Patents

Literature

37results about How to "Little effect on properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Raw oil dewatering and desalting process

InactiveCN1772845AReduce irregular movementImprove dehydration (desalination) effectDewatering/demulsification with electric/magnetic meansDemulsifierWave field

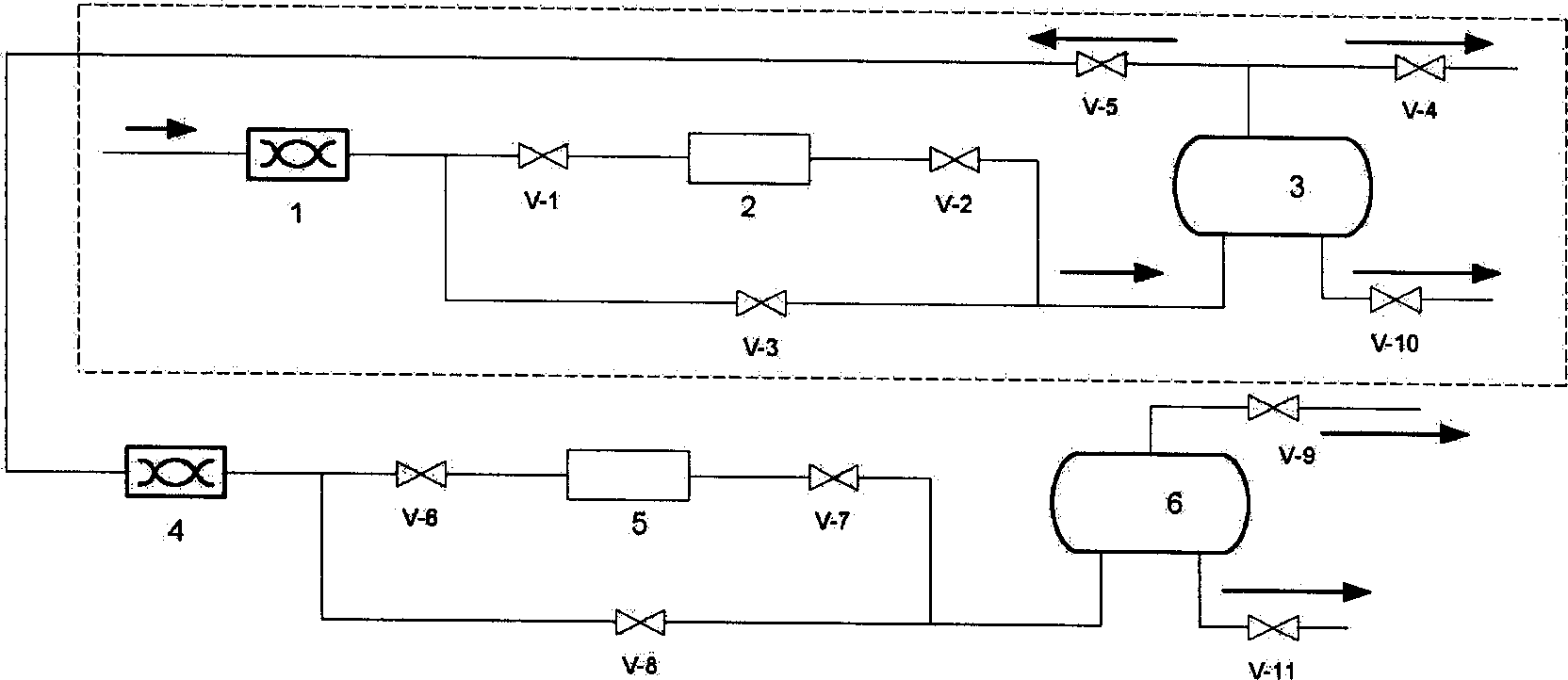

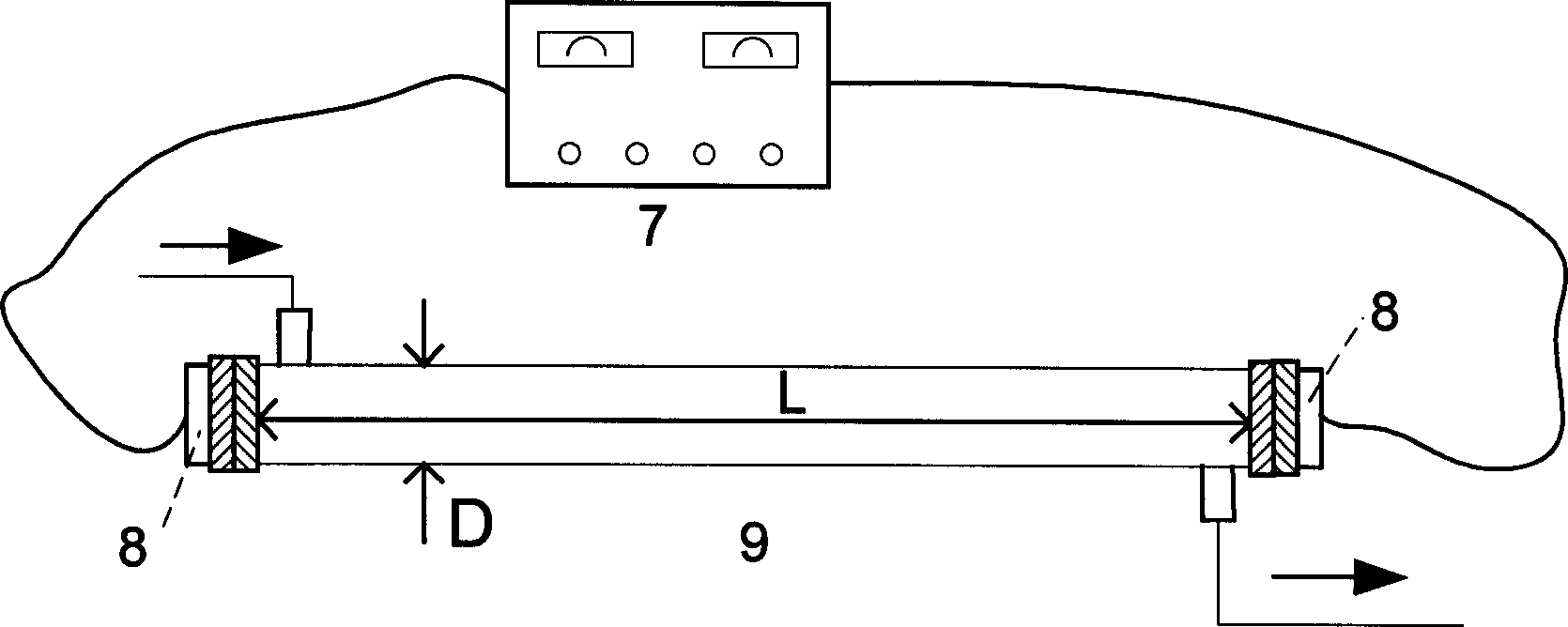

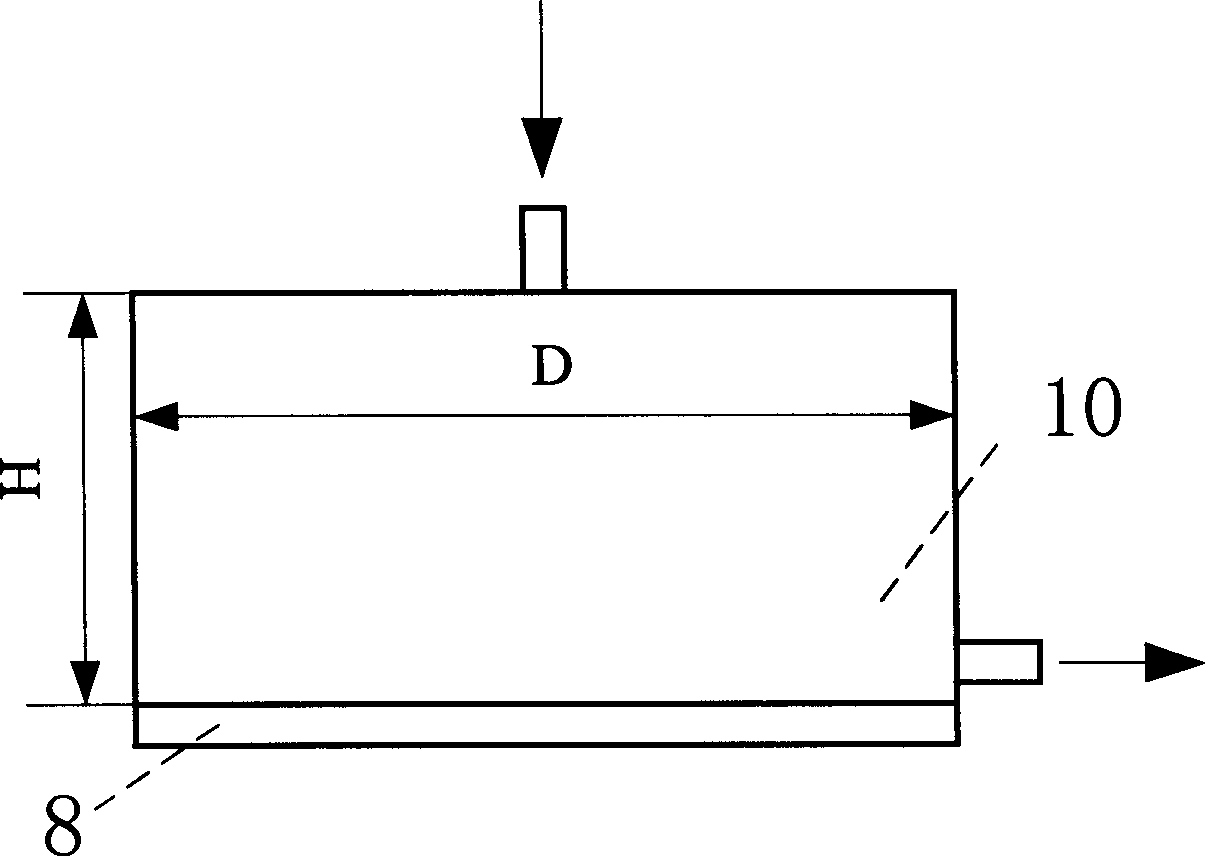

The present invention relates to raw oil dewatering and desalting process, and is especially combined stationary ultrasonic wave-electric field process of dewatering and desalting various kinds of oil product. The technological scheme is that stationary ultrasonic wave field and electric field are combined for oil dewatering and desalting aim. That is, raw oil is first added with fresh water and demulsifier and mixed in static mixer or other mixer, then acted with stationary or traveling ultrasonic wave, and finally dewatered and desalted in a conventional electric desalter. The present invention is one improved and reinforced oil product dewatering and desalting process and has raised oil product adapting capacity and low water and salt content of product.

Owner:YANGZI PETROCHEM +1

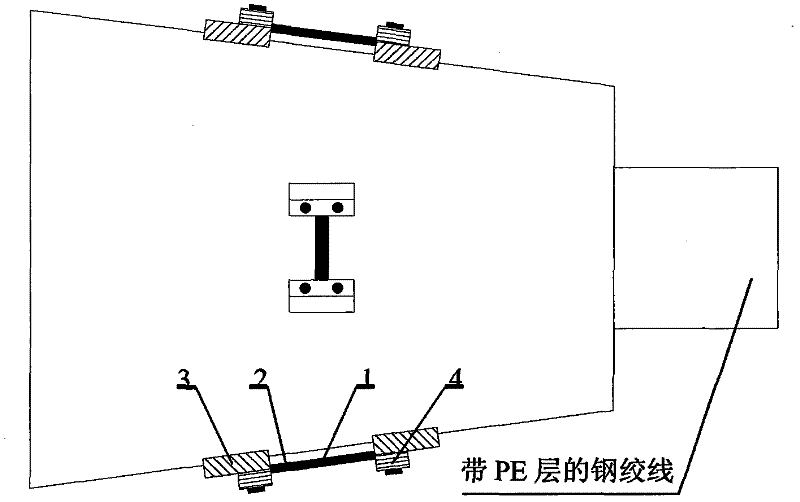

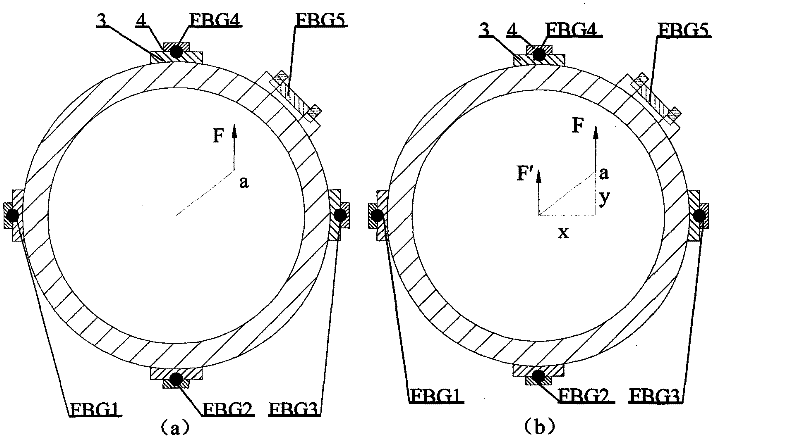

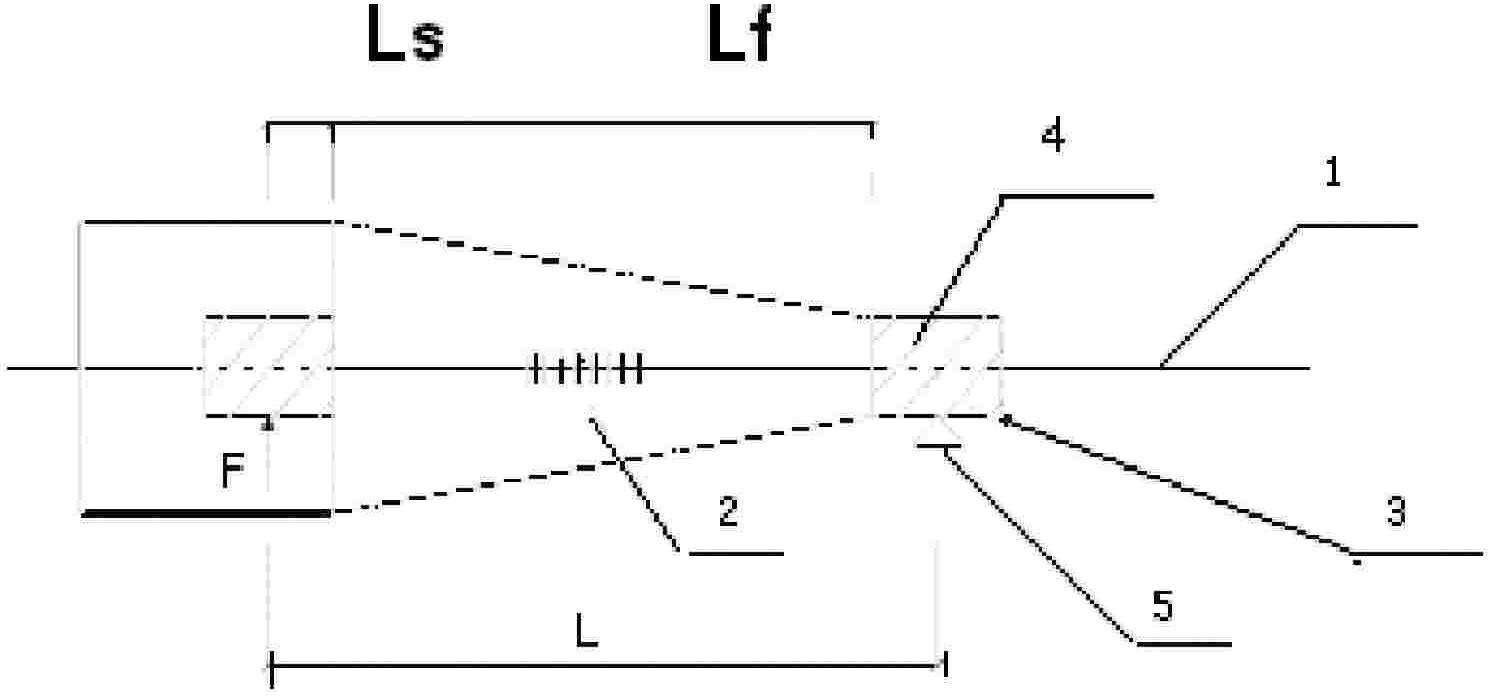

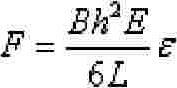

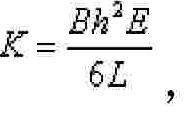

Fiber grating cable tension transducer with temperature self-compensation function

InactiveCN102230834AWith online real-time cable force monitoringRealize online real-time cable force monitoringForce measurement by measuring optical property variationGratingSelf compensation

The invention provides a fiber grating cable tension transducer with a temperature self-compensation function, belonging to the field of transducer technologies. The transducer provided by the invention is characterized by comprising a metal baseplate, a clamping piece, a micro fiber grating strain transducer and a cable component of fiber transmission. The measuring sensitivity of the transducer can be adjusted by changing sizes of elements of the transducer in accordance with actual requirements, thus being suitable for monitoring cable tension of the different cables in real time. The fiber grating cable tension transducer can measure the cable tension of the cables indirectly by measuring an anchor head structure and utilize the properties of the fiber grating to improve the cable tension sensitivity coefficients of the transducer, and is not influenced by structural materials and external environments. The fiber grating cable tension transducer can eliminate influences of eccentric forces on measuring values, realize the temperature self-compensation and overcome the defects that a traditional electric transducer is subjected to electromagnetic interference easily and is poor in long-term stability, and has the advantages of high accuracy, light weight, low influences on the properties of the structure and the like.

