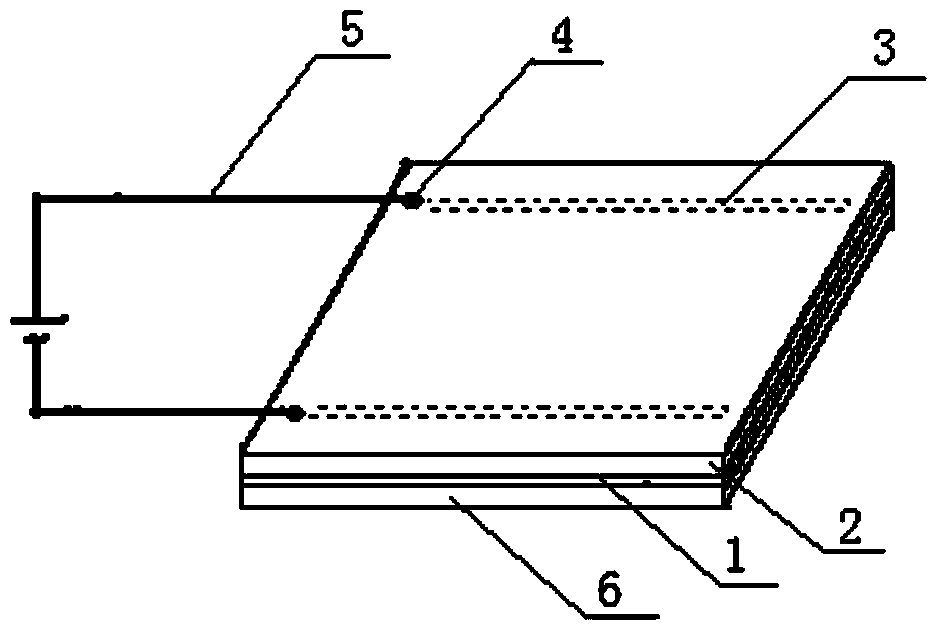

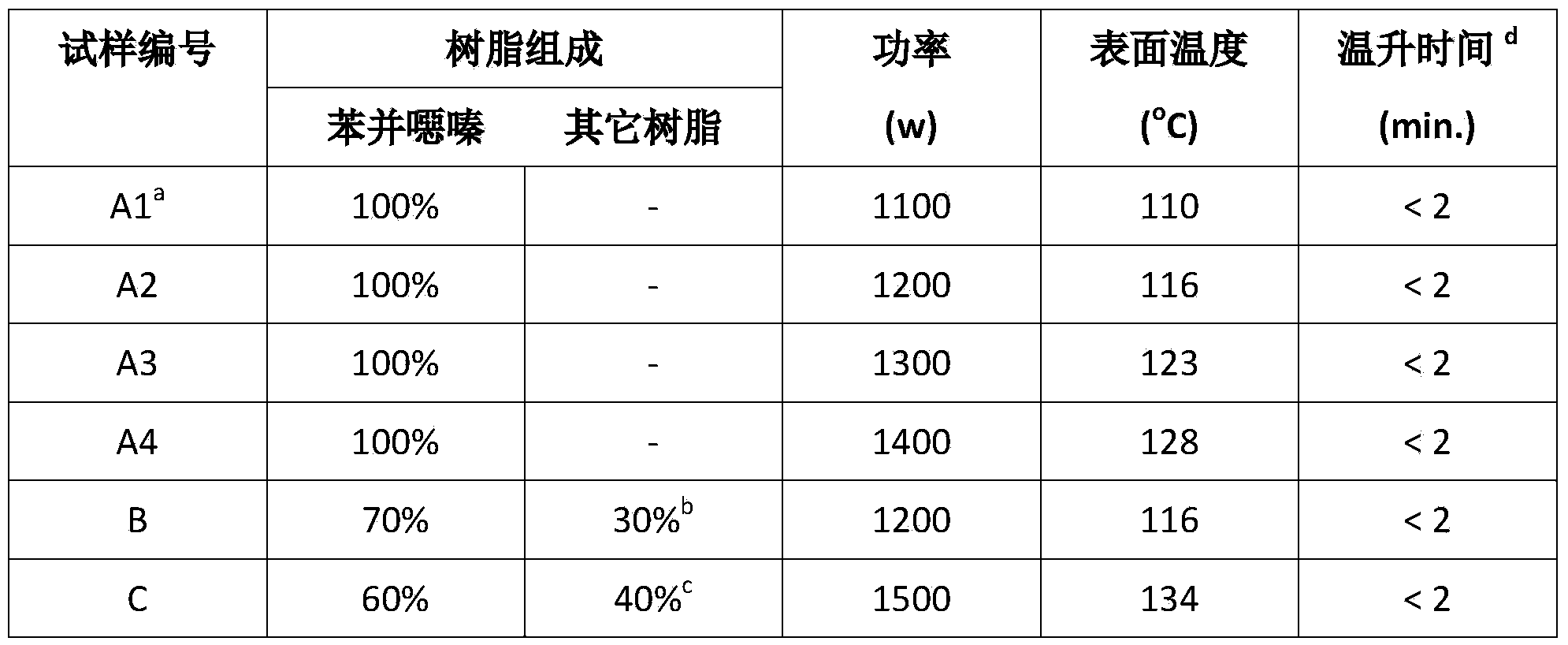

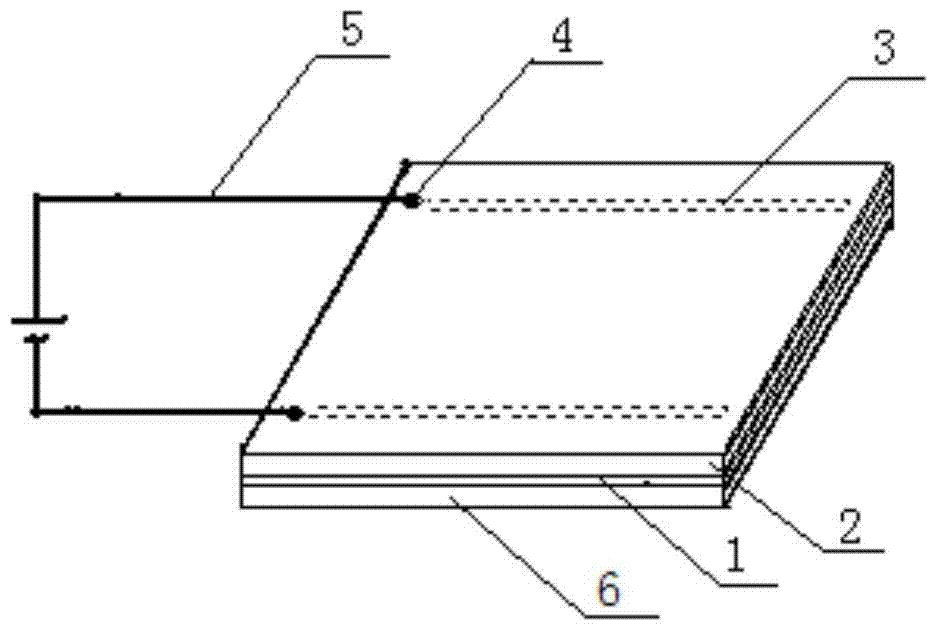

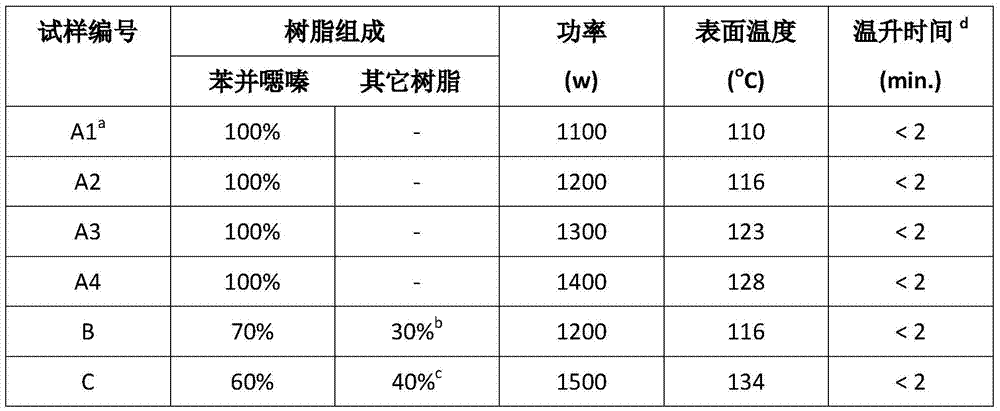

High-power carbon fiber electric heating plate, production process and application device

ActiveCN104290414ALow costTo promote metabolismLamination ancillary operationsSynthetic resin layered productsEpoxyFiber

The invention discloses a high-power carbon fiber electric heating plate, a production process and an application device. The high-power carbon fiber electric heating plate comprises a plurality of layers, namely a benzoxazine resin insulation layer I, carbon paper and a benzoxazine resin insulation layer II which are sequentially arranged from top to bottom, wherein the middle layer of carbon paper is encapsulated up and down by the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II; a conductive material in contact with the carbon paper is also encapsulated between the carbon paper and the benzoxazine resin insulation layer I and / or between the carbon paper and the benzoxazine resin insulation layer II; the conductive material is used as an electrode and is connected with a power supply by virtue of a lead; the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II respectively comprise cured benzoxazine resin or cured and modified benzoxazine resin; glass cloth is used as a resin reinforcing material. According to the high-power carbon fiber electric heating plate, epoxy resin is replaced by the benzoxazine resin and the modified resin of the benzoxazine resin, so that the carbon fiber electric heating plate with high-heat-resistance upper and lower insulation layers and development power reaching 1100-1500w is obtained.

