Ginger rapid drying device

A technology for quick drying and ginger, applied in directions such as drying, drying machine, and drying machine combination, can solve the problems of inappropriate drying of ginger, high production cost, long drying time, etc., achieve rapid heating, prevent discoloration , the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

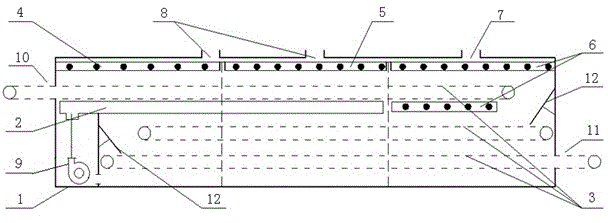

[0014] figure 1 It is a schematic structural view of the present invention, as shown in the figure, the ginger quick drying device of the present invention includes a fuselage 1, a fluidized bed and a ginger conveying mesh belt 3 running through the fuselage 1; Infrared heating zone, mid-wave infrared heating zone and far-infrared heating zone, a short-wave infrared heating tube group 4 is arranged on the inside and above of the short-wave infrared heating zone, a medium-wave infrared heating tube group 5 is arranged on the inside and above the medium-wave infrared heating zone, and A far-infrared heating tube group 6 is arranged above the infrared heating zone, an air inlet 7 is arranged above the far-infrared heating zone, and an air outlet 8 is respectively opened above the short-wave infrared heating zone and the medium-wave infrared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com