Preparation method of spherical particles of thermoplastic plastic

A technology for thermoplastics and spherical particles, which is applied in the field of preparation of thermoplastic spherical particles, and can solve problems such as low economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

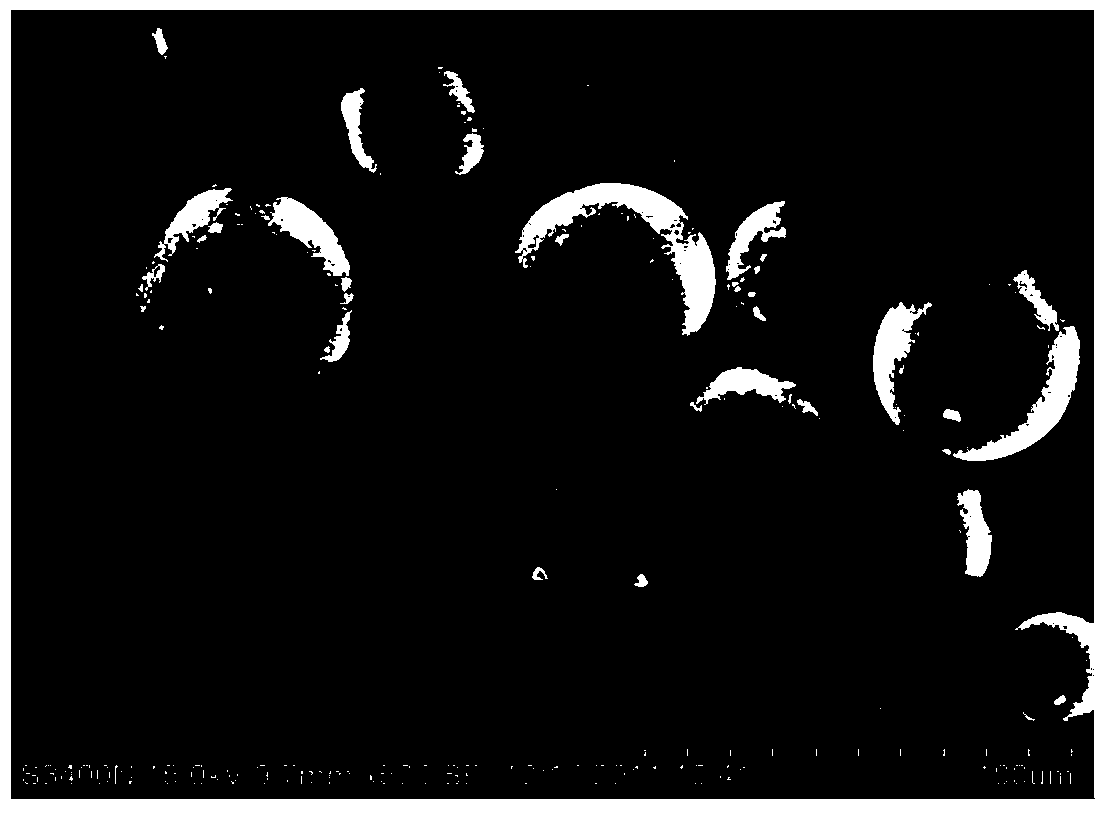

Image

Examples

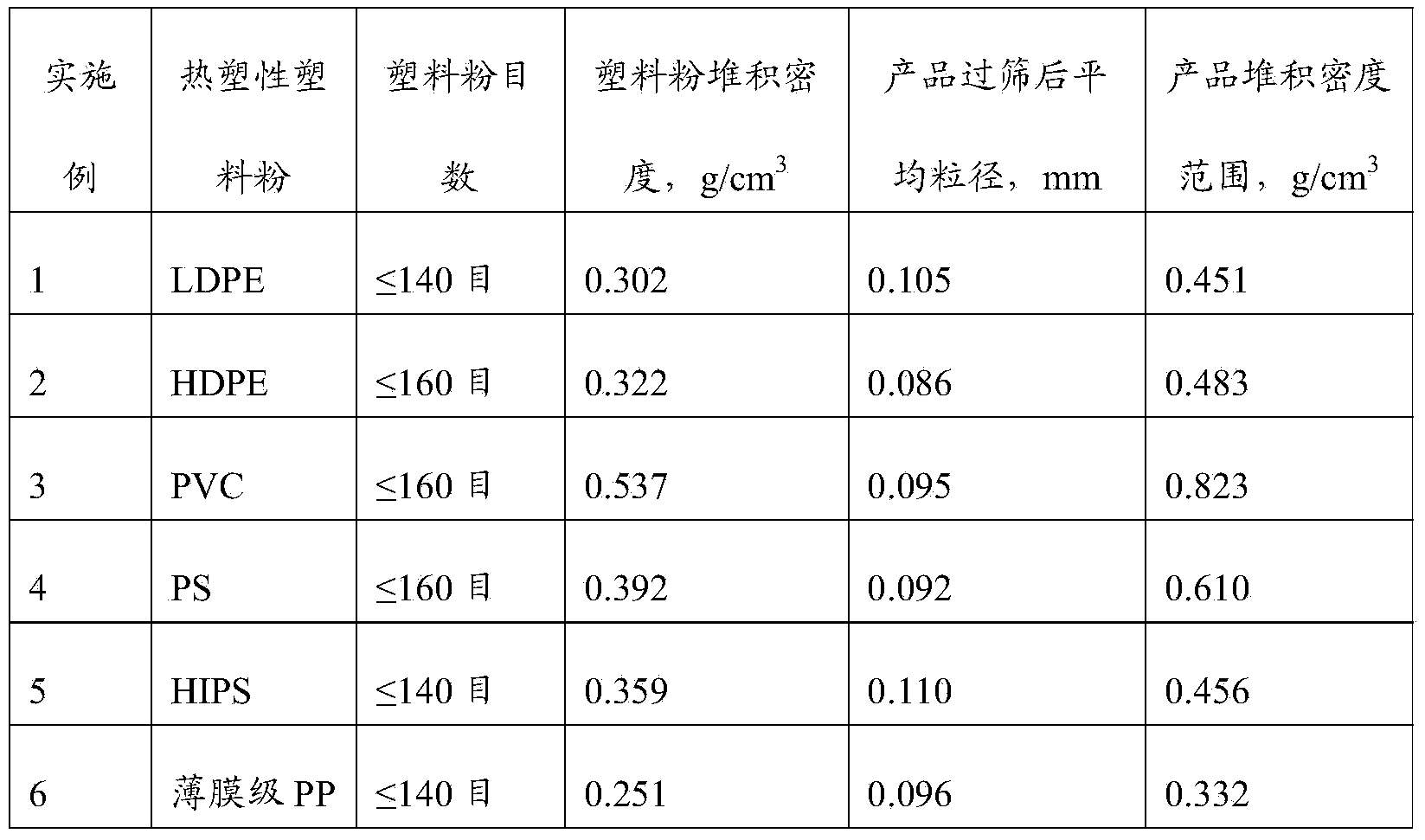

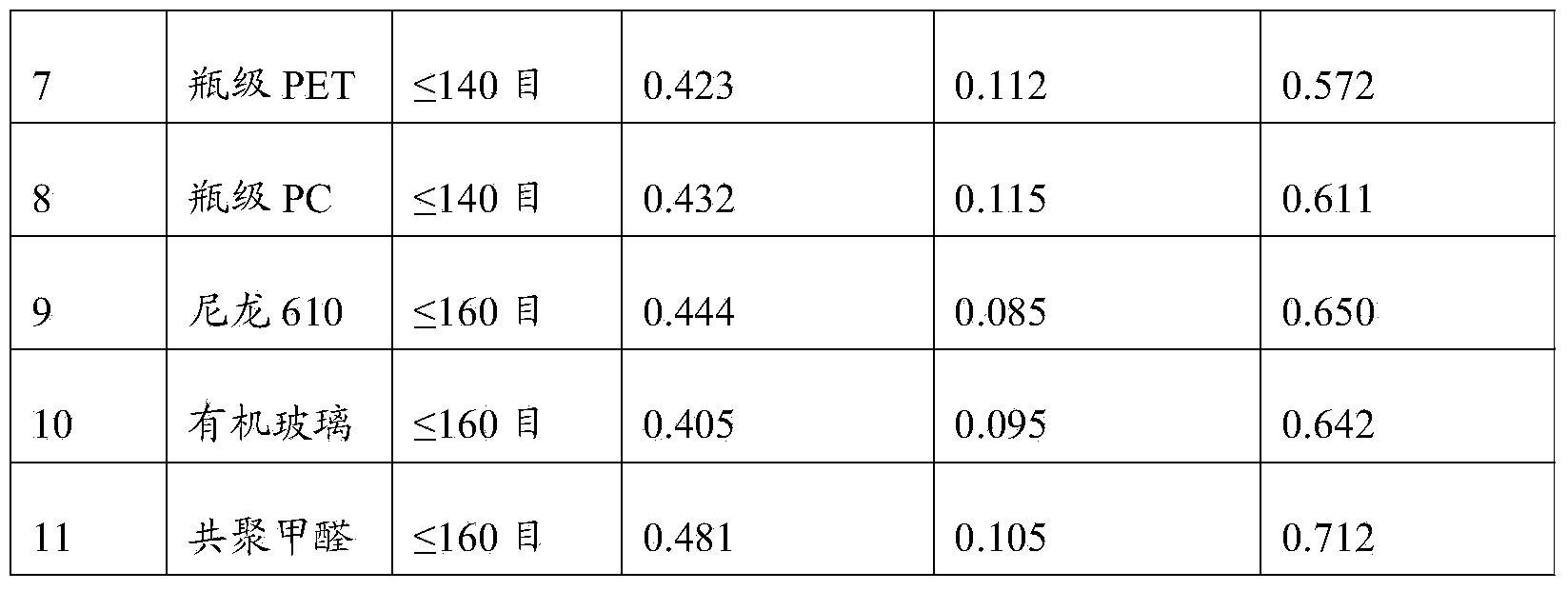

Embodiment 1

[0020] Put 100g of crushed LDPE (low-density polyethylene) powder in a 1000ml flask, add 500ml of xylene and 2ml of OP-10 (alkylphenol polyoxyethylene ether), fully stir and disperse, heat to 90°C, and keep warm for about 4 hours After cooling, filter, wash, dry, pulverize and sieve to obtain spherical LDPE powder. The product properties are shown in Table 1.

Embodiment 2

[0022] Put 20g of pulverized HDPE (high-density polyethylene) powder, 1.5g of stearic acid, 1ml of cyclohexane and 250ml of water in a 500ml autoclave, stir and disperse evenly, then heat to 128°C, and the pressure in the autoclave is 0.19MPa , Cool after 4 hours, take out the mixed liquid from the kettle, filter, wash, dry, pulverize and sieve to obtain the product. The product properties are shown in Table 1.

Embodiment 3

[0024] Put 25g of crushed PVC (polyvinyl chloride) powder, 250ml of water, 1g of polyvinyl alcohol (1799) and 8.3ml of cyclohexanone in a 500ml autoclave, disperse evenly, heat to 135°C, and then The pressure is 0.20 MPa. After 3 hours, cool down, take out the mixed liquid from the kettle, filter, wash, dry, pulverize and sieve to obtain the product. The product properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com