Owner:SHANDONG UNIV

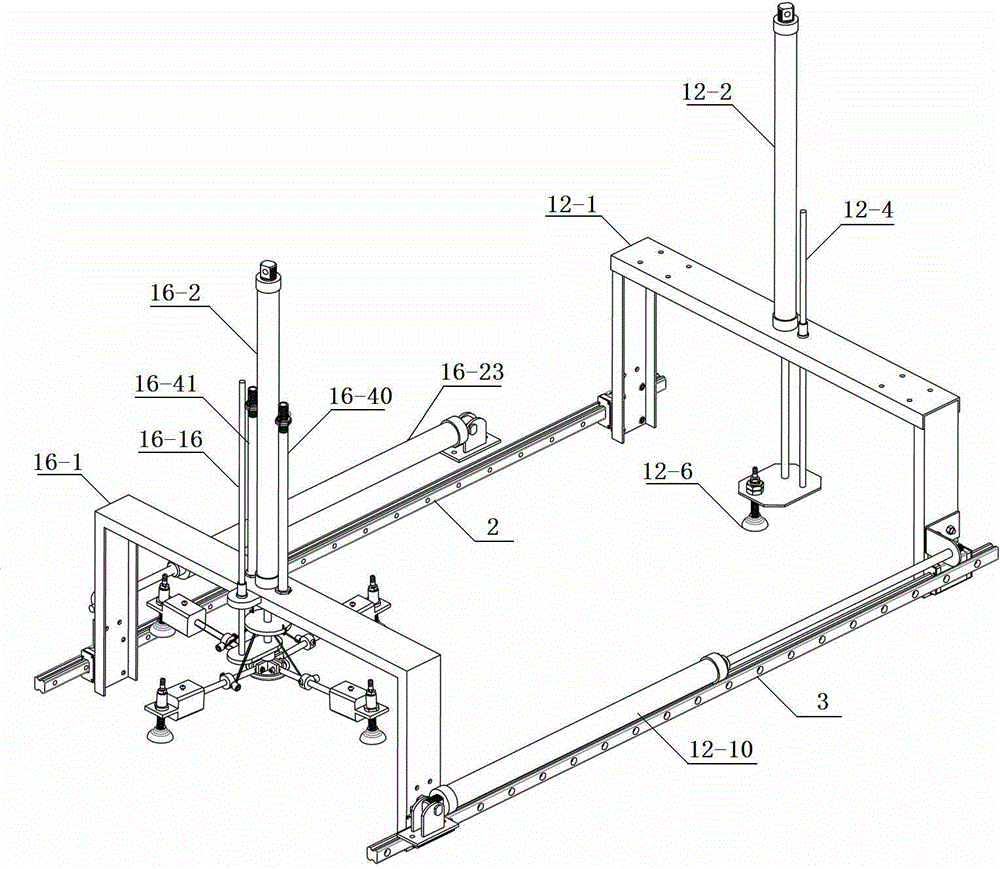

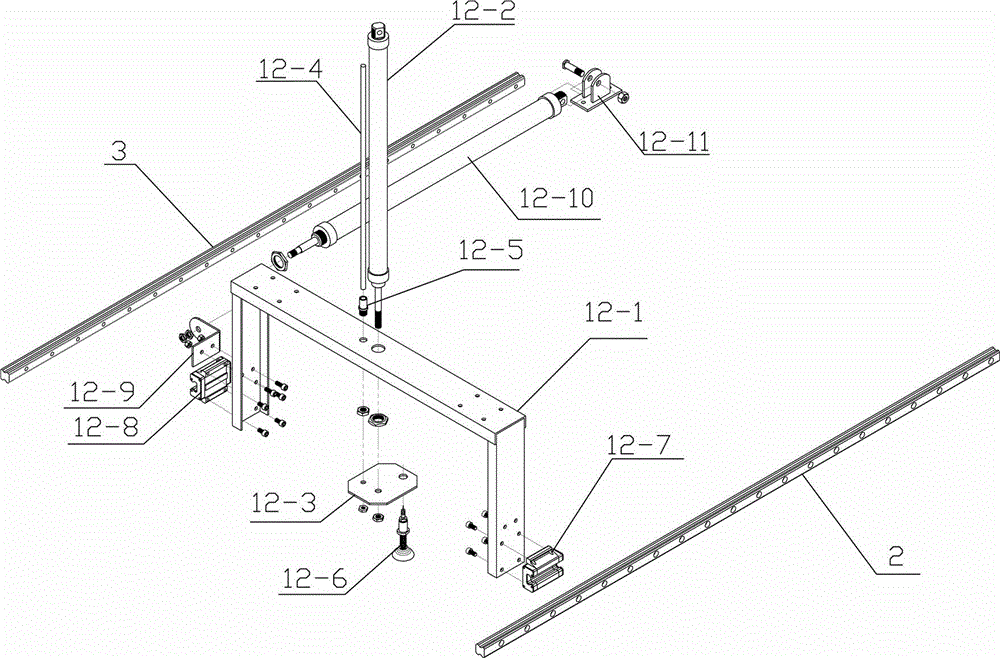

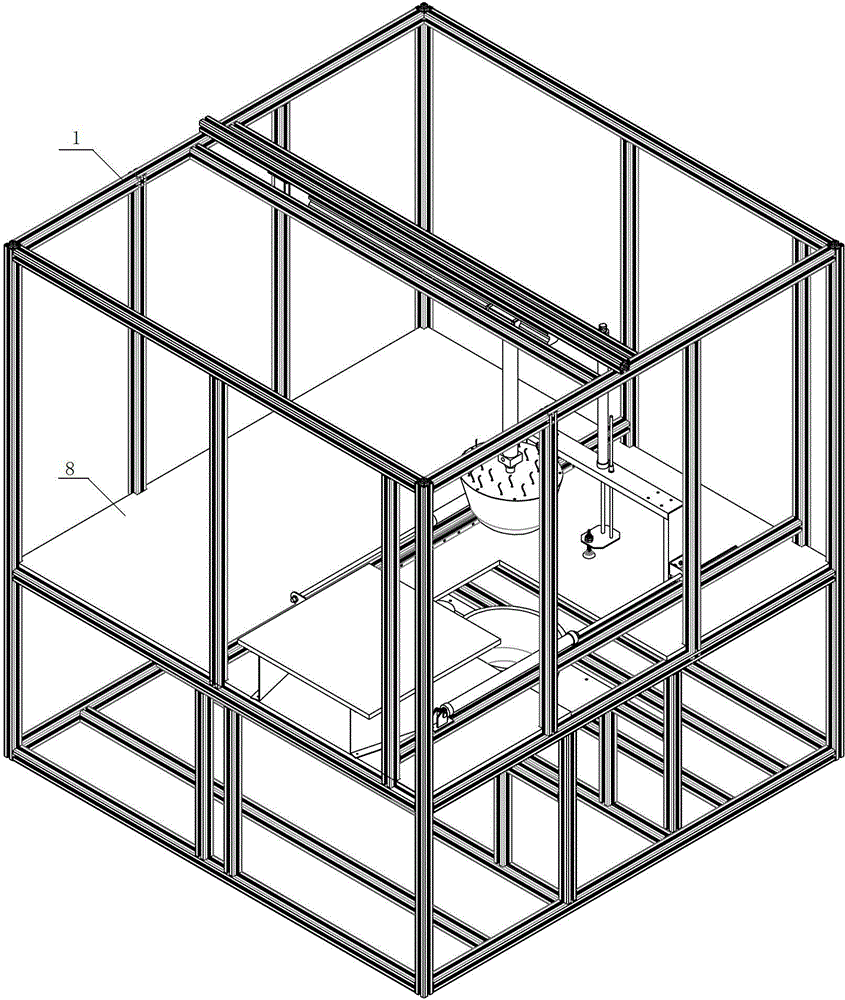

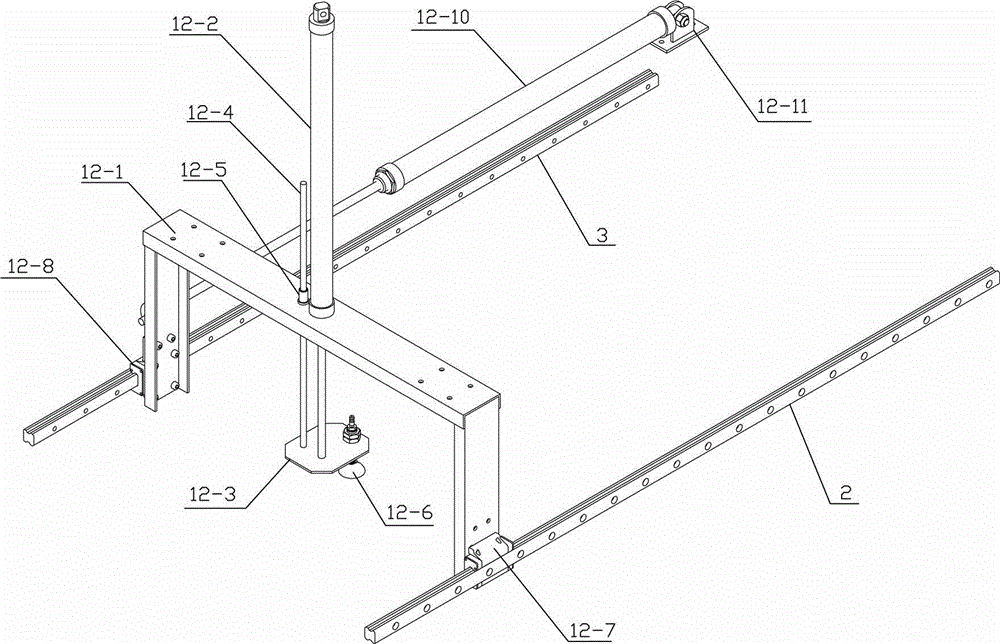

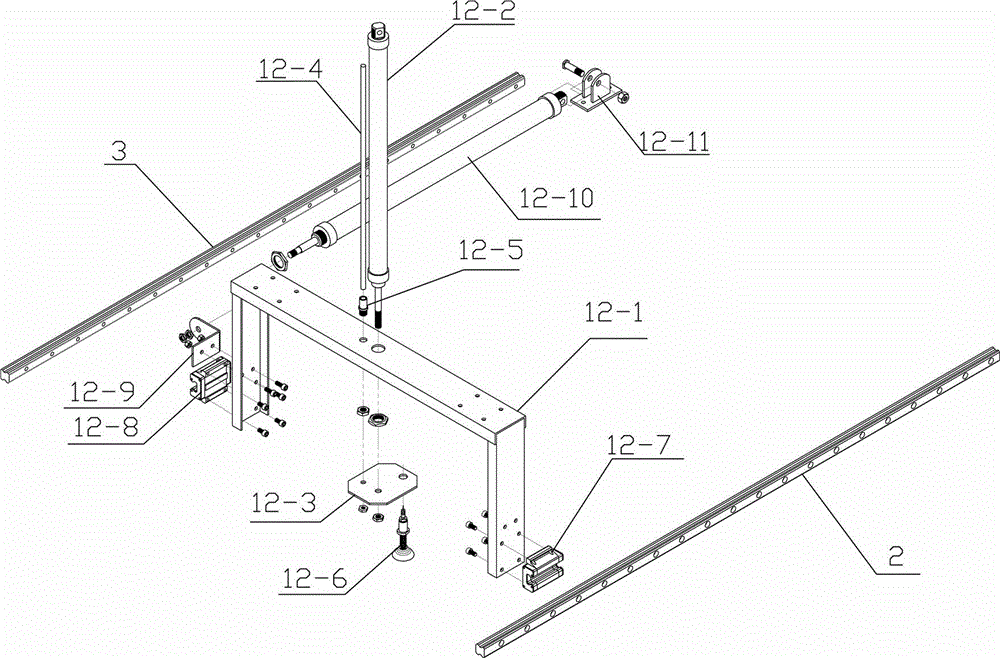

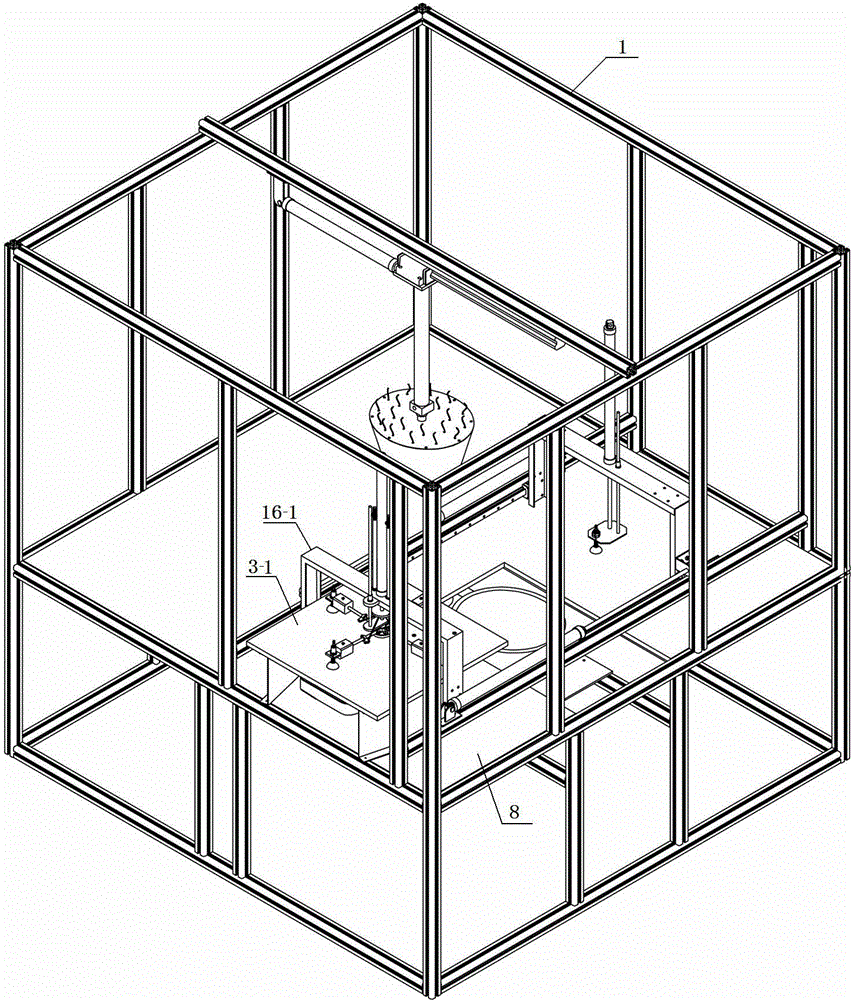

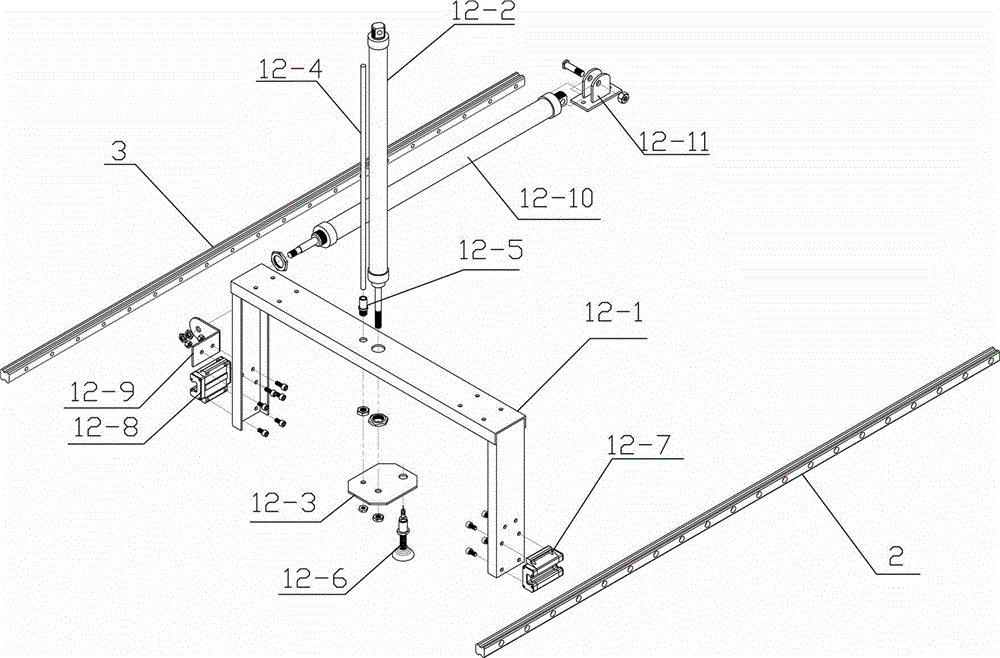

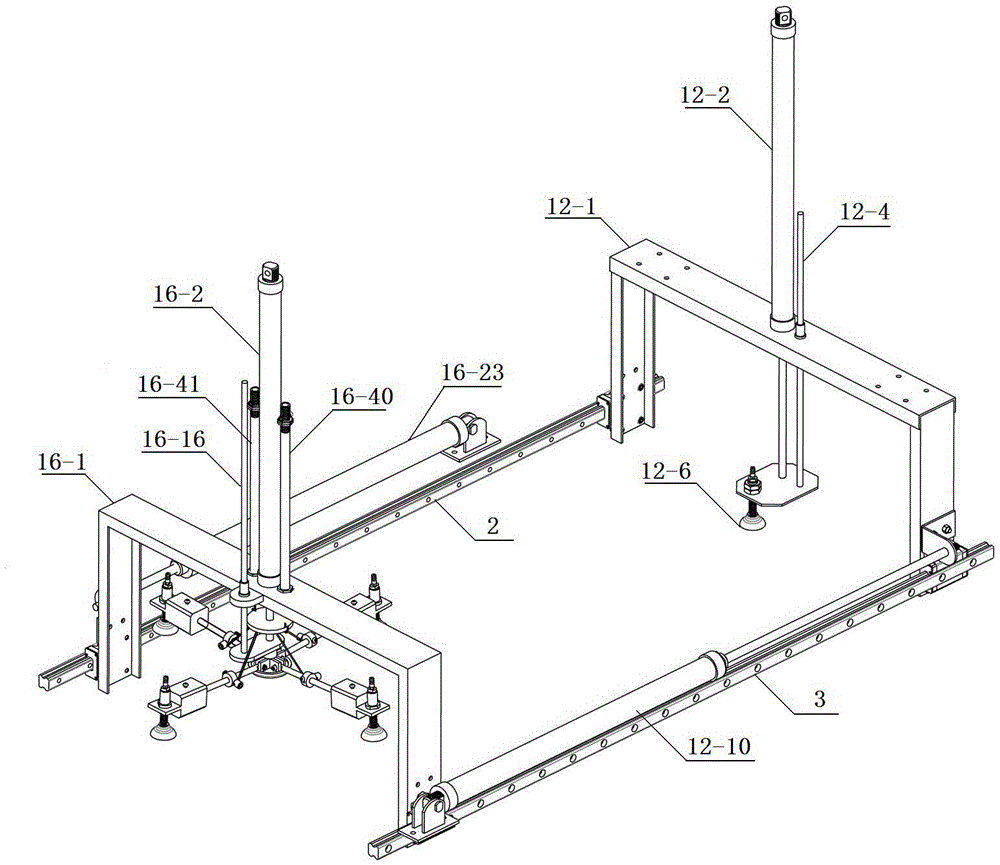

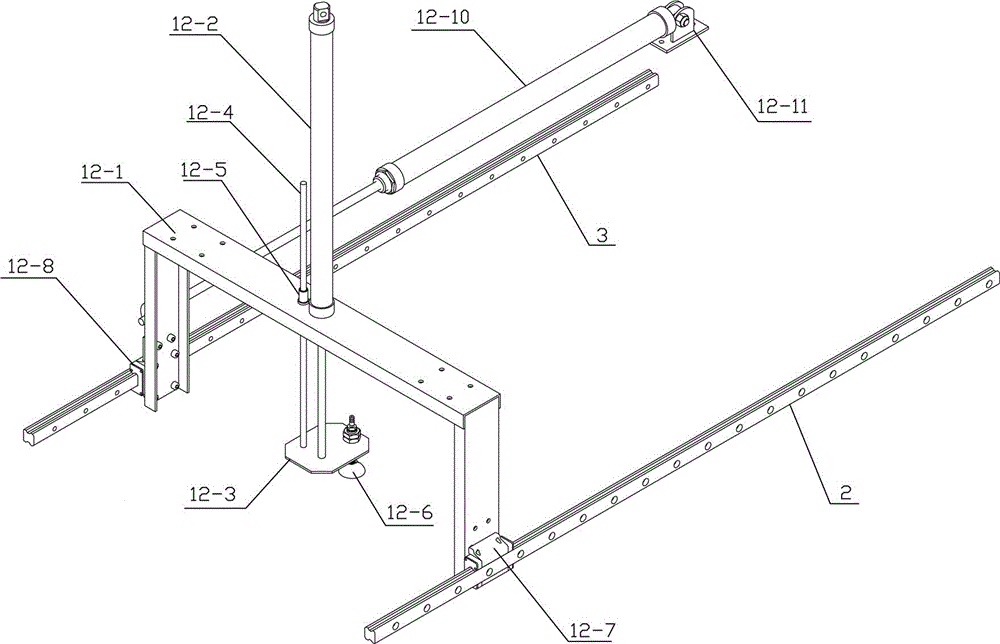