Owner:DALIAN UNIV OF TECH

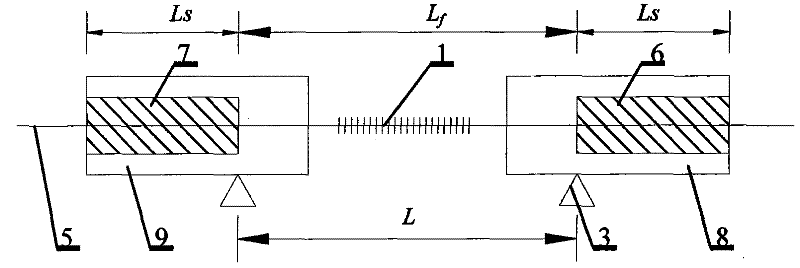

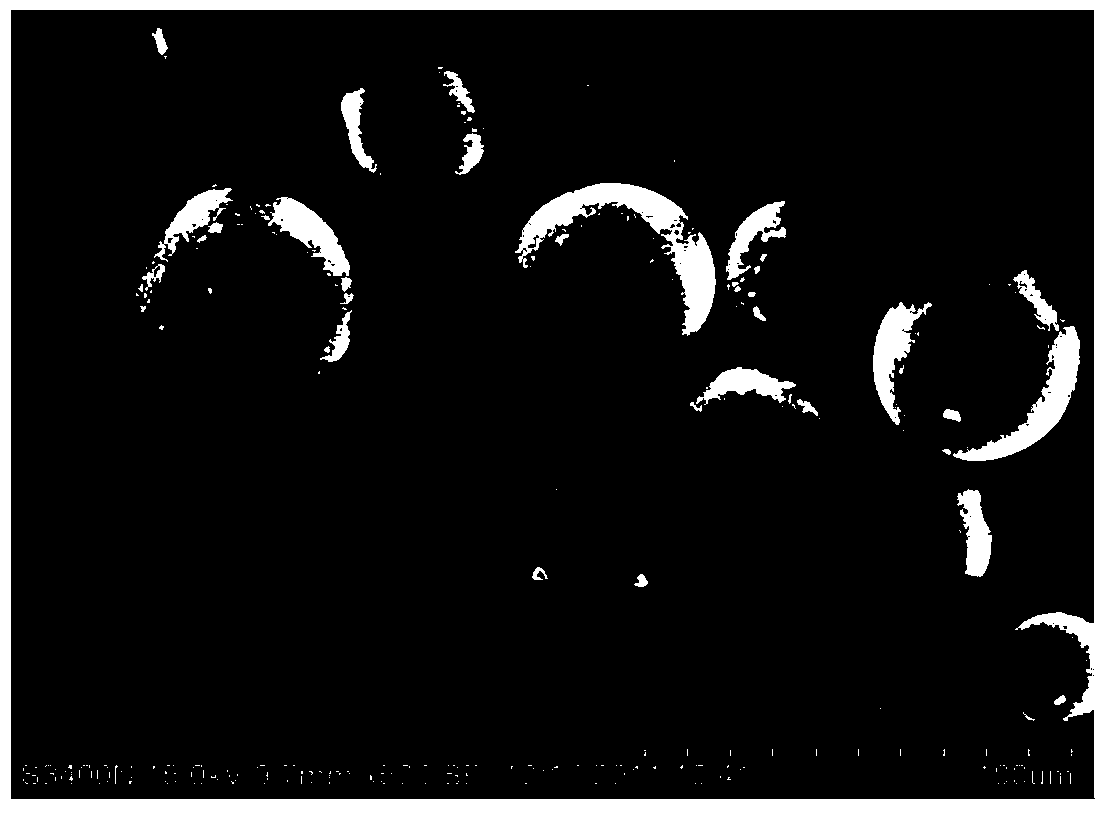

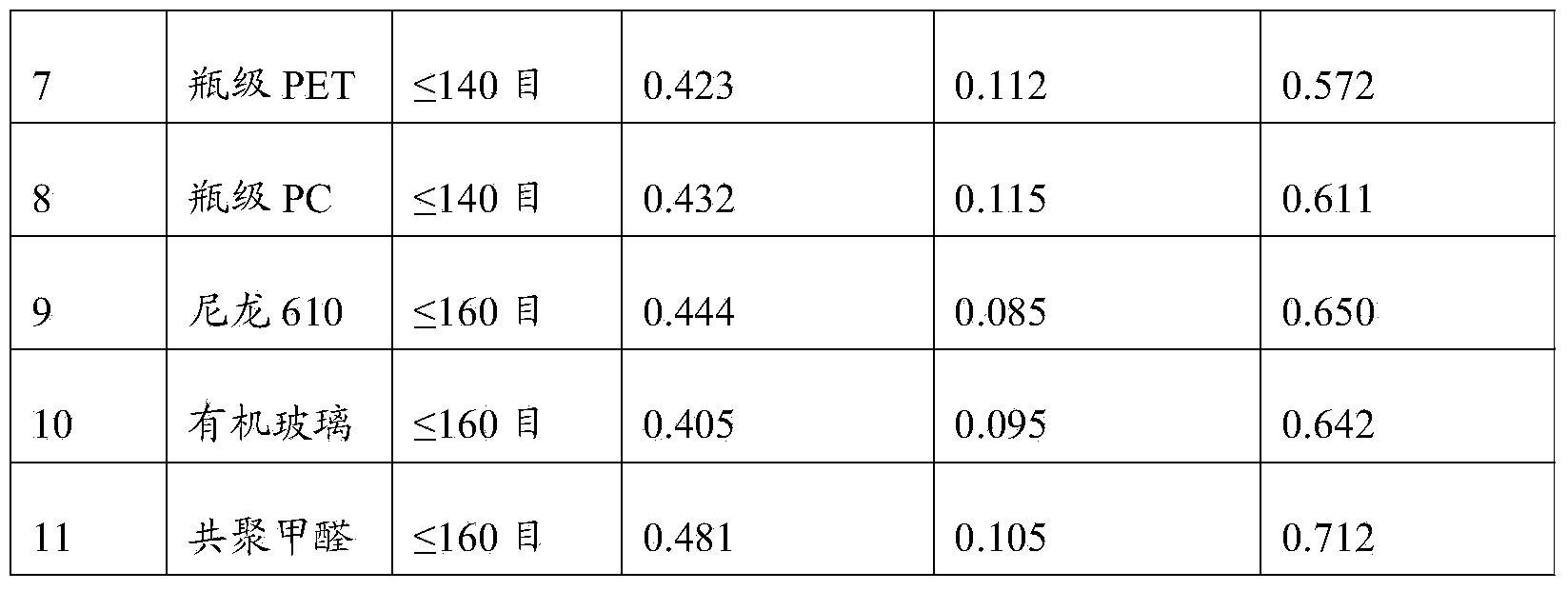

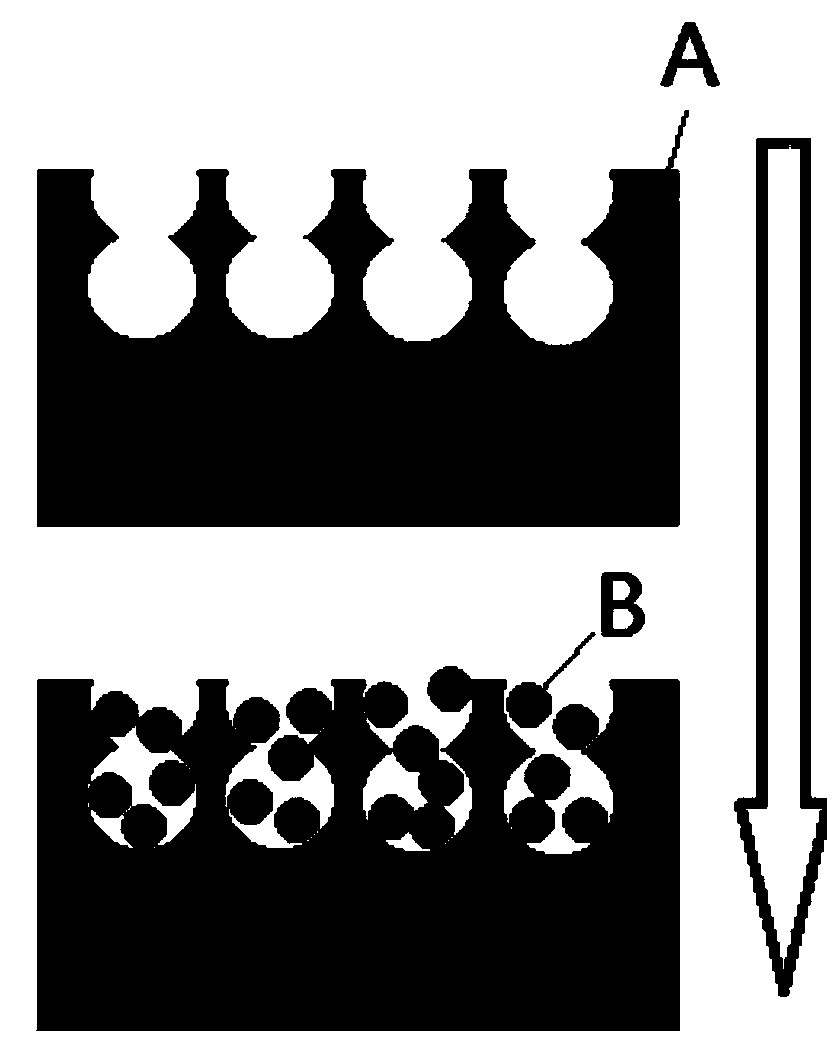

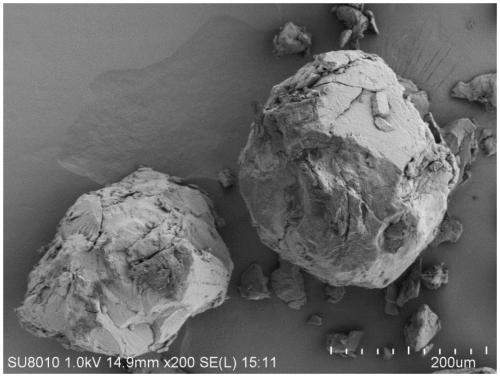

Preparation method of spherical particles of thermoplastic plastic

The invention relates to a preparation method of spherical particles of a thermoplastic plastic. The method comprises the following steps: S1, mixing thermoplastic plastic powder, a deformation assistant and a surface protection stabilizer to obtain a raw material mixture; S2, adding the raw material mixture into a dispersing medium and heating, then, separating the heated mixture, washing the filter residue and drying, and finally crushing the filter residue and sieving to obtain the spherical particles of a thermoplastic plastic. The particles prepared by the method provided by the invention are better in degree of sphericity, and have the characteristics of wide application range and no limit by types of plastic (polymers). Appropriate deformation assistants, surface protection stabilizers and operating conditions can be found for nearly all thermoplastic polymers to obtain the spherical particles. The spherical particles have less influence on property of the material such as molecular weight, component distribution and melt fluidity.

Owner:张兴华 +1

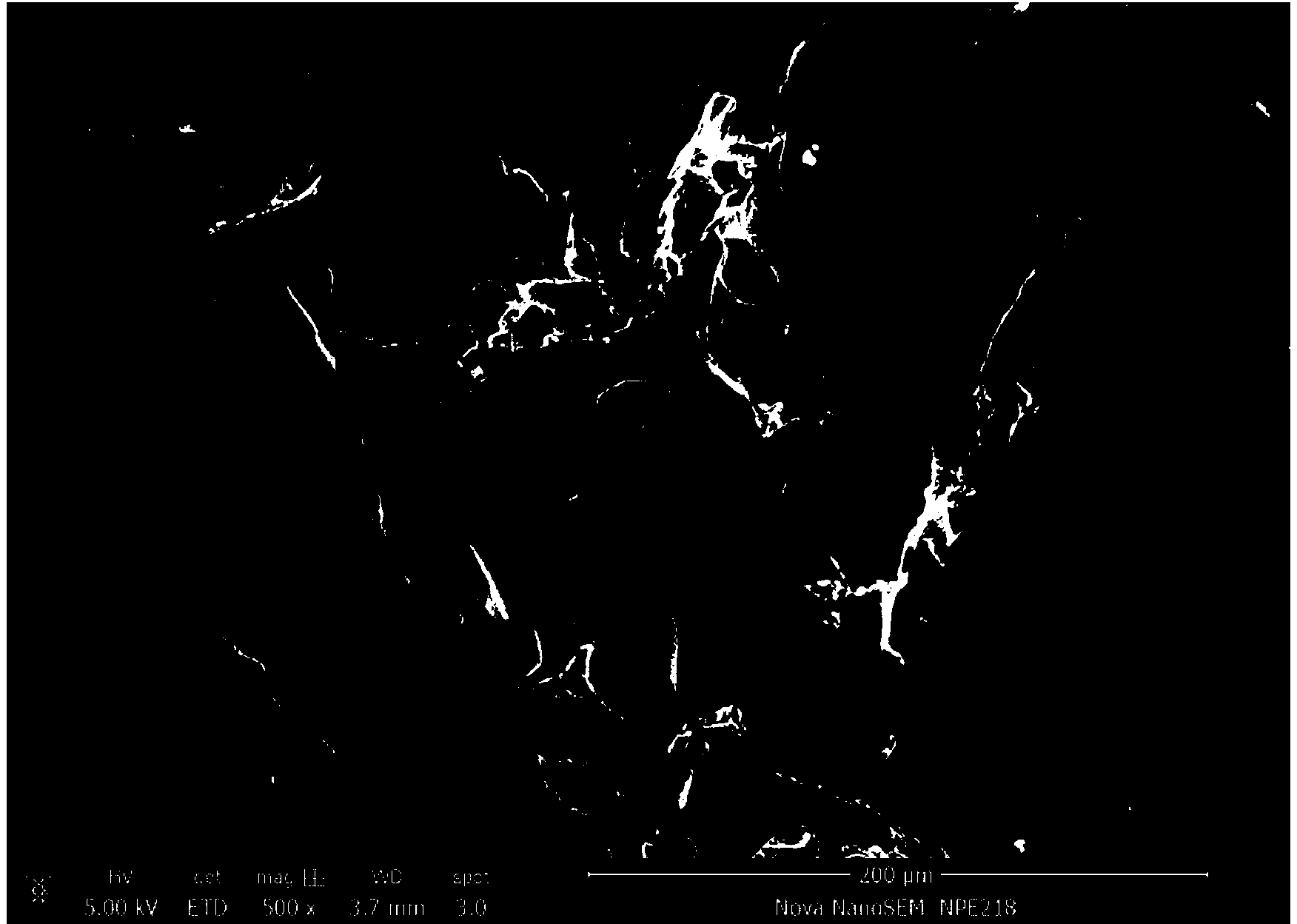

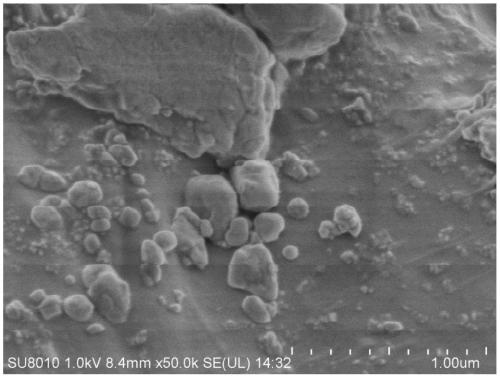

Nano zirconia alcohol slurry and preparation method thereof

InactiveCN102350236ALittle effect on propertiesSimple processMixing methodsGrain treatmentsAlcoholWear resistant

