A kind of early-strength and fast-hardening type rockfill grouting recycled concrete and preparation method thereof

A recycled concrete and rockfill technology, applied in sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of low replacement rate of recycled aggregates, difficulty in ensuring strength, and slow strength growth rate, etc., to achieve No need to control the workability of concrete, high replacement rate of recycled aggregate, and the effect of improving strength stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

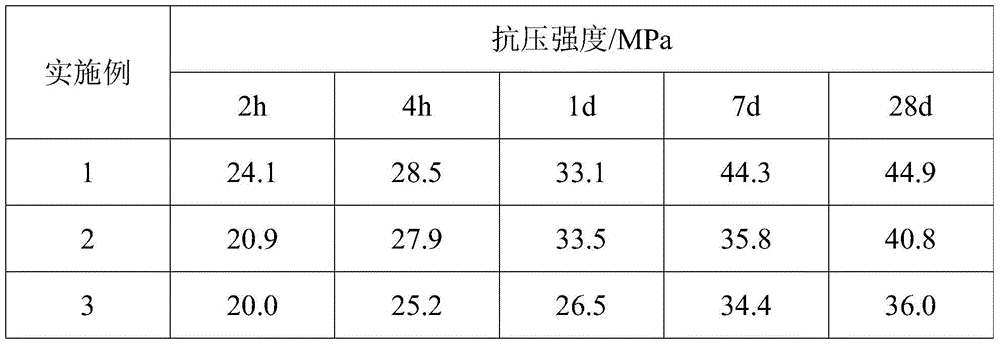

Examples

Embodiment 1

[0045] Step 1, weigh 50.0% of 42.5-grade rapid-hardening sulfoaluminate cement, 2.0% of anhydrite, 0.5% of polypropylene fiber with a length of 6mm, 1.5% of polycarboxylate superplasticizer powder, and lithium carbonate according to mass percentage. 0.4%, boric acid 0.6%, graded quartz sand 45.0%, the sum of the mass percentages of the above-mentioned components is 100%, and the above-mentioned components are added to a gravity-free mixer and fully mixed to obtain a self-compacting dry powder;

[0046] Step 2, crushing and screening the waste concrete to obtain graded recycled coarse aggregate with a particle size of 5.0-31.5mm, and measuring the moisture content of the recycled coarse aggregate;

[0047] Step 3, fix the formwork according to the engineering component design drawings, pour the recycled coarse aggregate into the filling formwork, each time the filling height is not greater than 30cm, and record the weight of the recycled aggregate;

[0048] Step 4: Determine th...

Embodiment 2

[0051] Step 1, weigh 50.0% of 42.5-grade rapid-hardening sulfoaluminate cement, 2.0% of anhydrite, 0.5% of polypropylene fiber with a length of 6mm, 1.5% of polycarboxylate superplasticizer powder, and lithium carbonate according to mass percentage. 0.4%, boric acid 0.6%, graded quartz sand 45.0%, the sum of the mass percentages of the above-mentioned components is 100%, and the above-mentioned components are added to a gravity-free mixer and fully mixed to obtain a self-compacting dry powder;

[0052] Step 2, crushing and screening the waste concrete to obtain graded recycled coarse aggregate with a particle size of 5.0-31.5mm, and measuring the moisture content of the recycled coarse aggregate;

[0053] Step 3, fix the formwork according to the engineering component design drawings, pour the recycled coarse aggregate into the filling formwork, each time the filling height is not greater than 30cm, and record the weight of the recycled aggregate;

[0054] Step 4: Determine th...

Embodiment 3

[0057] Step 1, weigh 50.0% of 42.5-grade rapid-hardening sulfoaluminate cement, 2.0% of anhydrite, 0.5% of polypropylene fiber with a length of 6mm, 1.5% of polycarboxylate superplasticizer powder, and lithium carbonate according to mass percentage. 0.4%, boric acid 0.6%, graded quartz sand 45.0%, the sum of the mass percentages of the above-mentioned components is 100%, and the above-mentioned components are added to a gravity-free mixer and fully mixed to obtain a self-compacting dry powder;

[0058] Step 2, crushing and screening the waste concrete to obtain graded recycled coarse aggregate with a particle size of 5.0-31.5mm, and measuring the moisture content of the recycled coarse aggregate;

[0059] Step 3, fix the formwork according to the engineering component design drawings, pour the recycled coarse aggregate into the filling formwork, each time the filling height is not greater than 30cm, and record the weight of the recycled aggregate;

[0060] Step 4, determine th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| slump | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com