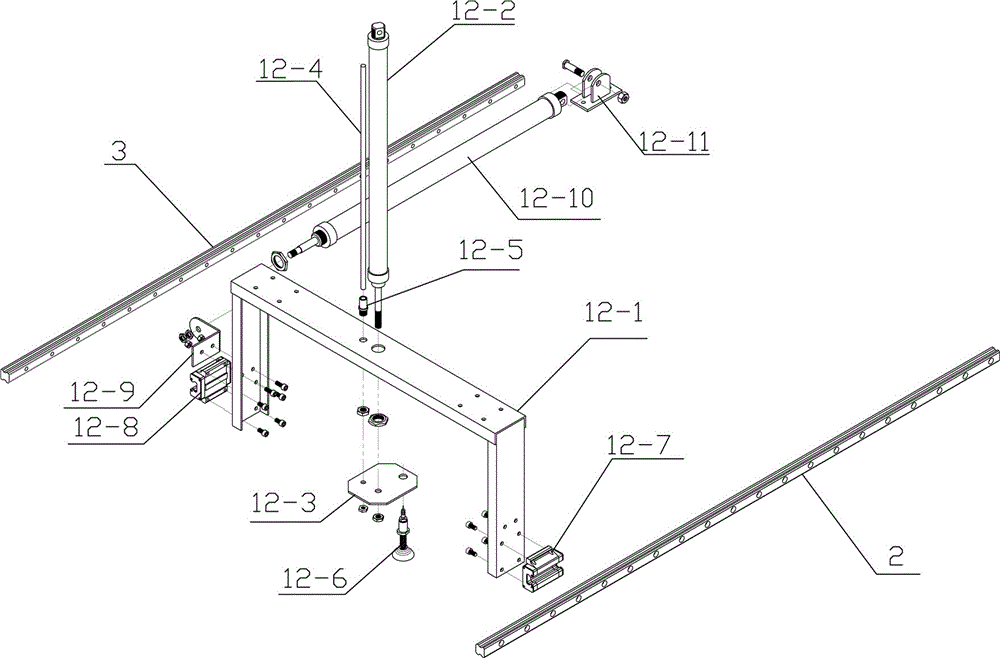

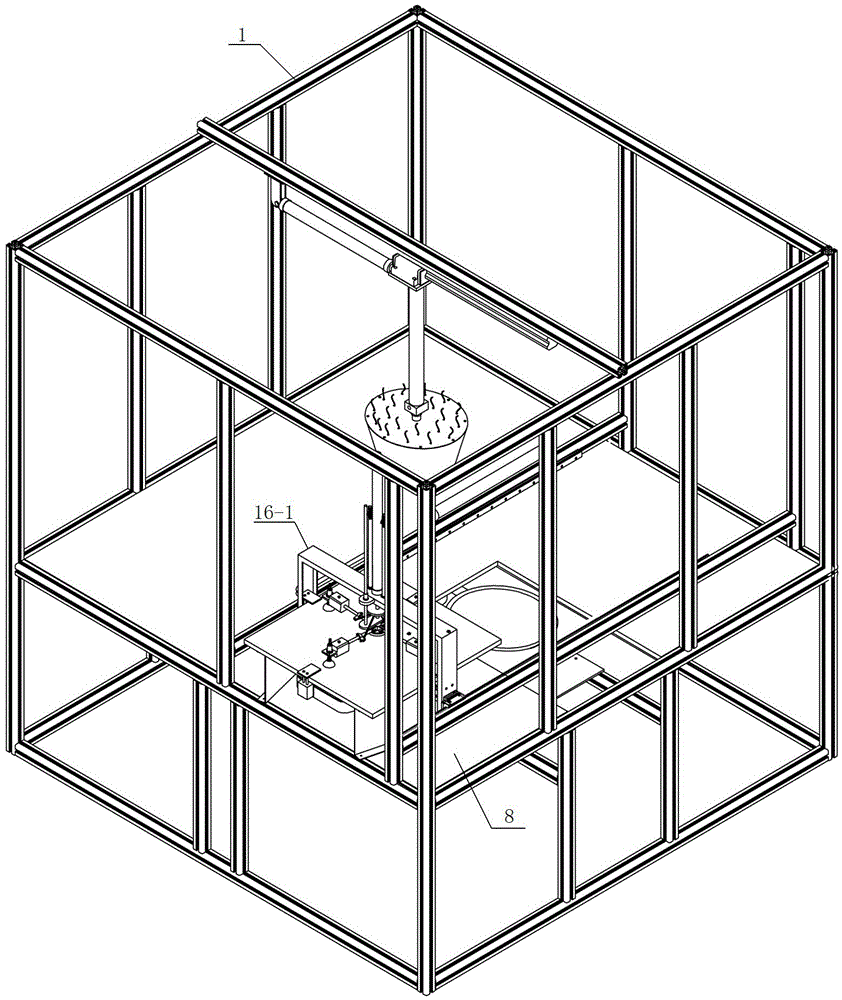

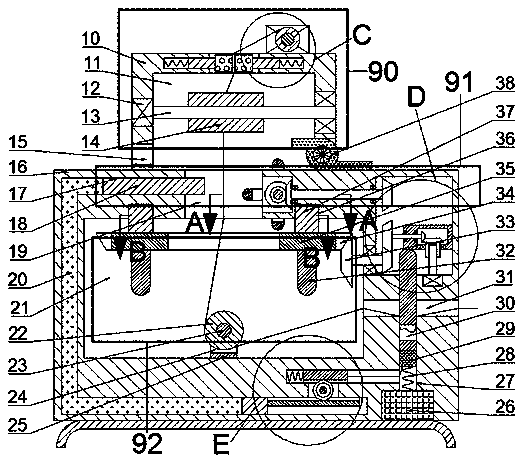

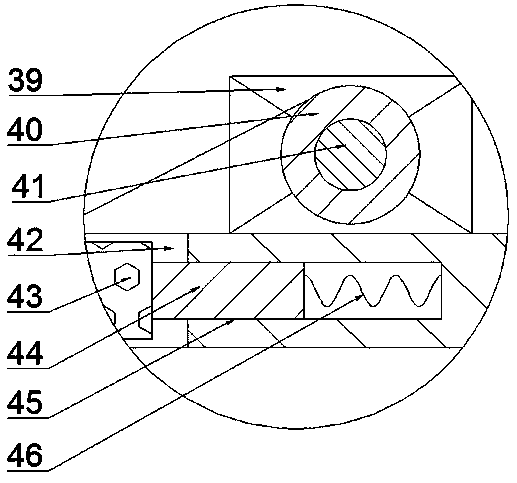

Sheet taking/feeding and cloth folding/gathering device of automatic sheet paver of bulletproof helmet

ActiveCN104097334ADoes not affect contraction and expansionHeats up quickly and evenlyConveyor partsEngineeringMechanical engineering