The invention discloses a nano zirconia alcohol slurry and a preparation method thereof. The nano zirconia alcohol slurry comprises, by weight, 1-60 parts of nanometer level ZrO2 powder, 0.05-10 parts of dispersant and 30-99 parts of solvent. The preparation method is as below: the dispersant is added and dissolved in the organic solvent; then the nanometer level ZrO2 powder is added in the mixture and dispersed by a high speed bowl mill for 0.2-10 h, so as to obtain the oil slurry. The technology of the invention is simple, has a short processing time, easily controlled process and high application value. The nano zirconia slurry prepared by the invention is a highly decentralized, uniformized and stabilized slurry, can be widely applied to fields of high strength and high-toughness wear resistant product, functional ceramic, structural ceramic, electric device and refractory material, etc.

Owner:BEIJING NACHEN TECH DEV

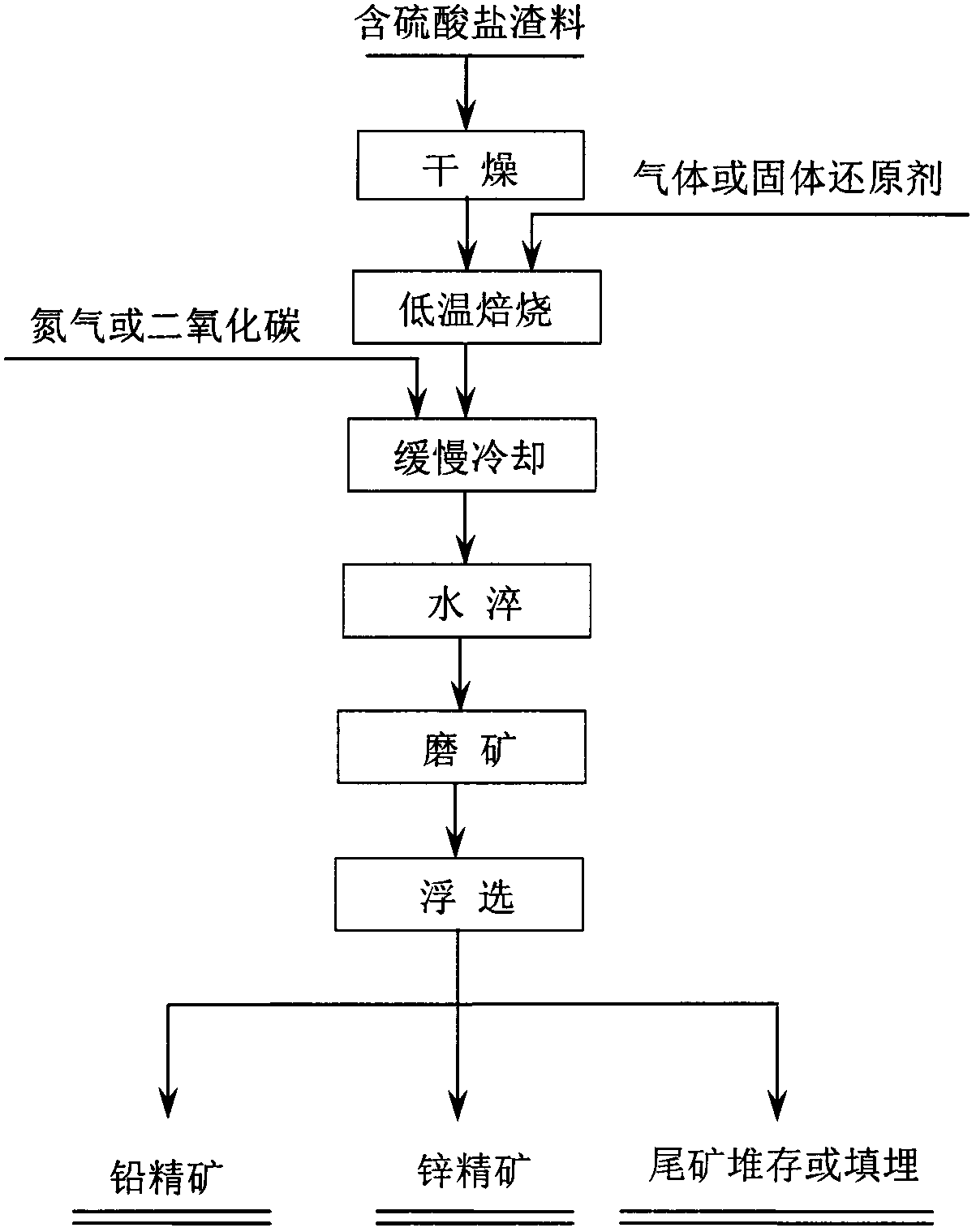

Dressing-smelting combined treatment method for sulfate-containing lead-zinc smelting slags

InactiveCN103103344ALittle effect on propertiesImprove qualityFlotationProcess efficiency improvementLead zincTreatment costs

The invention discloses a dressing-smelting combined treatment method for sulfate-containing lead-zinc smelting slags, and belongs to the field of dressing and smelting. For solving the environmental problems caused by the difficult mineral dressing and recycling of lead sulfate and zinc sulfate containing materials and the stockpiling, percolation and leaching and the like of slag charges, the dressing-smelting combined treatment method for sulfate-containing lead-zinc smelting slags comprises the following steps: 1) drying: carrying out heating and drying treatment on slag charges; 2) roasting: adding a reducing agent into the dried slag charges so as to carry out reduction roasting; 3) after the roasting is completed, slowly cooling the slag charges, and after the temperature of the slag changes is reduced to below 200 DEG C, carrying out water quenching on the slag charges so as to obtain water-quenched slags; and 4) grinding and floatation: after the water-quenched slags are subjected to ore grinding and grading, taking a material with the particle size of less than 75 mu m and carrying out flotation separation on the material so as to obtain a lead concentrate and a zinc concentrate. According to the invention, the lead content of the obtained lead concentrate is more than 55%, and the recovery rate is more than 80%, the zinc content of the zinc concentrate is more than 35%, and the recovery rate is more than 75%; and the method disclosed by the invention has the characteristics of low treatment cost, no heavy metal pollution, and high lead and zinc metal recovery rates.

Owner:CENT SOUTH UNIV

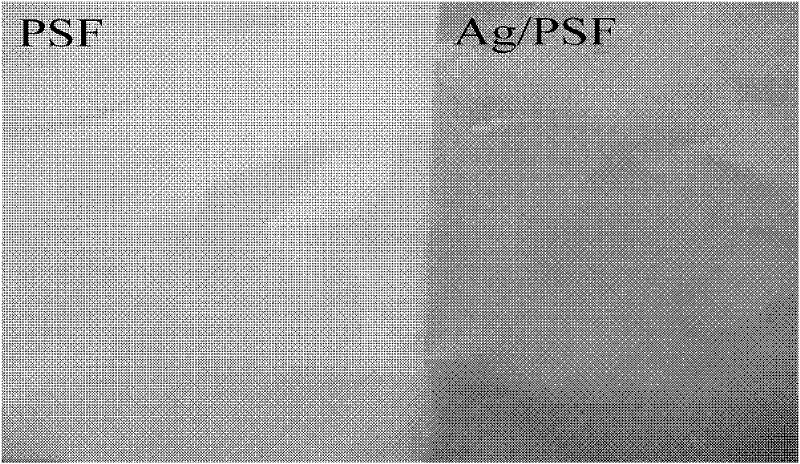

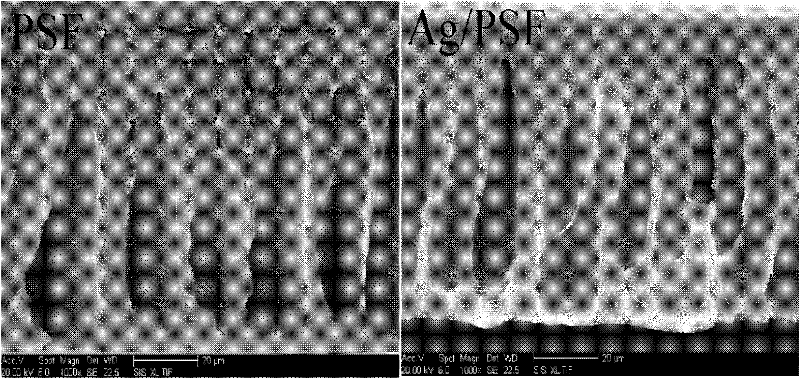

Antimicrobial polysulphone flat ultrafiltration membrane and preparation method thereof

InactiveCN102553466APlay the role of sterilization and disinfectionAvoid pollutionSemi-permeable membranesPhase conversionFiltration

The invention provides an antimicrobial polysulphone flat ultrafiltration membrane, relates to an antimicrobial polysulphone flat ultrafiltration membrane and a preparation method thereof, and aims to solve the problem that in the prior art, the nanomaterial is hard to be dispersed uniformly and needs to be pretreated. The antimicrobial polysulphone flat ultrafiltration membrane is a silver nanoparticle-polysulphone composite flat ultrafiltration membrane which is prepared from polysulphone and silver nanoparticles by immersion precipitated phase conversion process, polysulphone is used as a film-forming material, and silver nanoparticles are prepared by liquid phase reduction of silver nitrate and used as an antimicrobial additive. The mass percentage of polysulphone in the mixture is 8% to 26%, silver nitrate accounts for 0.1% to 1% of the total mass, the reducing agent accounts for 5% to 20% of the total mass, the pore forming agent accounts for 3% to 10% of the total mass, and the solvents are in the balance. The ultrafiltration membrane plays a role of killing microorganisms and sterilizing in addition to filtration, the membrane surface is not contaminated, and the effluent quality is improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

Process for preparing superparamagnetic starch

InactiveCN1970575AWide variety of sourcesGood environmental protectionSurgeryOrganic/organic-metallic materials magnetismFerrous saltsSuperparamagnetism

The invention discloses a making method of superparamagnetism starch, which comprises the following steps: allocating starch milk through starch and deionized water; adjusting pH value; adding soluble ferrous salt solution to adsorb once; filtering in the vacuum or separating centrifugally; removing water to obtain sediment; adding hydrogen peroxide solution to oxidize once; dehydrating; washing; obtaining starch product with water; repeating these steps to obtain magnified starch product with water; drying; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

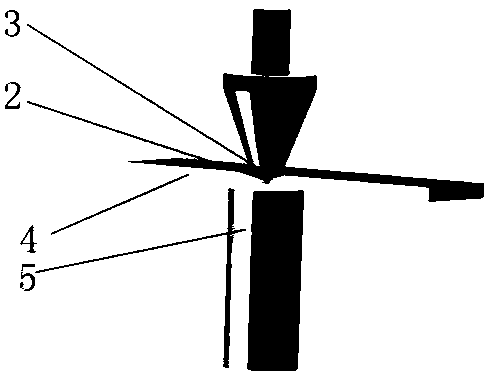

Device and method for preparing texture-controllable gradient nanometer structure

ActiveCN108188565AGrain refinementLittle effect on propertiesNon-electric welding apparatusPunchingEngineering

The invention discloses a device and method for preparing a texture-controllable gradient nanometer structure, and belongs to the technical field of gradient nanometer structure materials. The devicecomprises a holding area, a shaft shoulder and a plurality of stirring needles with different diameters below the shaft shoulder. The multiple stirring needles form a gradient structure. The gradientnumber of the stirring needles is selected according to the machining need and is particularly 1 to 50. The method includes the steps that a to-be-machined plate, an ultrasonic tool bit and relevant devices for the device for preparing the texture-controllable gradient nanometer structure are arranged, ultrasound is started, and the device is punched into the to-be-machined plate at the rotary speed of 1500-4000 rad / min; the downward punching speed is 3-30 mm / min; when a spliced type variable-section stirring tool shaft shoulder touches the to-be-machined plate, downward punching is carried out by 0.1-15 mm; downward punching is stopped, and the device carries out horizontal repeated multi-pass machining. The device is simple and low in cost, and the prepared gradient nanometer structure is controllable and wide in application.

Owner:SHENYANG AEROSPACE UNIVERSITY

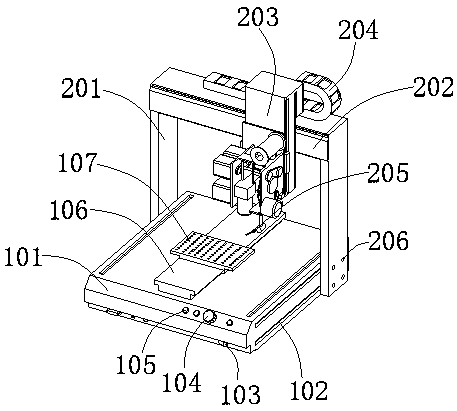

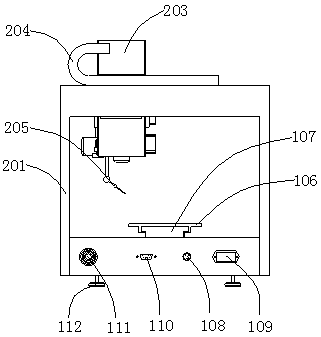

Automatic laser soldering machine

PendingCN110216345AReduce manufacturing costShort heating timeSoldering apparatusHeating timeEngineering

The invention relates to the technical field of laser soldering, and discloses an automatic laser soldering machine. The automatic laser soldering machine comprises an operation table device and a tinsoldering device, the top of the operation table device is fixedly provided with the tin soldering device, and the operation table device comprises a tin soldering machine operation table; connectingbosses are fixedly arranged on the two sides of the soldering machine operation table, a switch is fixedly arranged on the front surface of the tin soldering machine operation table, and a pluralityof operation buttons are fixedly arranged on the left side and the right side of the adjusting knob. The automatic laser soldering machine has the advantages of being short in heating time, fast in heating speed and small in influence on the property of surrounding devices due to local heating. During laser soldering tin, only the part irradiated by the light spot is heated by the laser, the localtemperature rises is faster, so that the welding spot can be quickly made to reach the temperature of the welding requirement, due to the fact that the temperature rise is fast and the time is short,and the temperature rise of the surrounding area of the welding spot is limited, so that the influence on other elements is relatively small.

