Desalination and dehydration method and device for oily waste

A dehydration device and waste technology, which are applied in separation methods, grease/oily substance/float removal devices, mining wastewater treatment, etc., can solve the problems of desalination and dehydration that are easily affected by the properties of raw materials, poor desalination effect, and short settling time. , to achieve good desalination effect, good effect and strong safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

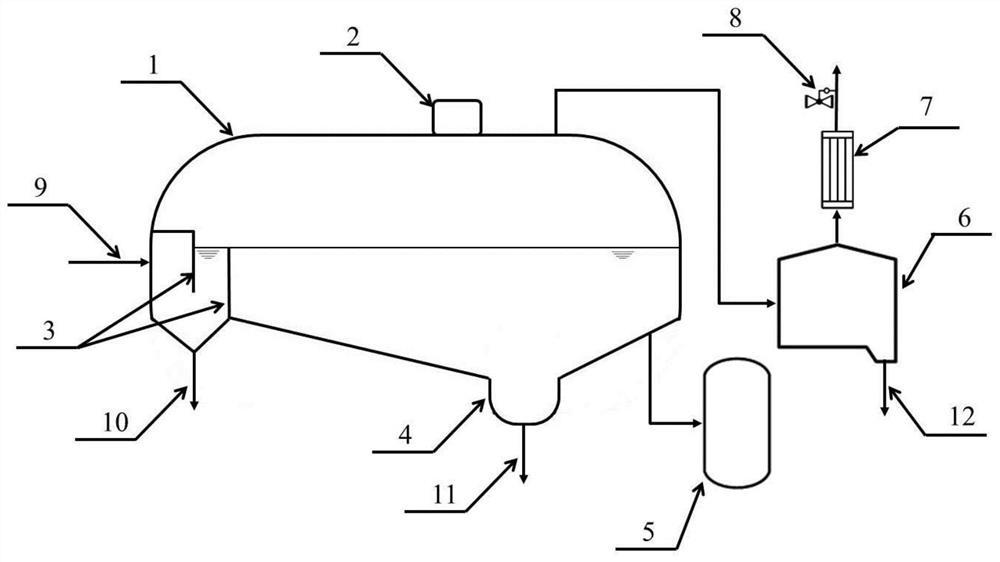

[0073] use figure 1 The shown device pumps dirty oil (water content is 37% by weight, salt content is 453mg NaCl / L, mechanical impurity is 3.3% by weight, and the balance is oil content) from inlet 9 to dehydration tank 1, through The U-shaped flow channel provided at the inlet 9 enters the main body of the dehydration tank 1, and then the pressure reducing valve 8 is closed to keep the dehydration tank 1 in a closed state, and the microwave reactor 2 is opened to carry out microwave heating to the dirty oil in the dehydration tank 1 ( The radiation frequency is 2450MHz, the power is 1200W), and when the temperature of the dirty oil is stabilized to 130°C, stop heating, and after the pressure in the dehydration tank is stabilized, the pressure relief valve 8 is opened to reduce the pressure in the dehydration tank 1 to normal pressure (approximately 101.3k...

Embodiment 2

[0076] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

[0077] According to the method described in embodiment 1, the difference is:

[0078] The treated oily waste is oil tank bottom sludge with a water content of 40.17% by weight, a salt content of 714mg NaCl / L, and mechanical impurities of 14.8% by weight;

[0079] The conditions of microwave heating include: the radiation frequency is 2450MHz, and the power is 1500W;

[0080] Microwave heating until the temperature of the oil sludge is 120°C, the condensed water collected in the light component reflux tank 6 after pressure relief accounts for 6% by weight of the water in the waste oil;

[0081] The moment the pressure is released, the temperature of the residual material in the dehydration tank 1 reaches 70° C., and it is kept at 70° C. for 30 minutes.

[0082] Wherein, the water content of the obtained purified oil was 0.9% by weight, and the dehydration ra...

Embodiment 3

[0084] This example is used to illustrate the method for desalting and dehydrating oily waste of the present invention.

[0085] According to the method described in embodiment 1, the difference is that the temperature of the waste oil heated by microwaves is 100° C., and the condensed water collected in the light component reflux tank 6 after pressure relief accounts for 2% by weight of the water in the waste oil.

[0086] Thus, the water content of the obtained purified oil was 13.1% by weight, and the dehydration rate was 64.6%; the salt content was 194 mg NaCl / L, and the desalination rate was 57.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com