Owner:JIHUA 3502 PROFESSIONAL GARMENT

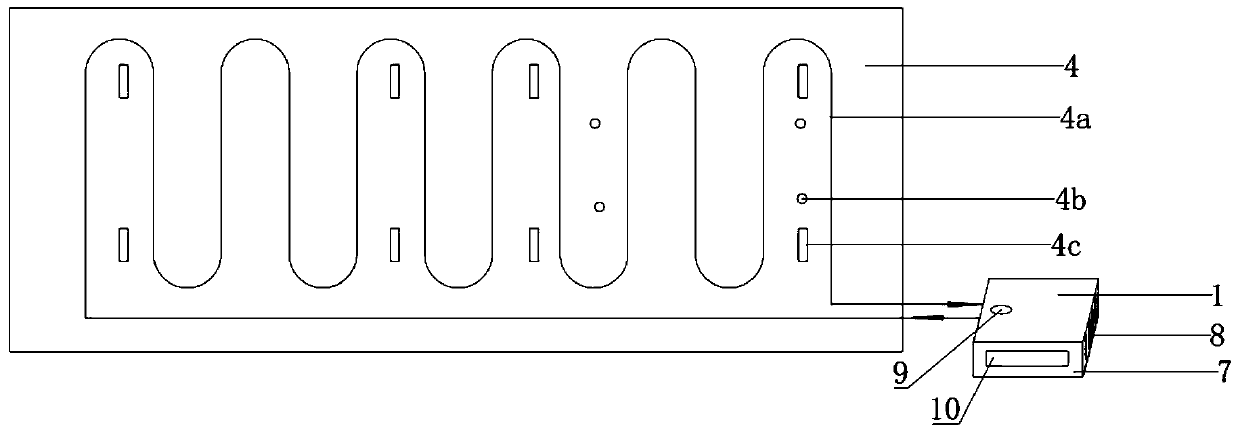

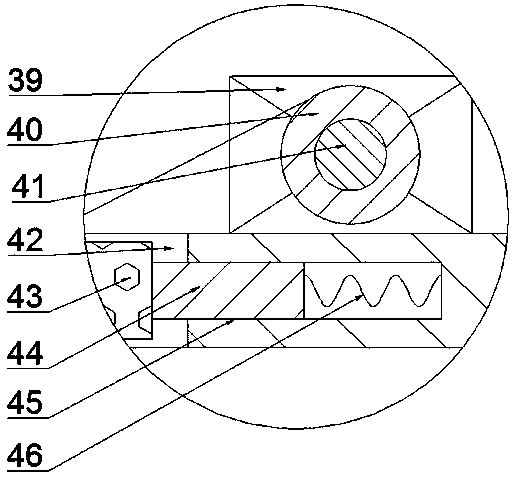

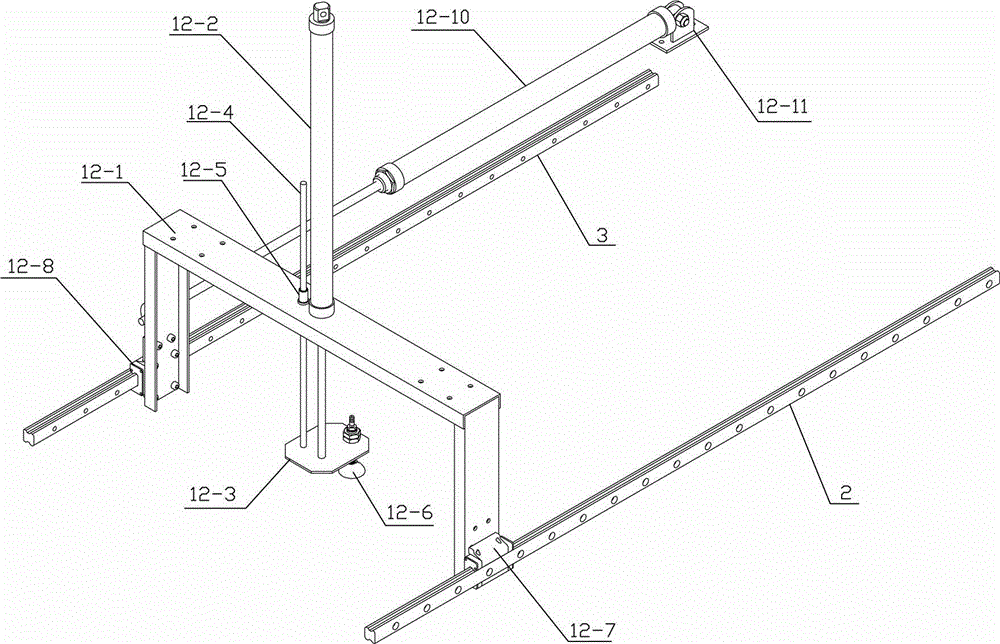

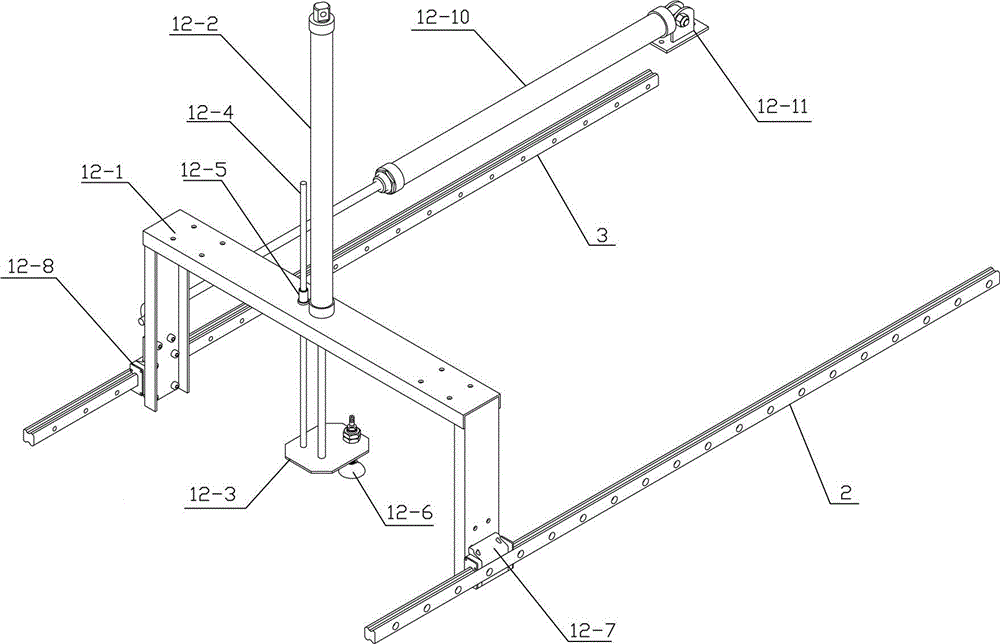

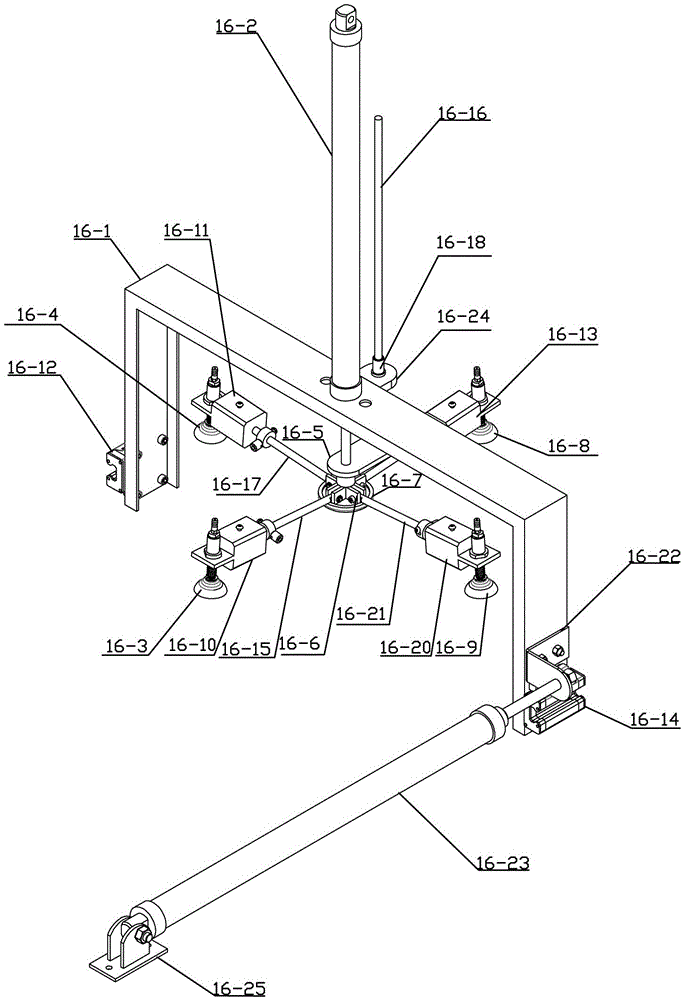

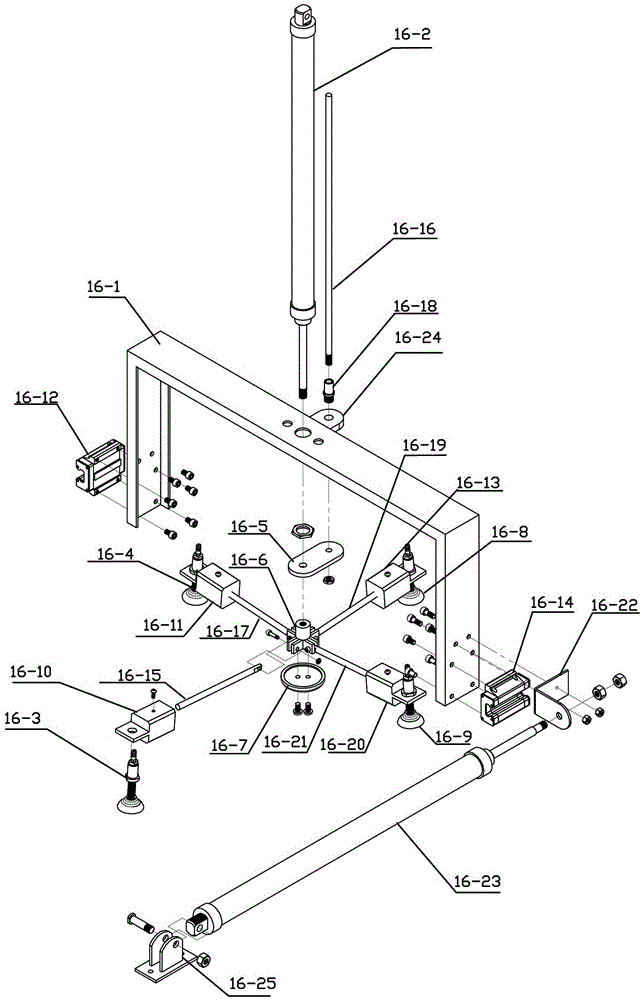

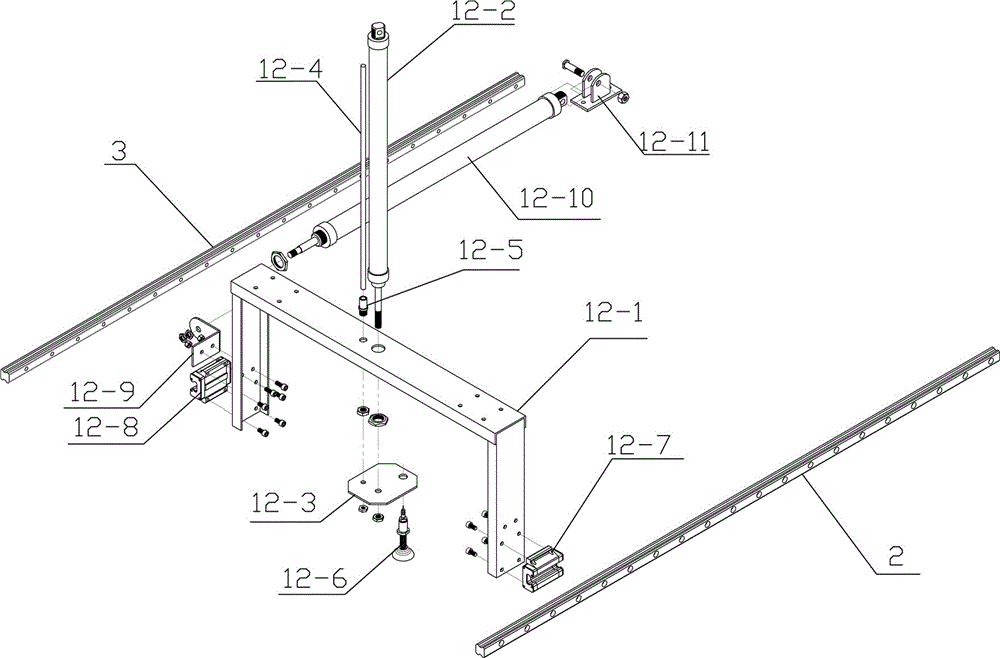

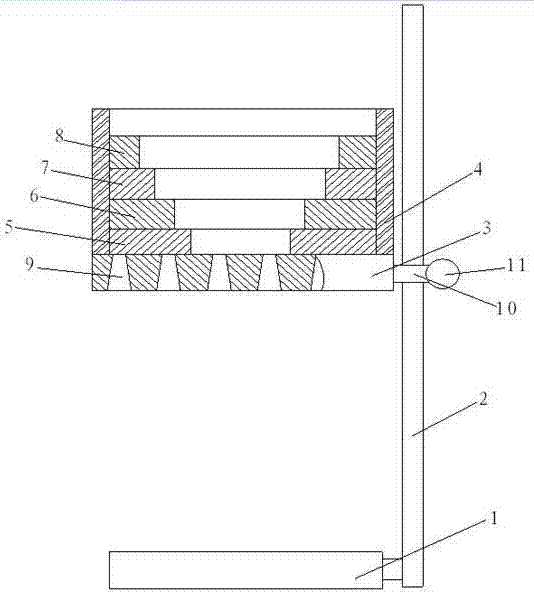

Small sheet taking/feeding device and mold of automatic sheet paver of bulletproof helmet

ActiveCN104097333ADoes not affect contraction and expansionHeats up quickly and evenlyConveyor partsMechanical engineeringStructural engineering

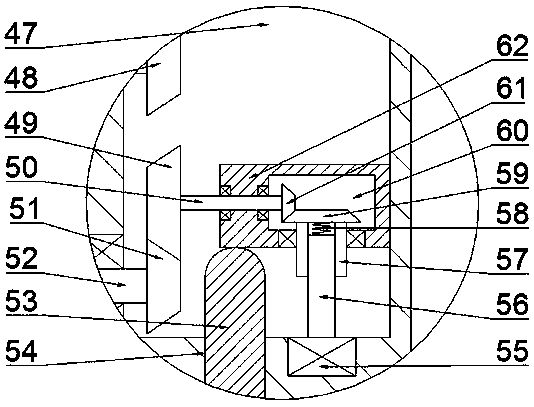

The invention relates to a small sheet taking / feeding device and a mold of an automatic sheet paver of a bulletproof helmet. The small sheet taking / feeding device is arranged between first and second sheet taking / feeding linear sliding rails of a frame body; and the mold comprises an upper mold arranged in the frame body of the automatic sheet paver of the bulletproof helmet and a driving device thereof, and a lower mold and a driving device thereof corresponding to the lower mold and the driving device thereof. The small sheet taking / feeding device sucks small sheets through small sheet suckers by vacuum to achieve the stability and the reliability; as a heating device is arranged on the upper mold, the temperature is automatically controlled and quickly and evenly risen, the sheets are heated for softening when being pressed and temporarily and slightly bonded, and the sheet paving uniformity is guaranteed; and the small sheet taking / feeding device and the mold are used for performing the bulletproof helmet sheet paving operation, so that the sheet paving quality is high, the operation is convenient, and the working efficiency is largely improved.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

A high-power carbon fiber electric heating plate, processing technology and application equipment

ActiveCN104290414BLow costTo promote metabolismLamination ancillary operationsSynthetic resin layered productsEpoxyFiber

The invention discloses a high-power carbon fiber electric heating plate, a production process and an application device. The high-power carbon fiber electric heating plate comprises a plurality of layers, namely a benzoxazine resin insulation layer I, carbon paper and a benzoxazine resin insulation layer II which are sequentially arranged from top to bottom, wherein the middle layer of carbon paper is encapsulated up and down by the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II; a conductive material in contact with the carbon paper is also encapsulated between the carbon paper and the benzoxazine resin insulation layer I and / or between the carbon paper and the benzoxazine resin insulation layer II; the conductive material is used as an electrode and is connected with a power supply by virtue of a lead; the benzoxazine resin insulation layer I and the benzoxazine resin insulation layer II respectively comprise cured benzoxazine resin or cured and modified benzoxazine resin; glass cloth is used as a resin reinforcing material. According to the high-power carbon fiber electric heating plate, epoxy resin is replaced by the benzoxazine resin and the modified resin of the benzoxazine resin, so that the carbon fiber electric heating plate with high-heat-resistance upper and lower insulation layers and development power reaching 1100-1500w is obtained.