Owner:广东费斯柯自动化科技有限公司

Wax-wrapped peroxide microcapsule and preparation method thereof

ActiveCN103102431AImprove thermal stabilityConvenient storage and transportationMicroballoon preparationMicrocapsule preparationWaxAlcohol

The invention discloses a wax-wrapped peroxide microcapsule and a preparation method thereof. According to the invention, a core material of the microcapsule is a peroxide, and the wall of the microcapsule is wax. The preparation method comprises the following steps: dissolving petroleum wax at a temperature of 50 to 90 DEG C by using a low molecule alcohol as a solvent, adding micro peroxide powder, controlling a stirring speed to be 3000 to 8000 r / min, carrying out cooling to a temperature of 25 to 30 DEG C, removing the solvent through vacuum filtration and carrying out blow drying with nitrogen so as to obtain the wax-wrapped peroxide microcapsule. The wax-wrapped peroxide microcapsule improves thermal stability of the peroxide, is convenient for storage and transportation, is especially applicable as a polymerization initiator and is beneficial for smoothness of reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

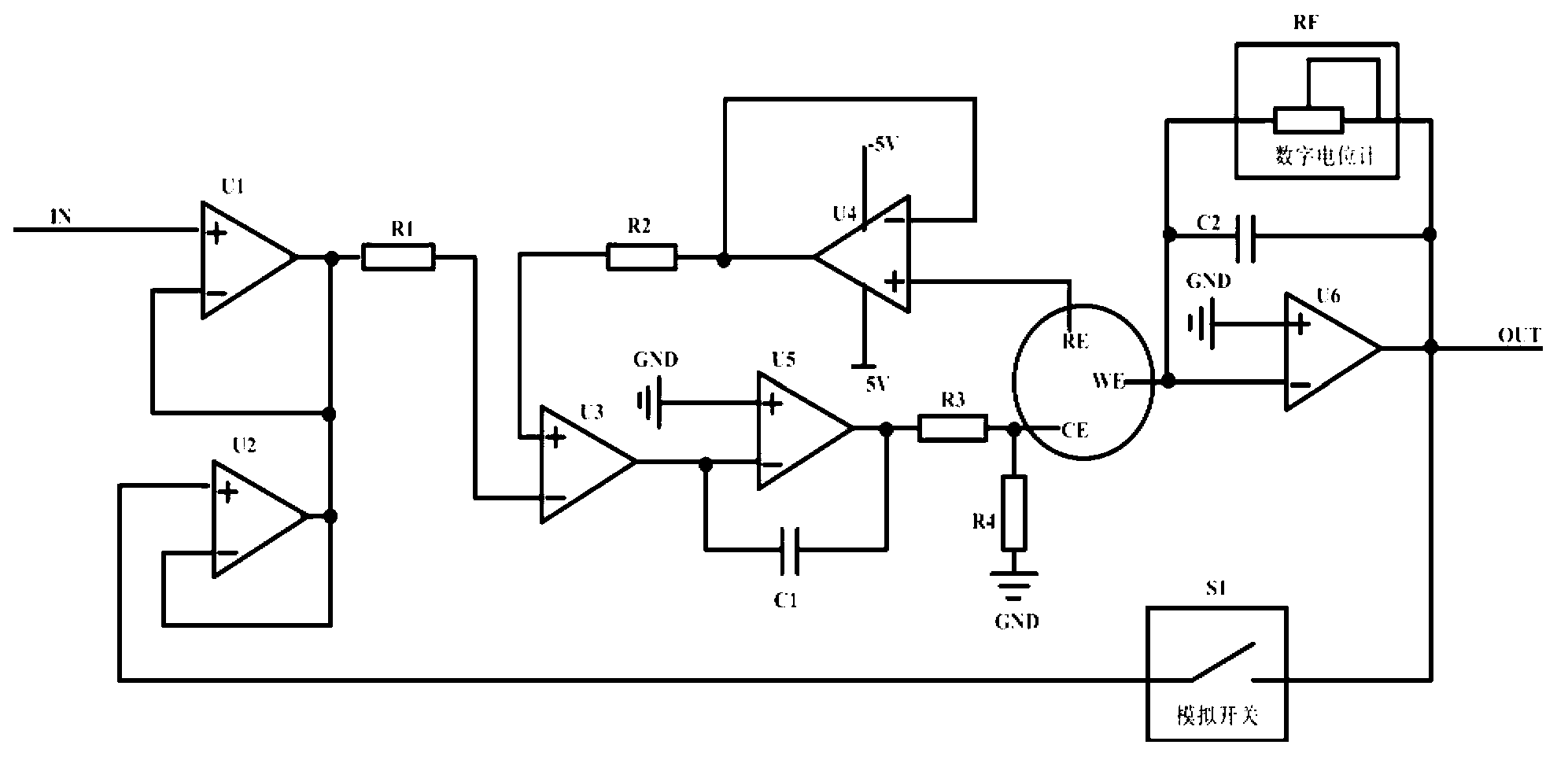

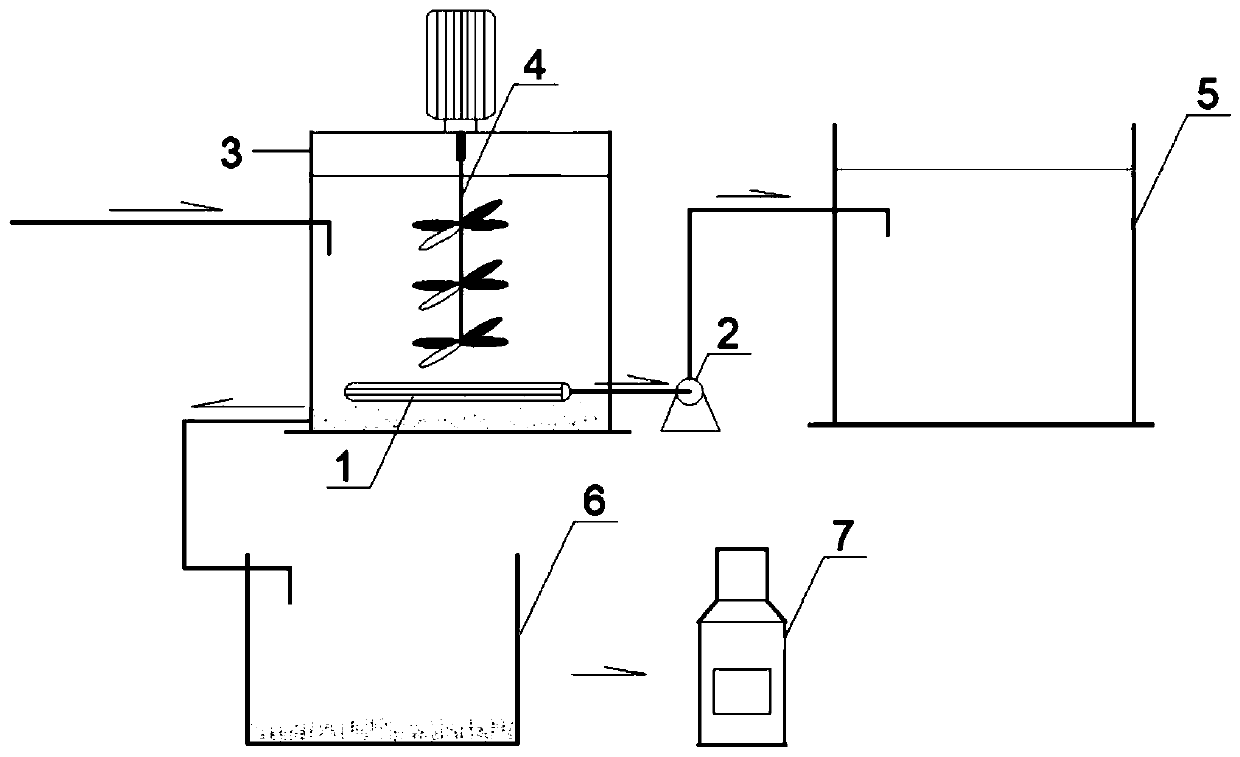

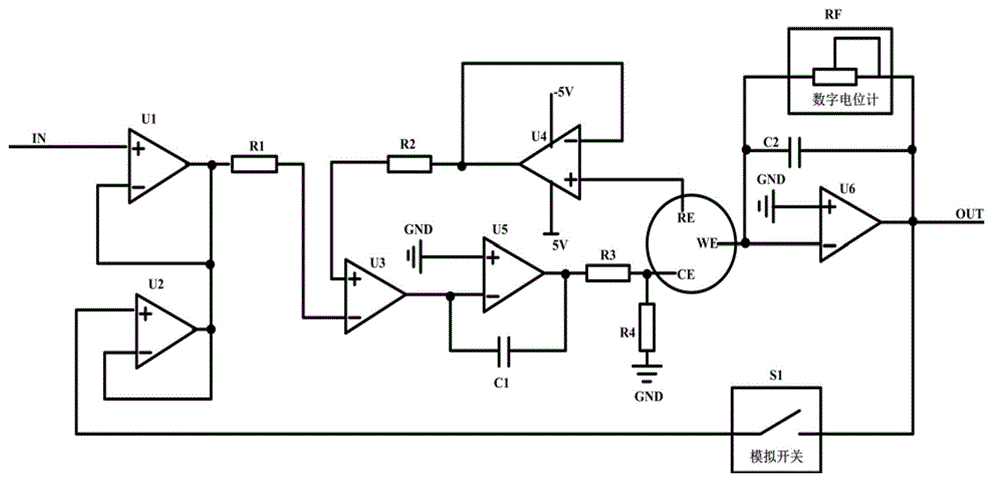

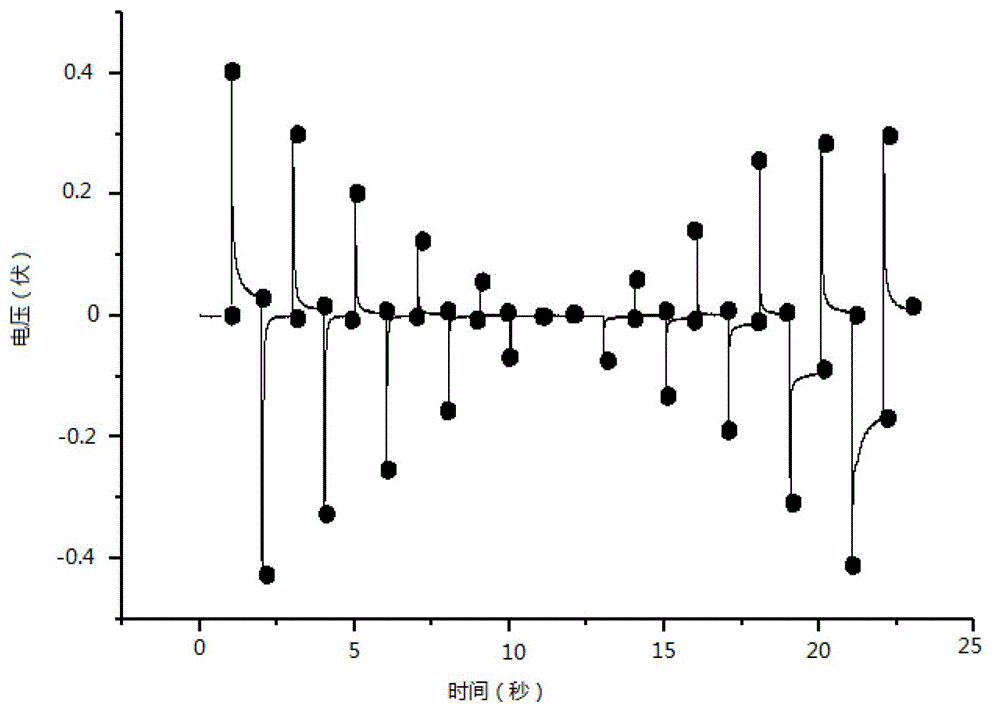

Intelligent chemical analysis system for distinguishing detection of weak electrolyte sample and method therefor

ActiveCN103267792ALittle effect on propertiesEasy to detectMaterial electrochemical variablesElectrical resistance and conductancePrincipal component analysis

The invention discloses an intelligent chemical analysis system for distinguishing detection of a weak electrolyte sample and a method therefor. The intelligent chemical analysis system is characterized by comprising an embedded module, a potentiostat and a three-electrode sensor. The method comprises that the self-developed potentiostat combines with the embedded module; a two-step excitation acquisition method is adopted; through the first excitation acquisition process, solution resistance is automatically fitted and an electrical signal produced by the solution resistance is added to a secondary excitation signal; and through the combination of the second acquisition process, real-time Fourier transform and principal component analysis, an optimized weak electrolyte solution whole-distinguishing graph is obtained. The method has good detection effects, a wide application scope and low influence on solution properties.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

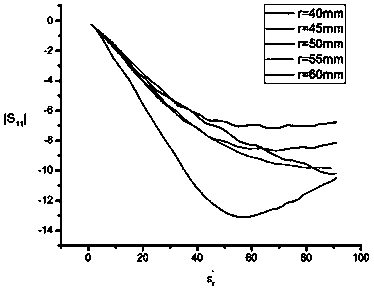

A size determination method of a chemical substance complex dielectric constant measuring device and the measuring device

PendingCN110441611ALittle effect on propertiesReduce wasteDielectric property measurementsMeasurement instrument housingDielectricSize determination

The invention discloses a size determination method of a chemical substance complex dielectric constant measuring device and the measuring device. The method includes the following steps: S101, calculating the monotonicity of S parameters corresponding to materials inside cavities with different dimensions of cavity bodies to determine optimal size of a monotonicity curve change; S102, making a cavity body by using the cavity body corresponding to the optimal size of the monotonicity as a model; S103, connecting the cavity body with a vector network analyzer; S104, selecting a substance corresponding to a dielectric constant close to a minimum value in a dielectric constant real parameter set as a first substance, selecting a substance corresponding to a dielectric constant close to a maximum value as a second substance, and independently putting the first substance and the second substance into the formed cavity body to separately measure S parameters of the first substance and the second substance and compare the S parameters; and S105, if an error after the comparison is less than a predetermined value, regarding the cavity body as a cavity body with the optimal size.

Owner:SICHUAN UNIV

Method for leaching and loading drug solution by using nanometer porous polylactic acid material

InactiveCN103910902ALarge specific surface areaLittle effect on propertiesChemical treatmentDrugs solution

The invention relates to a method for leaching and loading a drug solution by using a nanometer porous polylactic acid material. According to the method, a nanometer porous polylactic acid material is immersed in a drug solution to be loaded to render drugs enter nanometer holes and cracks of the inner surface of the micropores of the nanometer porous polylactic acid material, the drug loading of polylactic acid material carrier per unit volume is improved by using high specific surface area of microporous materials. Compared with the prior art, the nanometer porous polylactic acid material in the method has larger drug loading per unit volume, the drug is loaded without chemical treatment due to microporous physical absorption while the drug loading stability is high, the technology is simple, the processing conditions are mild, and the influence on the drug loading organism and the properties of the drug is small.

