Antimicrobial polysulphone flat ultrafiltration membrane and preparation method thereof

An ultrafiltration membrane and polysulfone technology, which is applied in the field of novel antibacterial polysulfone flat ultrafiltration membrane and its preparation, can solve the problems of difficult and uniform dispersion of nano-materials, and achieve the improvement of mechanical properties, water quality and mechanical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

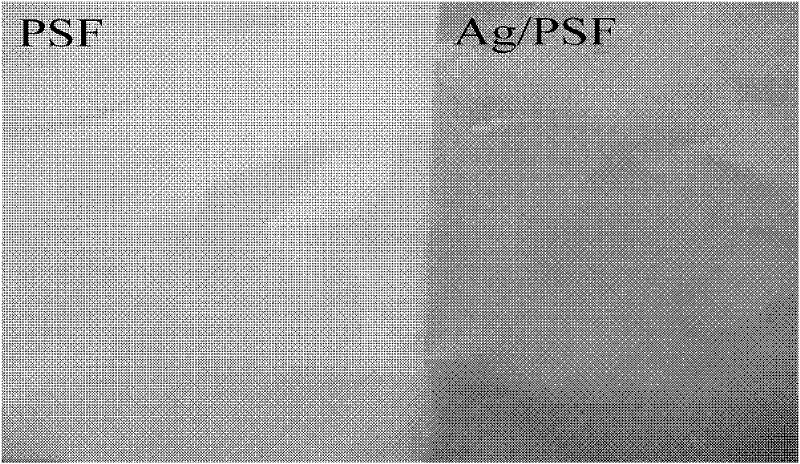

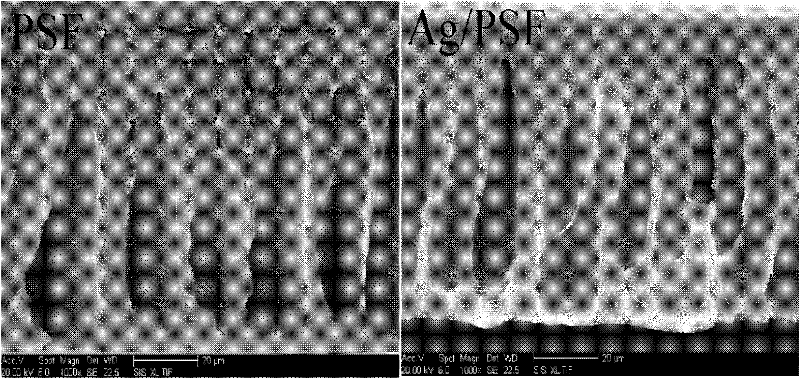

[0021] Embodiment 1: The antibacterial polysulfone flat ultrafiltration membrane of this embodiment uses polysulfone as the film-forming material, and the nano-silver particles prepared by the liquid phase reduction of silver nitrate method are used as the antibacterial additive, and are prepared by the immersion precipitation phase inversion method. The mass percentage of polysulfone in the mixture is 8% to 26%, silver nitrate accounts for 0.1% to 1% of the total mass, the reducing agent accounts for 5% to 20% of the total mass, and the porogen accounts for 3% to 10% of the total mass. %, and the rest are solvents.

[0022] The preparation method comprises the following steps:

[0023] 1. Preparation of nano silver:

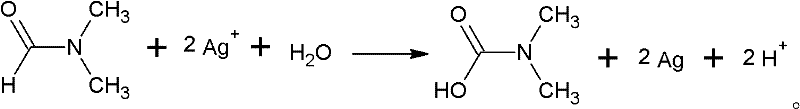

[0024] Silver nitrate is reduced by a liquid phase reduction method to obtain nano-silver, wherein N, N-dimethylformamide is used as a reducing agent for silver nitrate, and the reaction equation is:

[0025]

[0026] Add N, N-dimethylformamide solution acc...

specific Embodiment approach 2

[0036] Specific embodiment two: in the there-necked flask that stirring bar, thermometer, constant pressure funnel are housed, add the N that accounts for 20% of total mass, N-dimethylformamide (analytical grade, Tianjin Kemiou Chemical Reagent Co., Ltd.) solution ,heating. Take by weighing 0.5% of the total mass of silver nitrate (analytical grade, Beijing Fine Chemicals Co., Ltd.) particles, dissolved in 1% of the total mass of water and N, N-dimethylformamide (analytical grade, Tianjin Kemiou Chemical Reagent Co., Ltd.) in the mixed solution (mixing volume ratio is 1:1), through the constant pressure dropping funnel dropwise added to the boiling N, N-dimethylformamide, about 5mins added, at 120 ℃ The reaction was stirred for 2h.

[0037]At the same time, 20% polysulfone (viscosity of 0.58, produced by Dalian Polysulfone Material Co., Ltd.) was dissolved in 53.5% N-methyl-2-pyrrolidone by mass percentage, and 5% mass percentage was added. Polyvinylpyrrolidone K10 (analytic...

specific Embodiment approach 3

[0039] Embodiment 3: The preparation of nano-silver and its proportion are the same as in Embodiment 2. Dissolve the dried polysulfone with a mass percentage of 20% in N-methyl-2-pyrrolidone with a mass percentage of 53.5%, add polyvinylpyrrolidone K30 with a mass percentage of 5%, stir in a water bath at 60°C, and wait until It is dissolved into a uniform transparent solution, and the prepared nano-silver sol is added thereto, stirred at a constant temperature for about 2 hours, left standing for defoaming, and the film is formed according to the same method as in Embodiment 2.

[0040] The average pore diameter of the composite polysulfone ultrafiltration membrane obtained in this embodiment is 30nm, the porosity is 71%, and the maximum stress is 4.04N / mm 2 , the fracture stress is 4.02N / mm 2 . The pure water flux and rejection rate of the filter membrane are 104L / m 2 • h and 94%. The antibacterial rate against Escherichia coli is 83%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Maximum stress | aaaaa | aaaaa |

| Fracture stress | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com