Owner:SHANDONG UNIV

Process method for microwave-assisted extraction of solid-phase waste grease in kitchen waste by ionic liquid

InactiveCN108485818AImprove solubilityHigh activityFatty oils/acids recovery from wasteFatty substance recoveryOil and greaseEvaporation

The invention discloses a process method for microwave-assisted extraction of solid-phase waste grease in kitchen waste by ionic liquid. The process method comprises the following steps: (1) collecting the kitchen waste, washing, drying and crushing the kitchen waste into a powder sample; (2) weighing and putting a certain amount of sample into a non-metallic container, simultaneously adding the ionic liquid ([EMIM]EtSO4, EMIM]OAc and [EMIM]DEP and the like) and an alcohols solvent (methanol and ethanol) as a mixed extractant by a certain ratio, placing into a microwave reactor to extract thewaste grease; (3) taking the sample after the extraction is finished, firstly using rotary evaporation to remove the alcohols solvent, then using normal hexane to repeatedly extract the waste grease in the ionic liquid phase, and after standing for layering, obtaining normal hexane phase (upper layer) containing rich grease and the ionic liquid phase (lower layer) containing rich powder residue; (4) using rotary evaporation to remove the normal hexane in the upper-layer oil phase, drying by using a drying oven and finally obtaining the waste grease. The extraction process disclosed by the invention has the advantages of simple process, convenience in operation, high efficiency, low energy consumption, green and environment-friendly effects and the like.

Owner:SOUTHWEST PETROLEUM UNIV

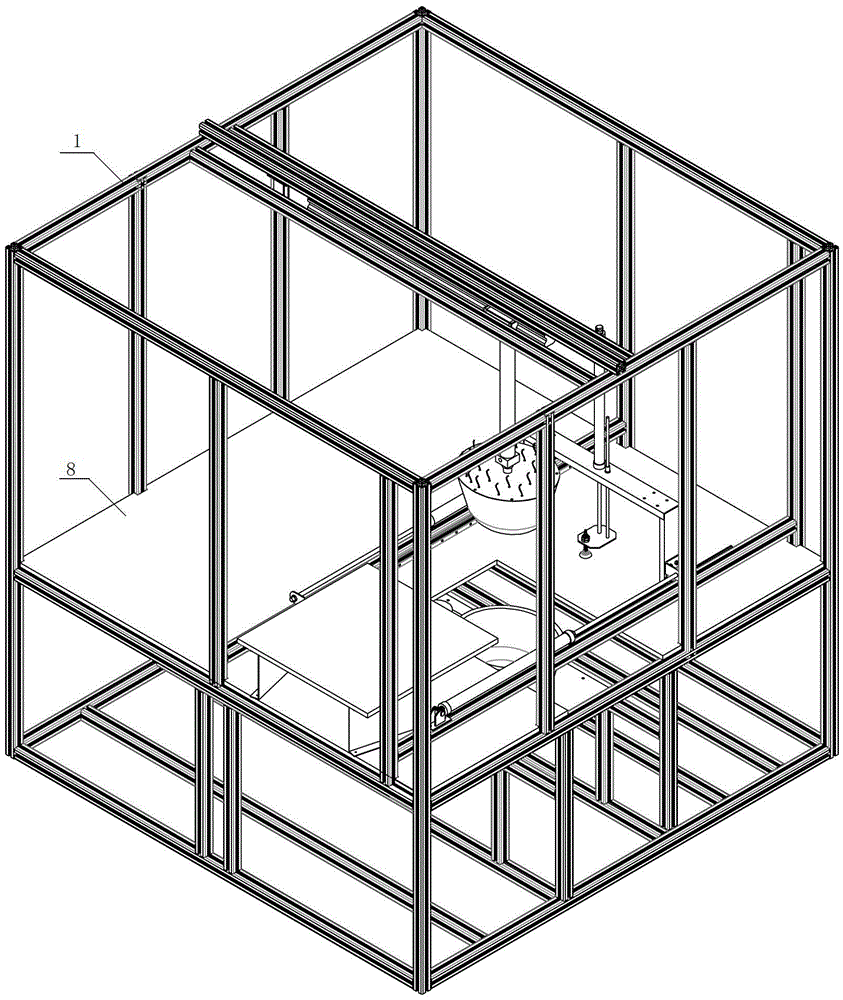

Automatic sheet paver of bulletproof helmet

ActiveCN104097331AThe upper and lower positional relationships are the sameOverlap fastConveyor partsMechanical engineering

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Ginger rapid drying device

InactiveCN102721271BHeats up quickly and evenlyMaintain moisture contentDrying solid materials with heatDrying machine combinationsFluidized bedEngineering

The invention discloses a ginger rapid drying device, which comprises a machine body, a fluidized bed and a ginger conveying wire belt penetrating the machine body, wherein the machine body is sequentially divided into a shortwave infrared heating area, a medium-wave infrared heating area and a far-infrared heating area, a shortwave infrared heating pipe nest is arranged on the inner upper part of the shortwave infrared heating area, a medium-wave infrared heating pipe nest is arranged on the inner upper part of the medium-wave infrared heating area, a far-infrared heating pipe nest is arranged on the inner upper part of the far-infrared heating area, the top of the far-infrared heating area is provided with an air inlet, and the top of the shortwave infrared heating area and the top of the medium-wave infrared heating area are respectively provided with an air outlet; and the fluidized bed comprises a bed body and a blower, wherein the blower is communicated with the bed body, the bed body is provided with an air blowing hole, and the bed body of the fluidized bed is arranged inside the shortwave infrared heating area and the medium-wave infrared heating area and is closely abutted against the lower side of the ginger conveying wire belt. By adopting a way combining the infrared heating and the fluidized bed as well as the hot air circulation, a purpose for rapidly drying ginger is realized, and simultaneously the ginger can be prevented from being discolored.

Owner:CHONGQING TECH & BUSINESS UNIV

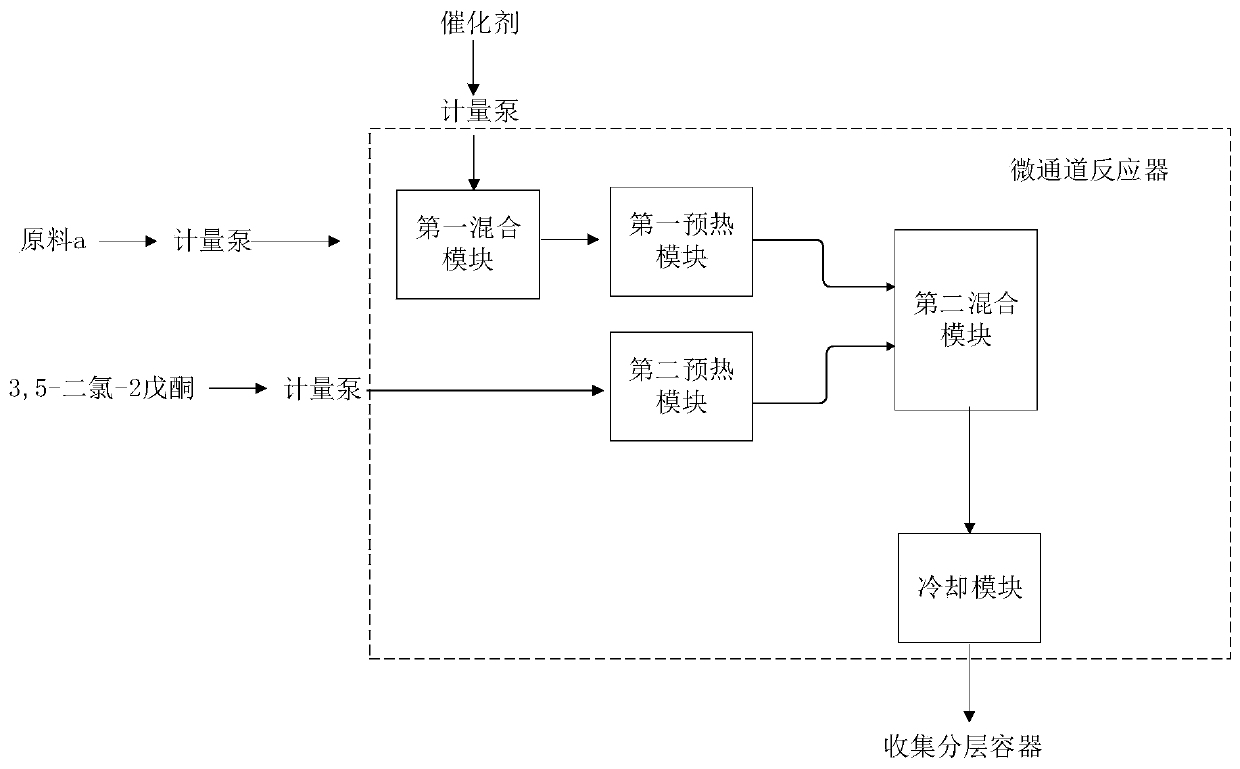

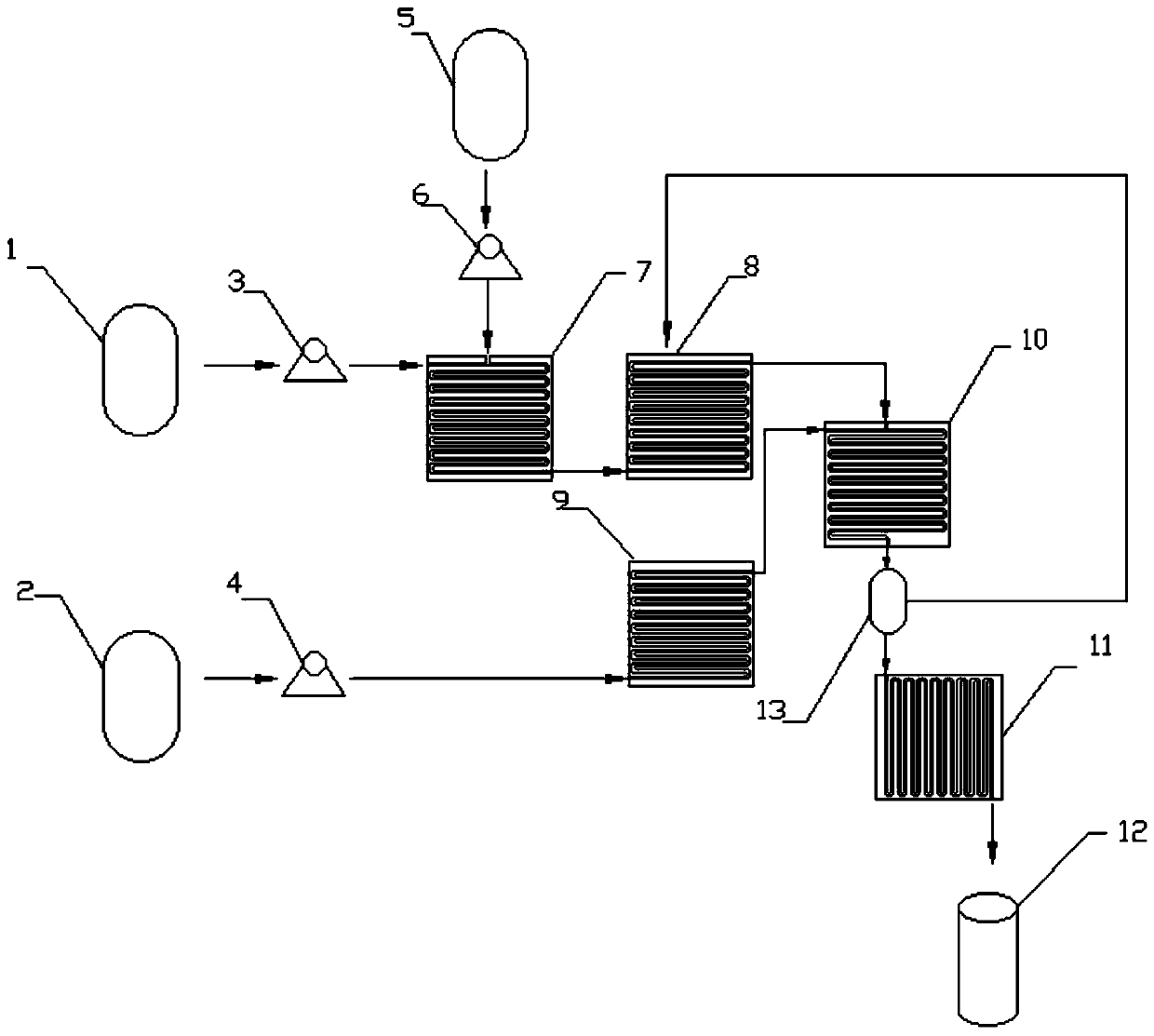

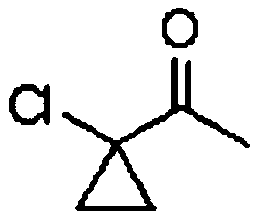

Method for preparing 1-(1-chlorocyclopropyl)ethanone by using micro-channel reactor

InactiveCN110256223AReduce hydrolysisLarge specific surface areaOrganic compound preparationChemical/physical/physico-chemical microreactorsReaction timingChemistry