Owner:SHANGHAI JIAO TONG UNIV

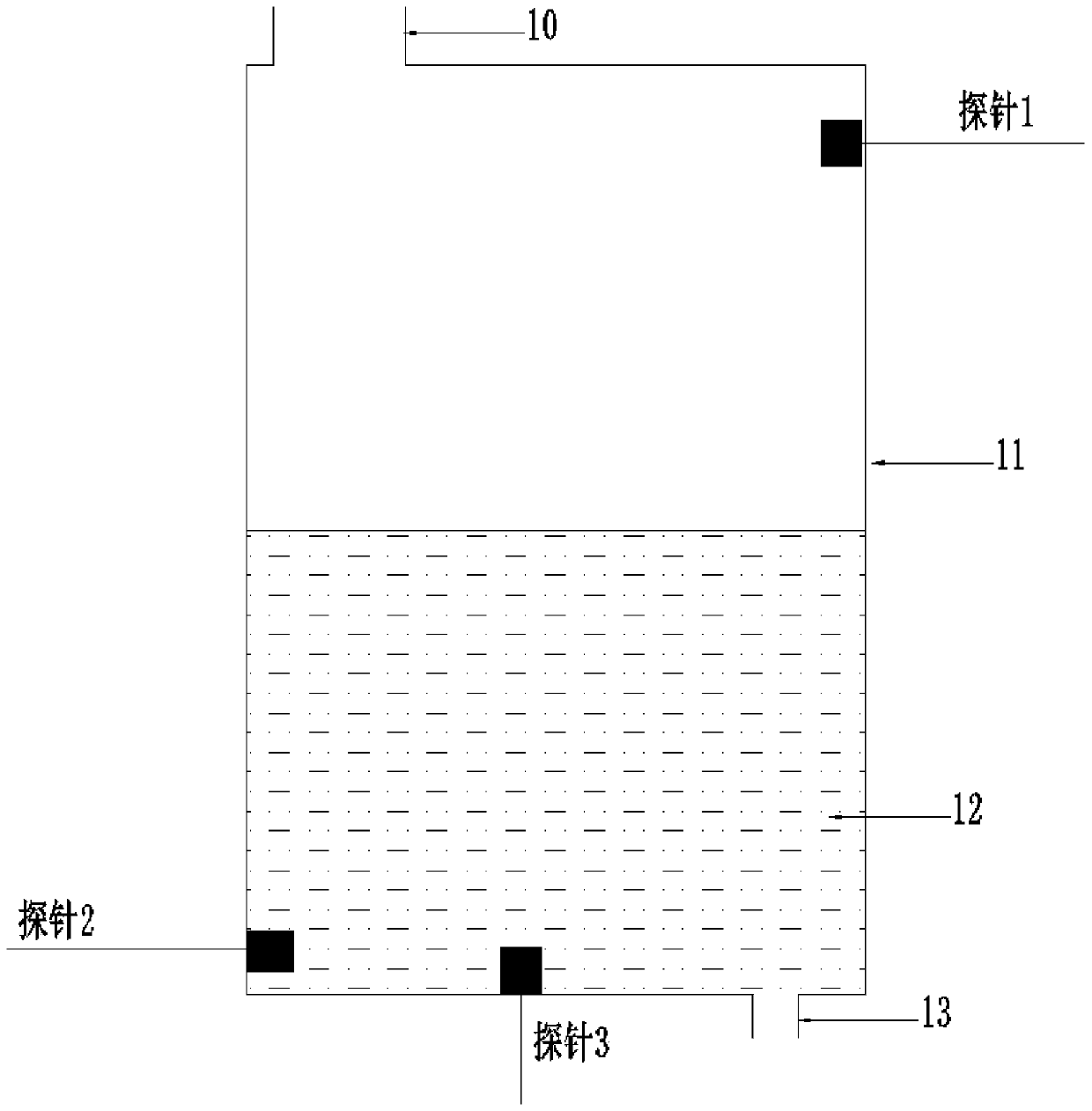

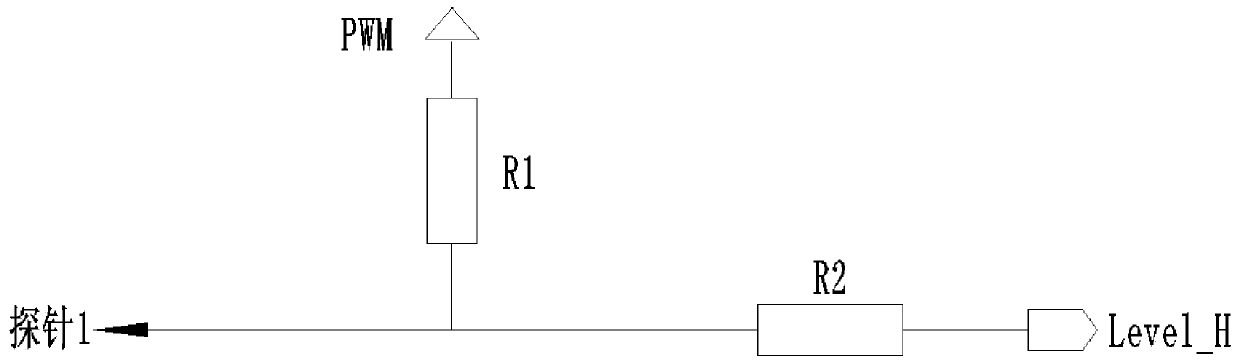

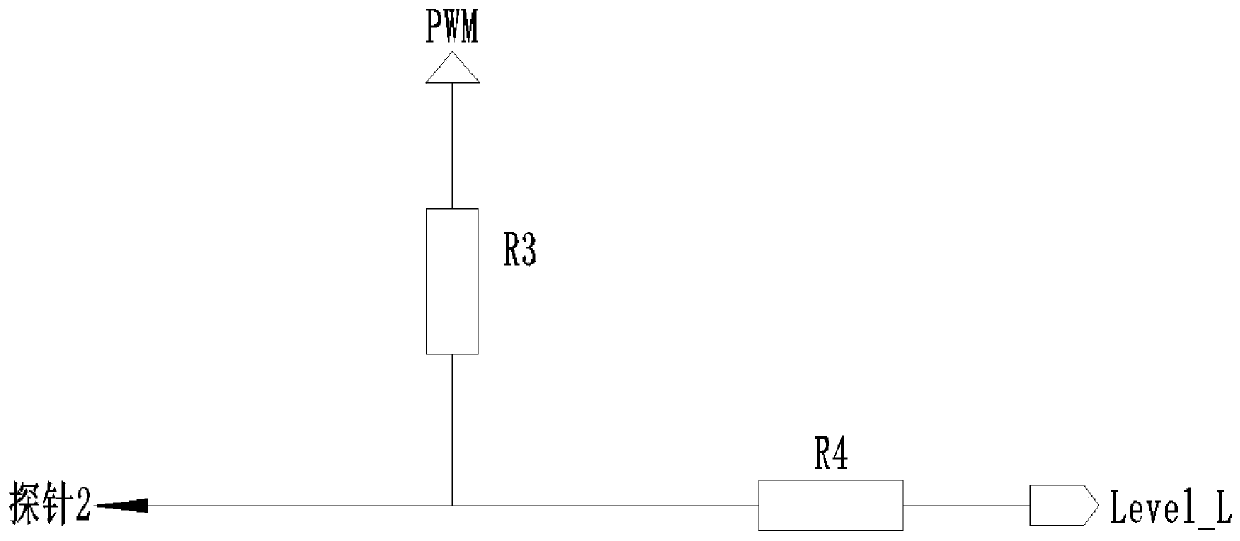

Liquid level detection device and method and dish washing machine

PendingCN110353589AAvoid interferenceImprove accuracyTableware washing/rinsing machine detailsElectrical resistance and conductanceCapacitance

The invention provides a liquid level detection device and method and a dish washing machine. The liquid level detection device comprises a first circuit, an energy storage circuit and a control chip,wherein the first circuit comprises a first metal probe positioned at a first set height of a liquid container; the first metal probe is connected to a first power supply end through a first resistor, and is connected to a first output end through a second resistor; the energy storage circuit comprises a third metal probe located at the lowest position of the liquid container; the third metal probe is grounded through an energy storage capacitor; the control chip has a driving end for outputting a pulse voltage to the first power supply end and a first acquisition end for acquiring a probe signal through the first output end; and whether liquid exists at the first set height or not is judged through the probe signal. According to the design, the influence of liquid properties is relatively small, and earth interference signals are isolated, so that the interference of the environment to the liquid level detection can be effectively avoided, and the accuracy of the liquid level detection is improved. Compared with the prior art of Hall detection, proximity switch detection or the like, the device is simple in circuit, easy to implement and relatively low in cost.

Owner:GREE ELECTRIC APPLIANCES INC

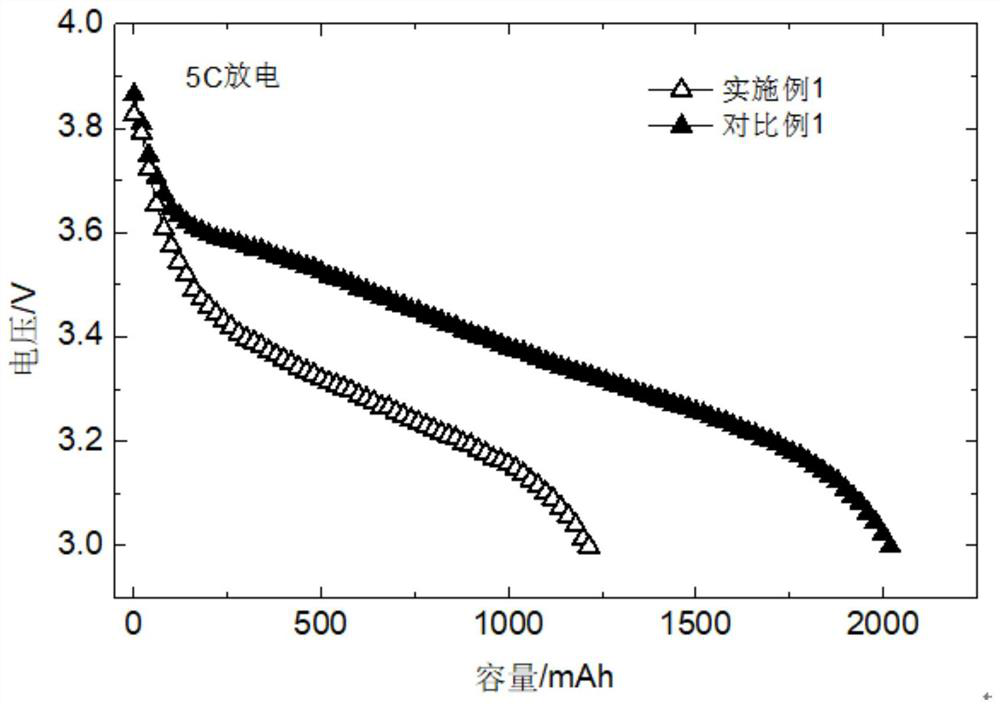

Lithium ion battery electrolyte and lithium ion battery

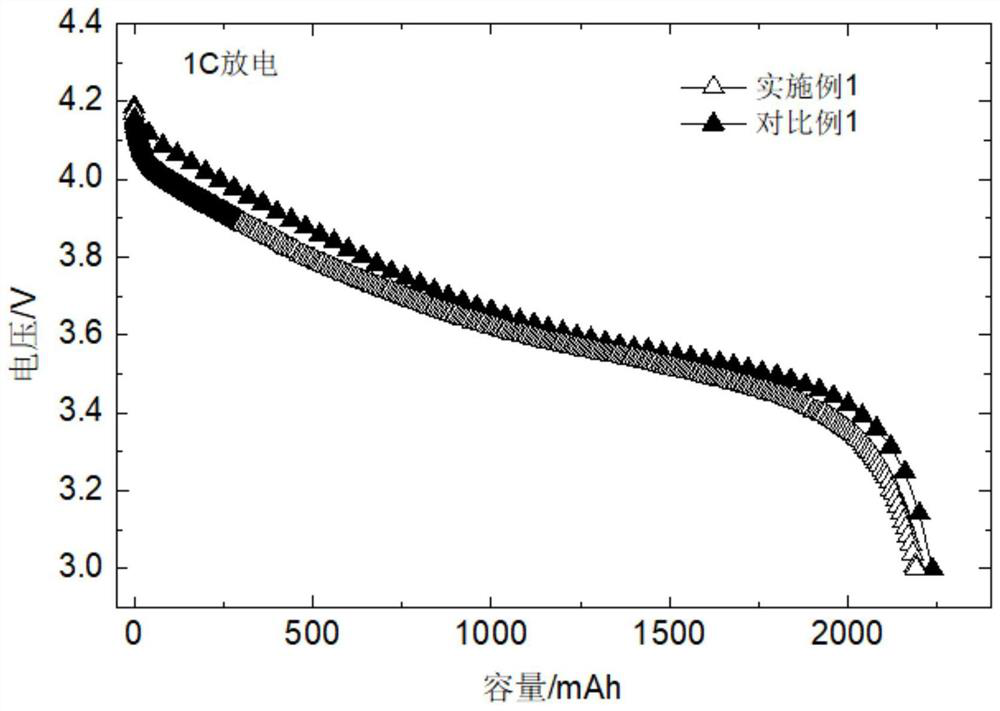

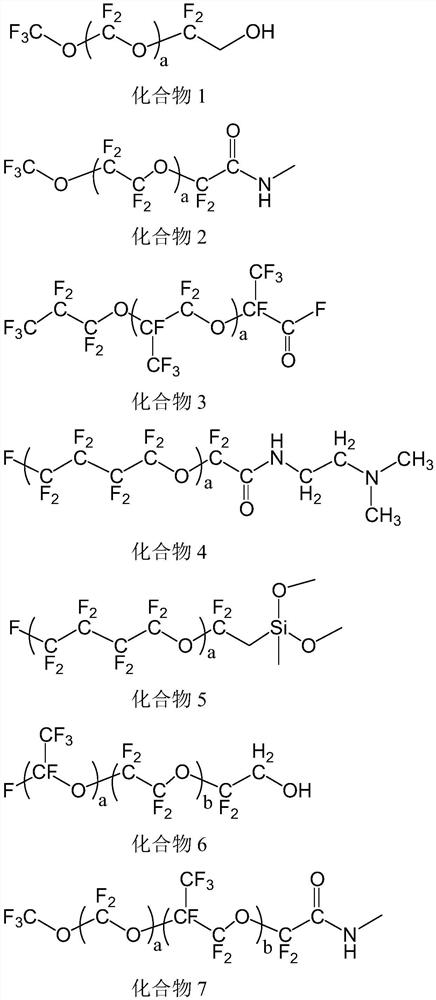

ActiveCN111864253AImprove securityDoes not affect other performanceSecondary cellsElectrolytic agentAcyl group

The invention relates to a lithium ion battery electrolyte. The electrolyte comprises a lithium salt, a solvent and a first additive, wherein based on 100 parts by weight of the electrolyte, the content of the first additive is 1-10 parts by weight, the first additive contains a compound shown as a formula (I): CxF<2x+1>Oy-A-R, and the weight-average molecular weight of the compound is 2000-5000;x and y are integers, x is greater than or equal to 0 and less than or equal to 6, y is greater than or equal to 0 and less than or equal to 1, A is a perfluoropolyether group, and R is selected fromone or more of a partially-fluorinated or completely-fluorinated alkyl alcohol group, an alkyl amide group, an alkyl acyl group, an alkyl amine group, an alkenyl carboxylate group and a siloxane group. The lithium ion battery containing the electrolyte disclosed by the invention is good in safety performance, and other electrochemical properties of the lithium ion battery can be ensured to be stable.

