Continuous desalination and dehydration method and device for oily sludge

A technology of oily sludge and sludge, which is applied in sludge treatment through temperature control, dehydration/drying/thickened sludge treatment, petroleum industry, etc., can solve the problem of low efficiency of desalination and dehydration methods, poor desalination effect, and easy desalination and dehydration effect Affected by the nature of raw materials and other issues, it achieves the effects of stable treatment effect, mild operating conditions, simple and economical expansion and transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] This example is used to illustrate the method for desalination and dehydration of oily sludge of the present invention.

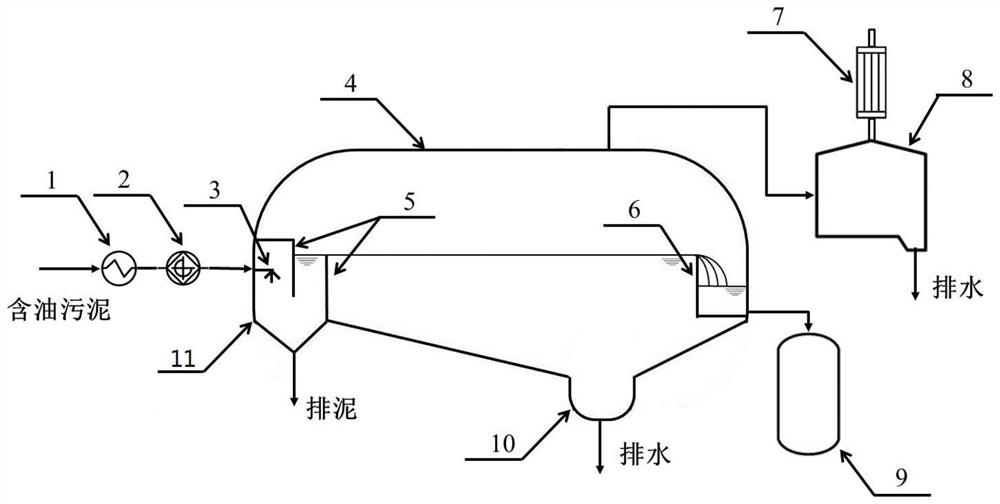

[0073] use figure 1In the device shown, the oil production sludge (water content 30% by weight, salt content 1258mg NaCl / L, mechanical impurity content 27.4% by weight, and the balance is oil content) is continuously transported at a flow rate of 1.5kg / h In the closed system of the pipeline, it is heated by the heater 1 to obtain a pressurized superheated material with a temperature of 160 ° C, and then it is continuously pumped to the dehydration tank 4 by the screw pump 2 with heat preservation and pressure, and the feed distributor 3 at the inlet is sprayed into the steady flow tank 11 provided there, and enter the main body of the dehydration tank 4 in the normal pressure system (about 101.3kPa) through the U-shaped flow channel, so that the superheated material under pressure is instantly vaporized, and the vaporized steam is condensed by the co...

Embodiment 2

[0076] This example is used to illustrate the method for desalination and dehydration of oily sludge of the present invention.

[0077] According to the method described in embodiment 1, the difference is:

[0078] The oily sludge is heated by the heater 1 to obtain a pressurized superheated material with a temperature of 150° C. After vaporization, the condensed water collected in the light component reflux tank 6 accounts for 5% by weight of the water content of the oily sludge;

[0079] The material in the dehydration tank 4 is kept at 80° C. for oil-water separation, and the residence time is 80 minutes.

[0080] Among them, the obtained purified oil had a water content of 2.3% by weight and a dehydration rate of 92.5%; a salt content of 110.7 mgNaCl / L and a desalination rate of 91.2%.

Embodiment 3

[0082] This example is used to illustrate the method for desalination and dehydration of oily sludge of the present invention.

[0083] According to the method described in embodiment 1, the difference is that the oil sludge processed is the mechanical cleaning oil sludge of refinery oil tank, and its water content is 24.9% by weight, and the salt content is 847mg NaCl / L, and mechanical impurity is 45% by weight. The amount is the oil content;

[0084] Among them, the obtained purified oil had a water content of 4.4% by weight and a dehydration rate of 82.3%; a salt content of 91.7 mgNaCl / L and a desalination rate of 89.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| dehydration rate | aaaaa | aaaaa |

| salt rejection rate | aaaaa | aaaaa |

| dehydration rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com