The invention provides a method for continuously preparing 1-(1-chlorocyclopropyl)ethanone by using a micro-channel reactor. Mixing and preheating of a raw material a and a catalyst, preheating of a 3,5-dichloro-2-pentanone, a cyclization reaction of the raw material a and the 3,5-dichloro-2-pentanone and cooling of the product are all carried out in the micro-channel reactor. The method has the advantages of simplicity in operation, high raw material conversion rate, high product yield, great shortening of the reaction time, reduction of byproducts, accuracy in control of the temperature in the reaction process, and continuity in the reaction.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

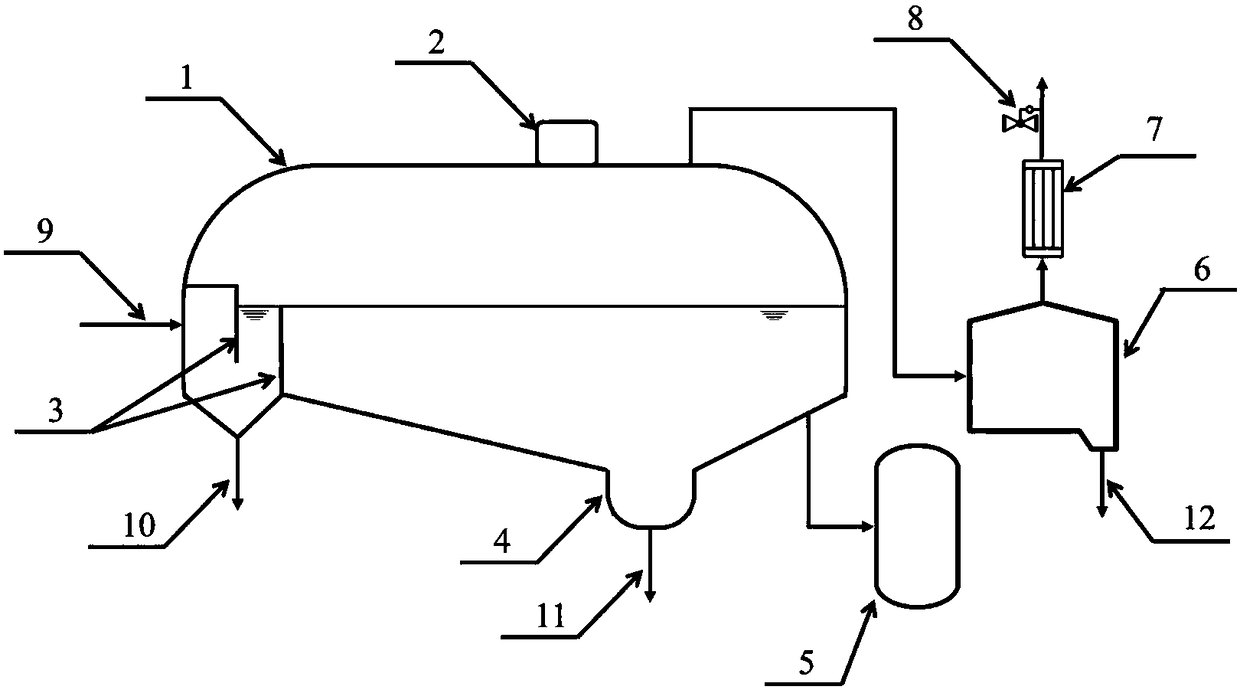

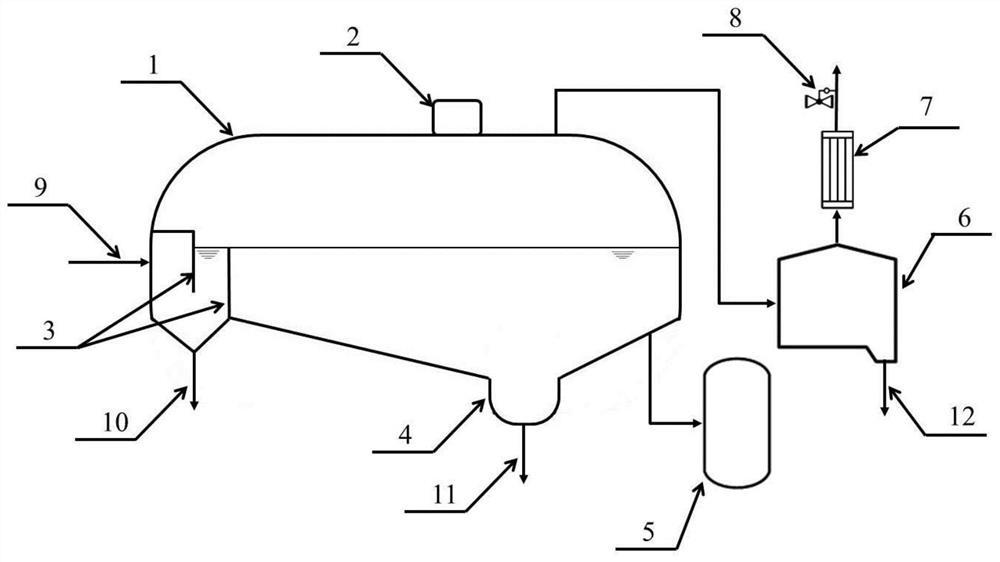

Desalination and dehydration method and device of oily waste

ActiveCN109399756ALittle effect on propertiesEasy to handleWaste water treatment from quariesFatty/oily/floating substances removal devicesDesalinationOil sludge

The invention relates to the field of dirty oil or oily sludge treatment, in particular to a desalination and dehydration method and device of oily waste. The desalination and dehydration method of the oily waste comprises the following steps: (1) performing microwave heating on the oily waste in a closed system to obtain a superheated material; (2) subjecting the superheated material to a pressure-reduction process to ensure that water being 60 percent by weight or less of the oily waste is vaporized to obtain vaporized steam and a residual material; and (3) leaving to stand the residual material for stratification to obtain purified oil at the upper layer and salty sewage at the lower layer. The desalination and dehydration method of the oily waste provided by the invention is short in settling time, good in desalination and dehydration effect and stable in desalination and dehydration effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of nano-titanium dioxide powder used for flue gas deodorization/denitration catalyst and its preparation method and application

ActiveCN104437469BSmall grainEvenly distributedDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsAmmonium paratungstateAdditive ingredient

The invention discloses nanometer titanium dioxide powder for a flue gas deodorization / denitration catalyst and a preparation method thereof. The nanometer titanium dioxide powder is prepared from the following ingredients in mass percentage: 50-100% of TiO2, 0-50% of SiO2, 0-15% of WO3 and 0-10% of V2O5; the preparation method of the nanometer titanium dioxide powder comprises the following steps: carrying out hydrolysis on titanyl sulfate or titanium sulfate used as a raw material in a microwave heating manner to obtain titanic hydroxide, filtering, washing, adding with deionized water, pulping to form 20-80% metatitanic acid slurry, adding with SiO2 sol, a V2O5 precursor-ammonium metavanadate and / or a WO3 precursor-ammonium paratungstate, adjusting the pH value to be within a range of 8-11, carrying out atmospheric-pressure microwave hydro-thermal treatment, performing filter pressing, microwave sintering and crushing to obtain the nanometer titanium dioxide powder. The invention also relates to an application of the nanometer titanium dioxide powder used as the flue gas deodorization / denitration catalyst.

Owner:河北林格环保科技有限公司

A device for taking and feeding material sheets and folding cloth in half of an automatic sheet laying machine for bulletproof helmets

ActiveCN104097334BDoes not affect contraction and expansionHeats up quickly and evenlyConveyor partsEngineeringMechanical engineering

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Horizontal type lateral heating boiler

The invention provides a horizontal type lateral heating boiler which comprises a water inlet. The water inlet is connected with a water pipe, and a heat conductor is arranged on the lateral side of the water pipe. A burner is arranged at the left side of the heat conductor, and an air blower is mounted on the lateral side of the burner and used for blowing heat of the burner to the heat conductor so as to heat water in the water pipe. The heat conductor is used for heating the water pipe rapidly and evenly, a water temperature detector is used for detecting the water temperature of the water pipe, and when the temperature meets the standard, the water enters a water storage tank, and a heat recoverer is used for recovering heat which is then released through a waste heat releaser during secondary water adding, so that the water pipe is heated. Heat loss in the hot water conveying process is prevented, economic benefits of enterprises are guaranteed, and the production cost of the enterprises is reduced.

Owner:WUHU MINGREN THERMAL ENERGY EQUIP

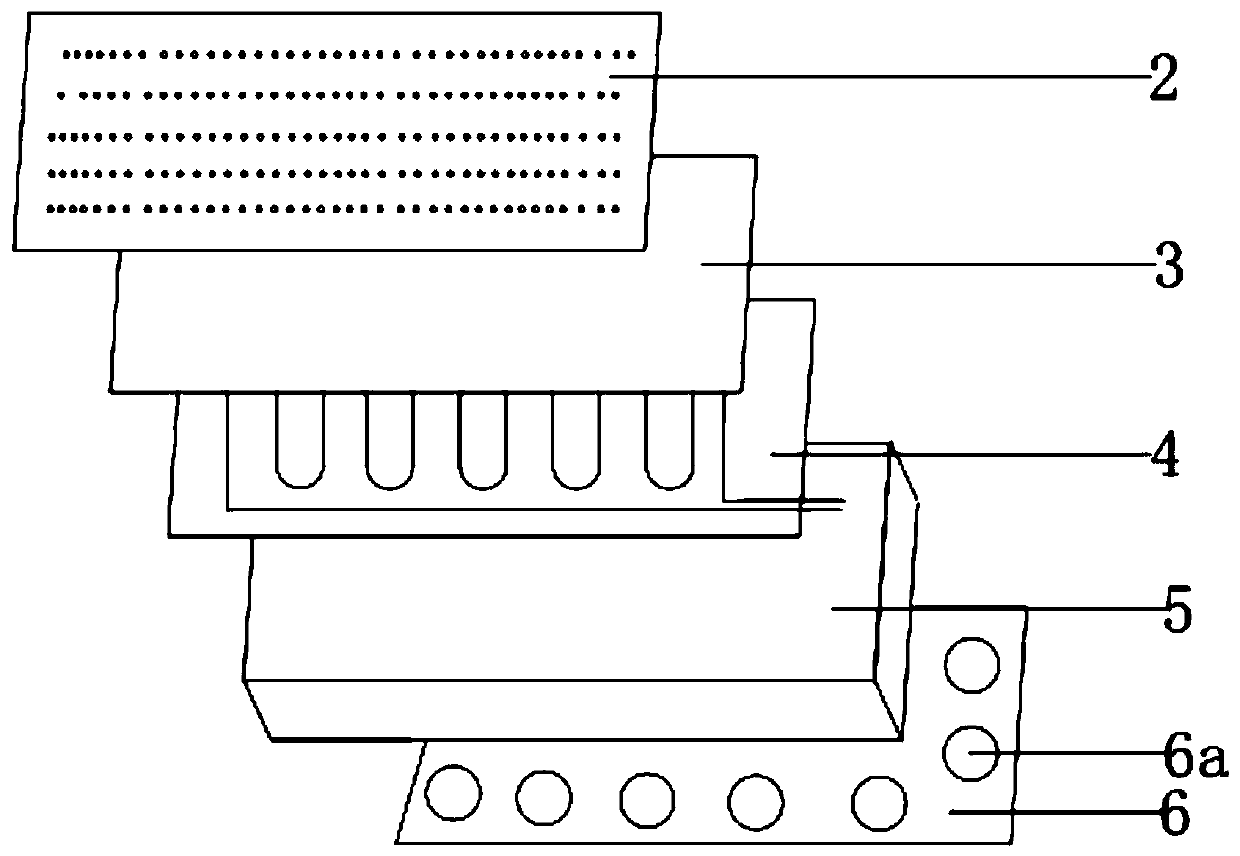

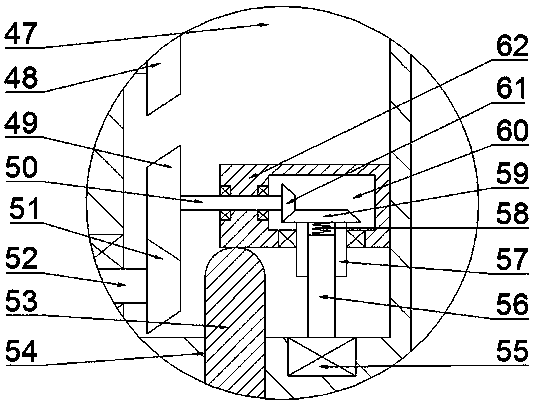

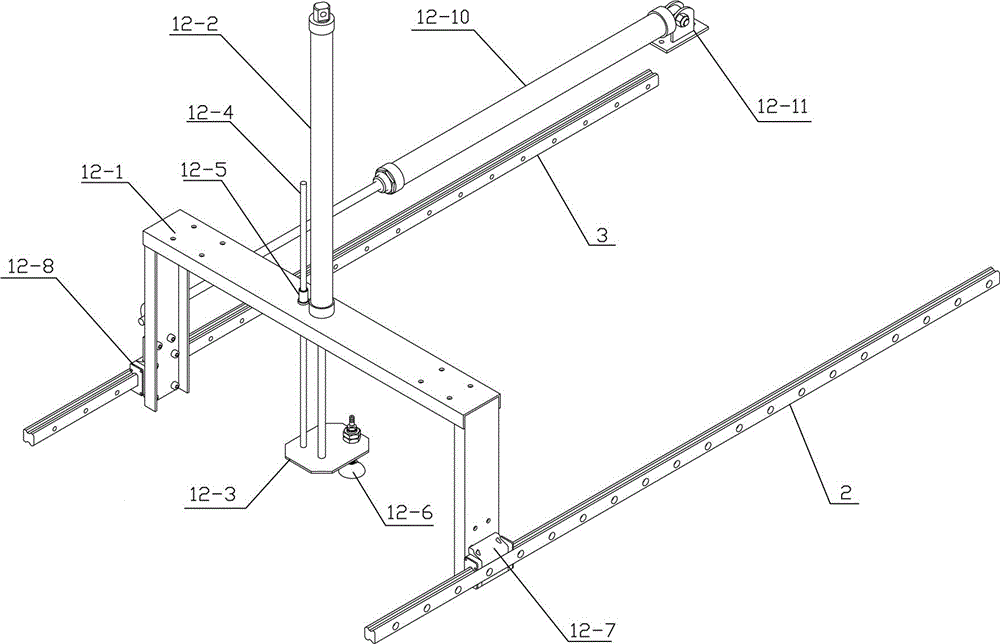

A mechanism consisting of a device for taking and feeding large pieces of an automatic sheet-laying machine for bulletproof helmets and a mold