Owner:HUIZHOU BYD IND

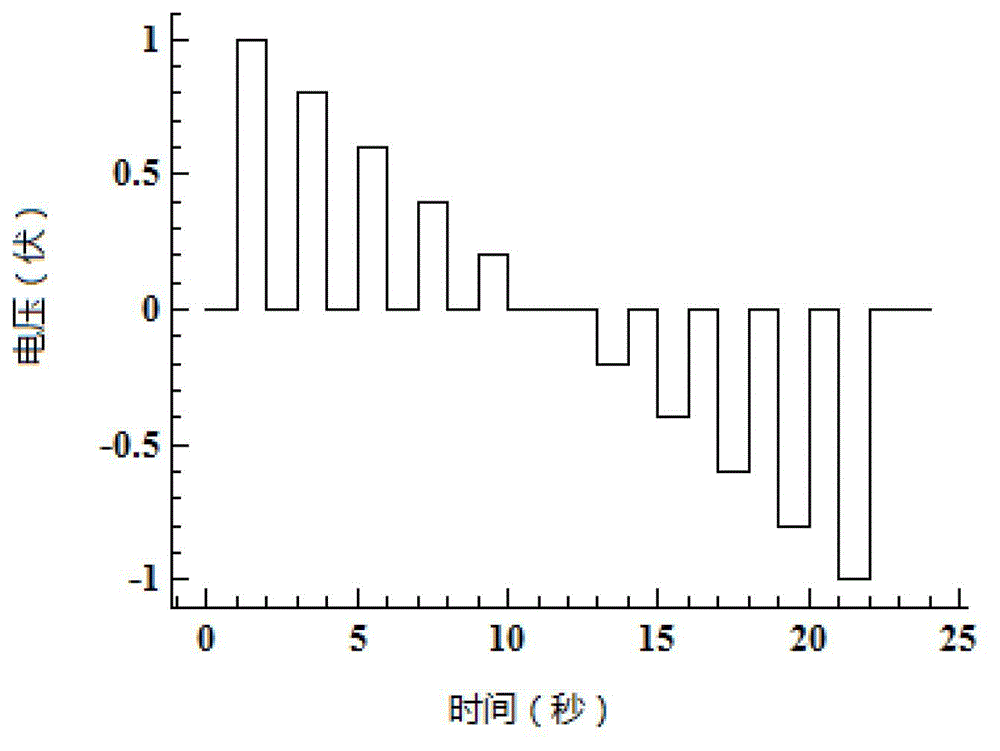

A method for in-situ electrochemical circulation well repair of chlorinated hydrocarbon polluted groundwater

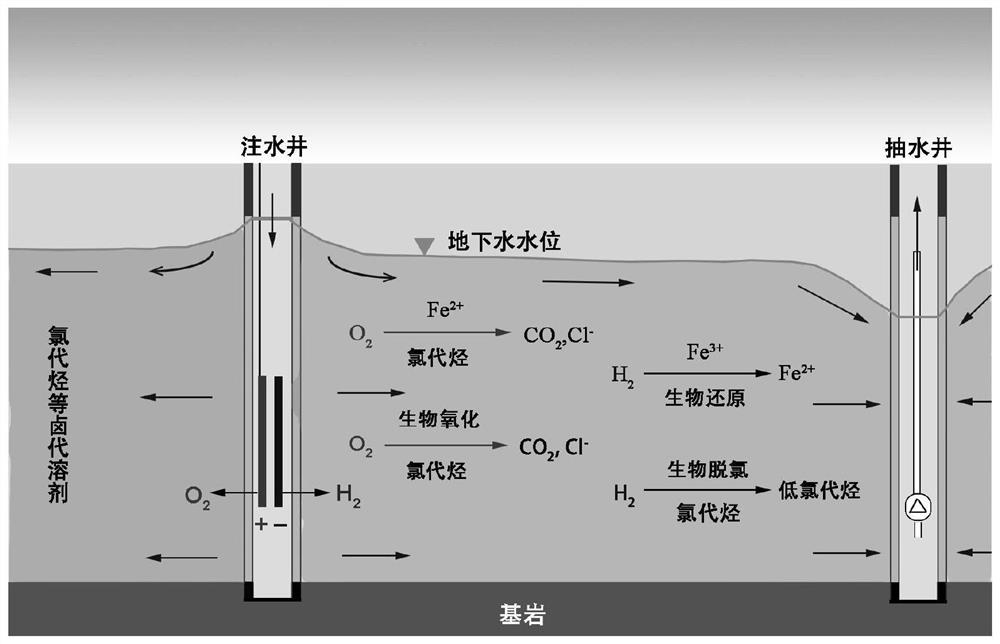

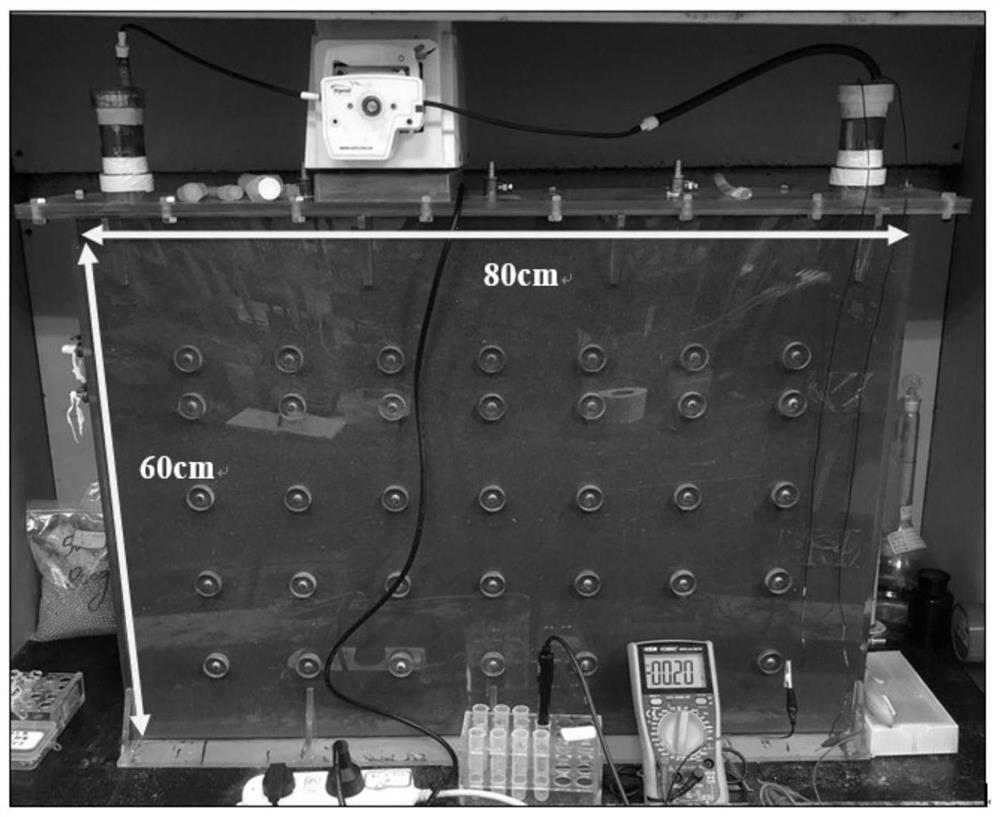

ActiveCN110357348BImprove repair effectLittle effect on propertiesWater contaminantsWater/sewage treatmentHydrocarbon contaminationElectrochemistry

The invention provides a method for repairing in-situ electrochemical circulation wells polluted by chlorinated hydrocarbons. The steps are as follows: dig wells in groundwater polluted areas, and install well pipes in the wells, wherein every two wells form a group, and in each group of wells, One well is used as a water injection well, and the other well is used as a water pumping well. The top end of the well pipe is open and the bottom end is closed. Several small holes are opened on the lower end of the well pipe; the anode plate is suspended into the water injection well and the cathode plate, the anode plate and the cathode plate are respectively connected to the positive pole and the negative pole of the power supply arranged outside the well through wires; the power supply is started to energize the anode plate and the cathode plate, and at the same time, the groundwater in the pumping well is continuously pumped by a water pump and injected into the water injection well In order to strengthen the groundwater flow circulation, the hydrogen and oxygen produced in the water injection wells diffuse to the aquifer under the action of the groundwater flow circulation to promote the chemical / microbial degradation of chlorinated hydrocarbons in the groundwater. The restoration method provided by the invention has stable effects and is environmentally friendly.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

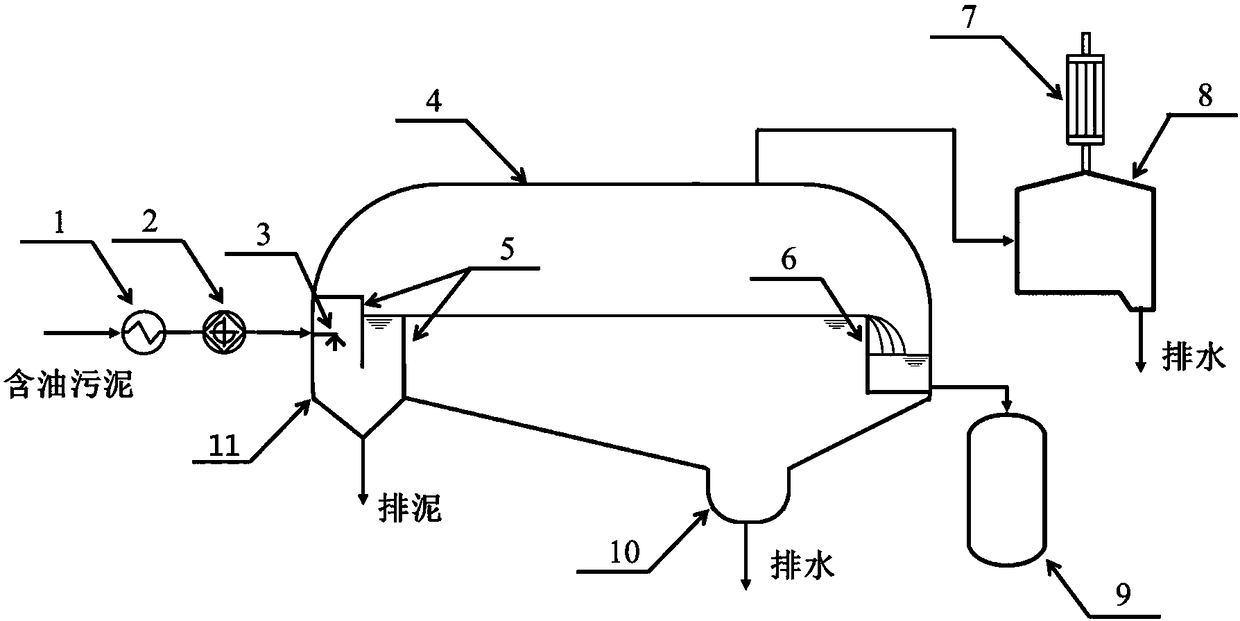

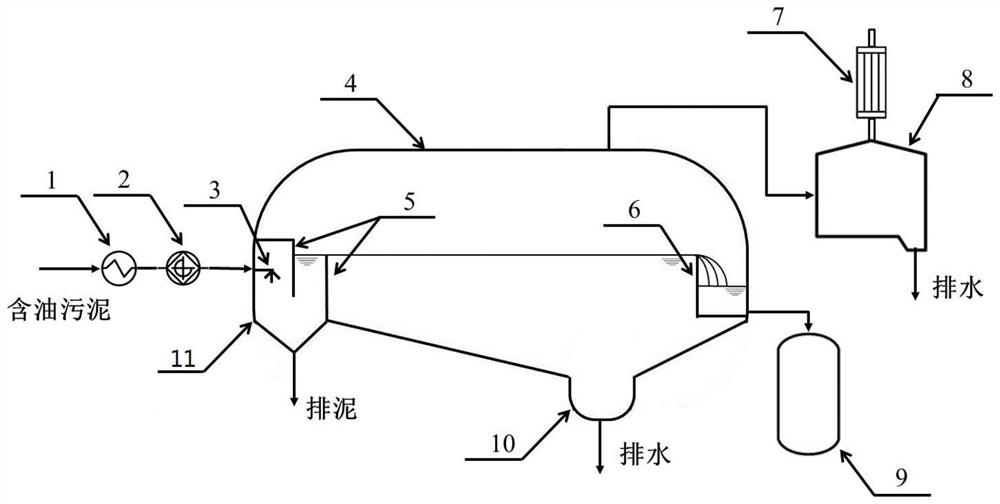

Continuous desalination and dehydration method and device of oily sludge

ActiveCN109399888ALittle effect on propertiesEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningDesalinationSewage

The invention relates to the field of oily sludge treatment, in particular to a continuous desalination and dehydration method and device of oily sludge. The continuous desalination and dehydration method of the oily sludge comprises the following steps: (1) continuously heating the oily sludge under a closed condition to obtain a pressurized superheated material; (2) continuously feeding the pressurized superheated material to a pressure-reducing system to ensure that water being 60 percent by weight or less of the oily sludge is vaporized to obtain vaporized steam and a residual material; and (3) performing oil-water separation on the residual material to obtain purified oil at the upper layer and salty sewage at the lower layer. By adopting the method provided by the invention, the oilysludge can be continuously treated, and the oil-water separation time is short, the desalination and dehydration effect is good, and the desalination and dehydration effect is stable.

Owner:CHINA PETROLEUM & CHEM CORP +1

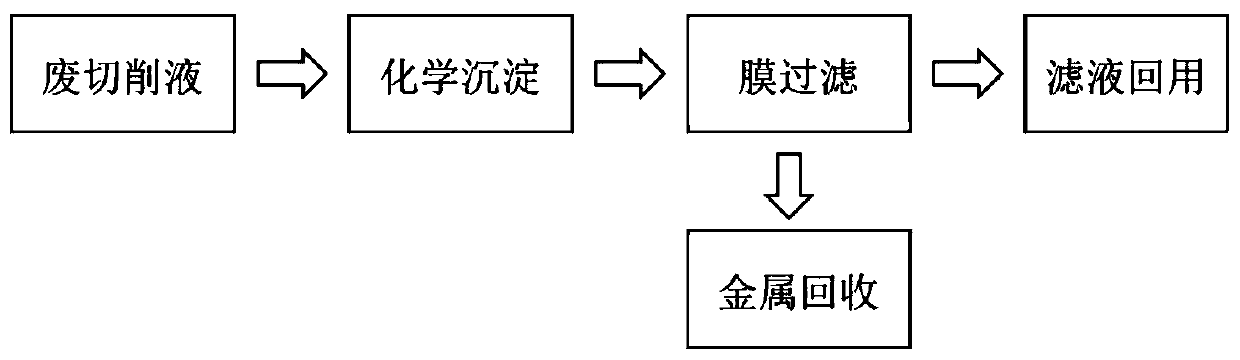

Cyclic utilization method of cutting fluid containing copper and nickel

PendingCN111394166AReduce turbiditySolve the problem of difficult precipitation and recyclingProcess efficiency improvementLubricant compositionOrganic sulfide compoundSulfide compound

The invention relates to a cyclic utilization method of cutting fluid, in particular to a cyclic utilization method of cutting fluid containing copper and nickel, and aims to solve the technical problems of complex treatment process and high treatment cost of the existing cutting fluid. Copper ions and nickel ions in the cutting fluid form precipitates through the chemical agent sulfide and the organic sulfide polymer griddling agent, the turbidity degree of the cutting fluid is reduced, the copper ions, the nickel ions and the metal chips in the cutting fluid are removed, and the precipitatesare separated from the cutting fluid through membrane filtration; metal precipitates generated by the medicament are low in water content and high in metal content, and metal substances in the metalprecipitates are recycled; after membrane filtration, the cutting fluid can be clarified and transparent, the recovery rate of the cutting fluid is high, the average recovery rate is 96%, the influence on the properties of the cutting fluid is small, the reusability is achieved, the discharge amount and the use amount of the cutting fluid are reduced and the cost is reduced. The method is appliedto recovery of the cutting fluid.