ActiveCN104108187BDoes not affect contraction and expansionHeats up quickly and evenlyConveyor partsEngineeringMechanical engineering

The invention relates to a large material sheet fetching and delivering device and a mould of a bulletproof helmet automatic sheet paving machine. The large material sheet fetching and delivering device is arranged between a first material sheet delivering linear slide rail and a second material sheet delivering linear slide rail. The mould comprises an upper mould, a driving device of the upper mould, a lower mould, and a driving device of the lower mould. The large material sheets are absorbed by a large material sheet sucking disc in sequence through the vacuum effect, and the adsorption is stable and reliable. The upper mould is provided with a heating device, the temperature is automatically controlled, the temperature rising is fast and uniform, and the heating device can heat the material sheets so as to soften the material sheets, while the contraction and expansion between the material sheets are not affected at the same time. The lower mould and the driving device of the lower mould can guarantee that the sheets be evenly paved. The large material sheet fetching and delivering device and the mould have the advantages of high sheet paving quality, convenient operation, and largely-improved work efficiency in the bulletproof helmet sheet paving operation.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

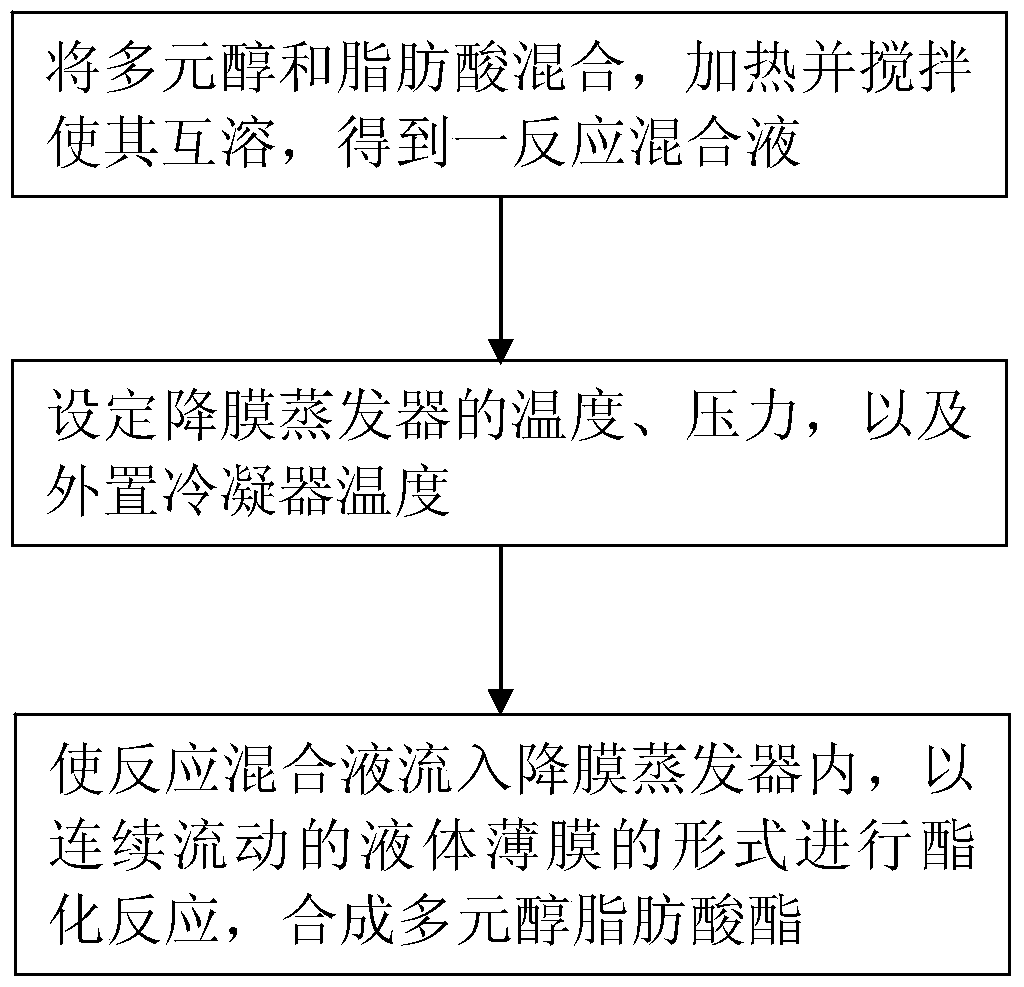

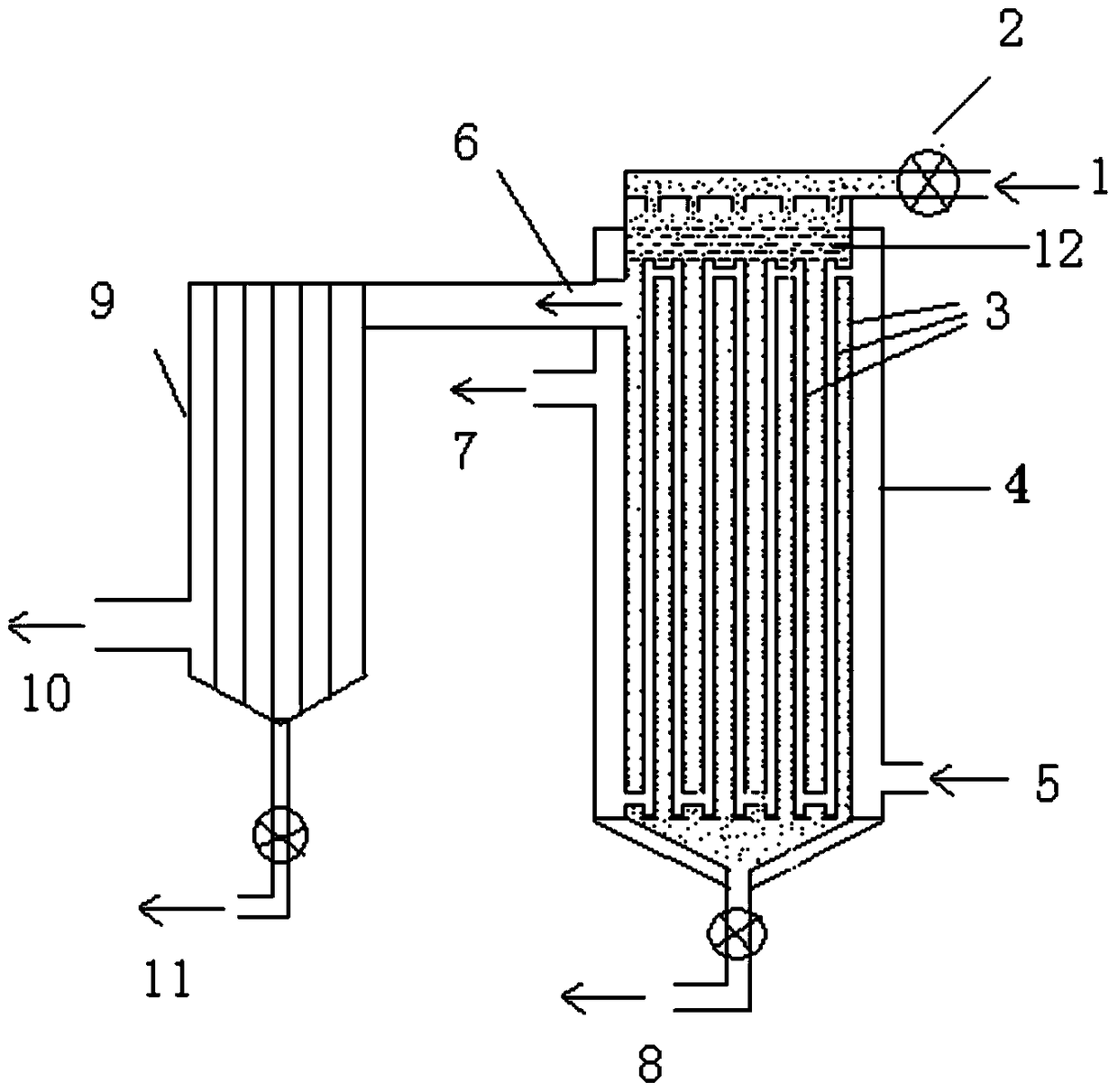

Method for Synthesizing Polyol Fatty Acid Ester Using Falling Film Evaporator

ActiveCN105732369BContinuous productionPromote escapeOrganic compound preparationCarboxylic acid esters preparationPolyolContinuous flow

The invention discloses a method for synthesizing polyol fatty acid ester by adopting a falling-film evaporator. The method comprises the following steps: mixing polyol and fatty acid in accordance with that the mole ratio of hydroxyl to carboxyl is 1: (1 to 1.6), carrying out heating and stirring so as to mutually dissolve the polyol and the fatty acid and obtain a reaction mixture solution; setting the temperature of the falling-film evaporator to 180 DEG C to 250 DEG C, setting the pressure to 5KPa to 60KPa, and setting the external condenser temperature to -20 DEG C to 30 DEG C; and enabling the reaction mixture solution to flow into the falling-film evaporator so as to form a continuous flowing liquid film, carrying out heating, and then, carrying out an esterification reaction so as to synthesize the polyol fatty acid ester. According to the method disclosed by the invention, the technical effects of high efficiency, environment-friendliness and environmental protection can be achieved.

Owner:PETROCHINA CO LTD

A textile fiber scouring and coloring device

ActiveCN110396788BGood colorImprove the efficiency of impurity removalLiquid/gas/vapor removalTextile treatment machine arrangementsTextile fiberPolymer science

The invention relates to a boiling-off coloring device for textile fibers. The device comprises a first device body, a first cavity is formed in the first device body, a boiling-off additive and caustic soda are added into the first cavity, and the boiling-off additive, the caustic soda and impurities, such as waxy substances and cotton seed hulls, in the textile fibers can be subjected to a chemical degradation reaction. According to the device, the textile fibers are subjected to boiling-off, dried and colored, the device conducts stirring while boiling-off is conducted, so that the boiling-off additive and caustic soda are sufficiently mixed with the textile fibers, the efficiency of removing the impurities of the textile fibers is high, and convenience is provided for following coloring for the textile fibers; the direction of the extrusion force generated by an L-shaped long plate on the surfaces of the textile fibers is opposite to the movement direction of the textile fibers, the device has a good extrusion effect, the boiling-off additive and caustic soda are recovered into the first cavity for recycling, the device is environmentally friendly, the textile fibers are dried,so that micropores in the fibers are heated to be expanded, diffusion during following coloring is quick and even, and the device has a good coloring effect, is high in overall automation degree andcan achieve circulation production.

Owner:扬州丽铂环保材料有限公司

A mechanism composed of a small tablet taking and feeding device and a mold of an automatic bulletproof helmet sheeting machine

ActiveCN104097333BDoes not affect contraction and expansionHeats up quickly and evenlyConveyor partsEngineeringMechanical engineering

The invention relates to a small sheet taking / feeding device and a mold of an automatic sheet paver of a bulletproof helmet. The small sheet taking / feeding device is arranged between first and second sheet taking / feeding linear sliding rails of a frame body; and the mold comprises an upper mold arranged in the frame body of the automatic sheet paver of the bulletproof helmet and a driving device thereof, and a lower mold and a driving device thereof corresponding to the lower mold and the driving device thereof. The small sheet taking / feeding device sucks small sheets through small sheet suckers by vacuum to achieve the stability and the reliability; as a heating device is arranged on the upper mold, the temperature is automatically controlled and quickly and evenly risen, the sheets are heated for softening when being pressed and temporarily and slightly bonded, and the sheet paving uniformity is guaranteed; and the small sheet taking / feeding device and the mold are used for performing the bulletproof helmet sheet paving operation, so that the sheet paving quality is high, the operation is convenient, and the working efficiency is largely improved.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Method for treating organic refractory pollutants in soil

PendingCN114433616AHeats up quickly and evenlyRapid and even distributionContaminated soil reclamationSoil scienceActive agent

The invention discloses a method for treating organic refractory pollutants in soil, which comprises the following steps: step S10, crushing and sieving the soil, adding a surfactant, and uniformly mixing; s20, after the soil treated in the step S10 is heated to 60-80 DEG C, a sodium persulfate aqueous solution is sprayed to the soil, and a degradation reaction is conducted; wherein the heating mode is microwave heating or steam heating. The invention aims at providing a method capable of effectively degrading organic refractory pollutants in soil and repairing the soil.

Owner:郑楷集团有限公司

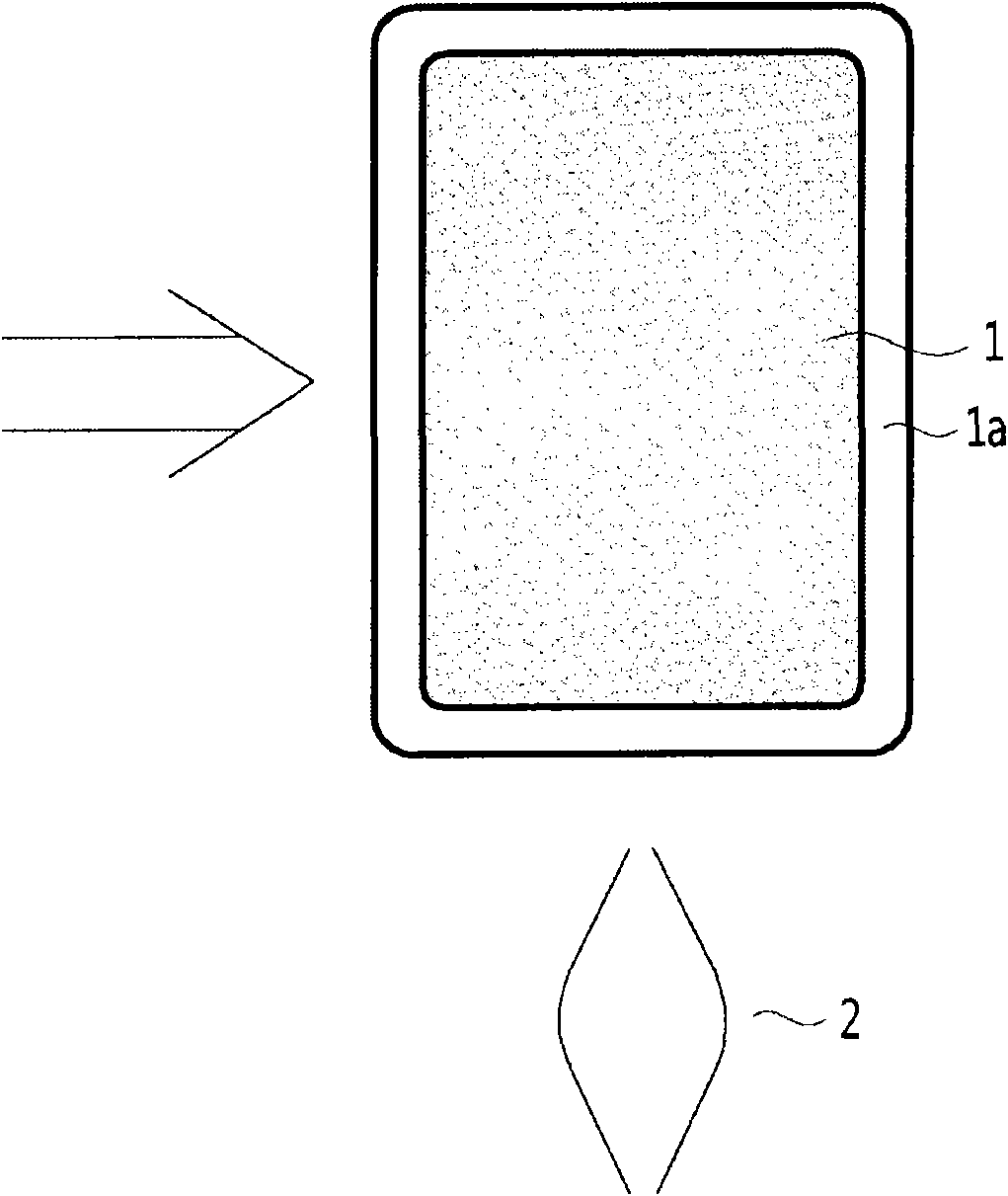

Metal foam matrix filter system for removing hydrocarbons from exhaust air and method thereof

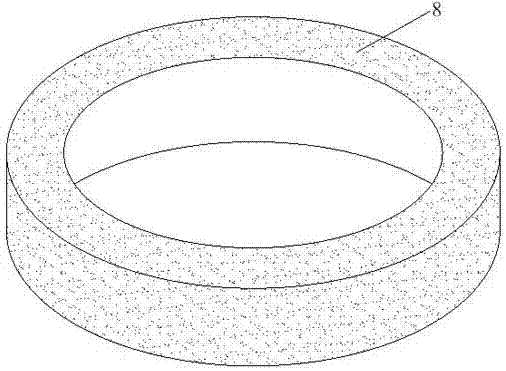

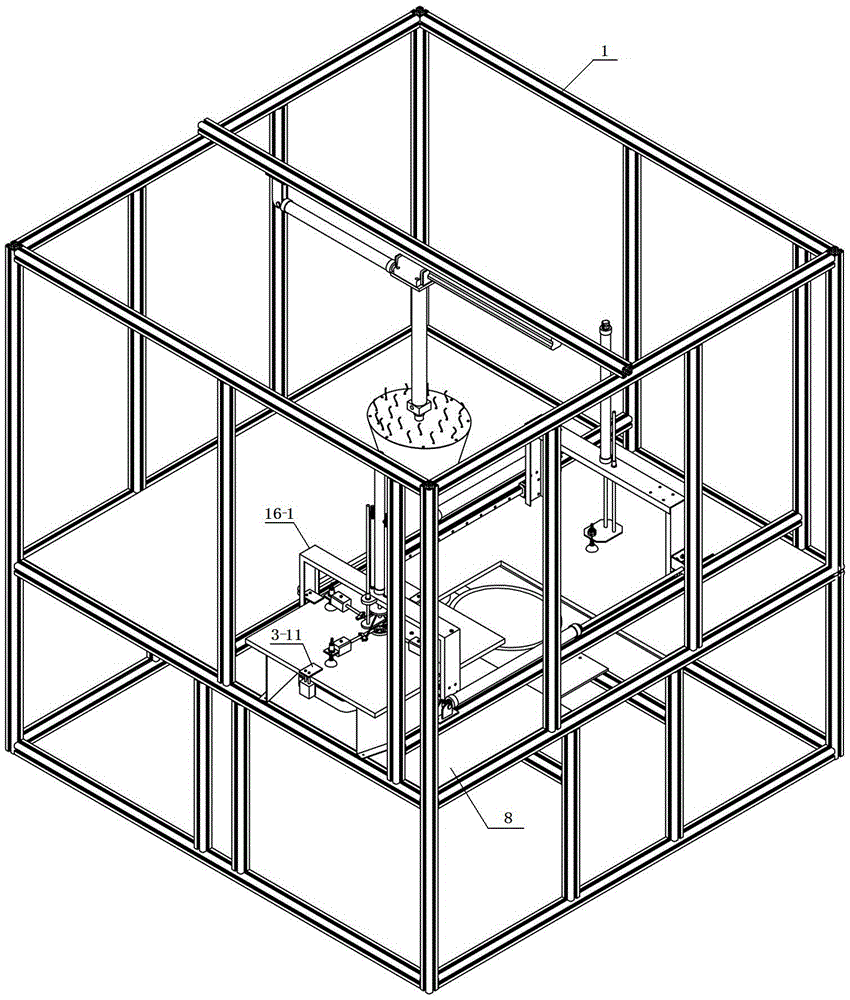

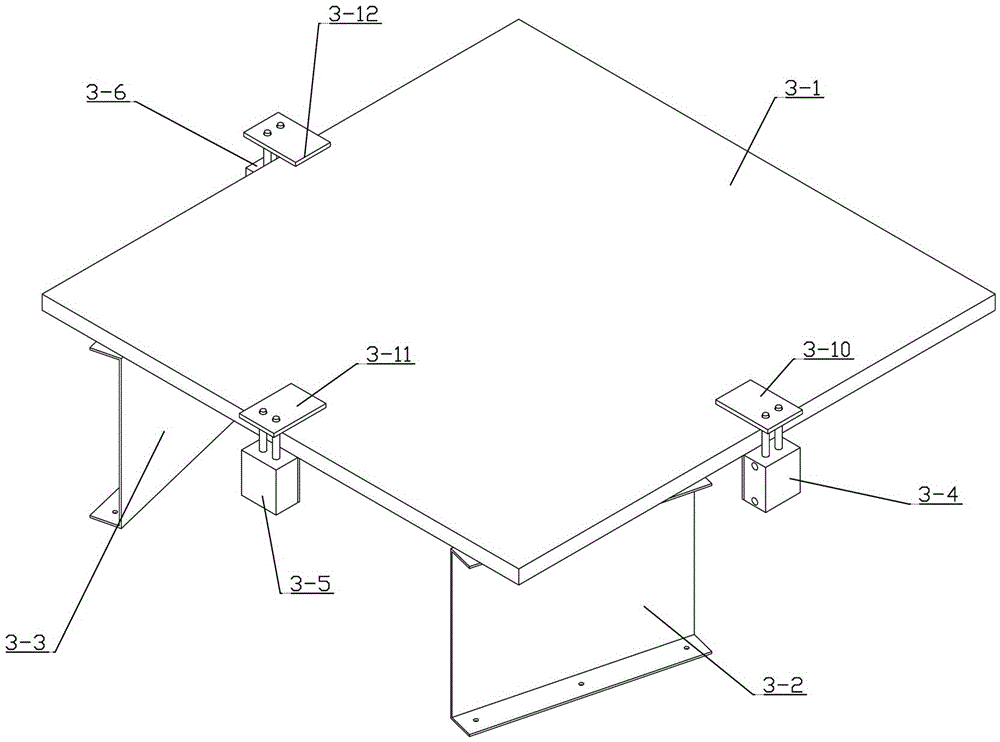

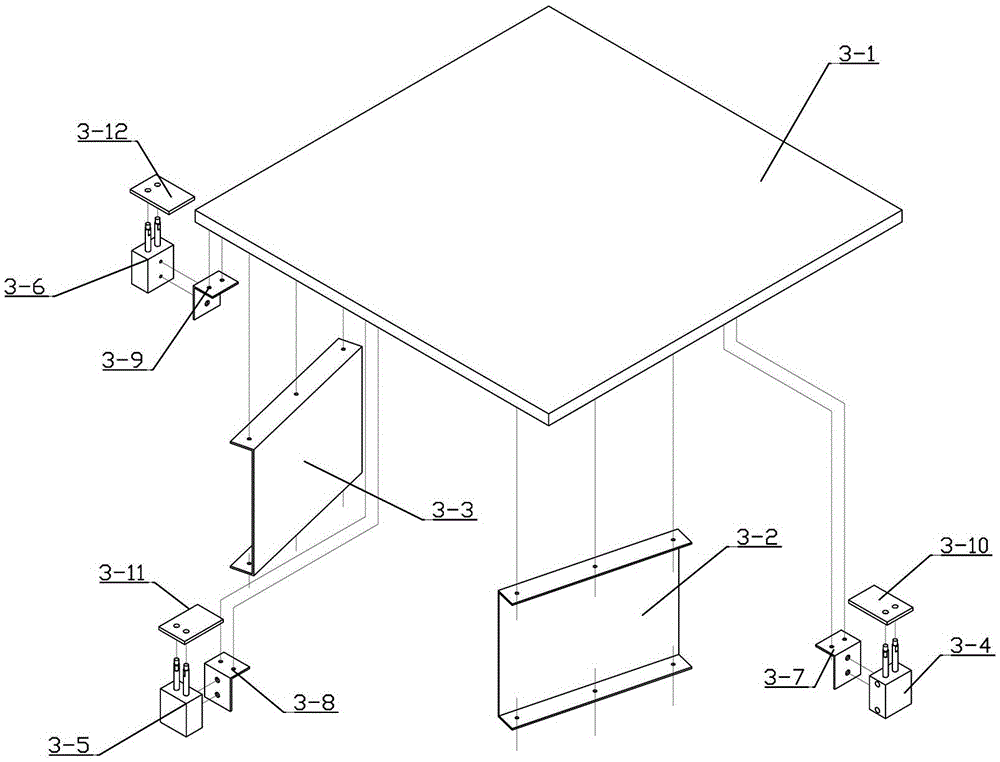

InactiveCN102039089AImprove thermal conductivityHeats up quickly and evenlyGas treatmentInternal combustion piston enginesFilter systemAlloy

The present invention relates to a metal foam matrix filter system for removing hydrocarbons from exhaust air and a method thereof. The filter system is provided with a metal foam component (1) and a heating device (2). The heating device (2) is designed for heating the metal foam component (1). The metal foam comprises at least one element which is taken as an alloy component and is used as an oxidation catalyst of hydrocarbon. A zeolite layer (1a) is coated on the metal foam component (1) behind the metal foam component (1) in a flowing direction. The invention also relates to a method for using the filter system.

Owner:ALANTUM CORP

A kind of flask heating support

Owner:JIANGYIN ZHENGZHONG SCI & EDUCATION EQUIP

A kind of bulletproof helmet precise automatic spreader

ActiveCN104097336BReduce frictional resistanceOverlap fastConveyor partsEngineeringMechanical engineering

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Desalination and dehydration method and device for oily waste

ActiveCN109399756BLittle effect on propertiesEasy to handleWaste water treatment from quariesFatty/oily/floating substances removal devicesThermodynamicsDesalination

The invention relates to the field of waste oil or sludge treatment, in particular to a method and device for desalting and dehydrating oily waste. The desalination and dehydration method of the oil-containing waste includes: (1) microwave heating the oil-containing waste in a closed system to obtain superheated material; (2) decompressing the overheated material so that the oil-containing waste The water below 60% by weight is vaporized to obtain vaporized steam and residual material; (3) the residual material is subjected to static stratification to obtain the purified oil of the upper layer and the saline sewage of the lower layer. The method for desalting and dehydrating oily waste of the present invention has short settling time, good and stable desalting and dehydrating effect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com