Owner:HUACHEN ENVIRONMENTAL PROTECTION ENERGY (GUANGZHOU) CO LTD

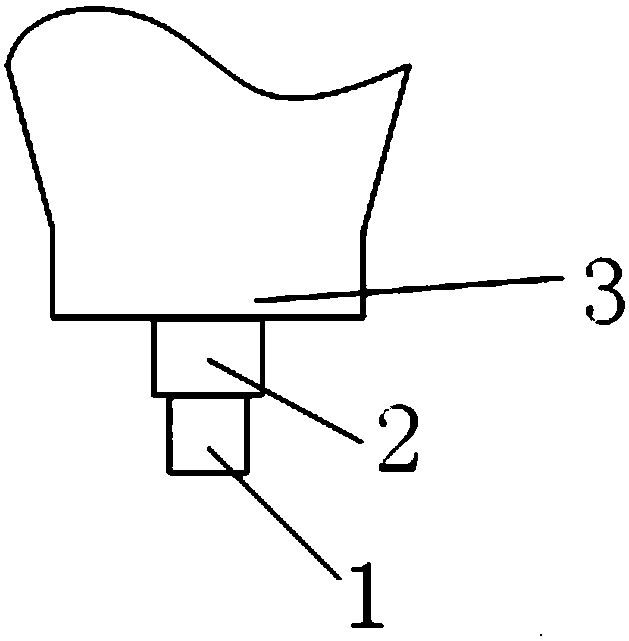

Optical fiber grating ice-pressure sensor

InactiveCN101701860BLow costImprove stabilityCladded optical fibreForce measurement by measuring optical property variationGratingSelf compensation

The invention discloses a contact type optical fiber grating ice-pressure sensor with better stability, which belongs to the field of sensing technologies. The sensor is characterized in that the contact type optical fiber grating ice-pressure sensor consists of a metal bottom plate, a metal protective case, a metal force-bearing panel, a clamping piece, a uniform strength beam, a micro-optical fiber grating strain sensor and a transmission optical cable component. The sensor is mounted on the structure through the metal bottom plate, the clamping piece fixes the micro-optical fiber grating strain sensor on the uniform strength beam through a screw, and the different shapes of the metal force-bearing panel can be changed according to the different force application structures; in addition, the measurement sensitivity of the sensor can be adjusted by changing the dimensions of devices according to actual demands, thereby being applicable to different types of model tests. The ice-pressure sensor can indirectly measure the ice-pressure by measuring the strain, and the pressure sensitivity coefficient of the sensor is improved by utilizing the natures of an optical fiber grating, which is not affected by materials. The ice-pressure sensor can well eliminate the affects of eccentric force on the measured value and realize the temperature self-compensation; and the ice-pressure sensor can simultaneously overcome the shortcomings that the traditional electric sensor is vulnerable to electromagnetic interferences, the long-term stability is poor and the like, and has the advantages of high precision, small volume, light weight, small affects on the natures of the structure and the like.

Owner:DALIAN UNIV OF TECH

Wax-wrapped peroxide microcapsule and preparation method thereof

ActiveCN103102431BImprove thermal stabilityConvenient storage and transportationMicroballoon preparationMicrocapsule preparationWaxAlcohol

The invention discloses a wax-wrapped peroxide microcapsule and a preparation method thereof. According to the invention, a core material of the microcapsule is a peroxide, and the wall of the microcapsule is wax. The preparation method comprises the following steps: dissolving petroleum wax at a temperature of 50 to 90 DEG C by using a low molecule alcohol as a solvent, adding micro peroxide powder, controlling a stirring speed to be 3000 to 8000 r / min, carrying out cooling to a temperature of 25 to 30 DEG C, removing the solvent through vacuum filtration and carrying out blow drying with nitrogen so as to obtain the wax-wrapped peroxide microcapsule. The wax-wrapped peroxide microcapsule improves thermal stability of the peroxide, is convenient for storage and transportation, is especially applicable as a polymerization initiator and is beneficial for smoothness of reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Process for preparing superparamagnetic starch

InactiveCN1970575BWide variety of sourcesGood environmental protectionSurgeryOrganic/organic-metallic materials magnetismSuperparamagnetismSynthetic Polymeric Macromolecules

The invention discloses a making method of superparamagnetism starch, which comprises the following steps: allocating starch milk through starch and deionized water; adjusting pH value; adding solubleferrous salt solution to adsorb once; filtering in the vacuum or separating centrifugally; removing water to obtain sediment; adding hydrogen peroxide solution to oxidize once; dehydrating; washing;obtaining starch product with water; repeating these steps to obtain magnified starch product with water; drying; obtaining the product.

Owner:SOUTH CHINA UNIV OF TECH

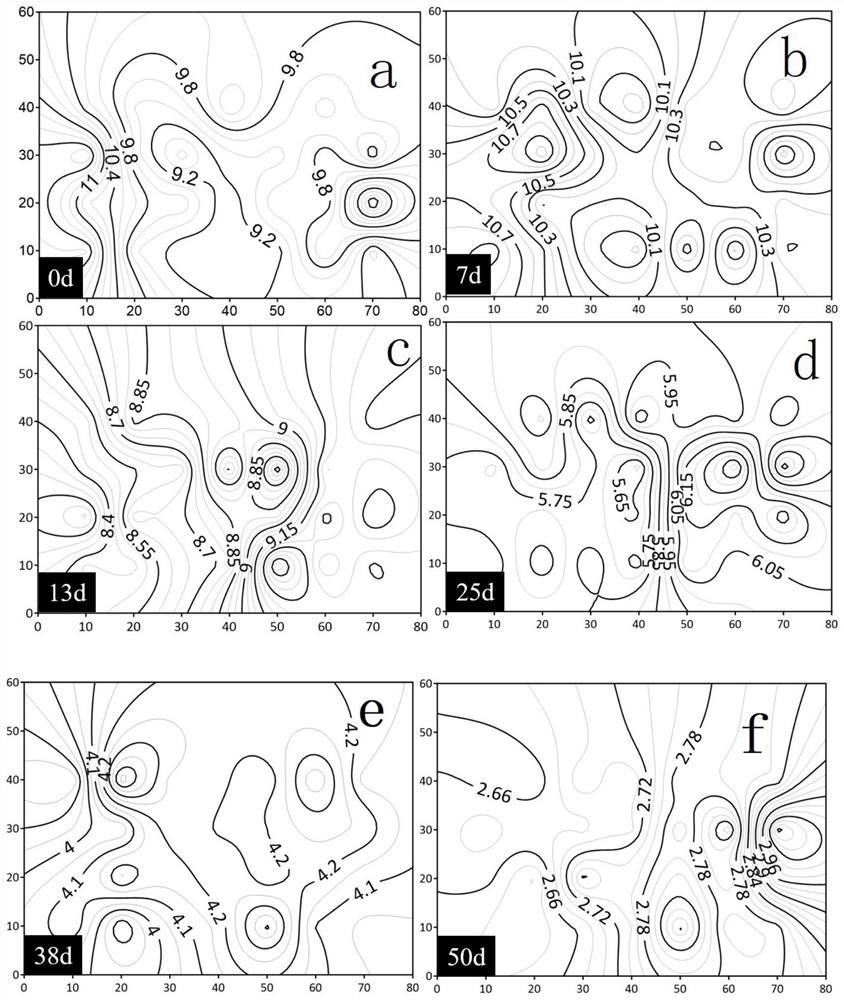

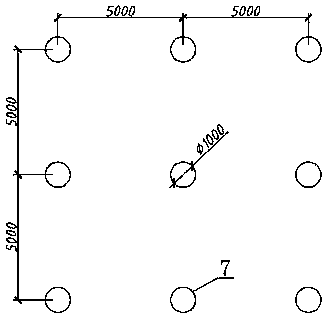

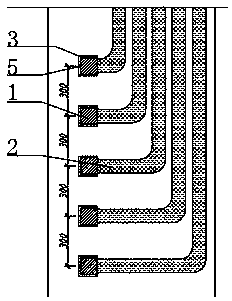

A kind of mud solidification in-situ test method

ActiveCN111562289BHigh measuring point densityLittle effect on propertiesMaterial analysis by electric/magnetic meansWater resource assessmentSoil scienceData collecting

The invention relates to the field of silt solidification detection, in particular to an in-situ testing method for silt solidification. The measuring points are connected with the data collector through the conductive solidified soil. The measuring point is composed of piezoelectric solidified soil, superelastic rubber film sleeve, mesh mold, plastic hose, and conductive solidified soil; the present invention proposes a measuring point arrangement requirement for measuring the solidified state of silt for piezoelectric solidified soil; the present invention Compared with the traditional layout scheme, the density of measuring points is larger, and the piezoelectric solidification state of different depths can be measured, which provides a test scheme for future research on silt solidification. The layout method provides a new idea; the measurement sensor in the present invention is piezoelectric solidified soil, which has little influence on the properties of the in-situ soil, and the measurement result is more accurate compared with the traditional scheme.

Owner:THE THIRD CONSTR & ENG OF CCFED +1

Intelligent chemical analysis system for distinguishing detection of weak electrolyte sample and method therefor

ActiveCN103267792BLittle effect on propertiesEasy to detectMaterial electrochemical variablesElectrical resistance and conductancePrincipal component analysis

The invention discloses an intelligent chemical analysis system for distinguishing detection of a weak electrolyte sample and a method therefor. The intelligent chemical analysis system is characterized by comprising an embedded module, a potentiostat and a three-electrode sensor. The method comprises that the self-developed potentiostat combines with the embedded module; a two-step excitation acquisition method is adopted; through the first excitation acquisition process, solution resistance is automatically fitted and an electrical signal produced by the solution resistance is added to a secondary excitation signal; and through the combination of the second acquisition process, real-time Fourier transform and principal component analysis, an optimized weak electrolyte solution whole-distinguishing graph is obtained. The method has good detection effects, a wide application scope and low influence on solution properties.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

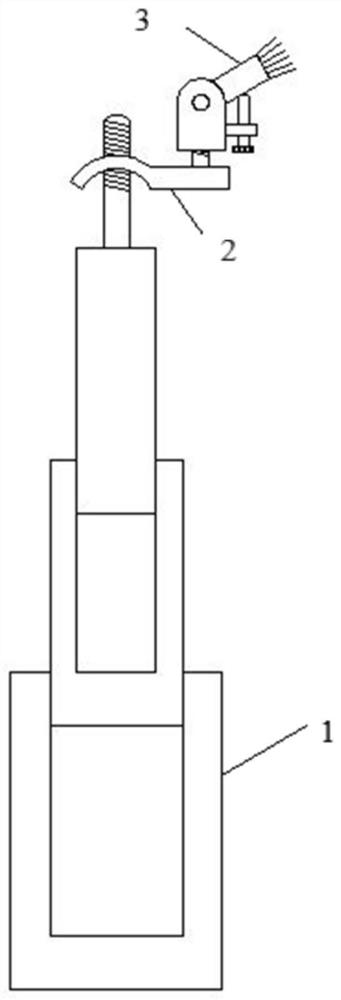

Fault detection method and sampler for oil overflow of oil-filled high-pressure casing

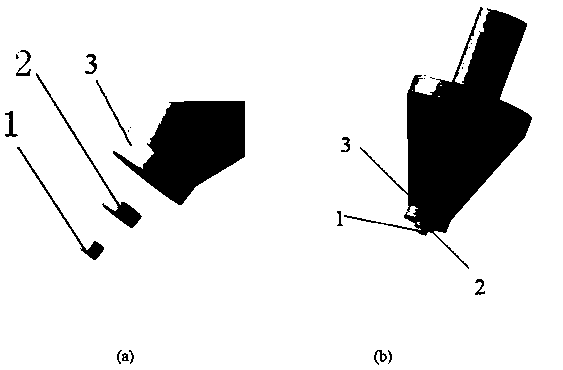

ActiveCN110296795BImprove accuracyHigh sensitivityDetection of fluid at leakage pointWithdrawing sample devicesChemical reactionAqueous ethanol

An oil flow overflow fault detection method for an oil-filled high-pressure casing, which performs unsaturated carbon-carbon bond detection by means of a chemical reaction, and determines whether an oil flow overflow fault occurs in the oil-filled high-pressure casing by means of the detection result of the unsaturated carbon-carbon bond. Specifically, a bromine carbon tetrachloride solution or a potassium permanganate aqueous ethanol solution is used as a detection reagent to detect a sample that is sampled from a surface of an oil-filled high-pressure casing to be tested, and it is determined whether the unsaturated carbon-carbon bond is detected according to whether a detection test paper is discolored, thereby determining whether an oil flow overflow fault has occurred in the oil-filled high-pressure casing to be tested. The present invention further relates to an oil flow overflow fault detection sampler for an oil-filled high-pressure casing, comprising a support rod (1), a sampling brush (3), and a fixing member (2) that is used for rotatably fixing the sampling brush and that is mounted at a top end of the support rod. The detection method and the sampler are simple and easy to operate, are resistant to environmental interference, and have the characteristics of accurate, sensitive and prompt detection.

Owner:WUHAN INTELLIGENT EQUIP IND INST CO LTD

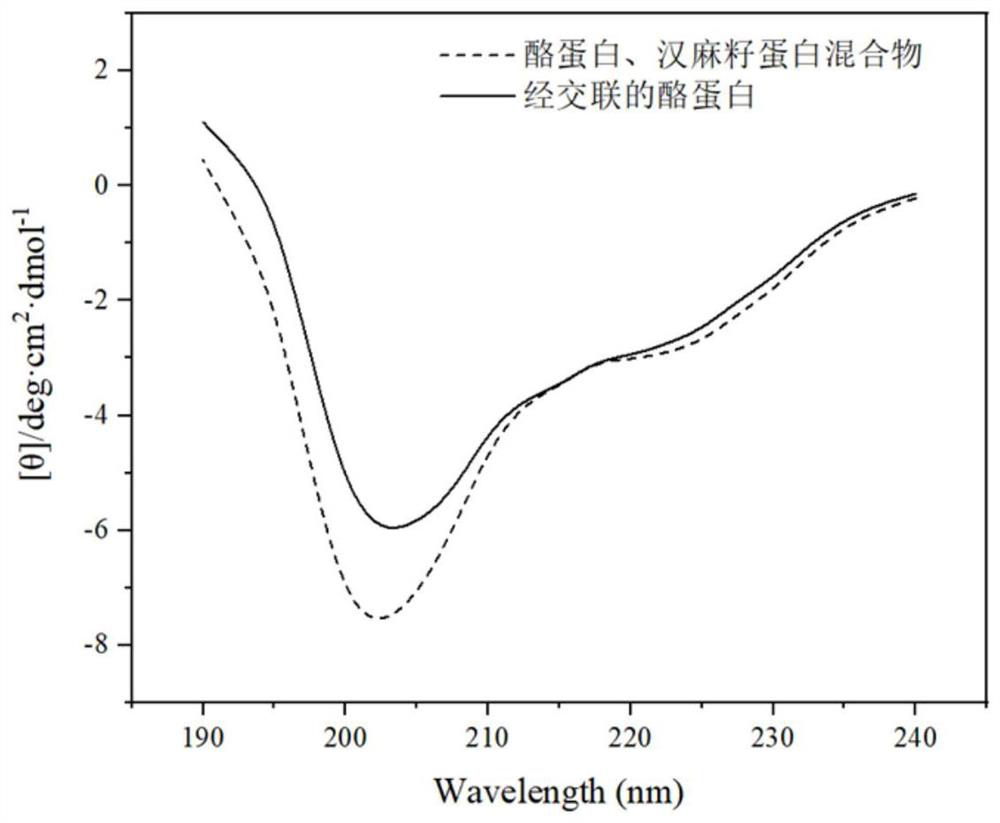

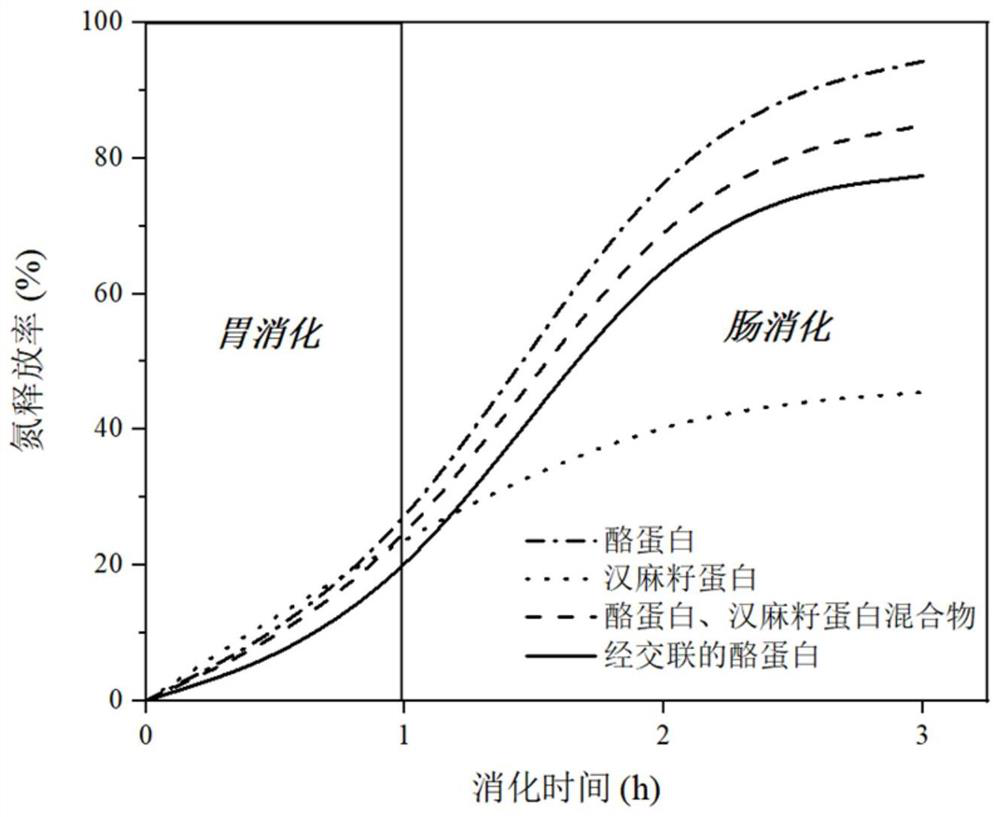

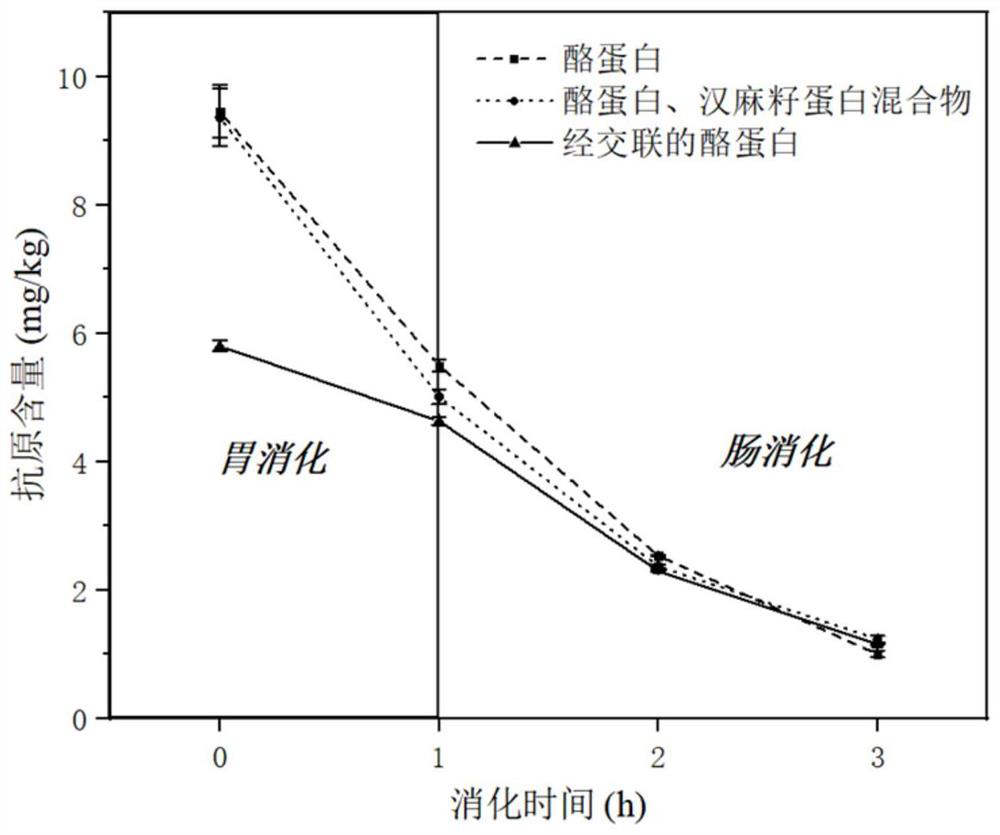

Method for improving enzymolysis resistance of casein and reducing sensitization

PendingCN114277074AImprove resistance to enzymatic hydrolysisAllergenicity reductionPeptide preparation methodsFermentationBiotechnologyNovel food

The invention relates to a method for improving enzymolysis resistance of casein and reducing sensitization, which is used for cross-linking China-hemp seed protein and casein through transglutaminase, and specifically comprises the following steps: (1) preparing a mixed solution of casein and China-hemp seed protein; (2) adding transglutaminase into the mixed solution of the casein and the hemp seed protein, and carrying out cross-linking reaction to obtain a cross-linked casein solution; and (3) placing the cross-linked casein solution in an environment of 3-5 DEG C, and terminating cross-linking. Compared with the prior art, the method has the advantages that the process steps are simple, the novel food resource, namely the hemp seed protein, is fully utilized, the casein is replaced by the hemp seed protein, the sensitization of the casein is further reduced, the enzymolysis resistance of the casein is improved, and the delivery effect of the casein on sensitive substances in the fields of food and pharmacy is improved.

Owner:SHANGHAI JIAO TONG UNIV

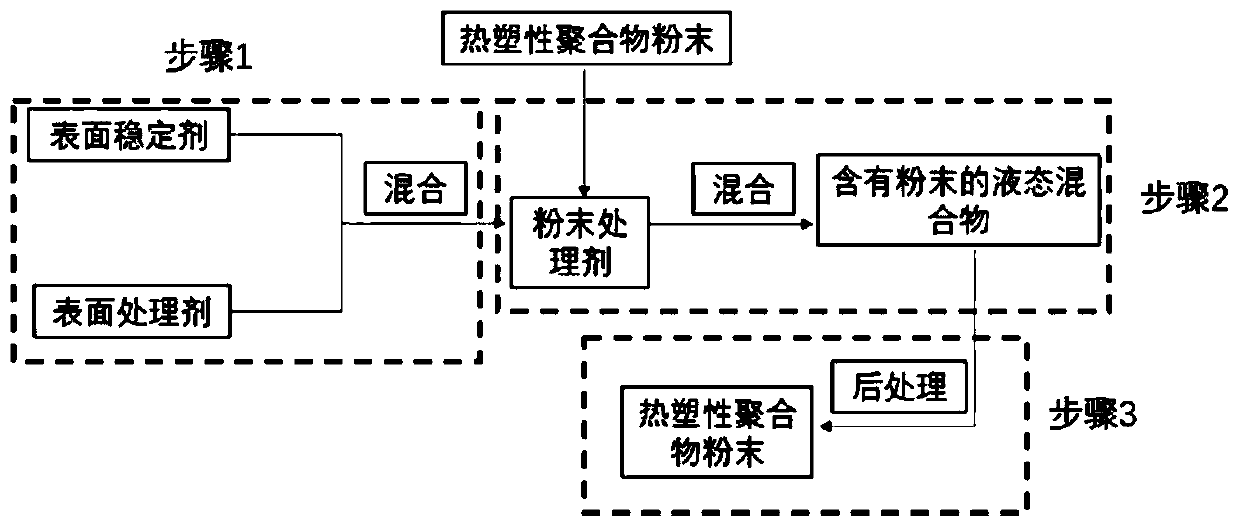

A treatment method for the fluidity of thermoplastic polymer powder

ActiveCN107955191BNo need for high temperature and high pressure treatmentThe method is simple and safePolymer sciencePolymer chemistry

The invention relates to a preparation method for improving the fluidity of thermoplastic polymer powder, which uses thermoplastic polymer powder as a raw material and comprises the following steps: step 1: uniformly mixing a surface stabilizer and a surface treatment agent to obtain a liquid powder treatment agent; step 2 : mixing thermoplastic polymer powder and liquid powder treatment agent to obtain a liquid mixture containing powder; step 3: separating solid and liquid from the mixture obtained in step 2 and drying to obtain treated thermoplastic polymer powder. The method controls the spheroidization of the powder by adjusting the solubility parameter of the surface treatment agent and the treatment time, and improves the fluidity of the powder. The method has a wide range of applications, is not limited by polymer types, and can realize the treatment of high-temperature-resistant thermoplastic polymer materials. The prepared powder can be used in powder coatings, 3D printing, cosmetics, additives, medicine and other fields.

Owner:WANHUA CHEM GRP CO LTD

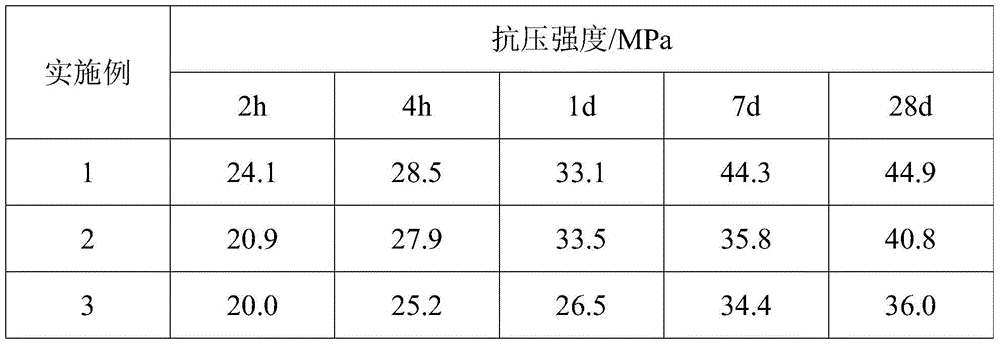

A kind of early-strength and fast-hardening type rockfill grouting recycled concrete and preparation method thereof

InactiveCN105198347BReduce intensity fluctuationsImproves strength and stabilitySolid waste managementSlurryUltimate tensile strength

Owner:怀化市港翔管桩有限公司

Continuous desalination and dehydration method and device for oily sludge

ActiveCN109399888BLittle effect on propertiesEasy to handleSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningThermodynamicsDesalination

The invention relates to the field of oil sludge treatment, in particular to a continuous desalination and dehydration method and device for oily sludge. The method for continuous desalination and dehydration of oily sludge comprises: (1) continuously heating the oily sludge under airtight conditions to obtain pressurized superheated material; (2) continuously sending the pressurized superheated material to the In the system, the water below 60% by weight in the oily sludge is vaporized to obtain vaporized steam and residual materials; (3) the residual materials are subjected to oil-water separation to obtain purified oil in the upper layer and saline sewage in the lower layer . The method of the invention can continuously process oily sludge, and has short oil-water separation time, good and stable desalination and dehydration effects.

Owner:CHINA PETROLEUM & CHEM CORP +1

Sludge solidification in-situ test method

ActiveCN111562289AHigh measuring point densityLittle effect on propertiesMaterial analysis by electric/magnetic meansWater resource assessmentSludgeMuck

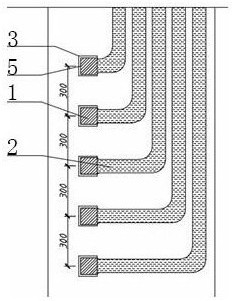

The invention relates to the field of sludge solidification detection, in particular to a sludge solidification in-situ test method. The method comprises the following steps: arranging piezoelectric solidified soil test points in parallel at multiple points of sludge in situ, distributing the piezoelectric solidified soil test points at equal intervals in the vertical depth, and connecting the test points with a data collector through conductive solidified soil. Each test point is composed of piezoelectric solidified soil, a super-elastic rubber film sleeve, a net-shaped mold, a plastic hose and conductive solidified soil. The invention provides a measuring point arrangement requirement for measuring a sludge solidification state of piezoelectric solidified soil; compared with a traditional arrangement scheme, the provided method has the advantages: the density of measuring points is higher, piezoelectric solidification states of different depths can be measured, and a testing scheme is provided for related research on sludge solidification in the future; the conductive solidified soil is prepared, and a new thought is provided for a soil body internal sensor arrangement method; the measurement sensor is piezoelectric solidified soil, and the influence on the property of an in-situ soil body is low; and compared with a traditional scheme, the measurement result is more accurate.

Owner:THE THIRD CONSTR & ENG OF CCFED +1

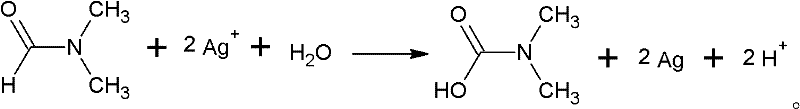

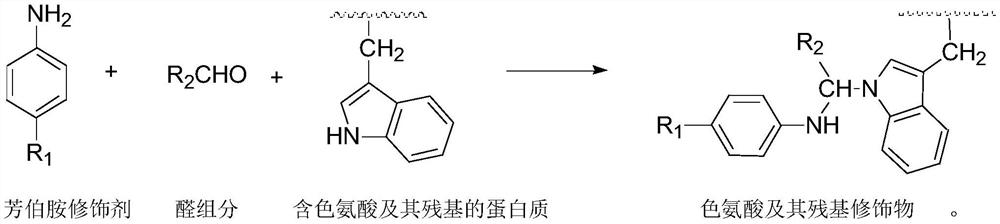

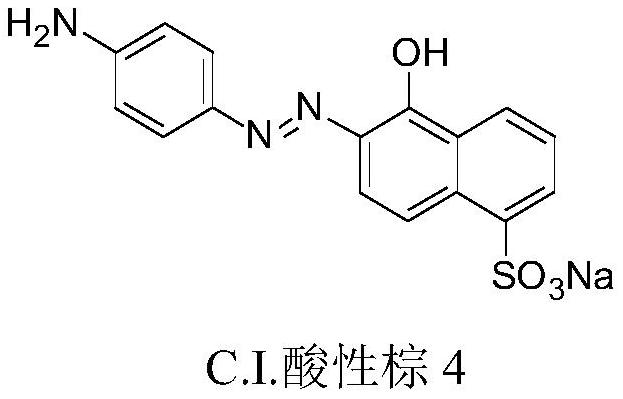

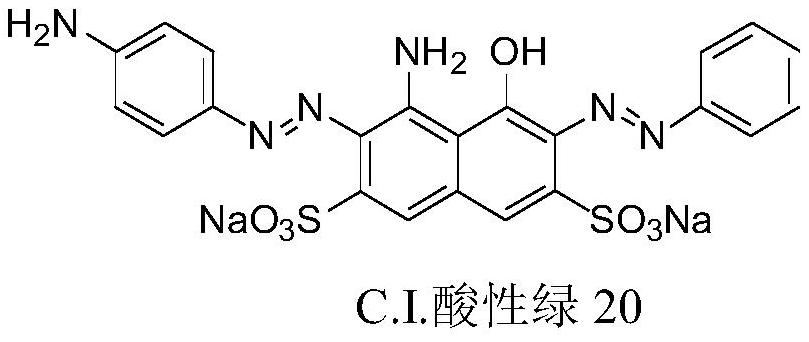

A highly selective chemical modification method targeting tryptophan and its residues

ActiveCN108129546BNo reactionLittle effect on propertiesPeptide preparation methodsCombinatorial chemistryChemical modification

The invention discloses a highly selective chemical modification method for tryptophan and residues of tryptophan. The method comprises the steps that: tryptophan or a substance containing a tryptophan residue is used as a modified object in water, under the action of an aldehyde component, highly selective three-component electrophilic substitution reaction are conducted on aromatic primary aminemodifiers and tryptophan / tryptophan residues in modified products, so that aromatic primary amine modifier molecules are covalently bonded to the tryptophan / tryptophan residues. In the chemical modification method, the aromatic primary amine modifiers have excellent selectivity for the tryptophan and the residues of tryptophan in proteins, and have no significant reactivity with other active amino acids and residues thereof; the covalent bonding forms among the aromatic primary amine modifier molecules and the tryptophan and the residues of tryptophan, and the durability is excellent.

Owner:ZHEJIANG SCI-TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com